Nailless binding device

A staple-free bookbinding and bookbinding machine technology, applied in directions such as bookbinding, can solve the problems of affecting the positioning accuracy of the slicing device 51 and the notch blade 52, the bookbinding quality, the needle tip lifting, affecting the cutting accuracy, etc., so as to improve the bookbinding accuracy and the binding quality, Reduce the fit gap and ensure the effect of accurate positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0067] In order to make the purpose, technical solution and advantages of the present invention clearer, the technical solution of the present invention will be clearly and completely described below. All other implementations obtained below fall within the protection scope of the present invention.

[0068] Before describing the specific implementation, it is stipulated that the binding position on the stapler is the front end, and the operating part of the handle is the rear end (it can also be regarded as the gripping part of the handle); and the direction of the line from the front end to the rear end is defined as the longitudinal direction .

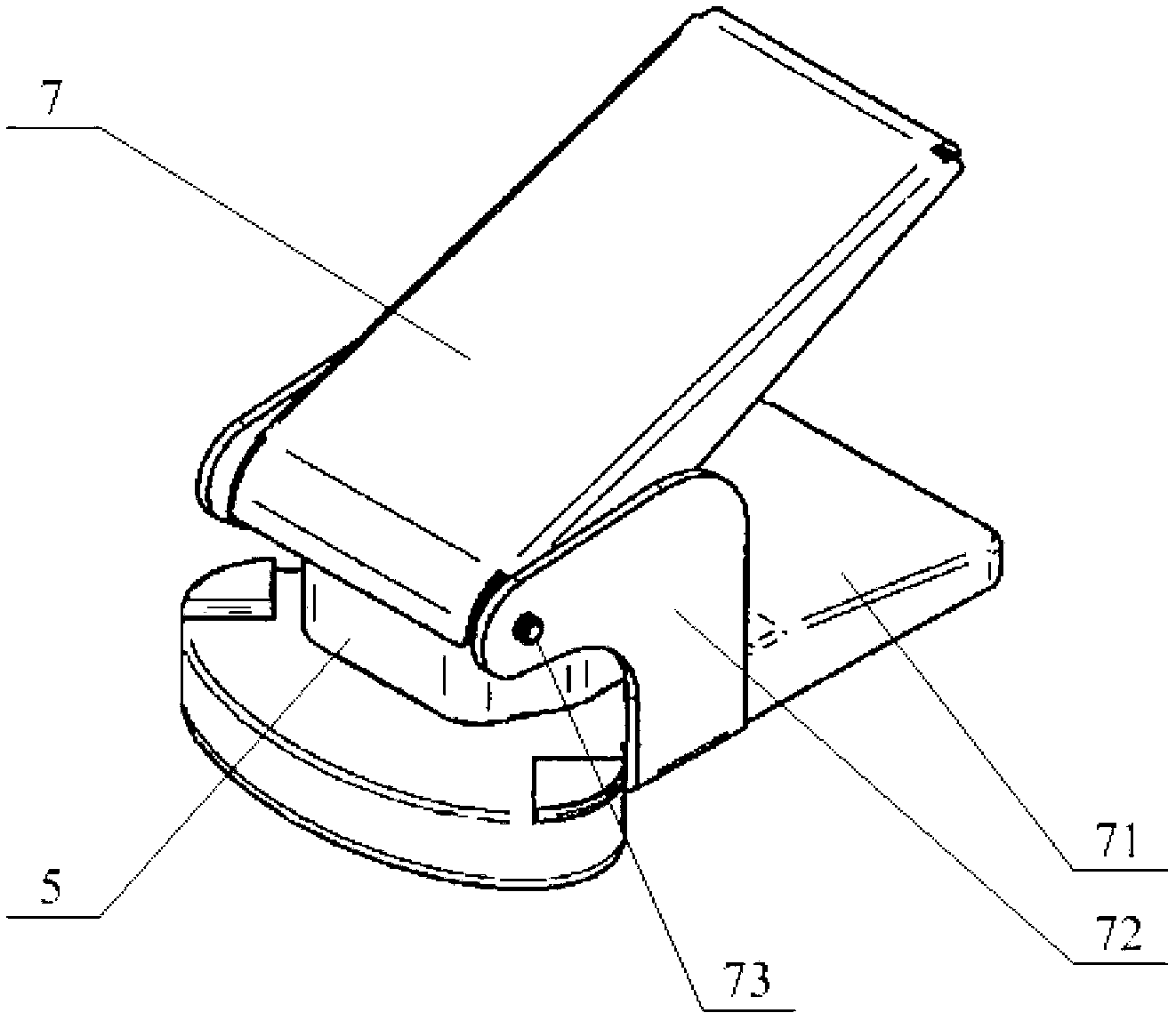

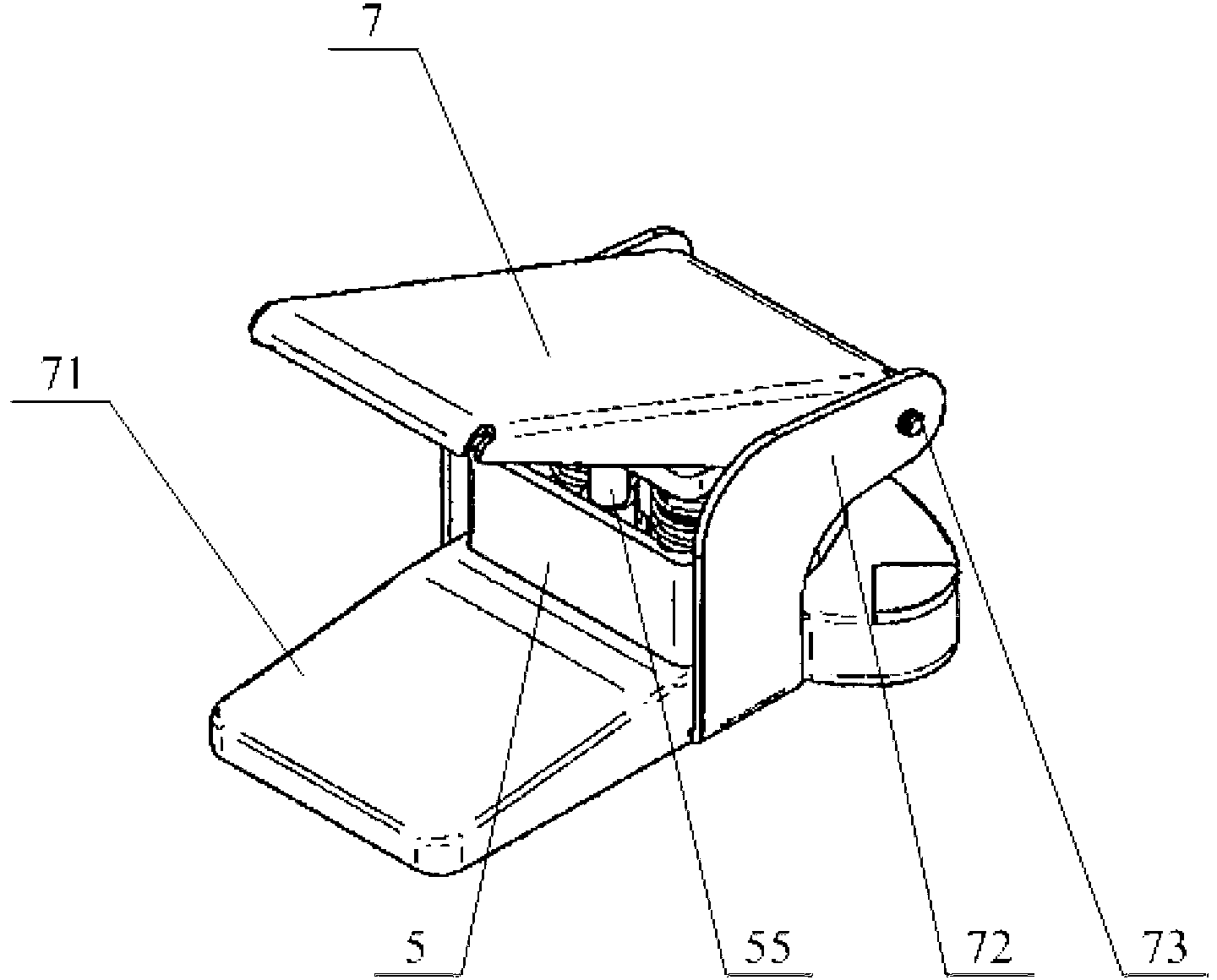

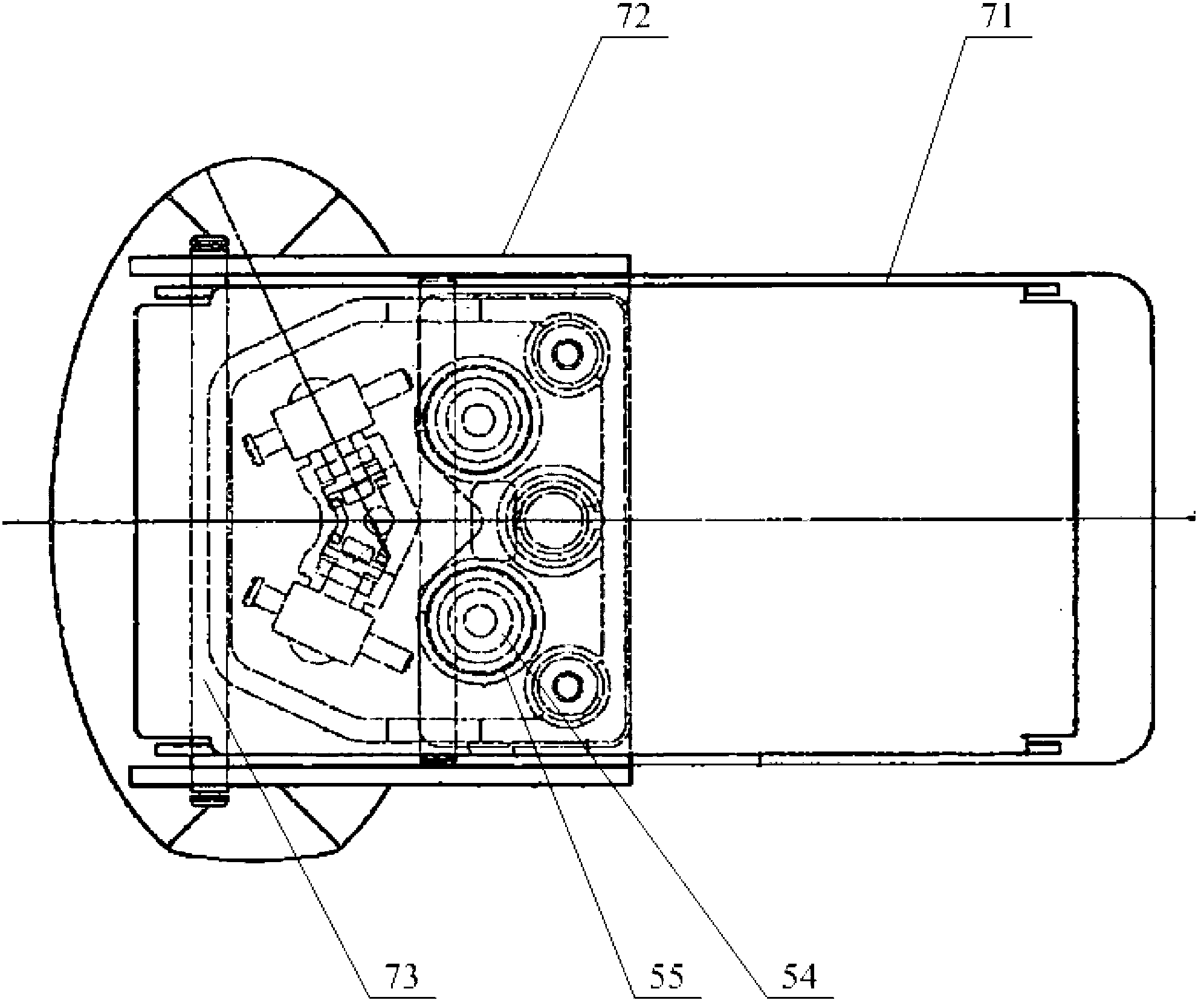

[0069] Such as Figures 8 to 11 As shown, the staple-free stapler provided by the embodiment of the present invention includes a handle 1, an abutment 2 and a binding machine 3, and the two sides of the abutment 2 along the longitudinal direction are provided with support plates 21, and the front ends of the handle 1 are placed on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com