Thread binding tool

A technology for binding tools and cavities, applied in the direction of binding, etc., can solve the problems of uneven binding effect, low efficiency, manual processing, etc., and achieve the effects of good practicability, reduction of manual operation, and reliable and stable transmission.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

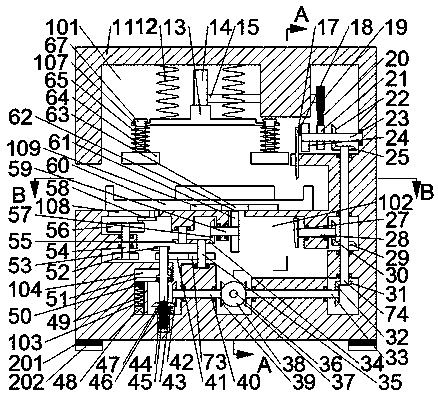

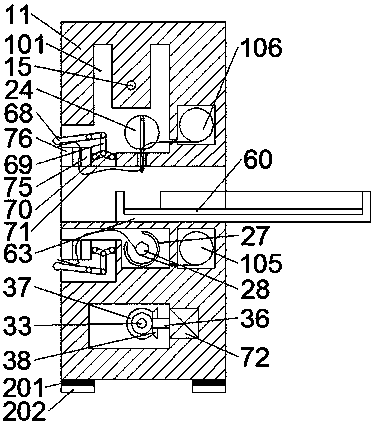

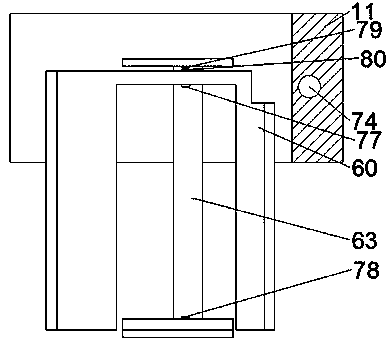

[0022] Such as Figure 1-Figure 5 As shown, a wire-binding binding tool of the present invention includes a body 11 and a first cavity 101 disposed in the body 11, a second cavity 102 is disposed below the first cavity 101, The second cavity 102 is rotatably provided with a first rotating shaft 36 extending forward and backward, and the front end of the first rotating shaft 36 is powered by the motor 72 fixedly arranged in the front end wall of the second cavity 102. connected, the rear end of the first rotating shaft 36 is fixedly provided with a first bevel gear 38, and the second rotating shaft 40 extending left and right is arranged in rotation in the second cavity 102, and the right side of the second rotating shaft 40 The end is fixedly provided with a second bevel gear 39 meshing with the first bevel gear 38 , the left end of the second rotating shaft 40 is fixedly provided with a third bevel gear 42 , and the second cavity 102 is rotatably provided with a vertically ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com