Overhead conductor fixing method

A technology for overhead wires and fixing methods, applied in the direction of overhead lines/cable equipment, etc., can solve the problems of easy loosening of binding wires, complicated binding process, inconvenient operation, etc., and achieve the effect of simple operation, firm binding, and improved installation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to make the above-mentioned features and advantages of the present invention more obvious and easy to understand, the following specific embodiments are given and the accompanying drawings are described in detail as follows.

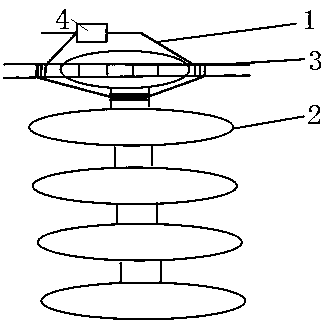

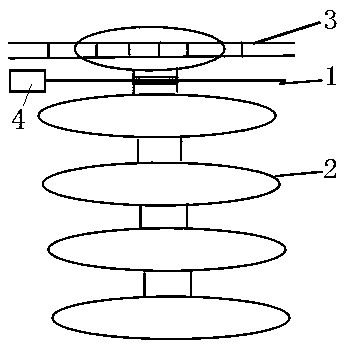

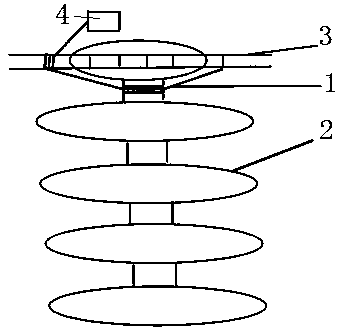

[0016] like Figures 1~4 As shown in the figure, an overhead wire fixing method, the fixing method includes the following steps: (1) wrapping the non-end of the steel wire seal 1 on the insulator 2; (2) wrapping one end of the steel wire seal on the side of the overhead wire 3 , the other end of the wire seal is wrapped around the other side of the overhead wire; (3) Finally, the two ends of the wire seal are fixed.

[0017] In the embodiment of the present invention, in step (1), the wire seal adopts a tightening type wire seal, one end of which is provided with a lock shell 4, and the other end is the tip of a lock cylinder inserted into the lock shell.

[0018] In the embodiment of the present invention, the tight wire seal is the pri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com