Special milling machine for square riser

A square and riser technology, applied in the field of square riser milling machines, can solve the problems of poor operating environment, low grinding efficiency, and major safety hazards for operators, so as to eliminate safety hazards, improve machining accuracy and quality, and reduce labor. the effect of strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

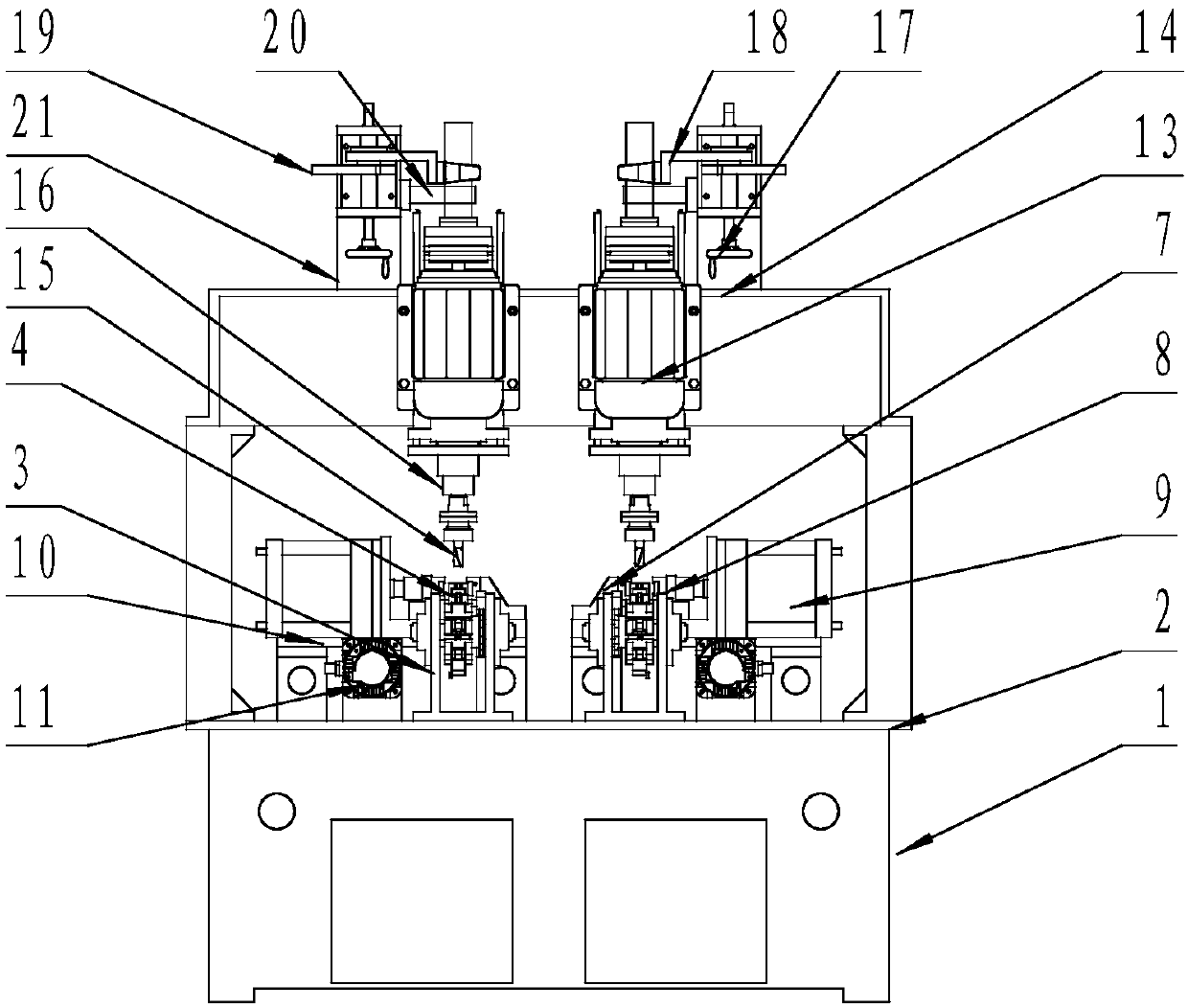

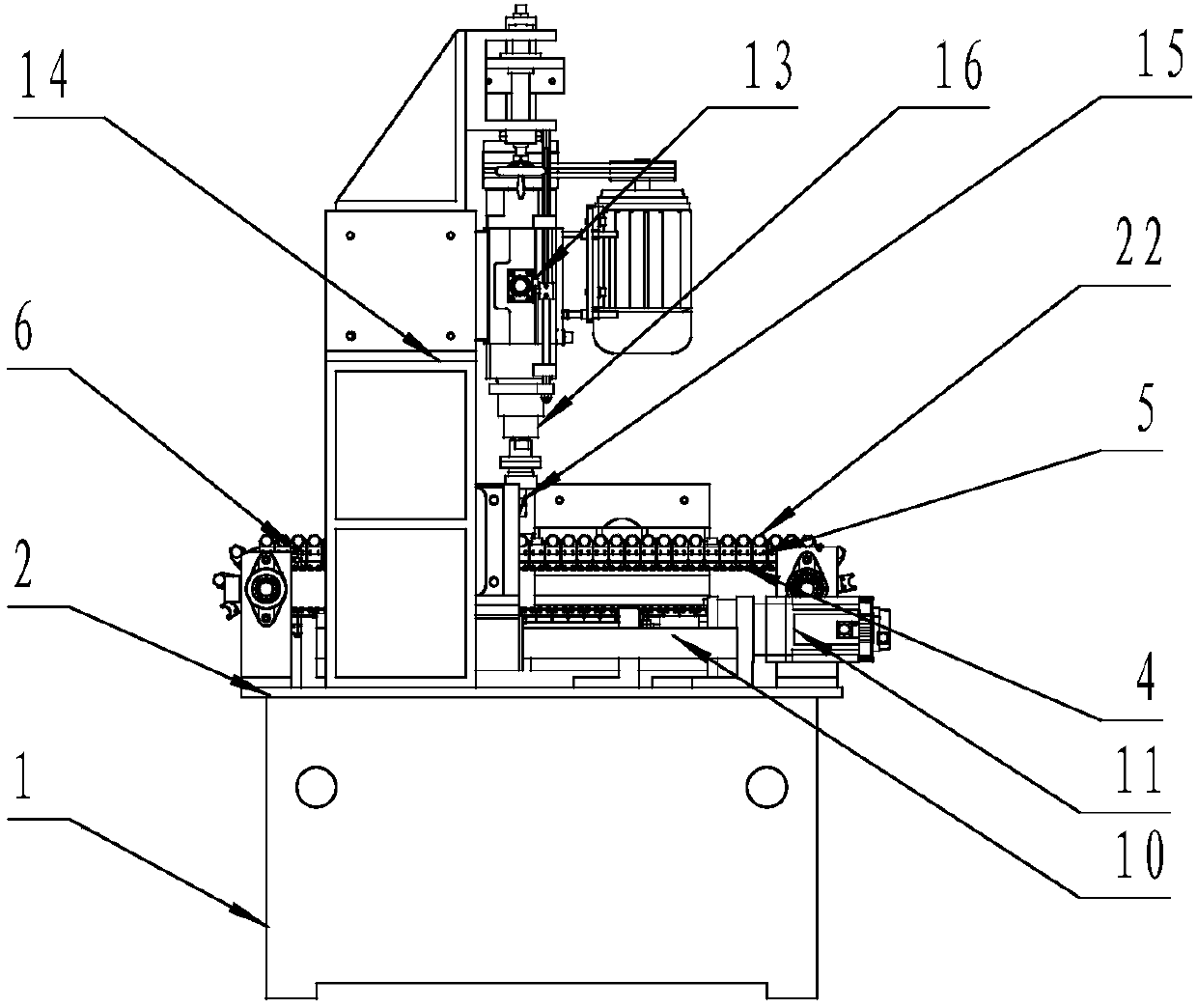

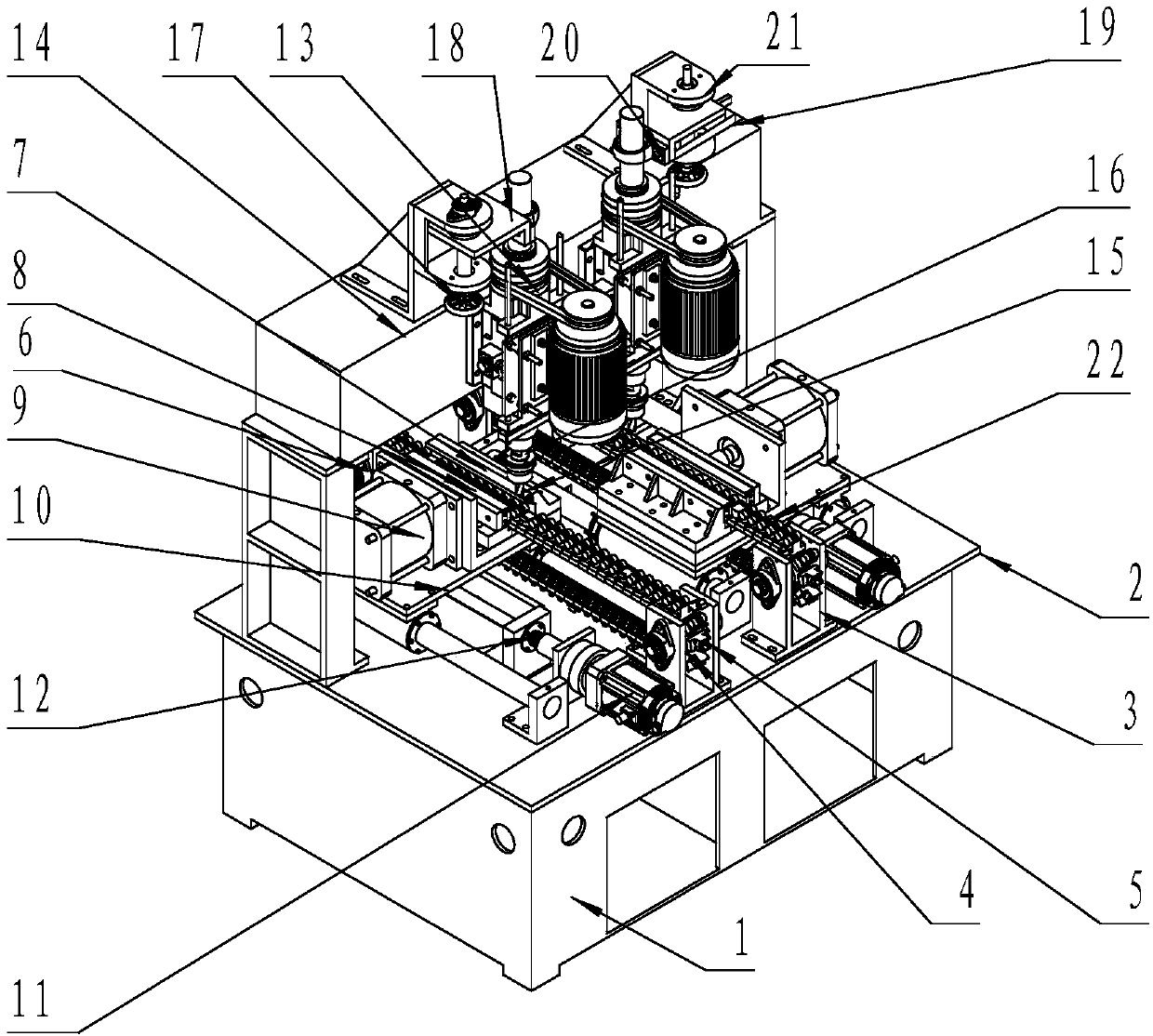

[0020] Such as figure 1 , figure 2 , image 3 As shown, a special square riser milling machine includes a frame 1 and a workbench 2 installed on the frame 1. It is characterized in that it includes two square risers symmetrically and longitudinally installed on both sides of the center line of the top surface of the