Gluing and binding machine

A technology of a perfect binding machine and a frame, which is applied in the field of structural improvement of the perfect binding machine, can solve the problems of reducing the adhesiveness, less dosage and the most uniform effect, deformation of the spine, etc., so as to increase the glued area and improve the glue The effect of reducing order quality and glue depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

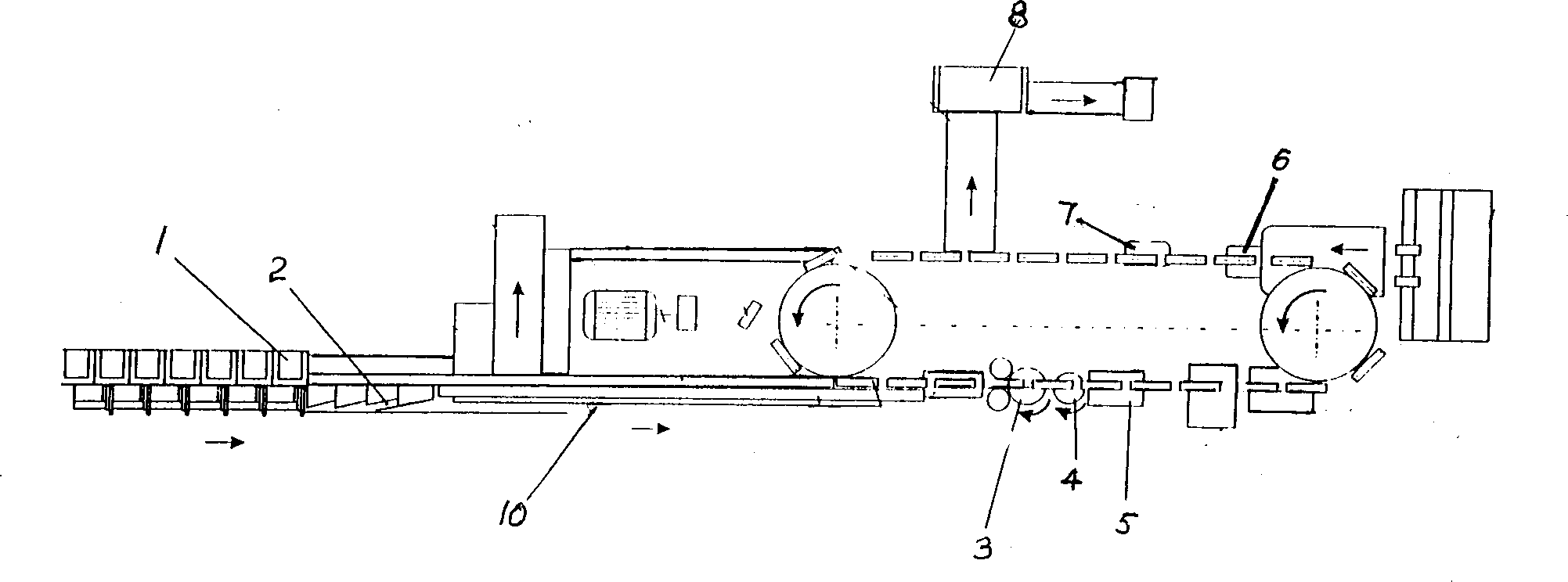

[0028] The present invention designs the embodiment of two kinds of perfect binding machines, in conjunction with each accompanying drawing, describe in detail respectively as follows:

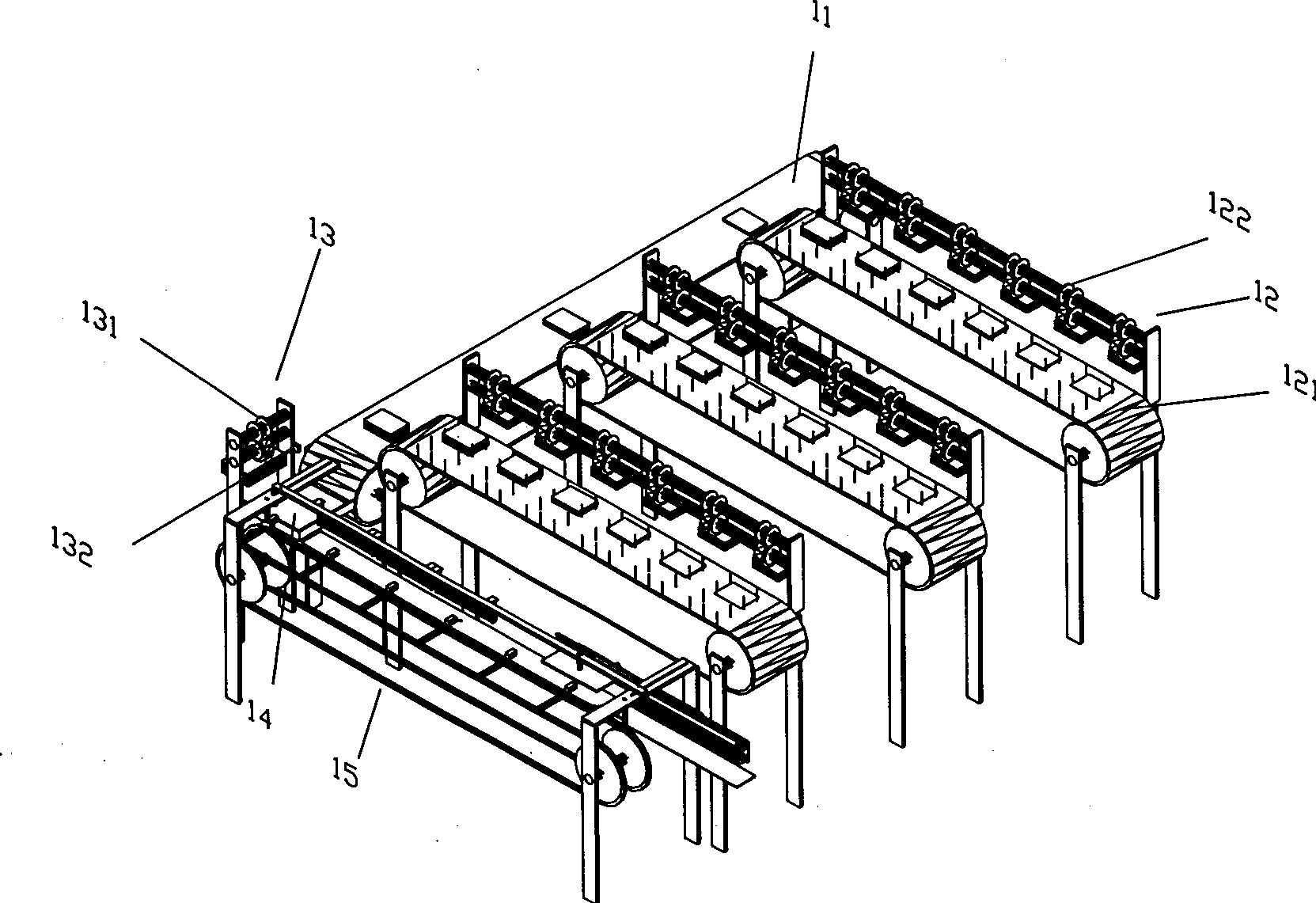

[0029] The general structure of a kind of perfect binding machine embodiment one that the present invention designs is as follows: figure 2 As shown, this embodiment is suitable for the perfect binding of various books, and its composition includes a collating mechanism 12, a cover conveying mechanism 13, a vibrating mechanism 14 and a perfect binding forming mechanism combined by a main conveyor belt 11 and controlled by a programmable controller. Agency15. The collating mechanism 12 is composed of a plurality of collating conveyor belts 121 and multiple groups of paper suction devices 122 installed on the frame; the cover conveying mechanism 13 is composed of a group of paper suction devices 131 and creasing wheels 132 mounted on the frame; The vibrating mechanism 14 is made of a receiving...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com