Patents

Literature

59results about How to "Realize automatic compression" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

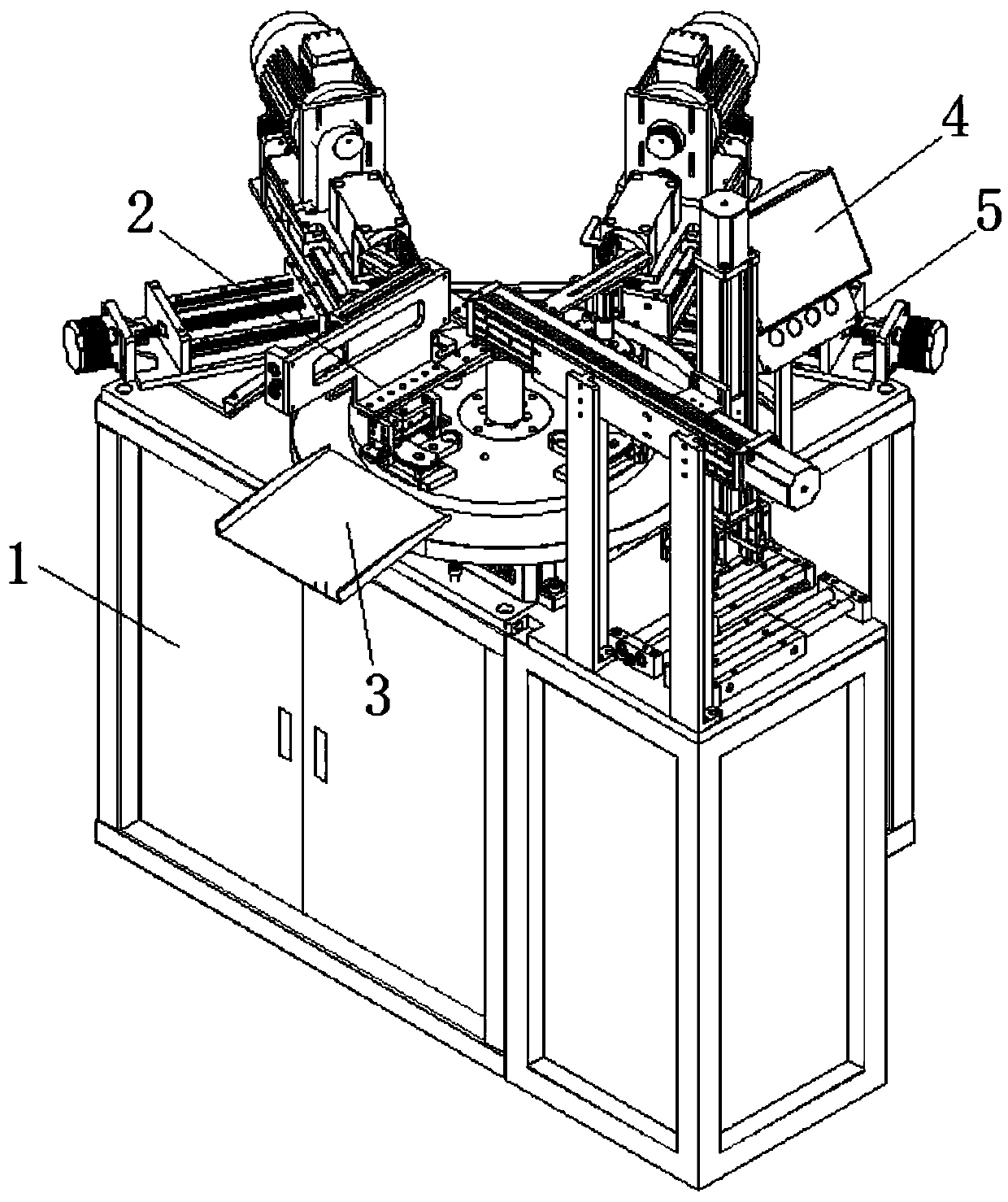

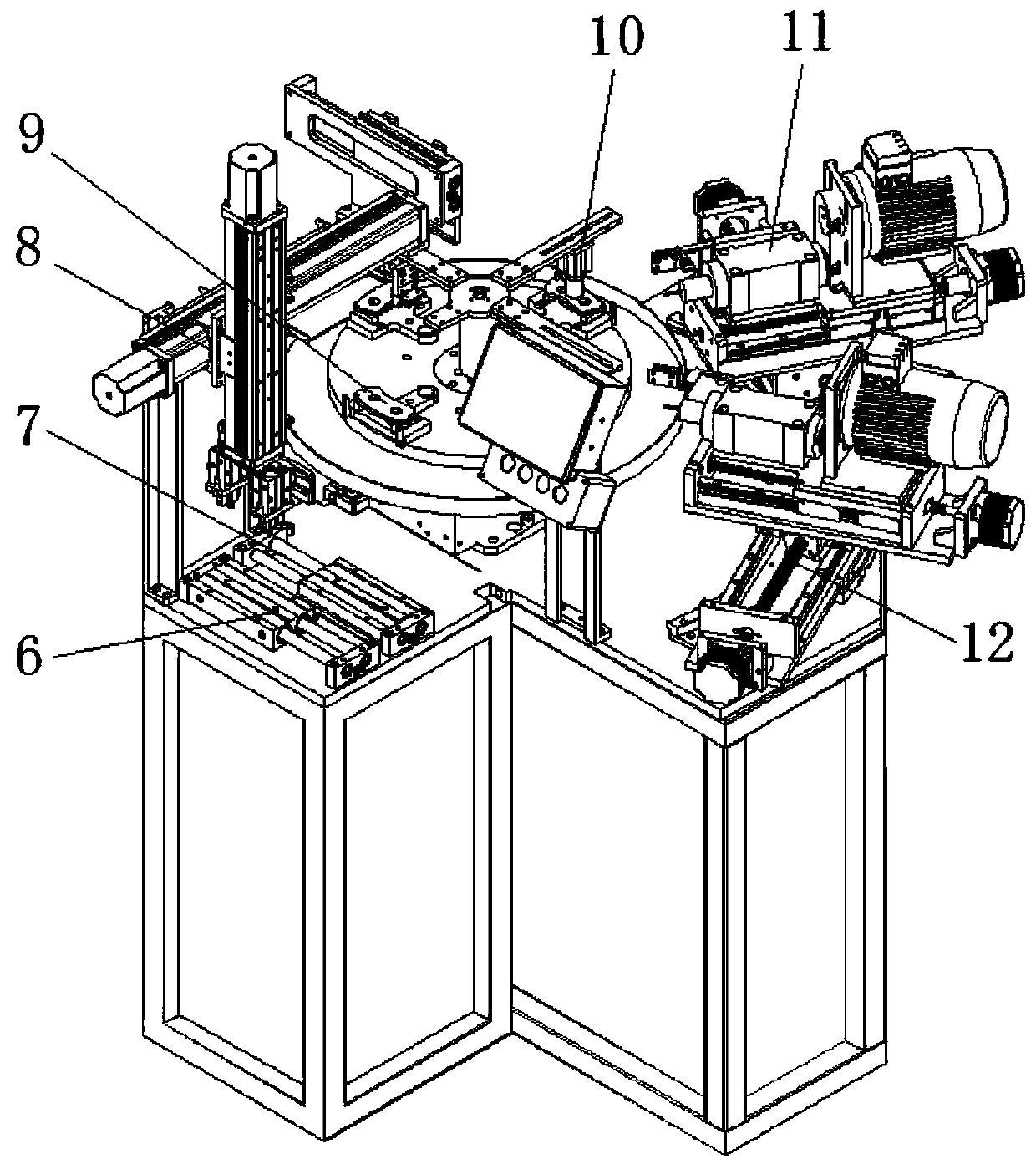

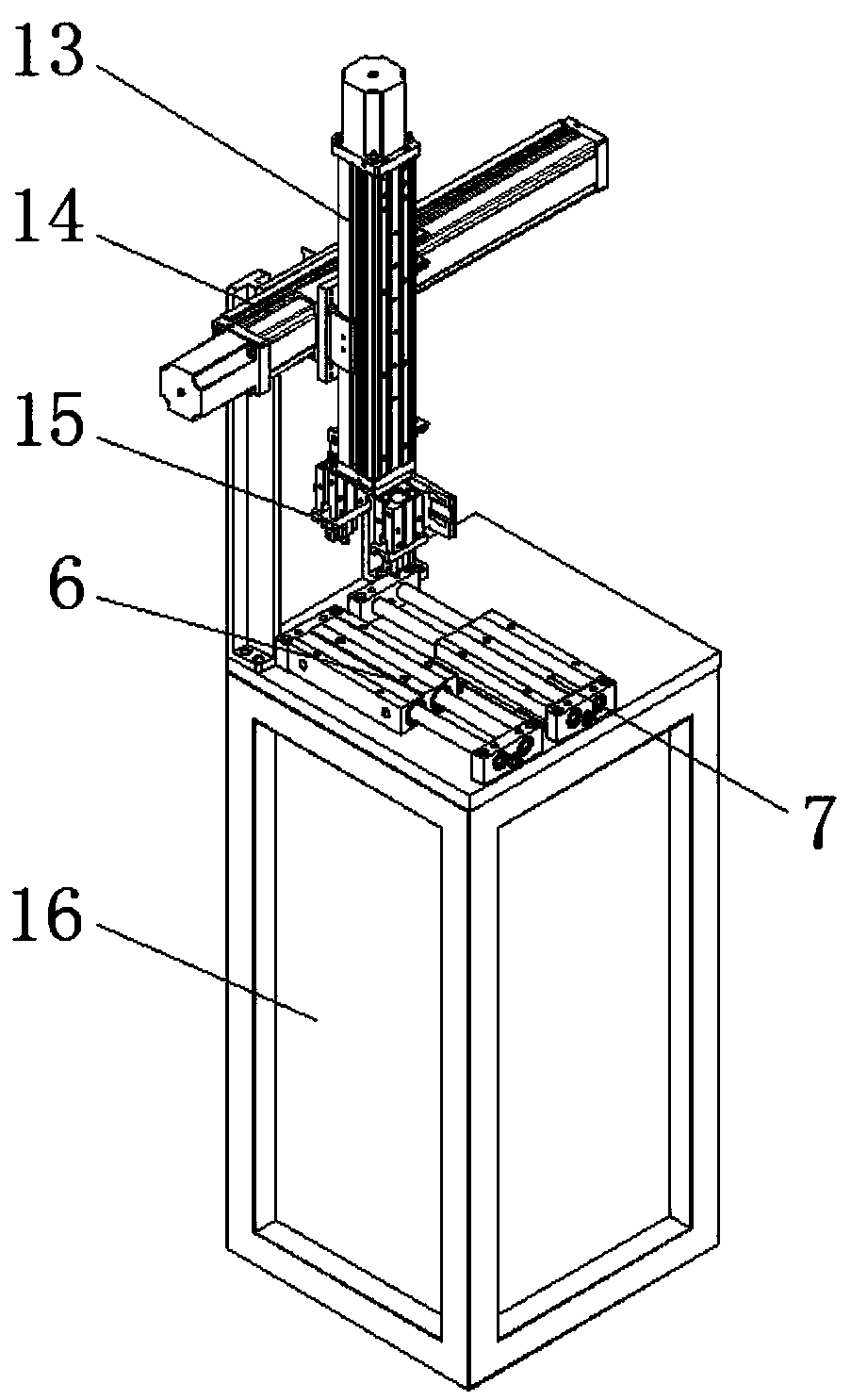

