Binding device for ancient volume imitating Chinese language and literature

A language and literature technology, applied in the field of binding devices imitating Chinese language and literature ancient scrolls, can solve problems such as inconvenience, low punching efficiency and unsafety, ancient scroll paper wrinkles, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

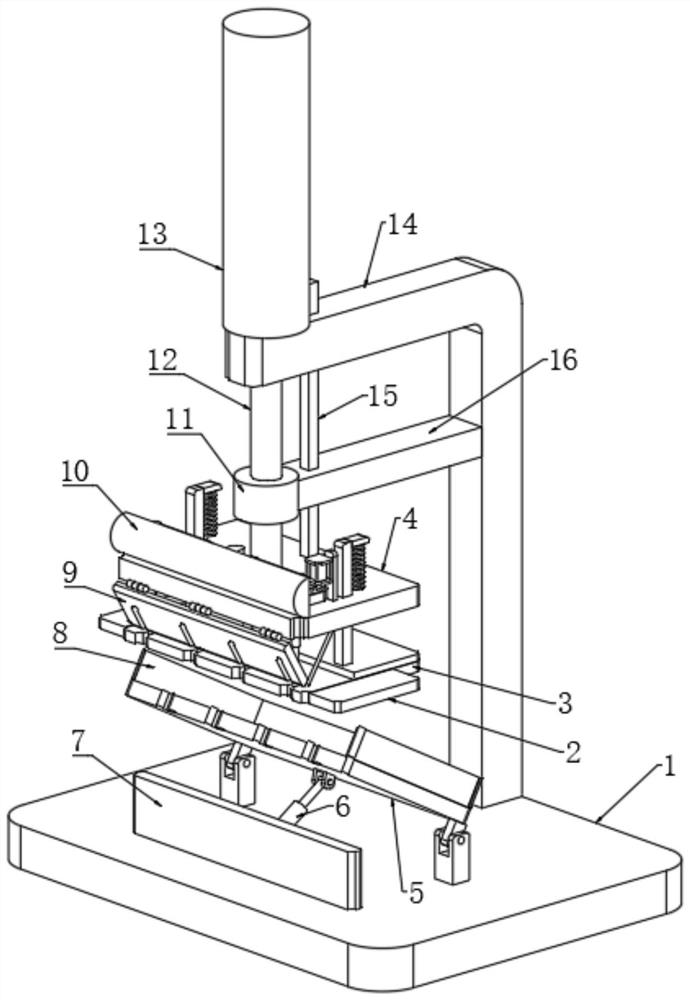

[0027] A binding device imitating an ancient scroll of Chinese language and literature, comprising a base 1, the upper end of the base 1 is fixedly connected with an inverted L-shaped fixed frame 14 on the rear side, and the upper end of the horizontal part of the fixed frame 14 is slidingly sleeved with a push rod through a round hole 12. The lower end of the push rod 12 passes through the round hole and is fixedly connected with the mounting plate 4. The upper end of the mounting plate 4 is connected with a punching mechanism on the front side. The lower end of the mounting plate 4 is provided with a pressure plate 3, and the left and right ends of the pressure plate 3 are fixed. Elastic steel plate 2 is connected, and the upper end of pressing plate 3 is connected with positioning mechanism, and positioning mechanism is connected with the side wall of mounting plate 4, and positioning mechanism comprises two guide rods 18 that are vertically arranged on the upper end of press...

Embodiment 2

[0029] Embodiment 2: the difference based on Embodiment 1 is;

