Improved porous wire type binding machine

A binding machine and wire-type technology, applied in the direction of binding, etc., can solve the problems of increased contact resistance of conductive rubber pads, damage to drills, conductive rubber pads, and excessive downward movement of drills, so as to reduce the probability of electrical failures and avoid manual operations. Effect of compression and manual decompression, avoiding decoupling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

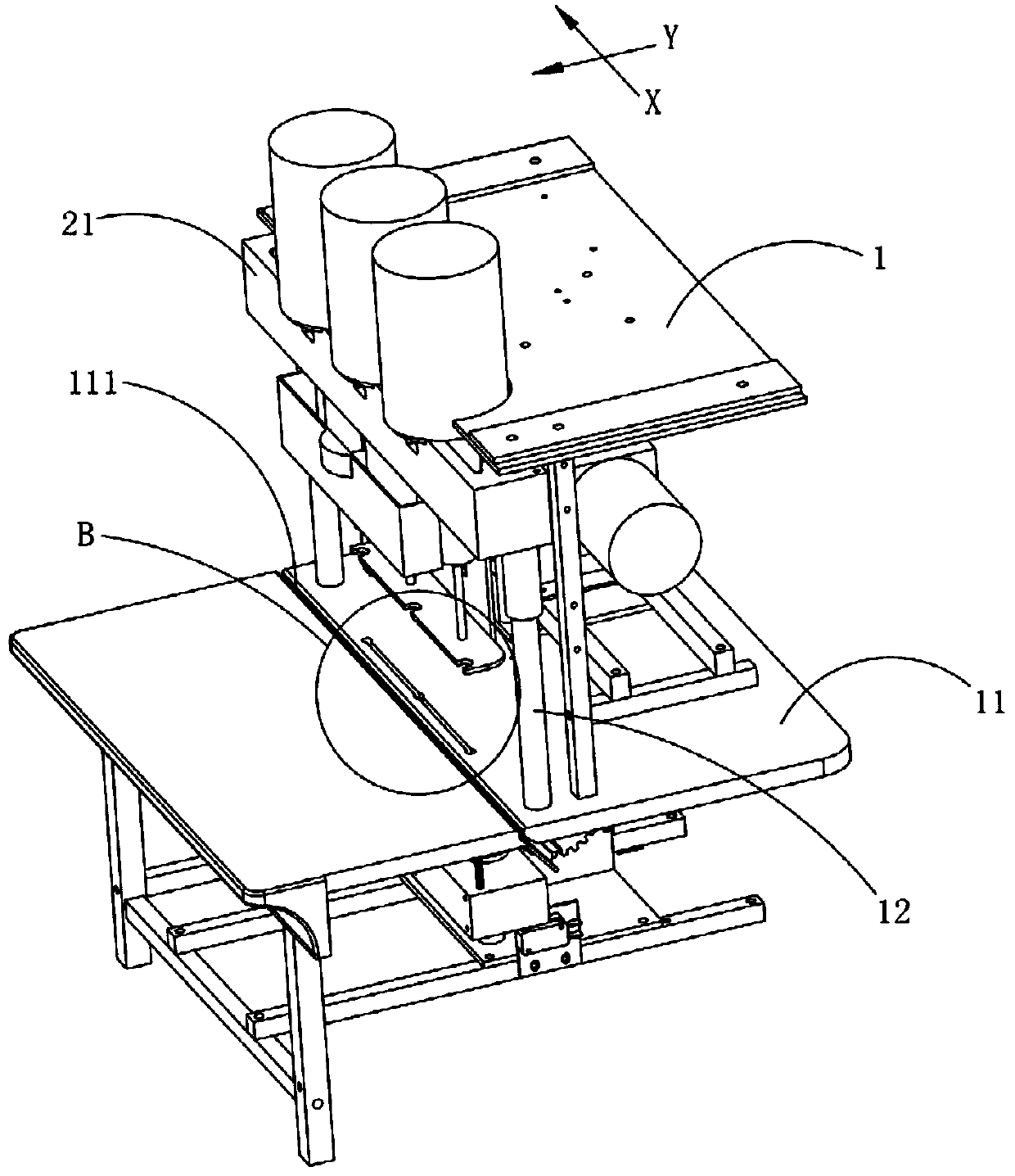

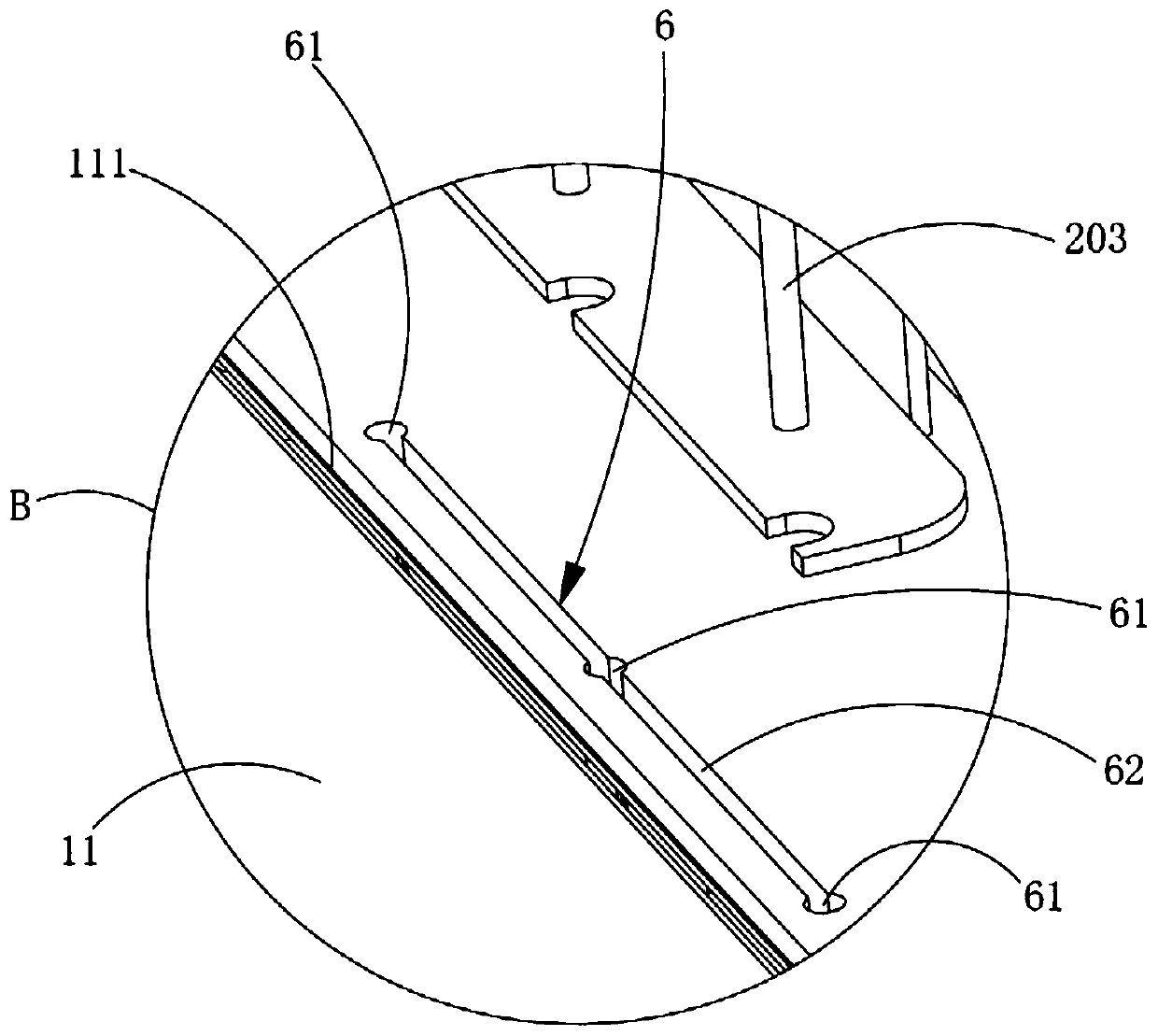

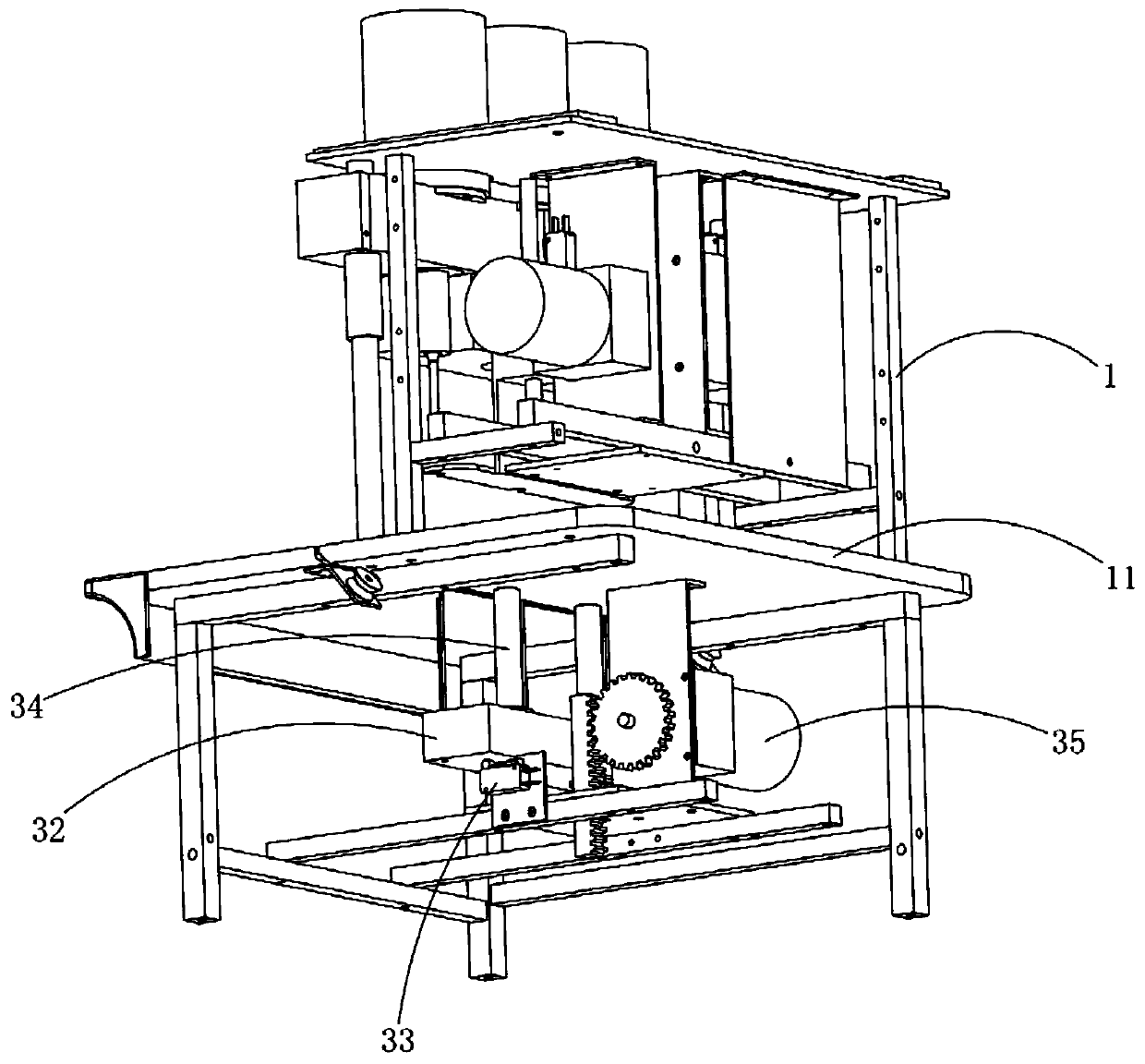

[0043] An improved perforated wire binding machine, such as Figure 1 to Figure 5 As shown, the multi-hole wire binding machine includes a frame 1, a control circuit, a binding platform 11, a drilling mechanism 2 and a wire feeding mechanism, and the binding platform 