Auxiliary support device for milling machine

An auxiliary support and milling machine technology, applied in milling machine equipment, milling machine equipment details, large fixed members, etc., can solve problems such as time-consuming and laborious, limited milling machine feed, affecting normal production, etc., to improve work efficiency, realize automatic milling, The effect of increasing the width

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

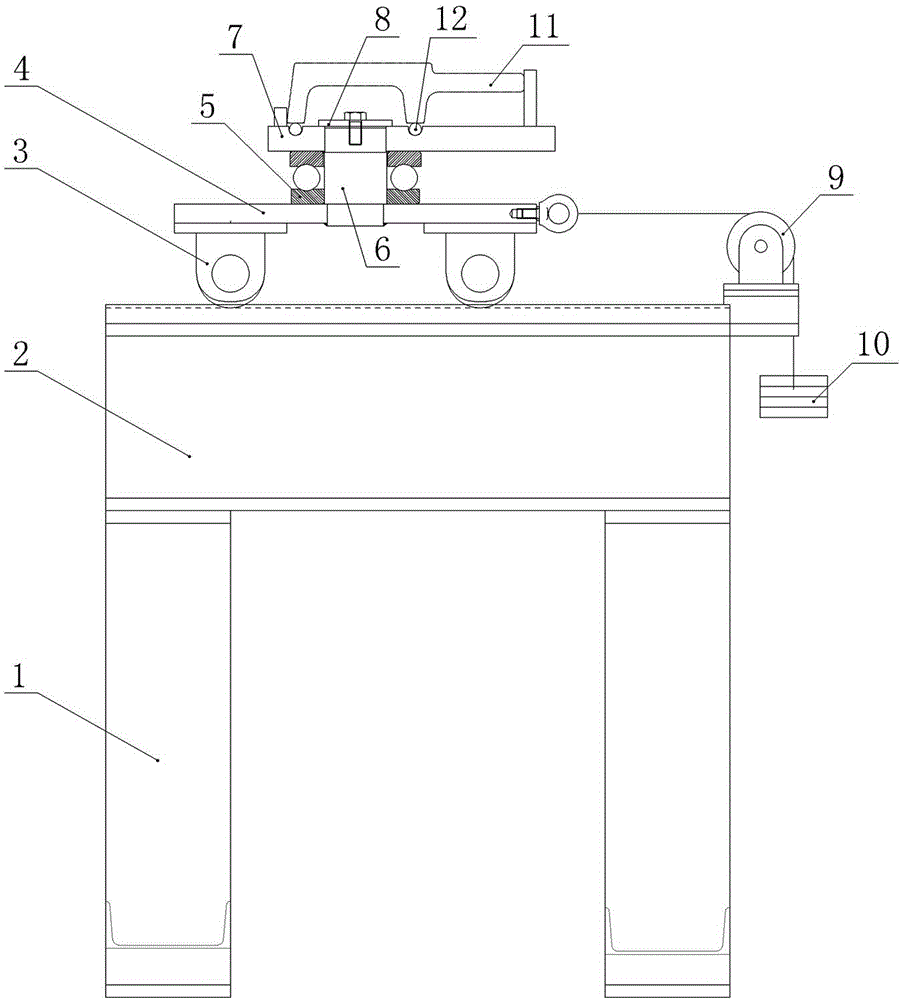

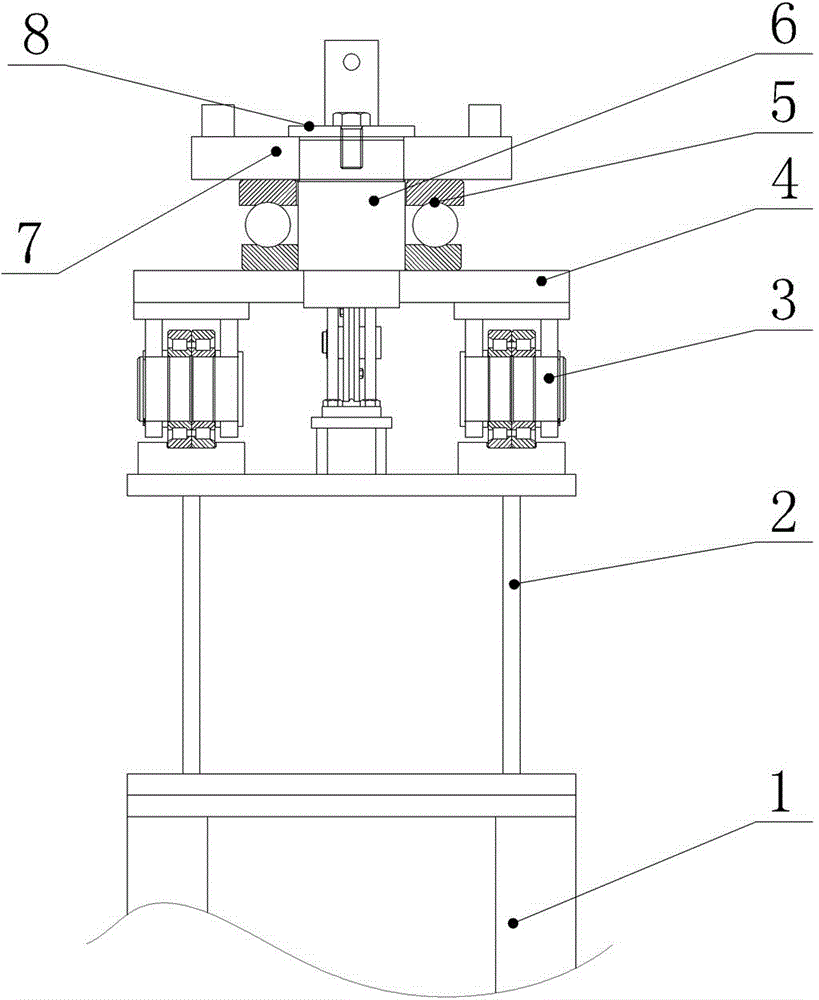

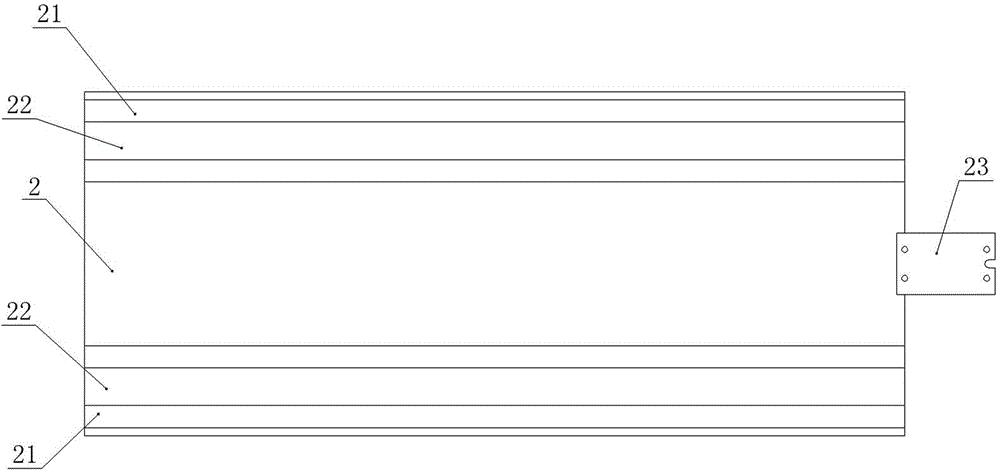

[0026] like figure 1 and figure 2 As shown, the front view and the left side view of the milling machine auxiliary support device of the present invention are provided respectively, which include a support 1, a base 2, a support wheel 3, a lower support plate 4, a bearing 5, a support shaft 6, and an upper support plate 7 , pressing plate 8, fixed pulley 9, counterweight 10. The shown base 2 is fixed above the support 1, and the support 1 is fixed on the foundation; image 3 and Figure 4 A top view and a left side view of the base 2 are given. Guide rails 21 parallel to each other are arranged along the length direction of the base 2 , and guide rail grooves 22 are opened on the guide rails 21 . Four support wheels 3 are fixed on the four corners of the lower surface of the lower support plate 4, and the bottom of the support wheels 3 is placed in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com