Automatic milling machine

A milling machine and automatic technology, which is applied to milling machine equipment, milling machine equipment details, metal processing, etc., can solve problems such as low production efficiency and increased work intensity of operators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

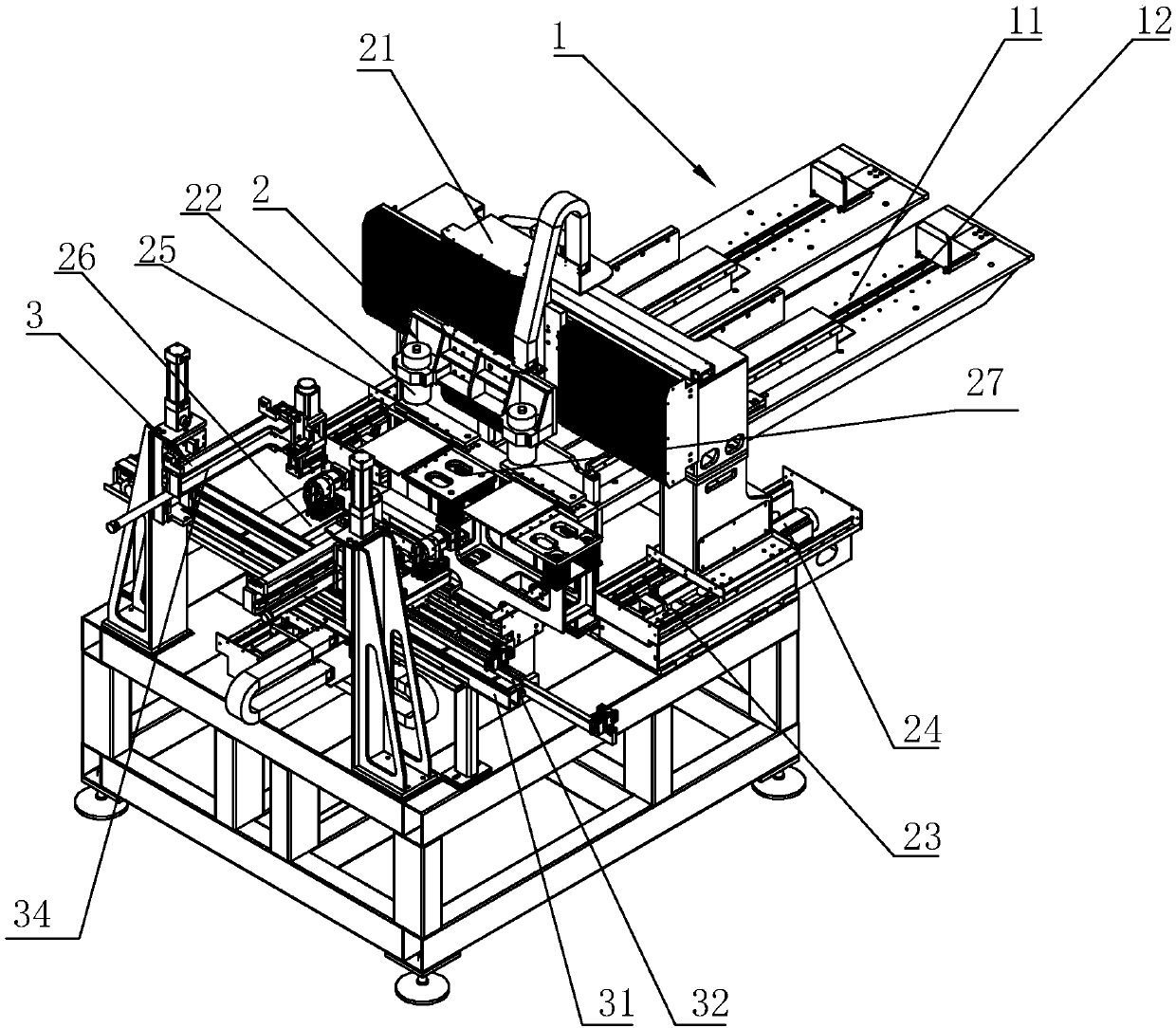

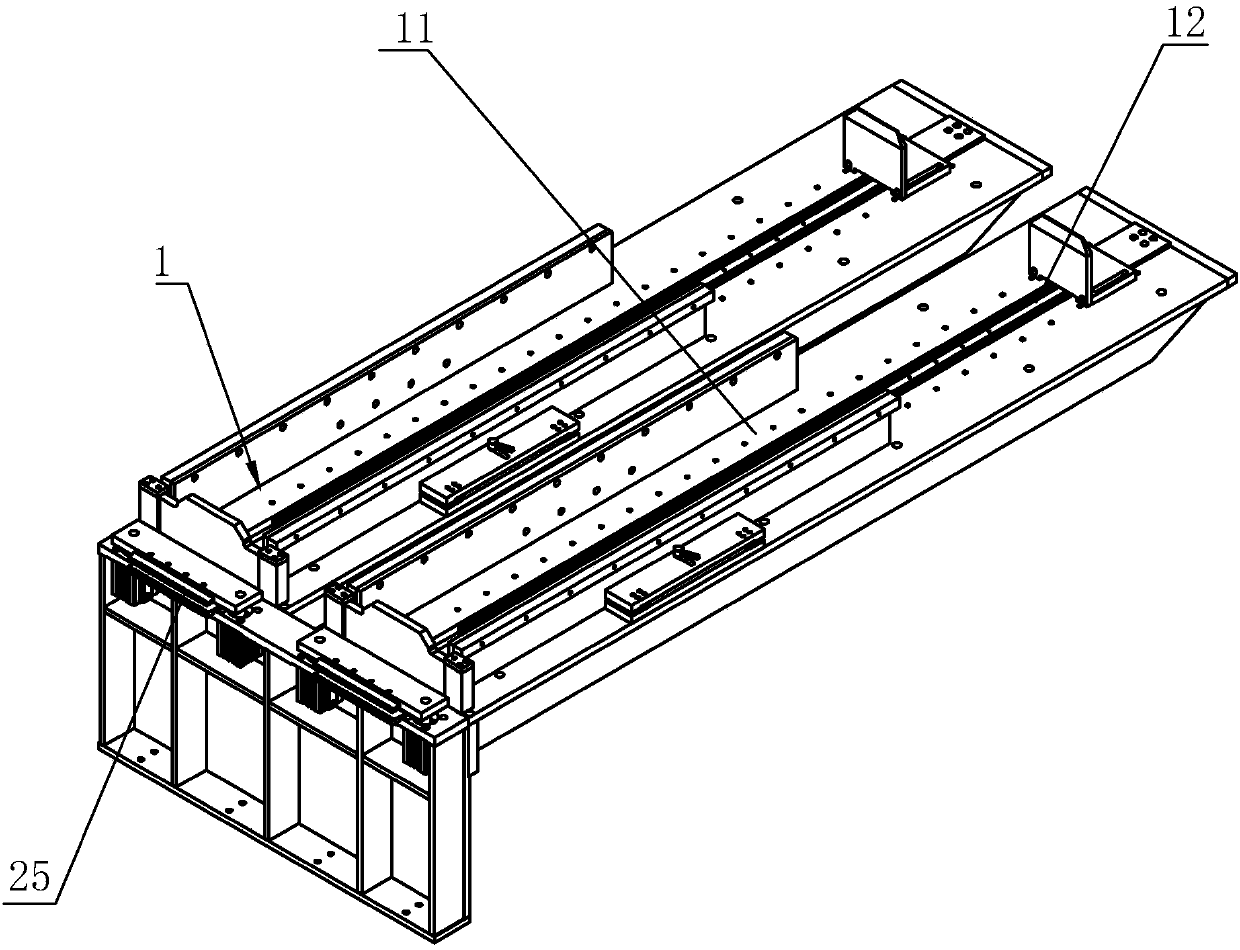

[0030] Refer to attached Figure 1 to Figure 6 The embodiment of an automatic milling machine of the present invention will be described in further detail.

[0031] An automatic milling machine, comprising a feeding mechanism 1, a milling mechanism 2 and a receiving and transferring mechanism 3, the milling mechanism 2 being placed between the feeding mechanism 1 and the receiving and transferring mechanism 3;