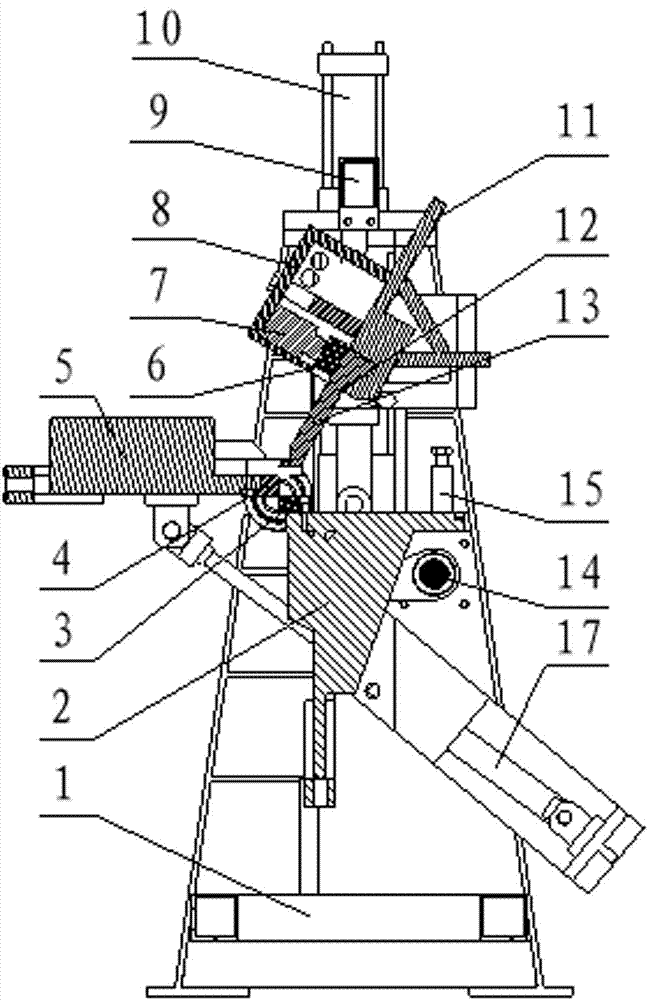

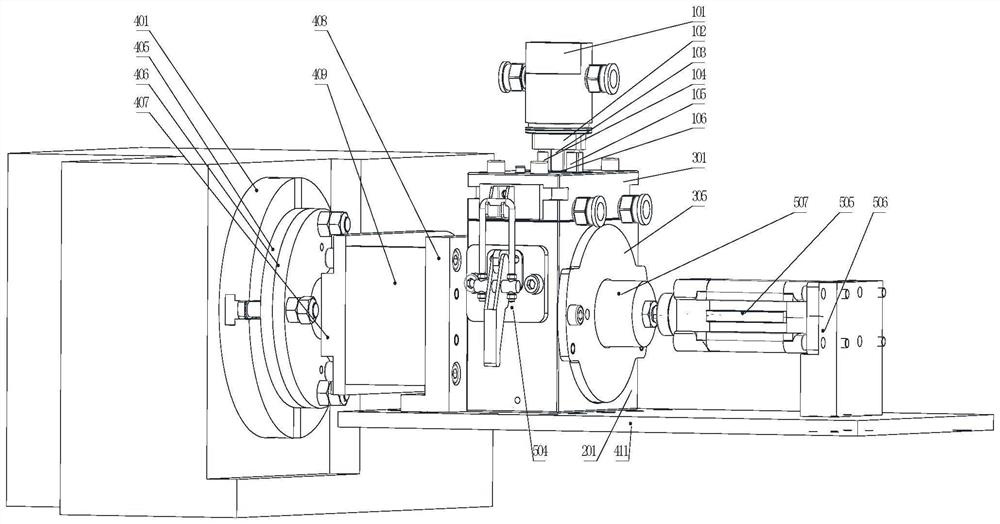

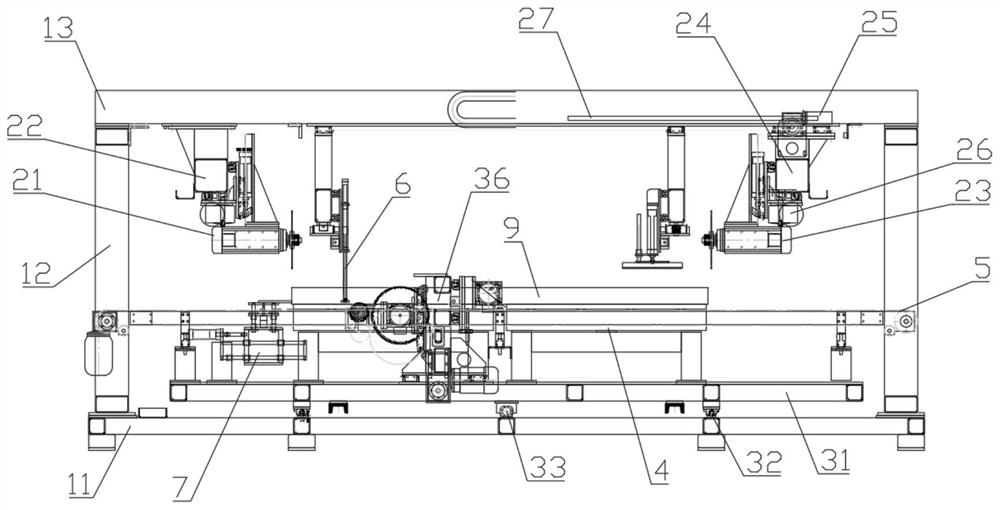

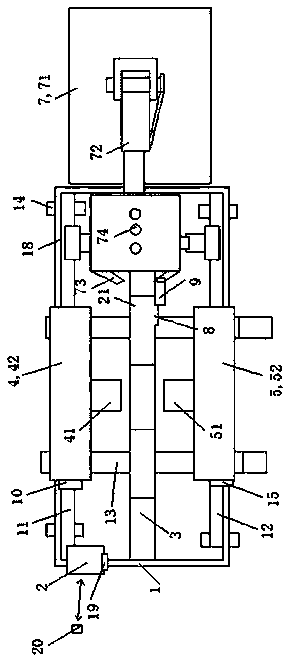

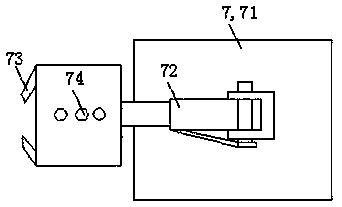

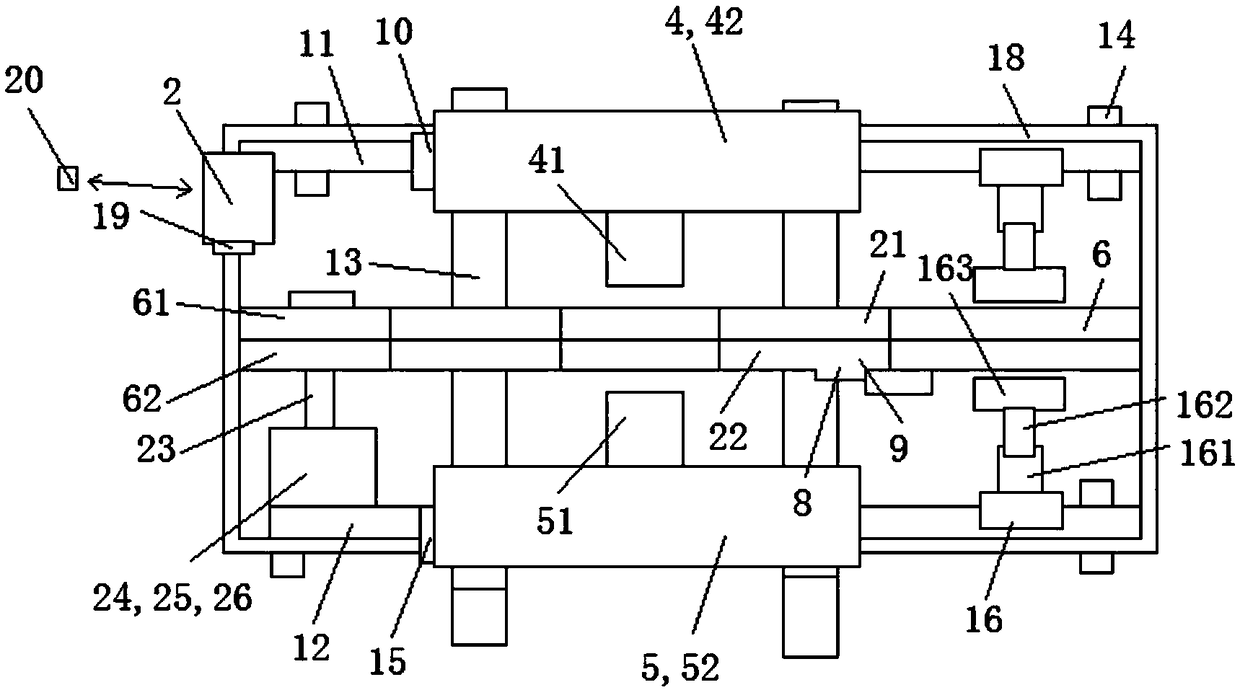

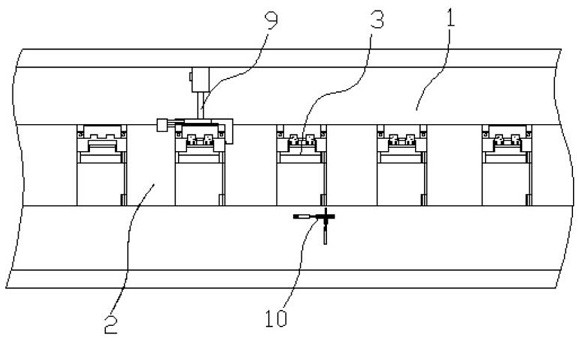

Friction plate steel backing full-automatic drilling machine

InactiveCN109551002AReasonable structural designShorten the processing cycleLarge fixed membersMetal working apparatusHuman–machine interfaceEngineering

