Lashing Technology for Waterway Transport of Oversized Cargo

A cargo and waterway technology, applied in transportation and packaging, ship accessories, ships, etc., can solve the problems of huge material and labor waste, ship deck damage, ship safety hazards, etc., to avoid fire safety hazards and reduce load-bearing requirements , binding fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

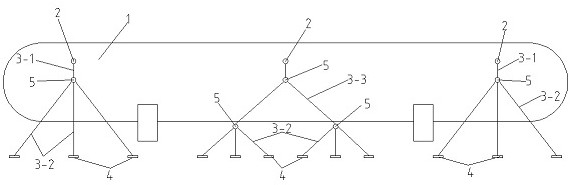

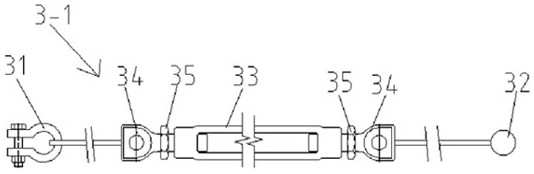

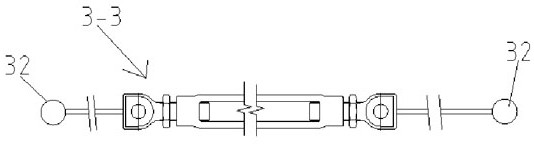

[0033] Such as Figures 1 to 10As shown, the present invention discloses a lashing process for waterway transportation of out-of-gauge cargo. A cargo 1 is provided with a plurality of securing points 2, and a plurality of universal boards 4 are arranged at fixed intervals on the deck of a ship. According to the tension of the securing points, The ratio of the bearing capacity per square meter of the deck, N layers of connectors 5 are set between each securing point 2 and the deck; when N is set to 1, a connector 5 is set on this layer, and a first steel rope 3- 1. One end is detachably connected to a fastening point 2, and the other end is connected to the one connecting piece 5. One ends of multiple second steel ropes 3-2 are respectively connected to different positions of the one connecting piece 5, and the other ends are respectively connected to the deck Multiple universal boards 4 on the deck are detachably connected; when N>1, one connector 5 is set on the first layer c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com