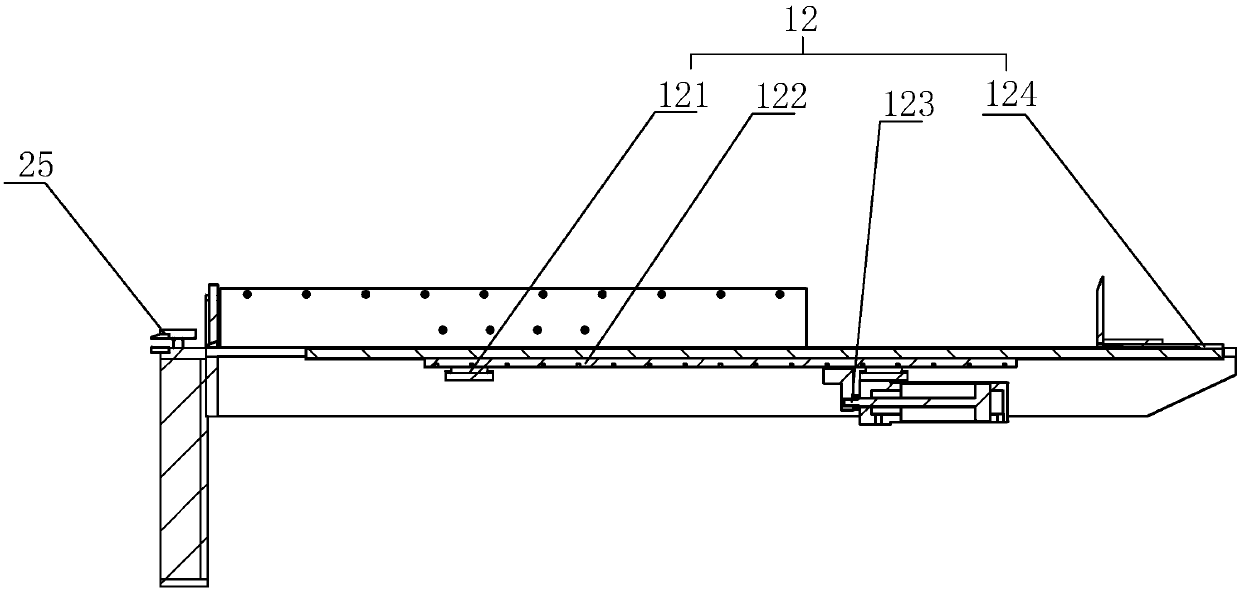

[0032] The feeding mechanism 1 includes a discharge space 11 for placing plates and a plate pushing device 12 for pushing the plates from the discharge space 11 to the milling mechanism 2;

[0033] Wherein the left limiting plate, the right limiting plate, the front limiting plate and the rear limiting plate encircle and form a discharge space 11 for placing plates, wherein the front limiting plate is provided with a discharge port for the plates to pass through; The rear limiting plate is provided with a waist-shaped hole, and the rear limiting plate adjusts the dist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com