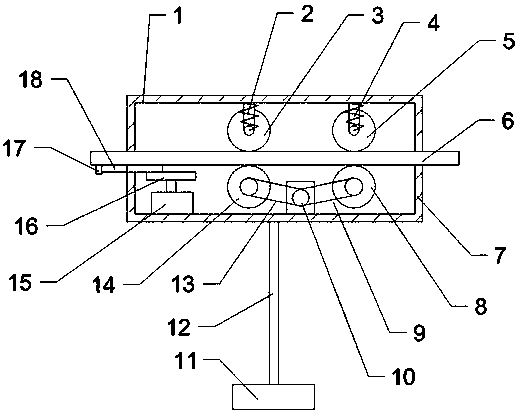

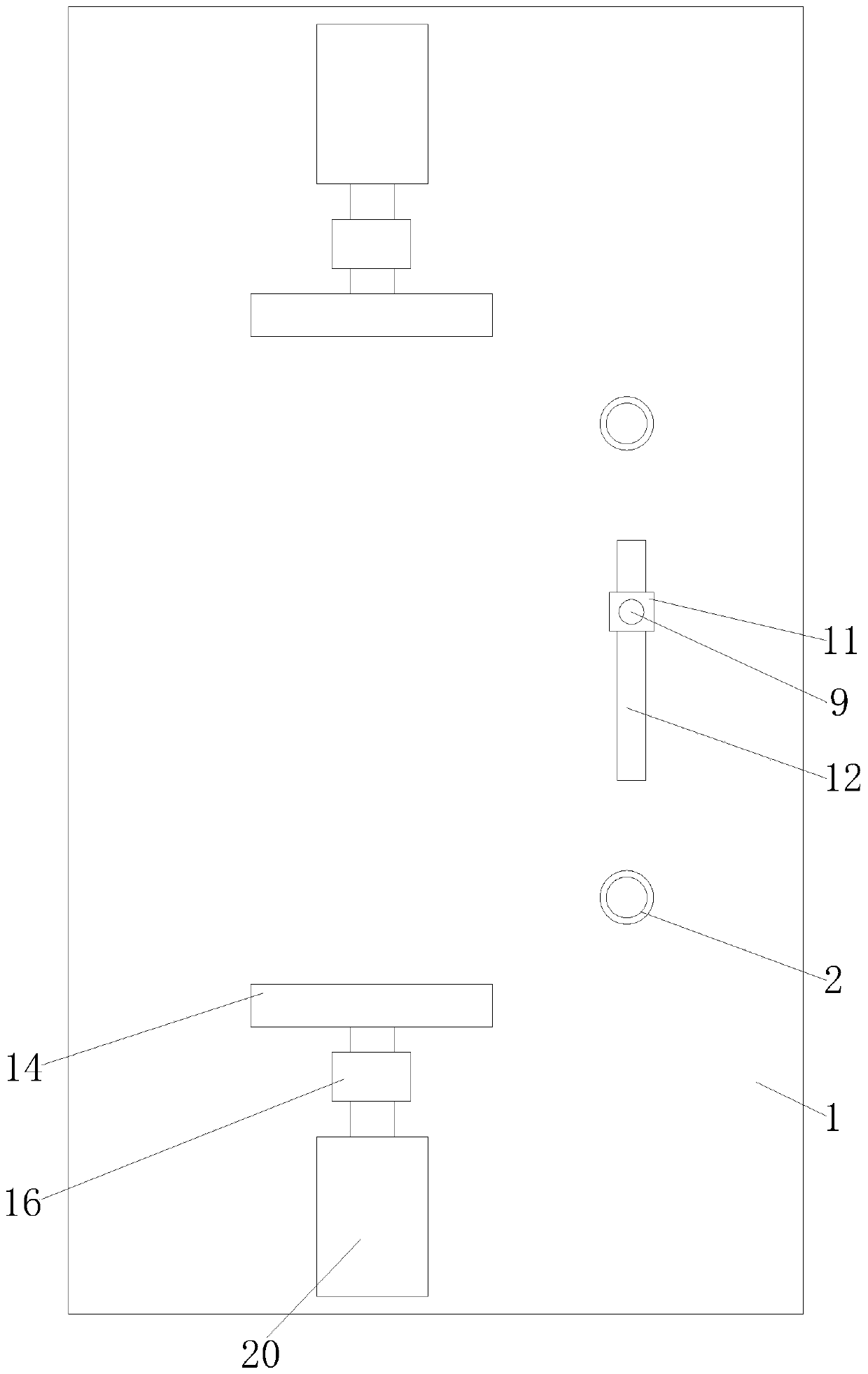

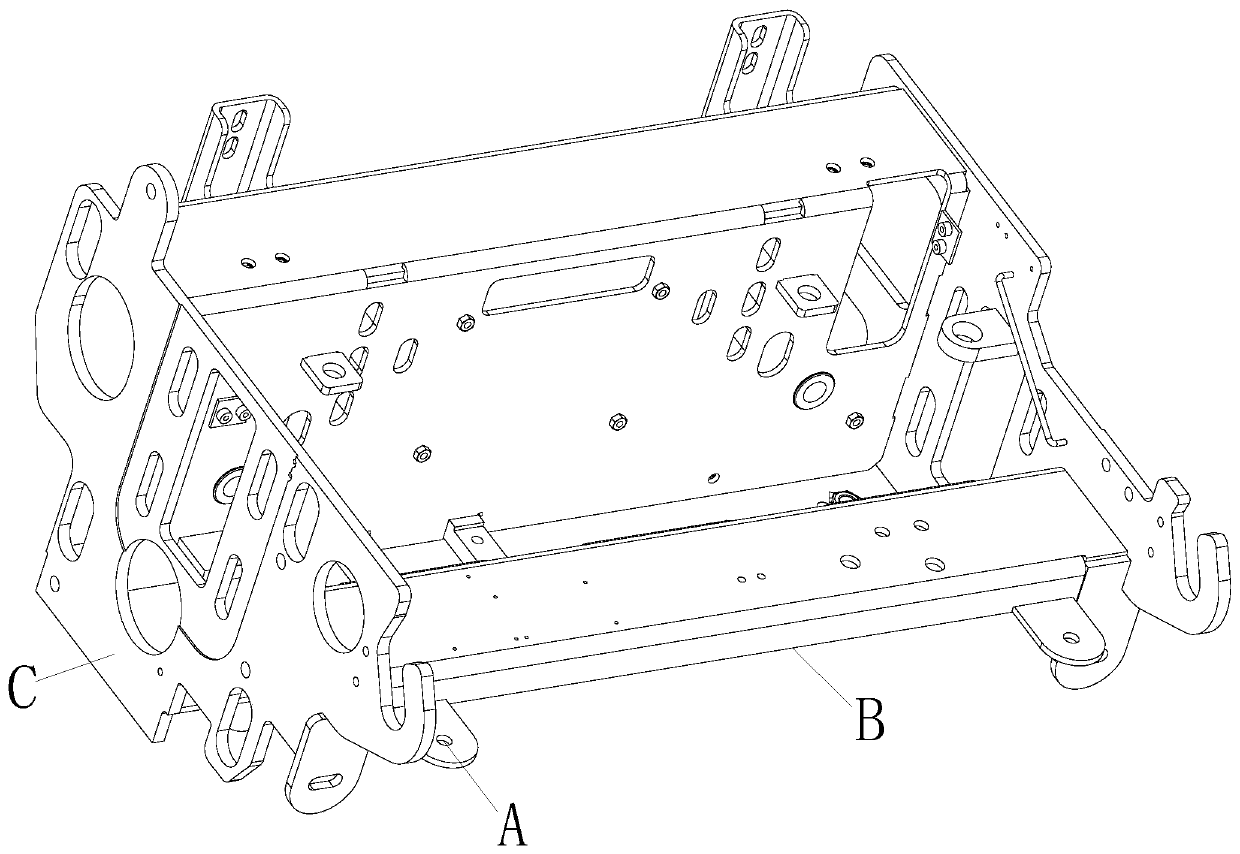

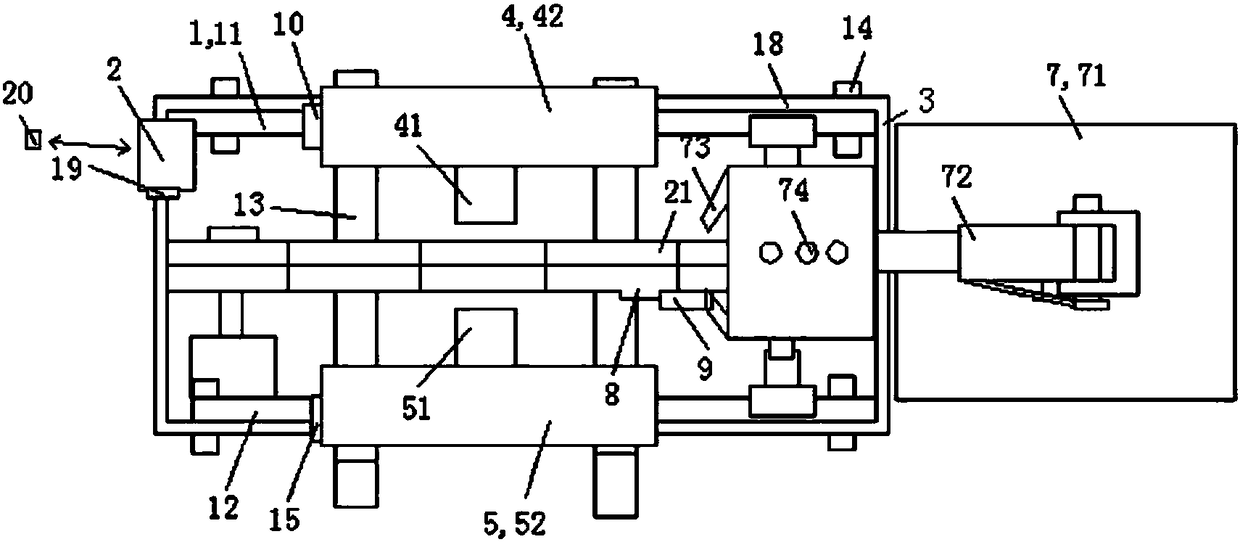

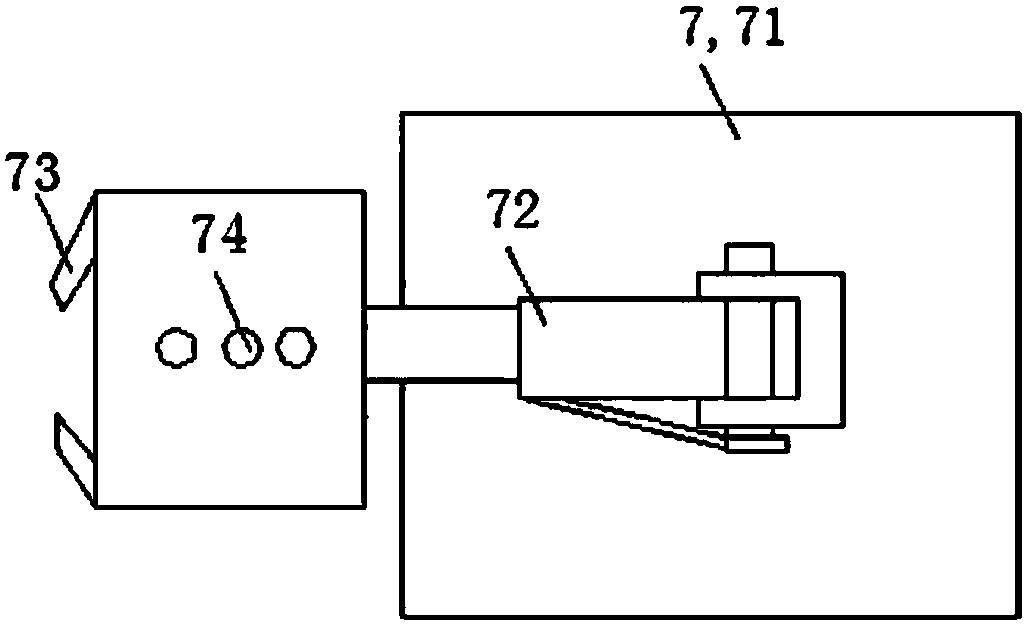

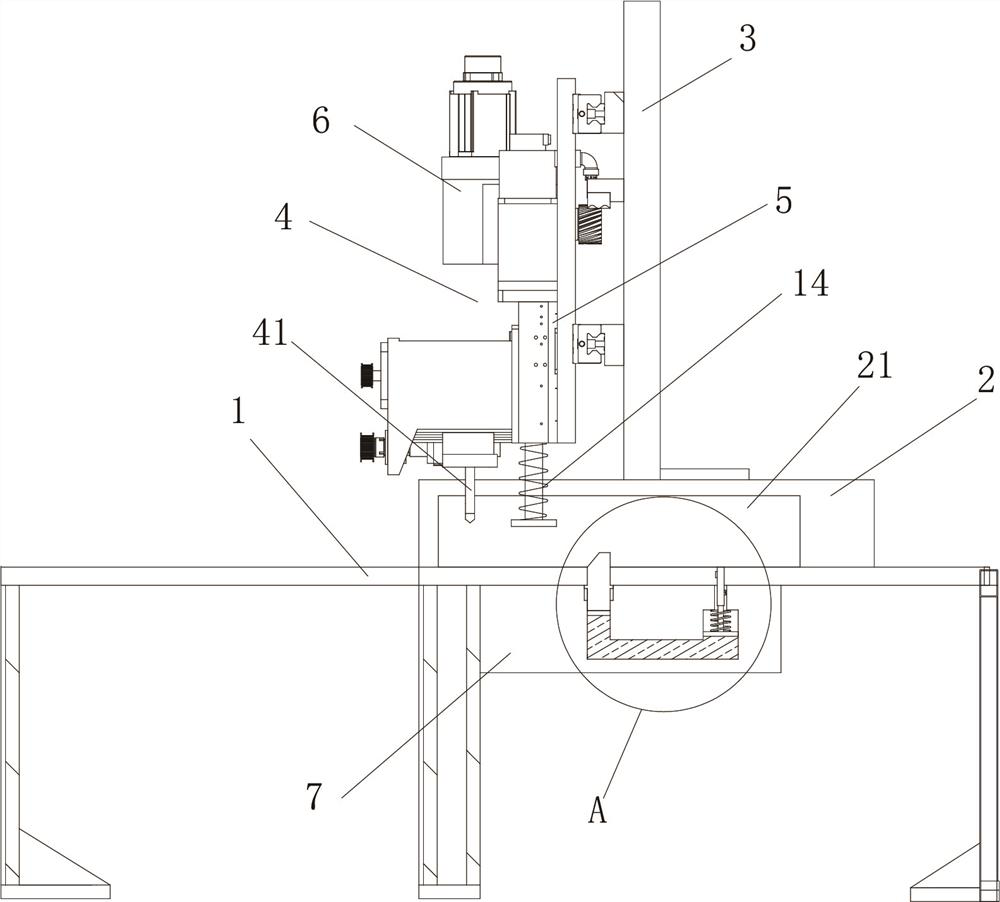

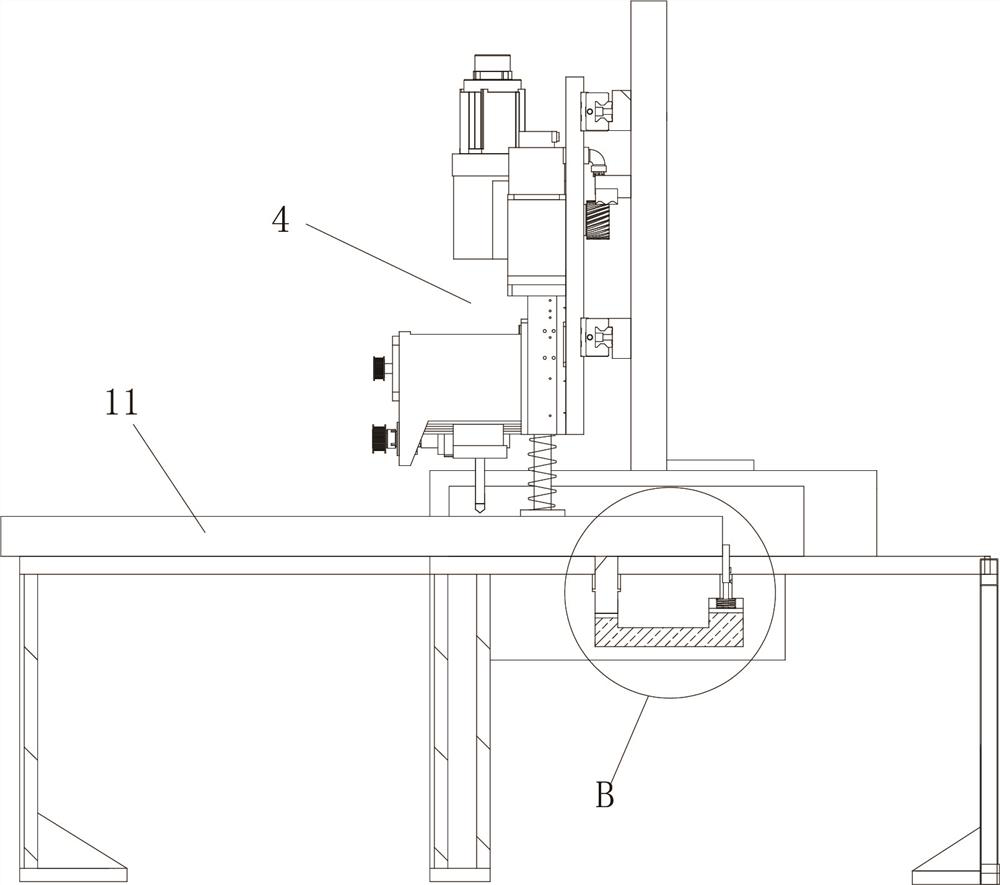

The invention discloses a friction plate steel backing full-automatic drilling machine. The friction plate steel backing full-automatic drilling machine comprises a machine frame, an automatic discharging device, a trough, a human-computer interface controller, a system supporting frame, a first tray assembly, a second tray assembly, an automatic feeding device, a multi-station rotation disc device, product pressing blocks, drilling power devices, an angle adjusting device and a sliding table Z shaft. The friction plate steel backing full-automatic drilling machine is a horizontal multi-station drilling machine, a multi-station rotation disc system is adopted so that feeding, drilling machining and discharging can be conducted at the same time, the structural design is more reasonable, small-size friction plate steel backings and small-included-angle friction plate steel backings can be machined, in addition, a friction plate steel backing of which the two holes are parallel is machined, the two holes are machined at the same time, mutual noninterference is achieved, the machining cycle is shortened, and the production efficiency is greatly improved from 25s / pcs to smaller than orequal to 10s / pcs; and through the scheme, the product automatic feeding function is achieved, the labor intensity of workers is greatly relieved, and the equipment automation degree is improved.

