Steel bar binding jig frame for component prefabrication

A technology of steel bar binding and tire frame, which is applied in the field of steel bar binding tire frame, can solve the problems of difficulty in ensuring the quality of rectangular steel bar frames, large labor waste, slow construction efficiency, etc., and achieves improved placement efficiency, high placement efficiency and accuracy. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

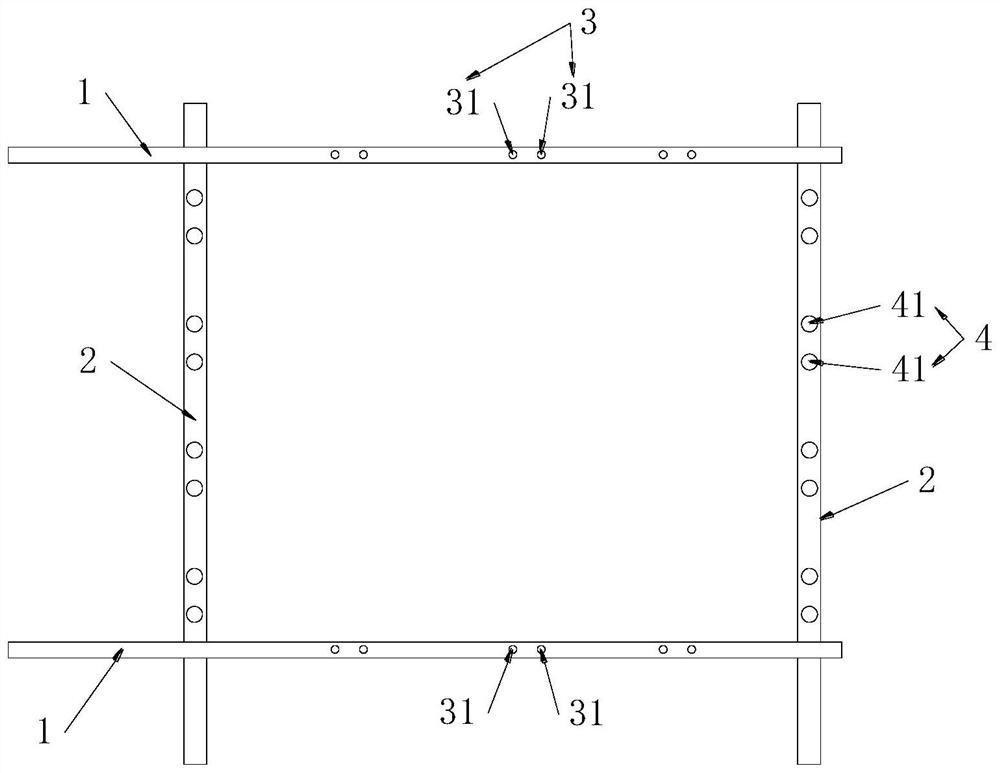

[0050] The present invention provides a steel bar binding tire frame for component prefabrication, see figure 1 , comprising two transverse supports 1 and two longitudinal supports 2, each of the transverse supports 1 is vertically connected to the two longitudinal supports 2;

[0051] The transverse support 1 is provided with a number of first positioning pieces 3, all of the first positioning pieces 3 are located between the two longitudinal supports 2, and are used for positioning the transverse reinforcement 12 relative to the two first positioning pieces 3 end of

[0052] The longitudinal support 2 is provided with a number of second positioning members 4, the second positioning members 4 are located between the two lateral supports 1, and are used for positioning the longitudinal reinforcing bars 22 relative to the two second positioning members 4. Ends.

[0053] The two transverse supports 1 are vertically connected with the two longitudinal supports 2 to form a recta...