11 is arranged at the middle part of the frame 1; Above, the drilling mechanism 2 has at least two drills 203; the wire feeding mechanism is positioned above or below the binding platform 11, and the wire feeding mechanism has the same machine needles 31 as the number of drills, and each machine needle 31 is connected to the corresponding drill respectively. 203 is longitudinally aligned or vertically aligned, and it is characterized in that: the binding platform 11 is provided with an avoidance notch 6, the avoidance notch 6 runs through the binding platform 11 up and down, the avoidance notch 6 is arranged below the drill 203, and each drill 203 vertically Straight alignment avoids notch 6; Binding platform 11 o...

Embodiment 2

[0080] The composition structure of the porous thread binding machine provided in this embodiment is basically the same as that of the porous thread binding machine provided in the above-mentioned embodiment 1, the difference is that, as Figure 14 As shown, a plurality of protrusions are symmetrically formed on the front and rear sides of the avoidance notch 6, and the protrusions are set in the shape of protruding teeth, and each protrusion is respectively surrounded by the edge of the avoidance notch 6 to form three drill matching holes. 61, each drill matching hole 61 is vertically aligned with the corresponding drill 203 respectively, each drill matching hole 61 is not provided with a threading groove 62 at a lateral interval, and a threading gap is formed between two adjacent protrusions before and after, so as to It is realized that the binding line passes through the binding platform 11 completely. The binding method of the perforated wire binding machine is the same a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com