Owner:杭州众享机械技术有限公司

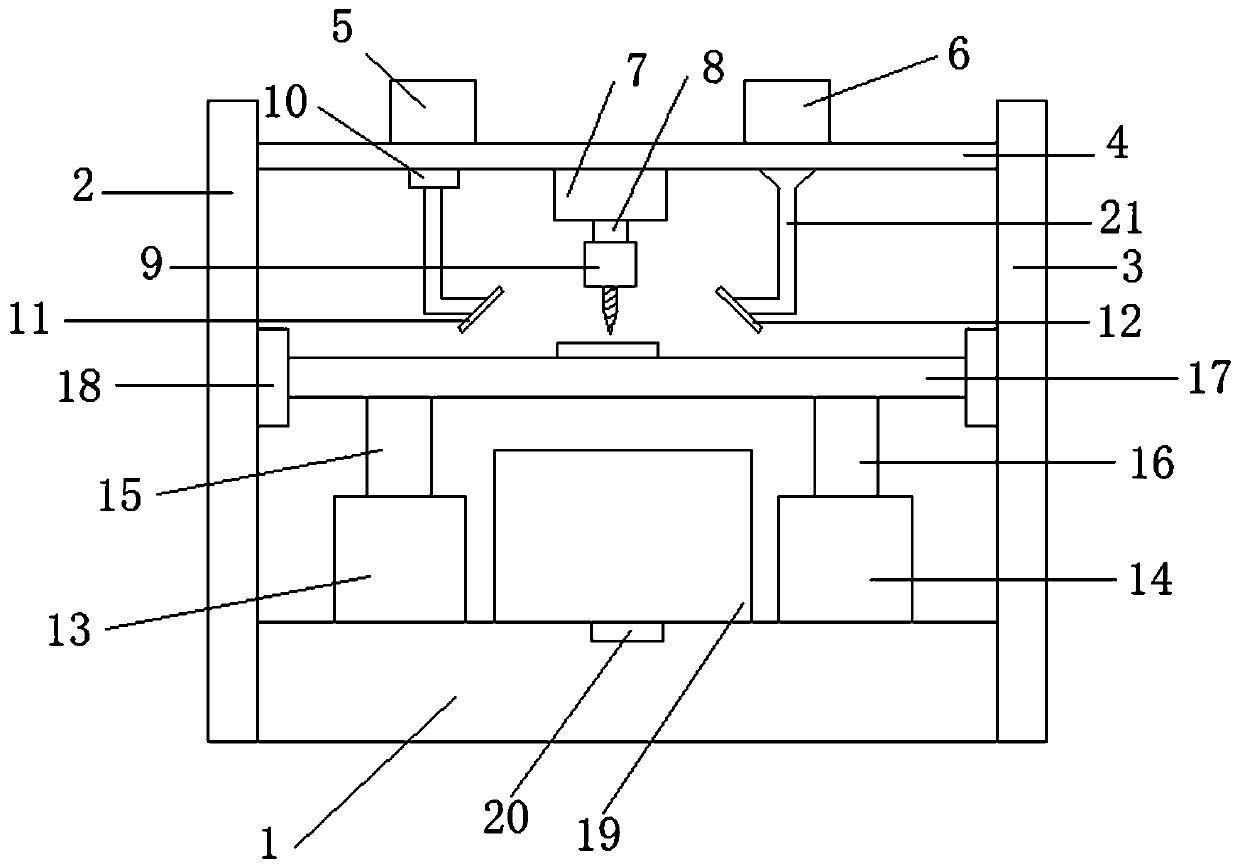

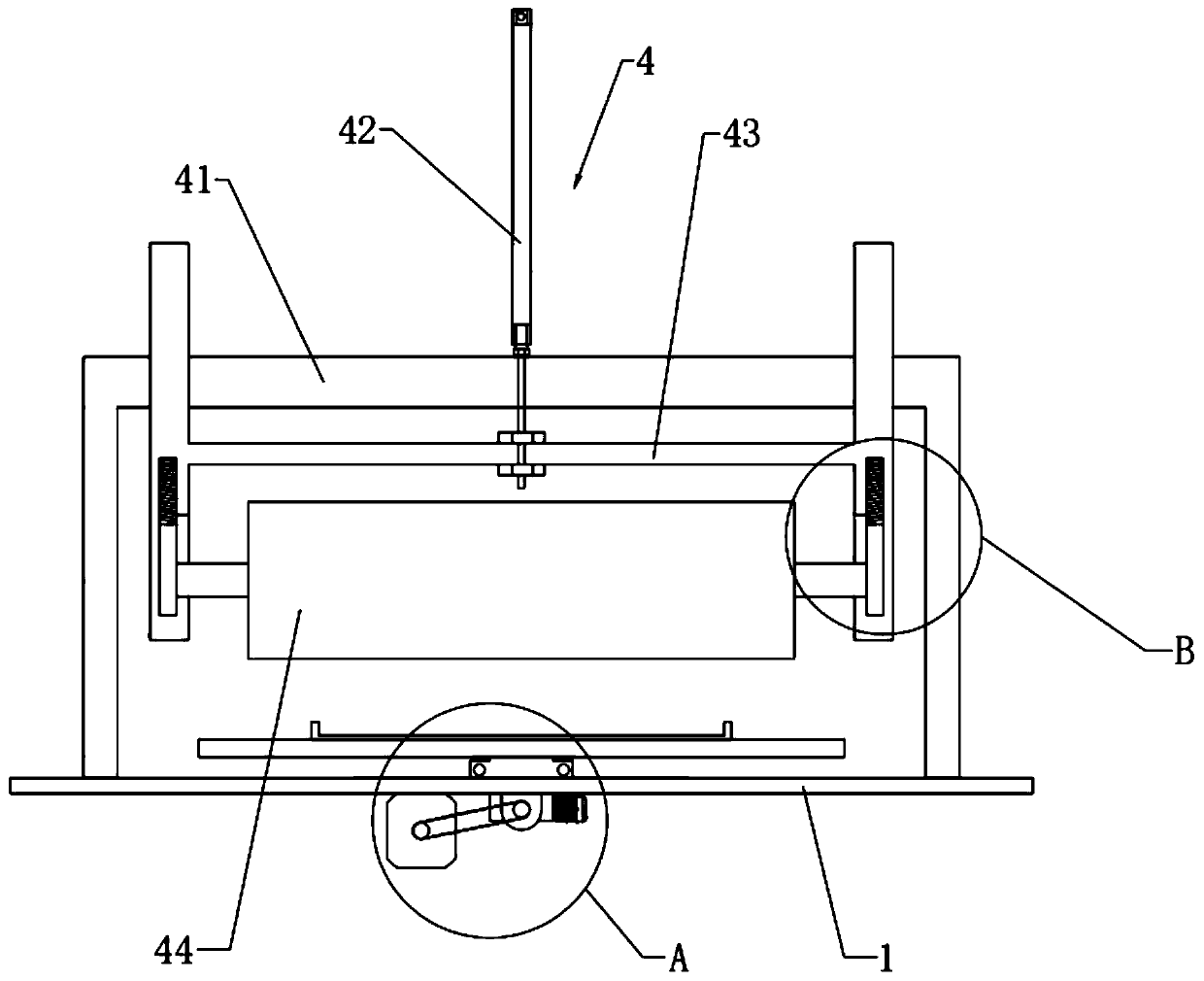

Efficient punching device for machines

InactiveCN110815387AEasy clampingEasy to clamp and positionCleaning using gasesMetal working apparatusHydraulic cylinderPunching

