Milling device of perfect binding machine for tabletop

A glue binding machine and milling technology, which is applied in the field of milling devices, can solve problems affecting the normal use of books, paper scraps cannot be cleaned in time, and affect the quality of glue coating, etc., and achieve the goals of improving binding quality, timely paper scraps, and convenient operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

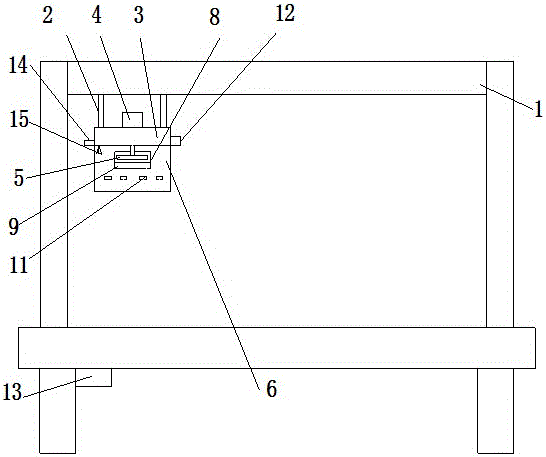

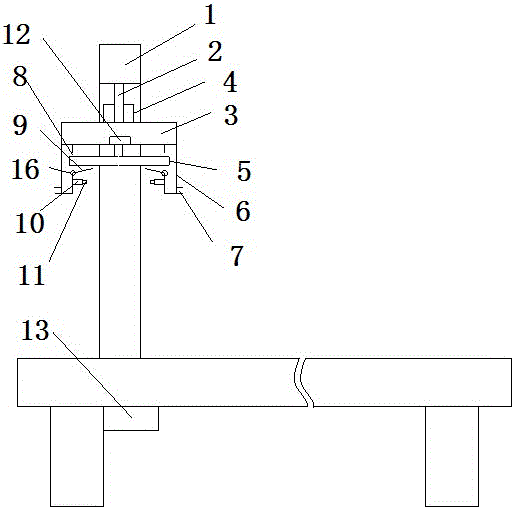

[0013] The present invention will be further described below in conjunction with the accompanying drawings and examples, but not as a basis for limiting the present invention.

[0014] Example. The milling and grinding device of the desktop glue binding machine is composed of figure 1 and figure 2 As shown, it includes a hydraulic rod 2 fixed on the slide rail 1 of the adhesive binding machine. The end of the hydraulic rod 2 is provided with a fixed plate 3, and a motor 4 is provided above the fixed plate 3. The motor 4 is connected to a milling cutter 5, and the milling cutter 5 is located at The bottom of the fixed plate 3; the two sides below the fixed plate 3 are provided with a dust suction shell 6, the bottom of the outer side of the dust suction shell 6 is provided with a dust suction pipe 7, and the inside of the dust suction shell 6 is provided with the position of the milling cutter 5 Corresponding to the dust suction opening 8, the lower end of the dust suction o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com