Production technology and product of prefabricated bridge slab

A production process and technology of bridge slabs, applied to bridges, manufacturing tools, bridge parts, etc., can solve problems such as damage to farmland resources, farmland destruction, coal-burning operation pollution, etc., and achieve the effect of reducing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

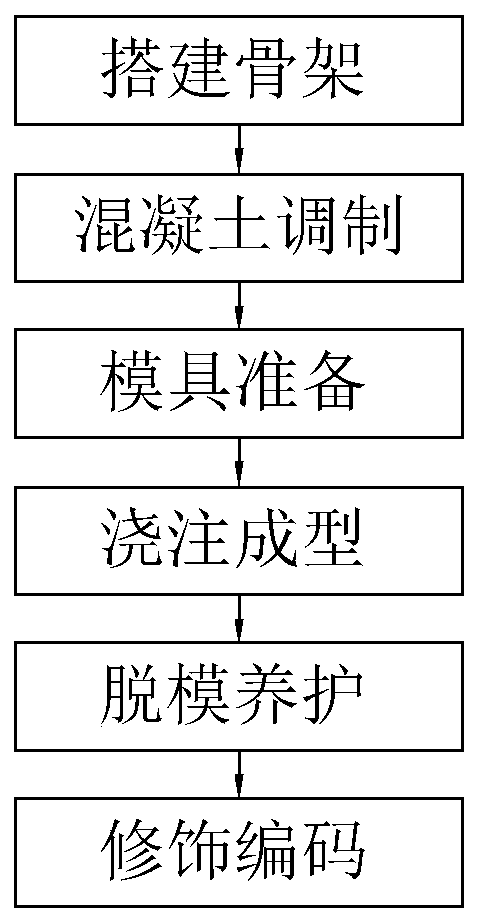

[0042] Such as figure 1 Shown, a kind of production technology of prefabricated bridge plate, comprises the following steps:

[0043] (1) Build the skeleton. The skeleton of the bridge slab is mainly composed of steel bars. First, the steel bars are spliced together to form the frame structure of the bridge slab. During the construction process, the intersections between the steel bars are bound and fixed with steel wires, and when the construction is completed The intersections between the steel bars are then welded and strengthened.

[0044] The steel bar can produce bending deformation, and the deformation resistance of the concrete structure can be greatly improved after being embedded in the concrete, and it is not easy to be completely broken after the concrete cracks, so as to achieve the purpose of improving the structural strength of the bridge slab.

[0045] (2) Concrete preparation. Before preparing concrete, it is necessary to prepare raw materials. The raw mate...

