A chuck tenon intelligent processing equipment

A technology of intelligent processing and collet mortise, which is applied in wood processing equipment, manufacturing tools, forming/shaping machines, etc., can solve problems such as cumbersome operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

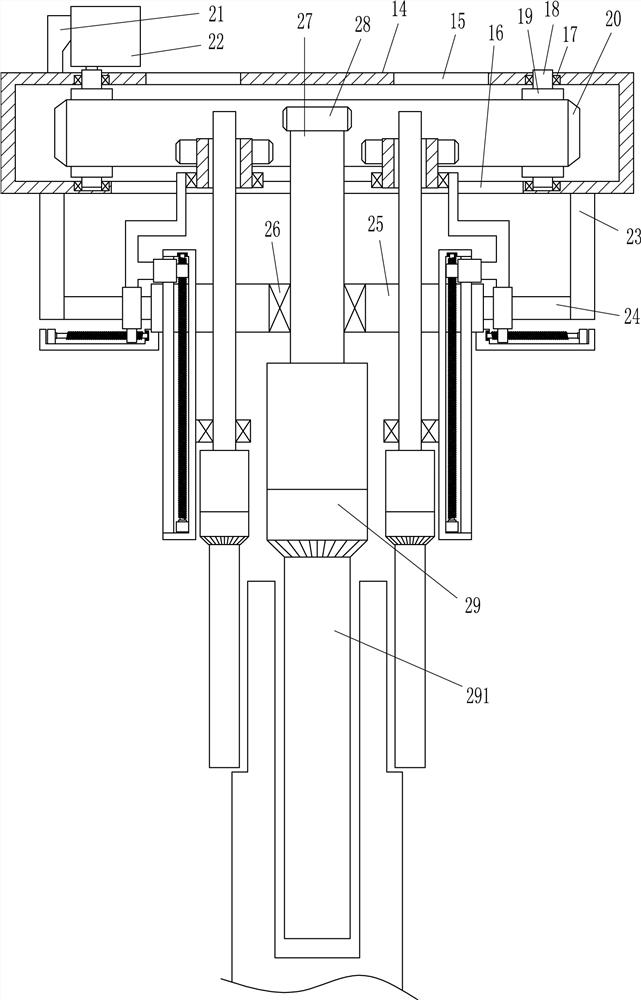

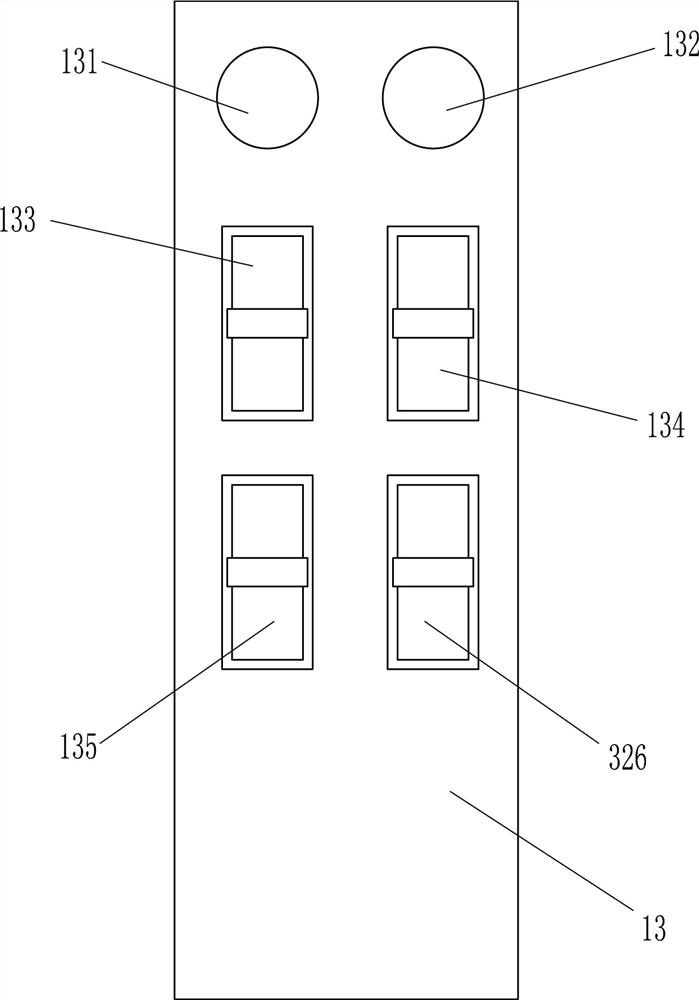

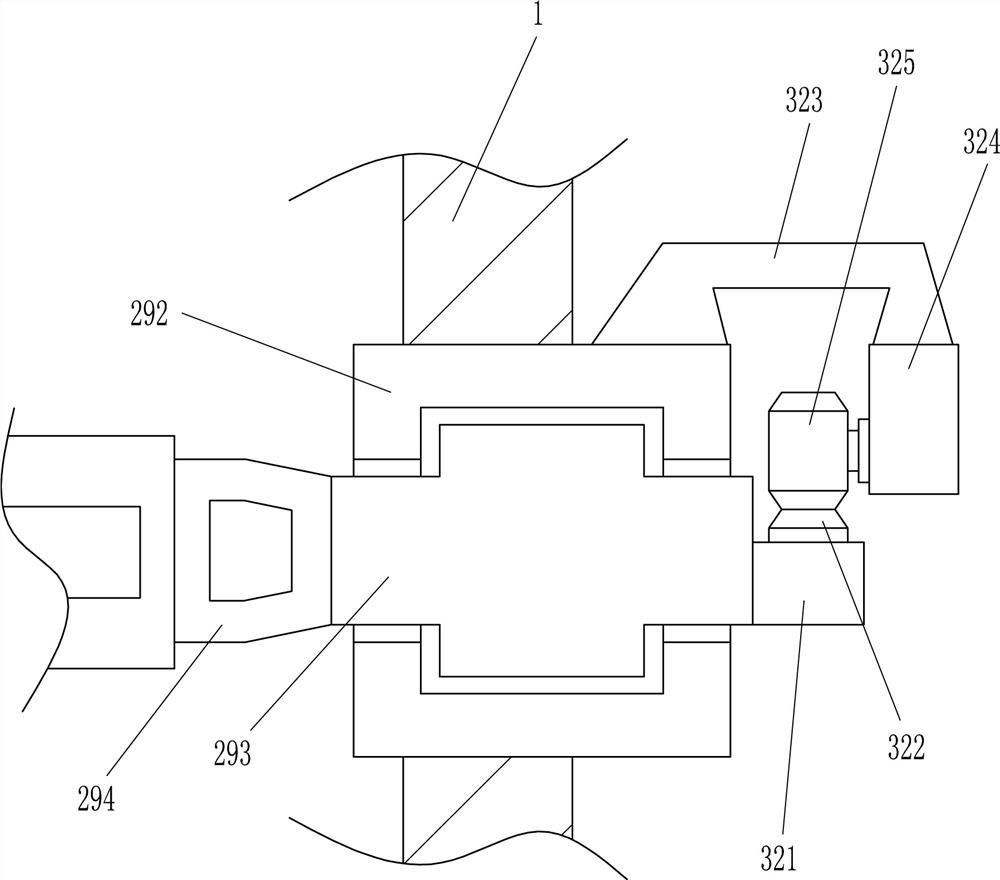

[0021] A chuck tenon intelligent processing equipment, such as Figure 1-9As shown, it includes installation box 1, wall hanging block 2, mounting screw 4, glass observation window 5, bushing 6, first rotating shaft 7, rotating block 8, cover plate 9, second rotating shaft 10, clamping block 11, control box 13. Main power switch 131, first switch 132, first ship-type switch 133, second ship-type switch 134, third ship-type switch 135, fixed box 14, first bearing seat 17, first rotating rod 18, first gear 19 , rack belt 20, first motor seat 21, first drive motor 22, bracket 23, first guide rail 24, connecting plate 25, second bearing seat 26, second rotating rod 27, second gear 28, first joint 29. The first milling cutter 291, slide rail 292, slide block 293, connecting block 294, side milling device 30 and clamping device 31, the upper and rear sides of the left and right walls of the installation box 1 are connected with the wall hanging block 2, the installation box It is c...

Embodiment 2

[0023] A chuck tenon intelligent processing equipment, such as Figure 1-9 As shown, it includes installation box 1, wall hanging block 2, mounting screw 4, glass observation window 5, bushing 6, first rotating shaft 7, rotating block 8, cover plate 9, second rotating shaft 10, clamping block 11, control