Clamp for milling excircle

An outer circumference and fixture technology, applied in clamping, milling machine equipment, manufacturing tools, etc., can solve the problems of cumbersome processing, difficult to guarantee processing accuracy, low processing efficiency, etc., to improve processing accuracy and efficiency, clamping and unloading. The effect of convenience and shortening of loading and unloading time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

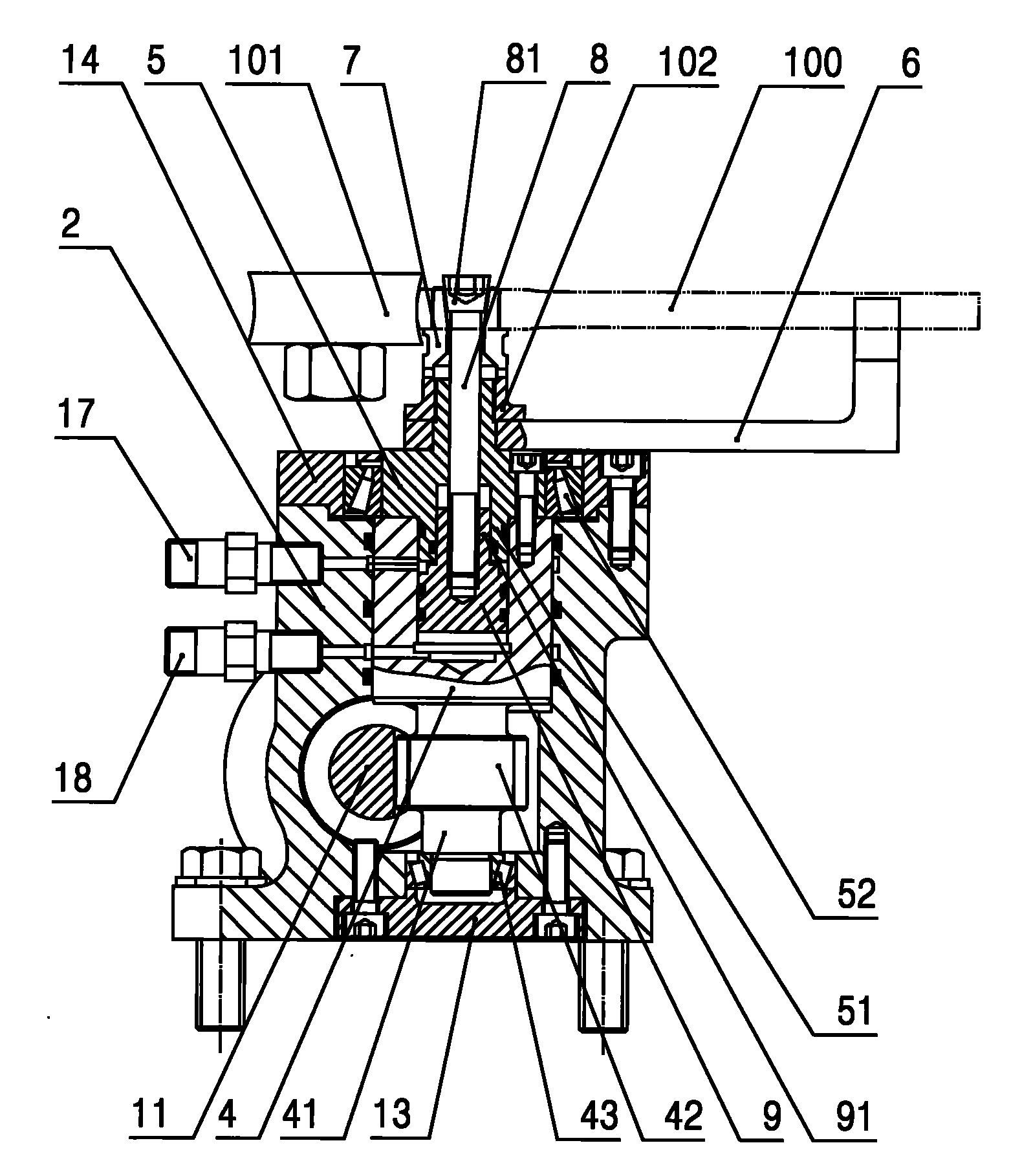