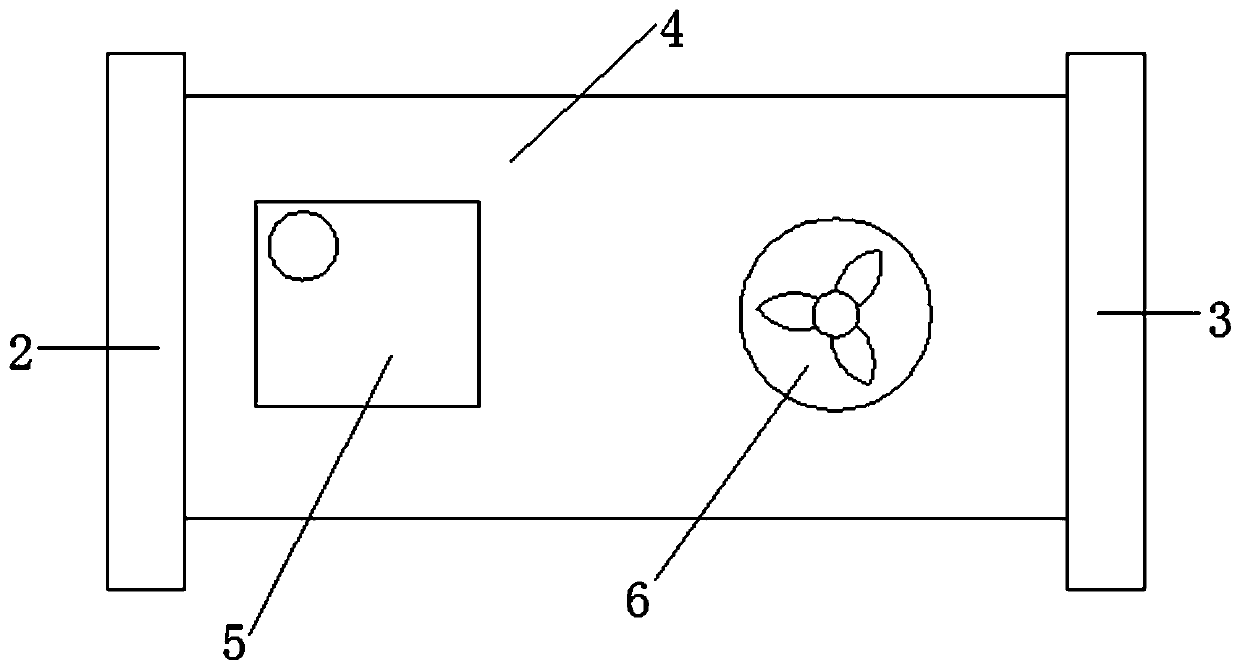

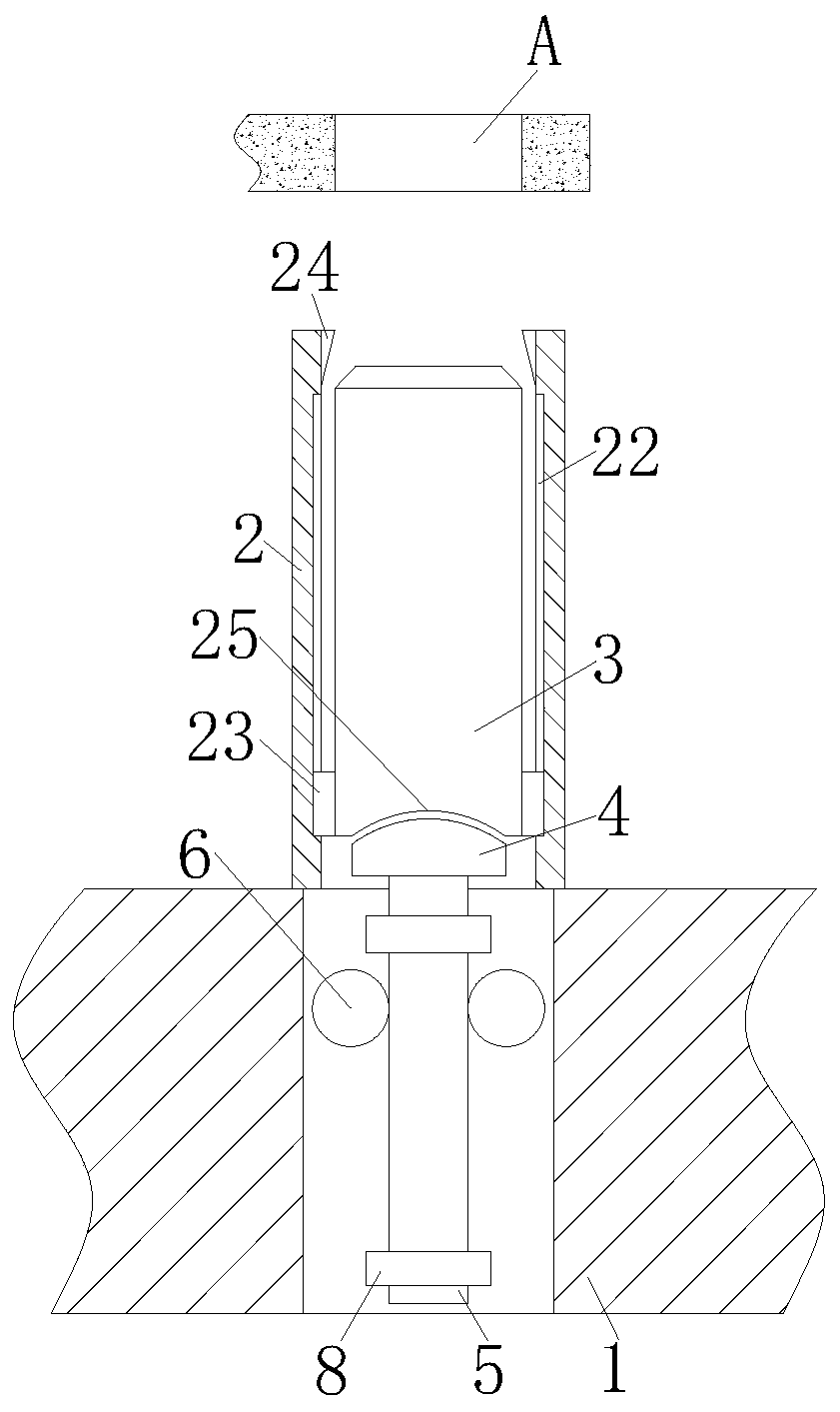

The invention relates to an efficient punching device for machines. The efficient punching device comprises a base, a first supporting plate is fixedly connected to the left end of the base, a secondsupporting plate is fixedly connected to the right end of the base, and a top plate is fixedly connected between the first supporting plate and the second supporting plate. A water tank and a draughtfan are fixedly connected to the top of the top plate, the draught fan is arranged at the right side of the water tank, and a first hydraulic cylinder is fixedly connected to the bottom of the top plate. A first motor is connected to the bottom of the first hydraulic cylinder through a first hydraulic telescopic rod, a drill is fixedly connected to the output end of the first motor, a water pump is connected to the bottom of the water tank through a water pipe, a sprayer is connected to the bottom of the water pump through a water pipe, the draught fan penetrates through the top plate to be connected with an air feeding pipe, and an air feeding plate is fixedly connected to the bottom end of the air feeding pipe. Convenience is brought to workpiece clamping and positioning, automatic clamping in the punching process is facilitated, and the safety and efficiency are higher; meanwhile, punched portions are conveniently cooled, and chippings generated in the punching process are conveniently collected.

