Binding machine and application method thereof

A binding machine and clamping device technology, applied in the field of binding machines, can solve the problems of inaccessibility and achieve the effect of convenient operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

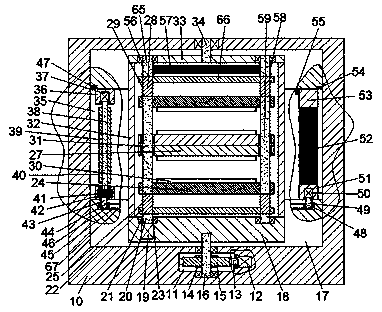

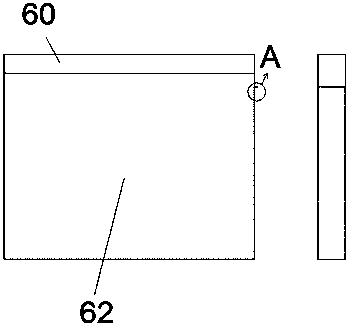

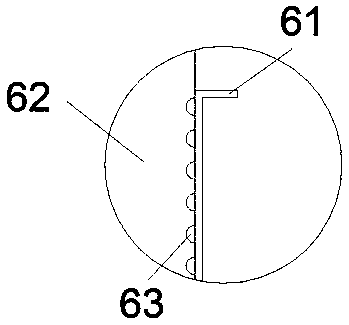

[0019] Combine below Figure 1-4 The present invention will be described in detail.

[0020] refer to Figure 1-4 , according to an embodiment of the present invention, a binding machine and its use method include a device main body 10, a paper wrap clamping device fixed in the device main body 10, a milling back fixed in the device main body 10 device, a hot-melt gluing device fixed in the device main body 10, the paper package clamping device includes a first working chamber 11 fixed in the device main body 10, the right side of the first working chamber 11 A first motor 12 is fixed inside the inner wall, and the output shaft at the left end of the first motor 12 is dynamically connected with a first rotating shaft 13 extending leftward into the first working chamber 11. There is a worm 14, and the front end of the worm 14 is meshed and connected with a worm wheel 15, and a rotatable second shaft 16 is fixed at the center of the worm wheel 15, and an opening is fixed in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com