workbench. Milling device; the square riser milling device includes a square riser conveying device, a square riser clamping device and a pushing operation device of the square riser clamping device, a square riser milling power unit and a stroke of the square riser milling power unit Control devices; also include air pressure and electrical devices;

[0021] The square riser conveying device comprises a strip frame 3, double ear chain 4, square riser seat 5, and the top surface of the square riser seat 5 is provided with a U-shaped groove for accommodating the square riser. The bar frame 3 is vertically installed on the top surface of one side of the workbench...

Embodiment 2

[0025] Such as figure 1 , figure 2 , image 3 As shown, a special square riser milling machine includes a frame 1 and a workbench 2 installed on the frame 1. It is characterized in that it includes two square risers symmetrically and longitudinally installed on both sides of the center line of the top surface of the workbench. Milling device; the square riser milling device includes a square riser conveying device, a square riser clamping device and a pushing operation device of the square riser clamping device, a square riser milling power unit and a stroke of the square riser milling power unit Control devices; also include air pressure and electrical devices;

[0026] The square riser conveying device comprises a strip frame 3, double ear chain 4, square riser seat 5, and the top surface of the square riser seat 5 is provided with a U-shaped groove for accommodating the square riser. The bar frame 3 is vertically installed on the top surface of one side of the workbench...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com