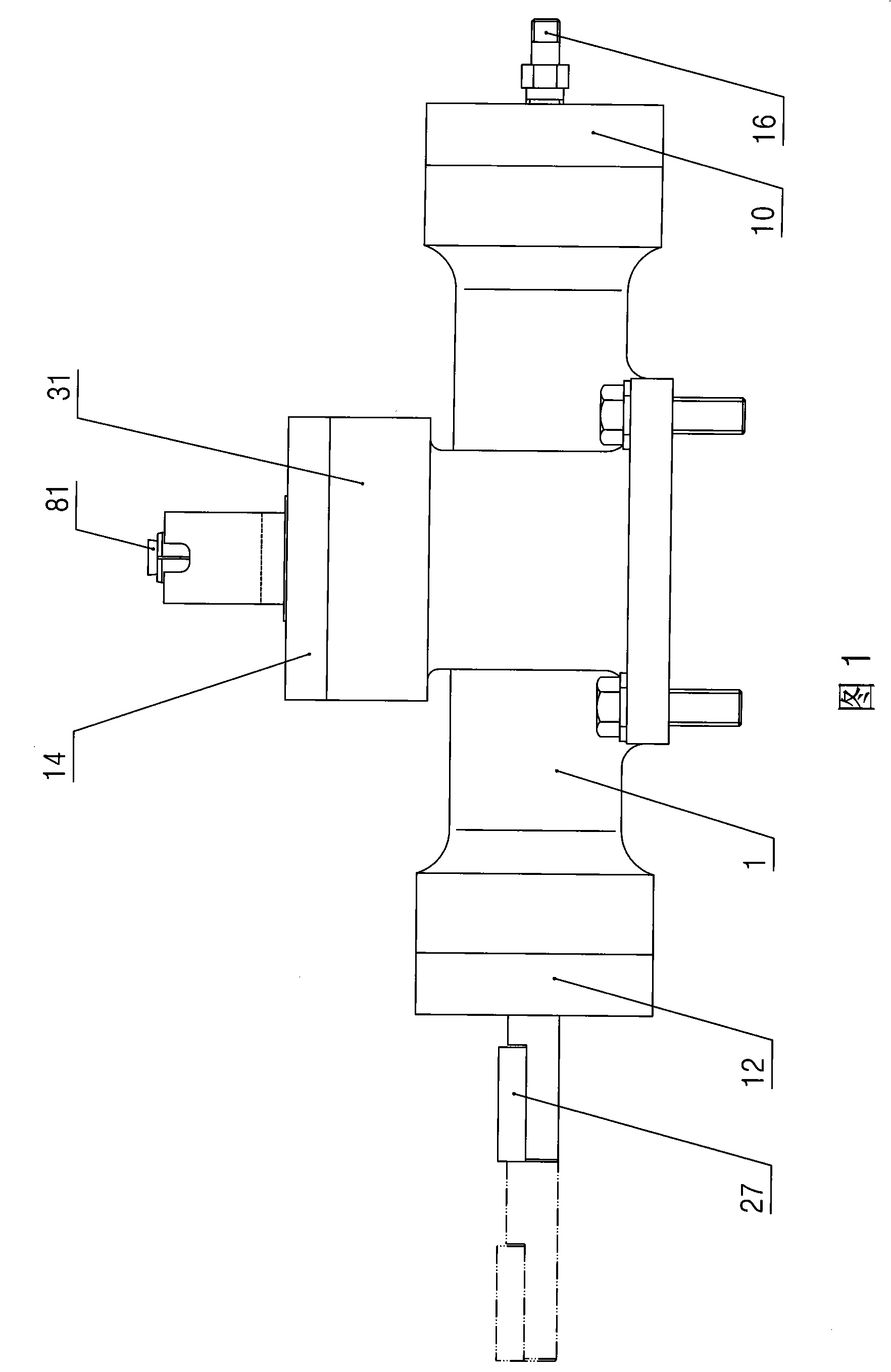

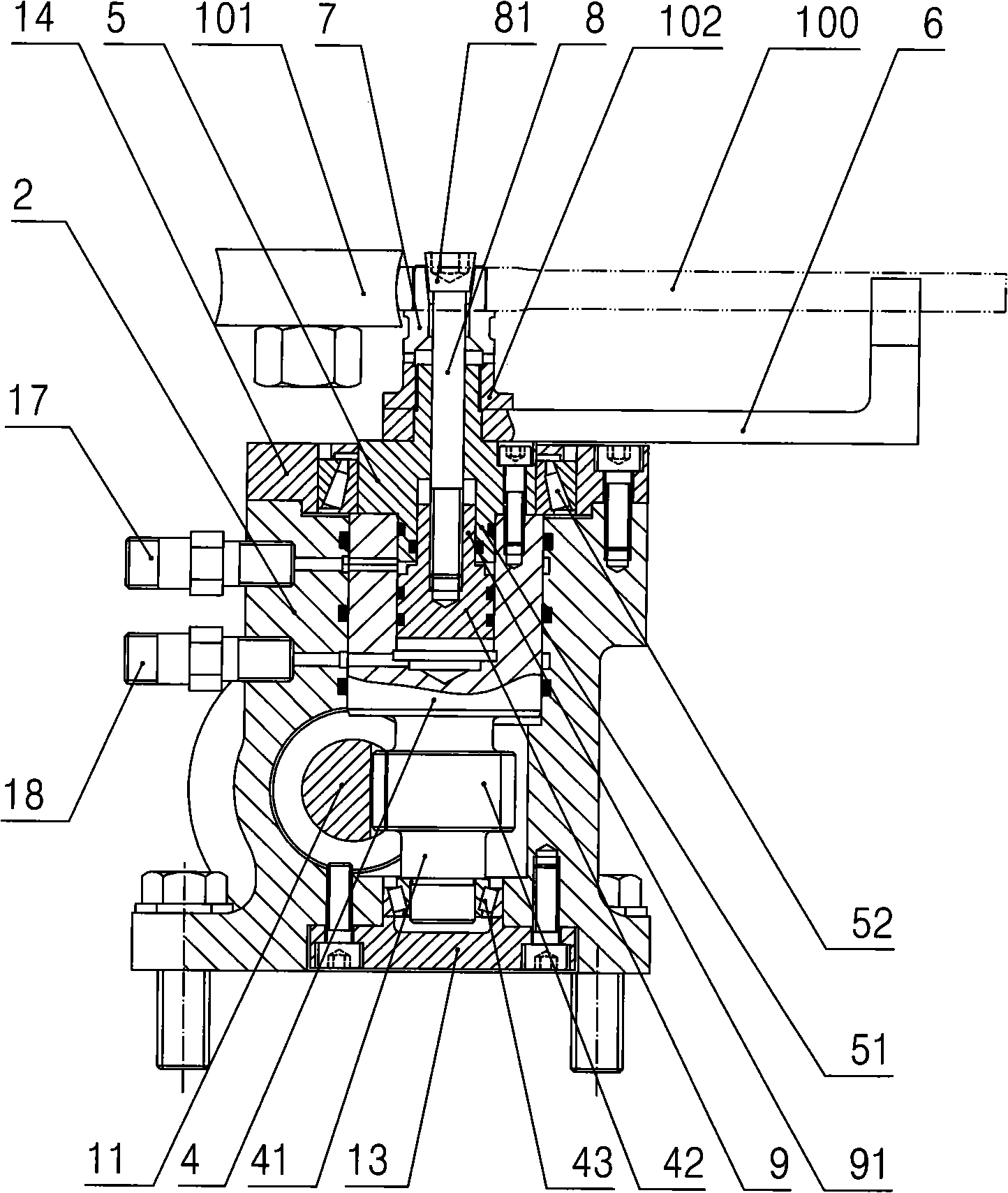

[0013] As shown in Fig. 1 and Fig. 2, the jig for milling the outer circumference of the present invention includes: a base 1, on which a cylinder 2 and a drive to rotate the rotating shaft 4 in the inner cavity of the cylinder 2 are arranged. The upper cover 14 is arranged on the cylinder body 2, and the lifting oil chamber is opened on the top of the rotating shaft 4, and the lifting piston 9 movably arranged in the lifting oil chamber divides the lifting oil chamber into upper and lower oil chambers, and the upper and lower oil chambers The chamber is dynamic and changes according to the position of the lifting piston 9. A lifting sealing ring is arranged between the side wall of the lifting piston 9 and the wall of the lifting oil chamber. Fixed, the sealing plug 51 arranged at the bottom of the transition shaft 5 is embedded in the liftin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com