Embodiment 2

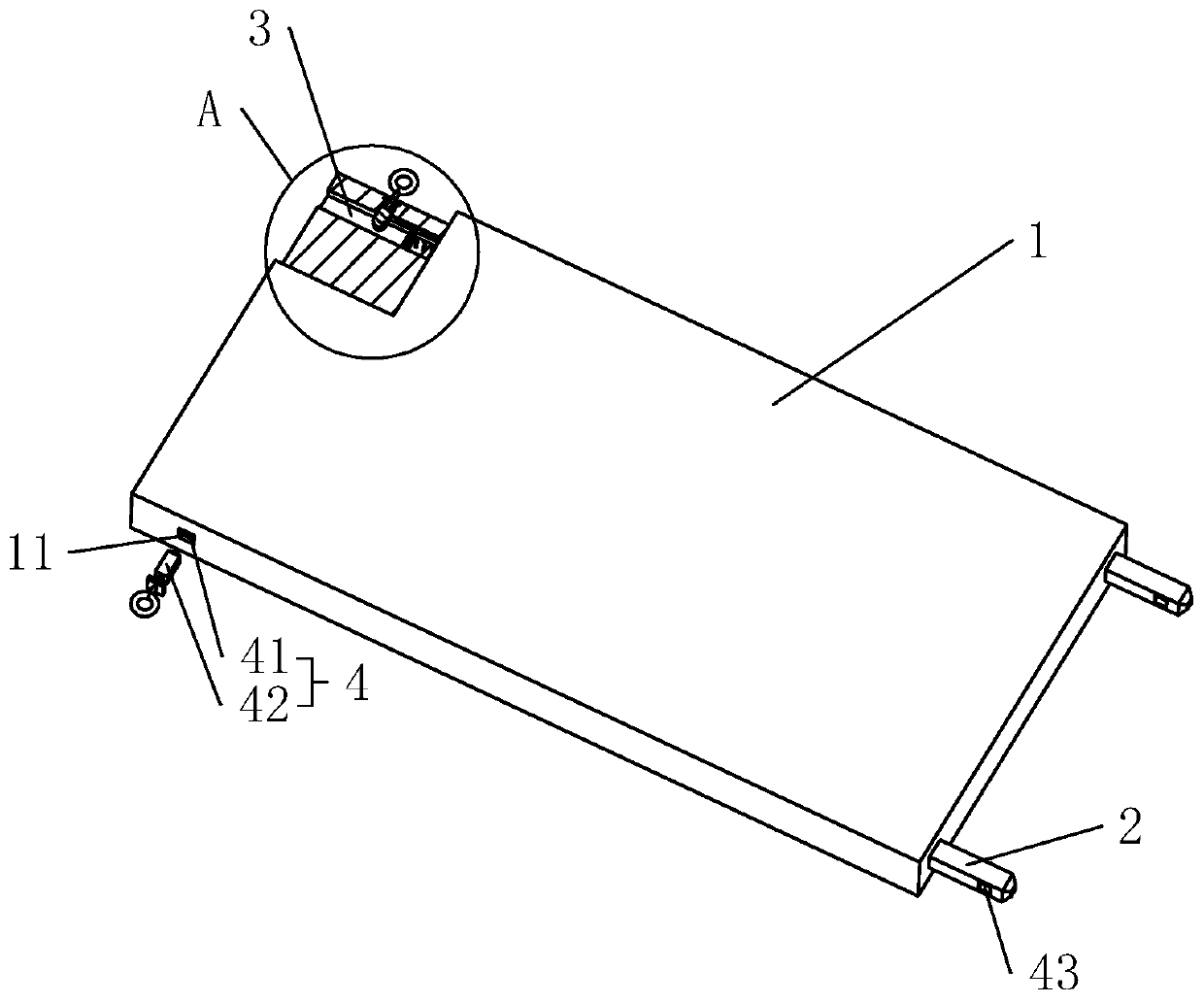

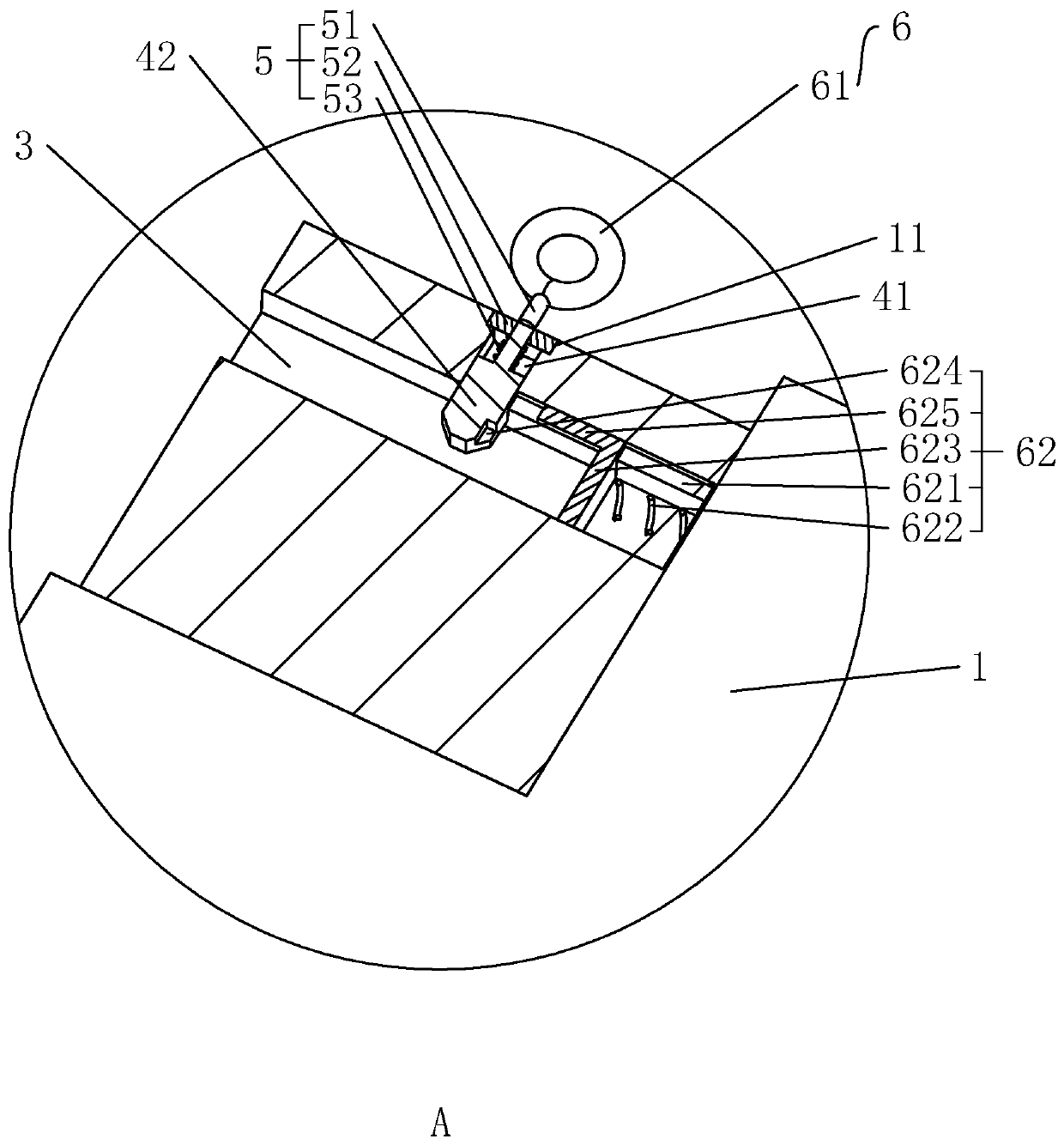

[0057] Such as figure 2 As shown, a prefabricated bridge plate includes a bridge plate body 1, an insertion column 2, and an insertion cavity 3. The bridge plate body 1 is in the shape of a cuboid; each bridge plate body 1 is provided with an insertion column 2 and an insertion cavity. 3. The plug-in column 2 and the plug-in cavity 3 are formed by installing embedded parts during the casting process of the bridge slab, and are mainly used for mutual plugging in the process of splicing the bridge slab body 1 to facilitate two adjacent pieces. The positioning between the bridge bodies 1 can also improve the connection strength between the bridge bodies 1 at the same time.

[0058] After the bridge plate body 1 is prefabricated, it is necessary to install a locking mechanism 4, which is used to lock the insertion column 2 when the insertion column 2 on the adjacent bridge plate body 1 is embedded in its own insertion cavity 3, so as to limit the two bridges. The plate body 1 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com