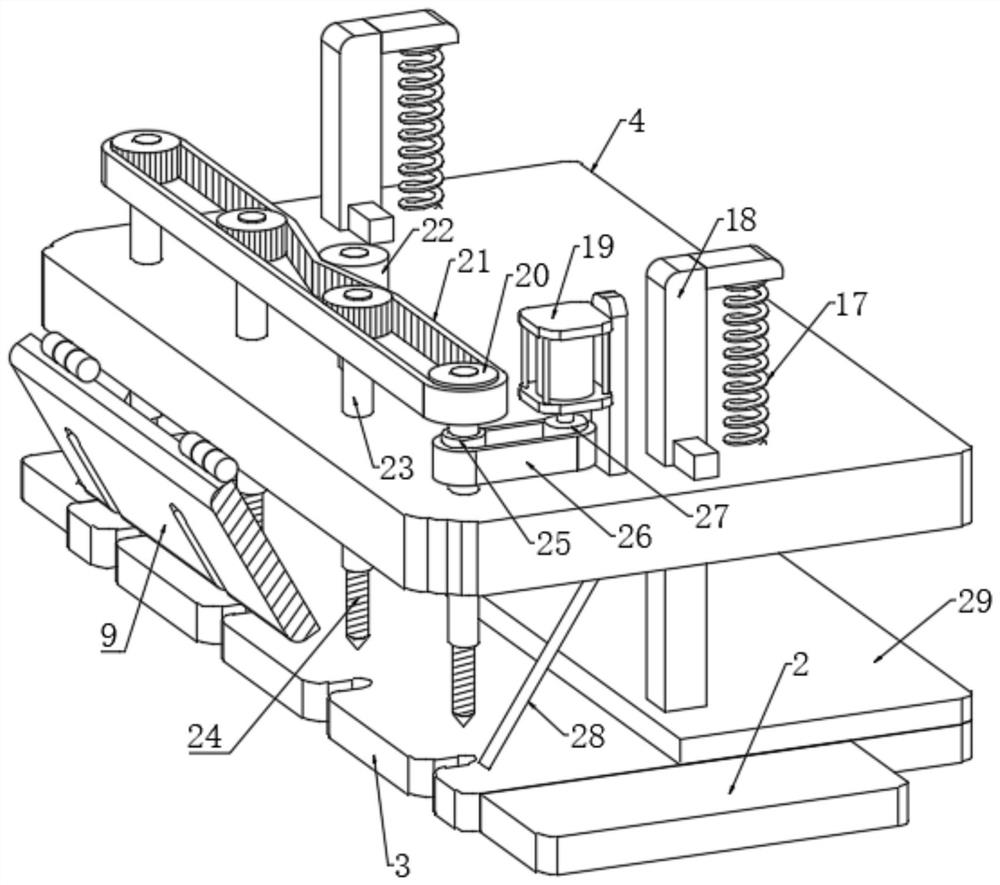

[0030] The punching mechanism includes a plurality of transmission shafts 23 connected to the front side of the upper end of the mounting plate 4 through rolling bearing vertical rotation. The spacing of the plurality of transmission shafts 23 is the same as the spacing of the plurality of gaps. Drill bit 24, the upper end of mounting plate 4 is provided with synchronous belt 21, is connected with a plurality of evenly distributed synchronous wheels 20 in synchronous belt 21, and a plurality of synchronous wheels 20 is fixedly connected with the coaxial center of the upper end of a plurality of transmission shafts 23 respectively, wherein The shaft wall of a power transmission shaft 23 is fixedly connected with the first pulley 25, the upper end of the mounting plate 4 is fixedly connected with the first motor 19 through the bracket, and the output end of the first motor 19 is fixedly connected with the second pull...

Embodiment 3

[0033] Embodiment 3: the difference based on embodiment 1 is;

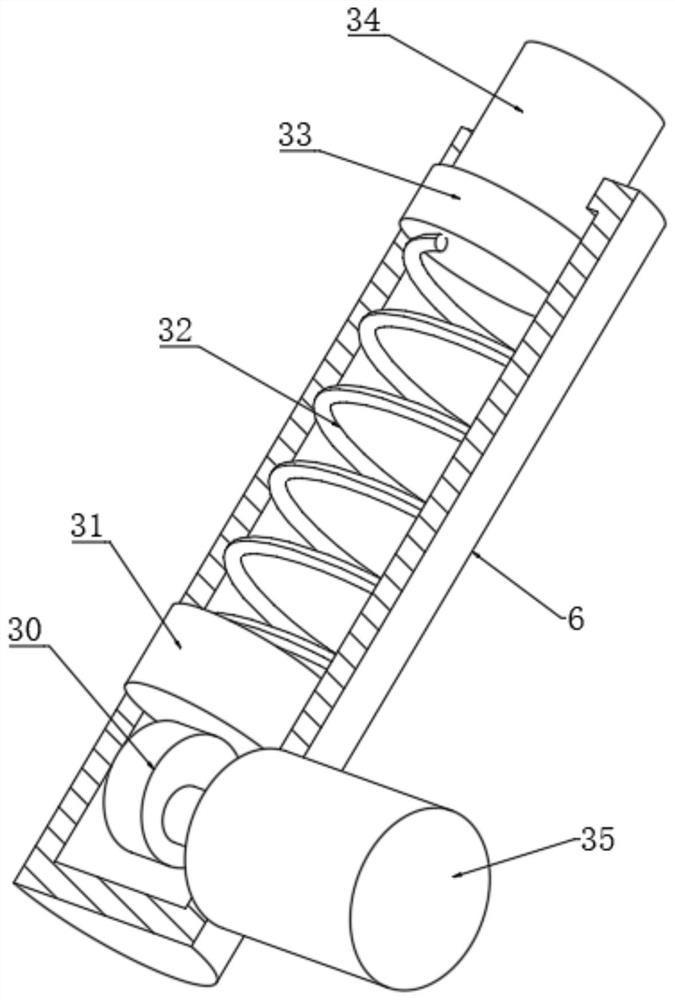

[0034] The support mechanism includes a support rod 34 slidingly socketed on one end of the housing 6 through a circular opening. One end of the support rod 34 is rotationally connected with the lower end of the bearing plate 5 through a pin, and one end of the support rod 34 passes through the circular opening and is fixedly connected with a circular plate. 33. A spring 32 is fixedly connected to one side of the circular plate 33. The elastic force of the spring 32 is less than the sum of the elastic forces of the two elastic steel plates 2. The end of the spring 32 away from the circular plate 33 is fixedly connected with a cylindrical block 31. The cylindrical block 31 is far away from the spring 32. An eccentric wheel 30 is slidably connected to one end of the housing 6, and a second motor 35 is fixedly connected to one side of the housing 6, and the output end of the second motor 35 penetrates the side wall of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com