box 13. Main power switch 131, first switch 132, first ship-type switch 133, second ship-type switch 134, third ship-type switch 135, fixed box 14, first bearing seat 17, first rotating rod 18, first gear 19 , rack belt 20, first motor seat 21, first drive motor 22, bracket 23, first guide rail 24, connecting plate 25, second bearing seat 26, second rotating rod 27, second gear 28, first joint 29. The first milling cutter 291, slide rail 292, slide block 293, connecting block 294, side milling device 30 and clamping device 31, the upper and rear sides of the left and right walls of the installation box 1 are connected with a wall hanging block 2, and the wall hanging block 2 ...

Embodiment 3

[0026] A chuck tenon intelligent processing equipment, such as Figure 1-9As shown, it includes installation box 1, wall hanging block 2, mounting screw 4, glass observation window 5, bushing 6, first rotating shaft 7, rotating block 8, cover plate 9, second rotating shaft 10, clamping block 11, control box 13. Main power switch 131, first switch 132, first ship-type switch 133, second ship-type switch 134, third ship-type switch 135, fixed box 14, first bearing seat 17, first rotating rod 18, first gear 19 , rack belt 20, first motor seat 21, first drive motor 22, bracket 23, first guide rail 24, connecting plate 25, second bearing seat 26, second rotating rod 27, second gear 28, first joint 29. The first milling cutter 291, slide rail 292, slide block 293, connecting block 294, side milling device 30 and clamping device 31, the upper and rear sides of the left and right walls of the installation box 1 are connected with a wall hanging block 2, and the wall hanging block 2 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com