A device for binding steel bars at beam-column joints

A technology of steel bar binding and beam-column joints, which is applied in the processing of building materials, construction, building construction, etc., can solve the problems of inconvenient carrying and the inability to guarantee the quality of steel bar binding at joints, etc., and achieve the effect of easy portability and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with accompanying drawing:

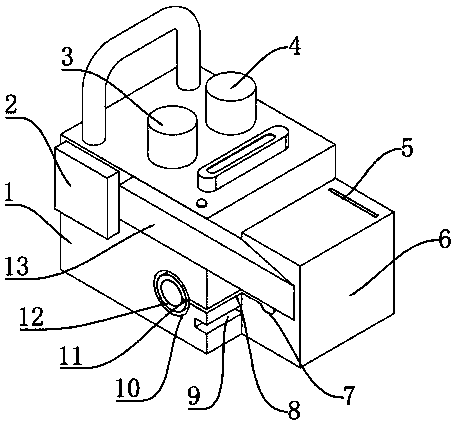

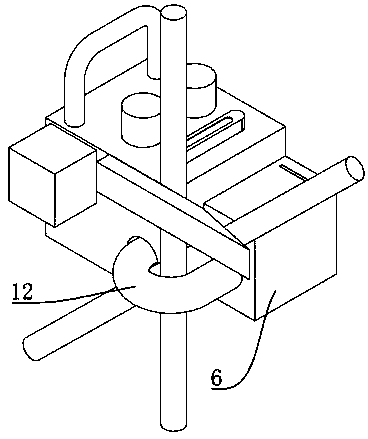

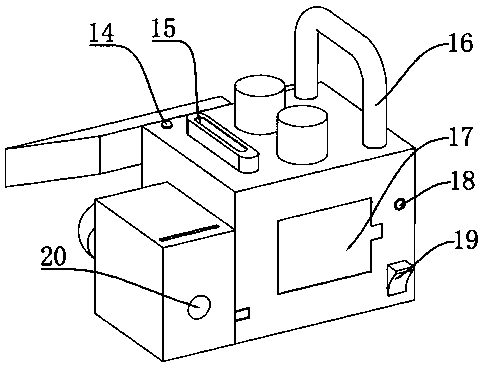

[0017] Such as Figure 1-Figure 3 As shown, a steel bar binding device for beam-column joints includes a fixing base 1, a top block 2 and a binding base 6, a handle 16 is installed on the top of the fixing base 1, and a top block is installed on one side of the handle 16 Button 3, a binding button 4 is installed on one side of the top block button 3, a level 15 is provided on one side of the binding button 4, an indicator light 14 is provided on one side of the level 15, and a Referring to the top block 2, a push rod 13 is installed on one side of the top block 2, a guide hole 10 is arranged below the push rod 13, a guide tube 12 is installed inside the guide hole 10, and a guide tube 12 is arranged on the guide tube 12. Elastic groove 11, the side of described guide hole 10 is provided with contraction groove 8, and described shrinkage groove 8 is provided with chute 9 be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com