Stapler having counting function

A stapler and functional technology, applied in the direction of nailing tools, manufacturing tools, staple tools, etc., can solve the problems of interrupting the staple process, poor cushioning effect of the base, and damage to the bound paper, etc., to achieve guaranteed Continuity, good cushioning effect, quality assurance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

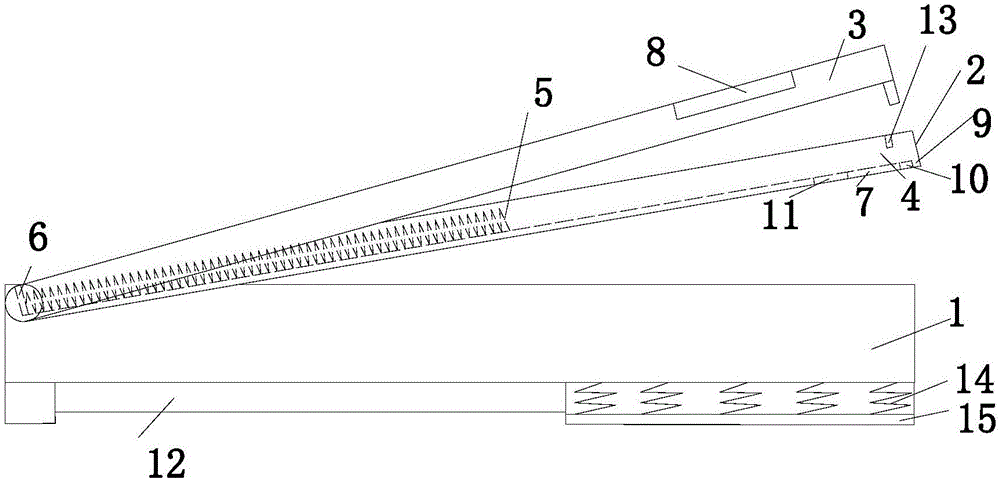

[0012] Embodiment: a kind of stapler with counting function, constitutes as figure 1 As shown, the base 1 is included, and the end of the base 1 is hinged with a needle storage chamber 2 and a needle pressing part 3, and the needle storage chamber 2 is located between the base 1 and the needle pressing part 3; There is a binding groove 4, a delivery spring 5 is arranged in the binding groove 4, a pressure sensor 6 is arranged at the end of the delivery spring 5, the pressure sensor 6 is connected with a controller 7, the controller 7 is connected with a display screen 8, and the display screen 8 is located at the pressure The surface of the needle part 3; the end of the binding groove 4 is provided with a needle opening 9, and the needle opening 9 is provided with a non-contact counter 10, and the non-contact counter 10 is connected with the controller 7; the controller 7 is connected with The buzzer alarm 11 located inside the needle storage chamber 2; the bottom of the base ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com