Embodiment 2

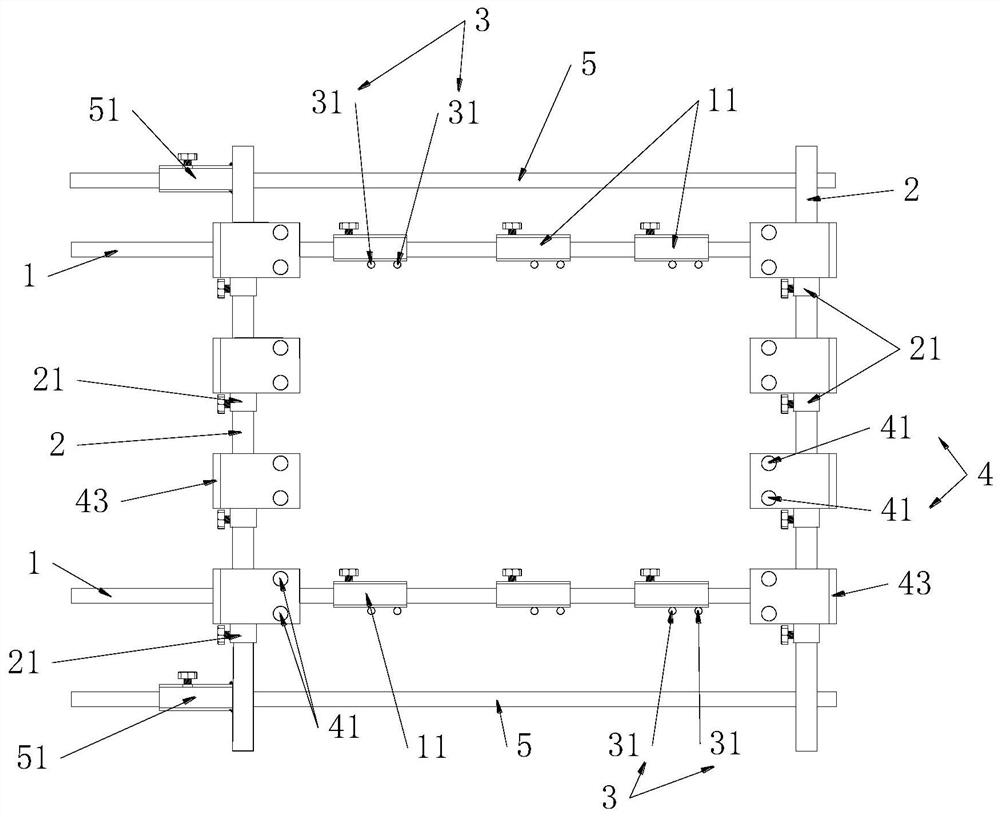

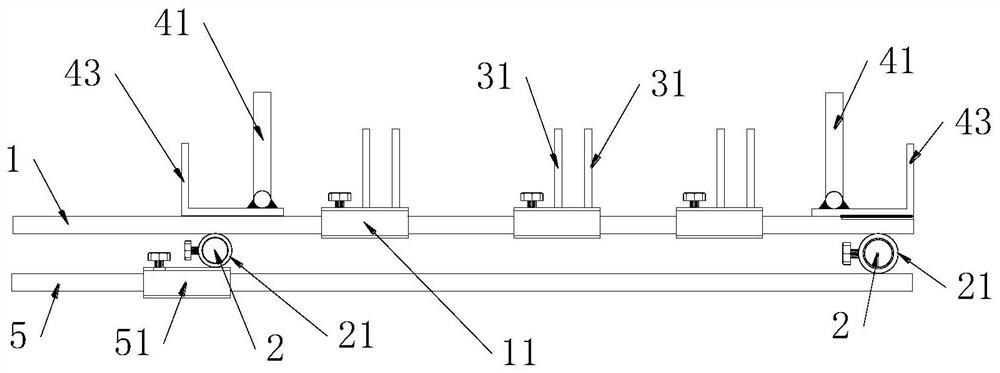

[0057] This embodiment provides a kind of steel bar binding frame for component prefabrication, see Figure 2-6 , which is different from the steel bar binding frame for component prefabrication described in the embodiment in that the first positioning part 3 is slidably connected to the corresponding lateral support 1, and the second locating part 4 is slidably connected to the corresponding The longitudinal support 2.

[0058] The first positioning member 3 can slide on the corresponding transverse support 1, and then adjust its position on the corresponding transverse support 1. According to the distance between two adjacent transverse steel bars 12 of the rectangular steel bar skeleton, Slidingly adjust the positions of the two adjacent first positioning members 3 accordingly, so that the same steel bar binding frame for component prefabrication can be applied to a rectangular steel bar frame with two adjacent transverse steel bars 12 with different spacings. The second p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com