Owner:户玉珠

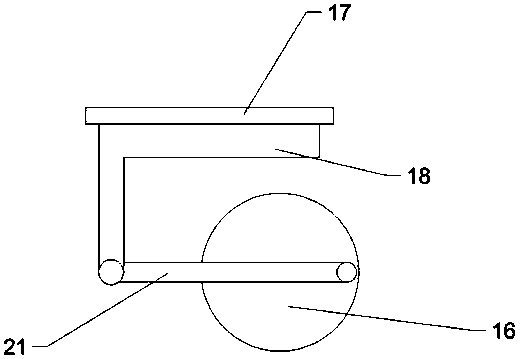

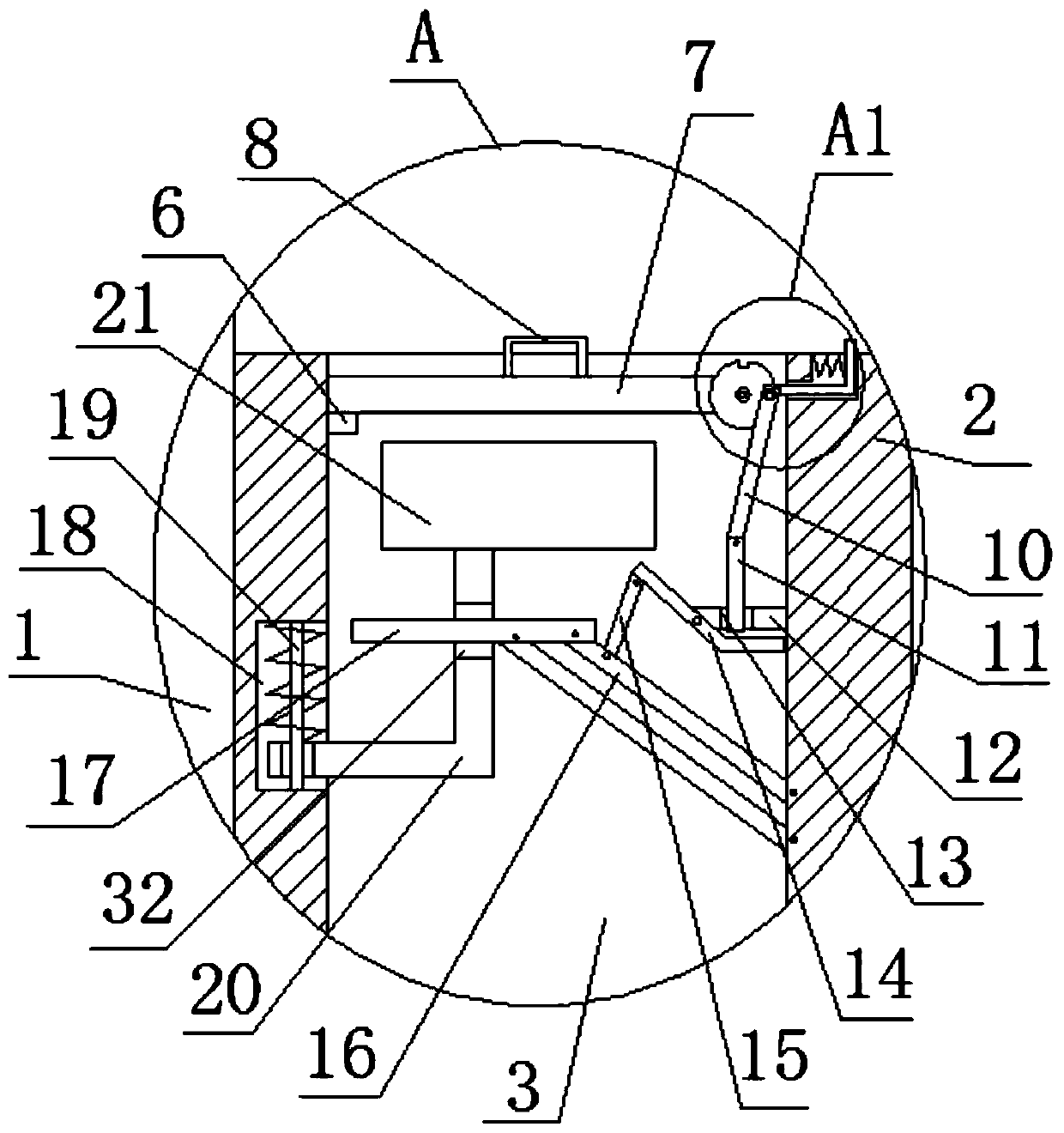

Cable defroster being convenient to install

InactiveCN108963935AEasy automatic compressionRealize automatic compressionOverhead installationDrive wheelEngineering

Owner:熊贱林

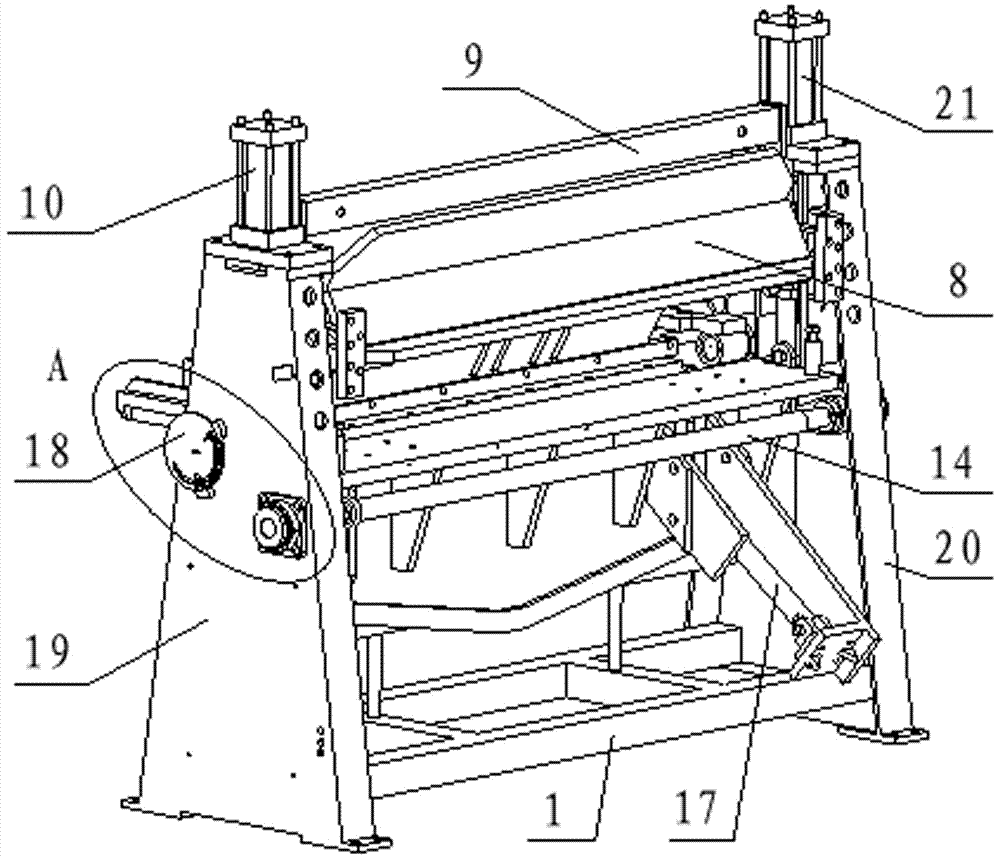

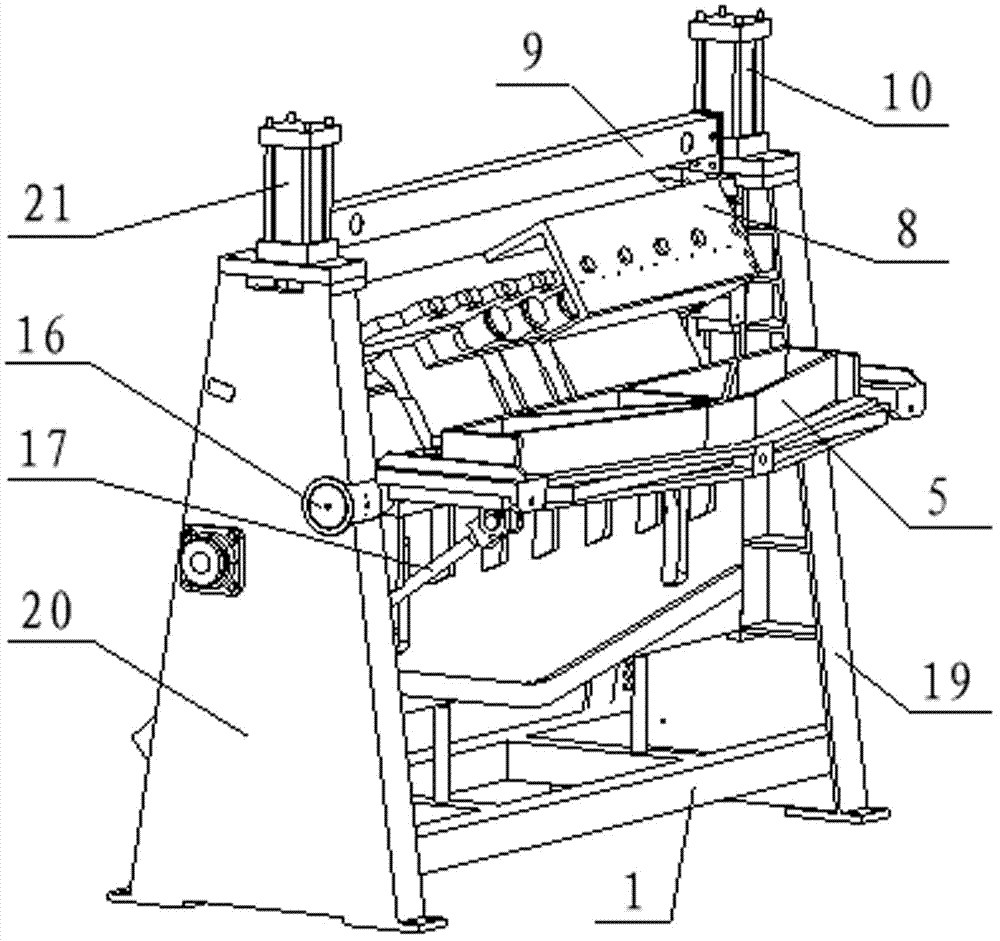

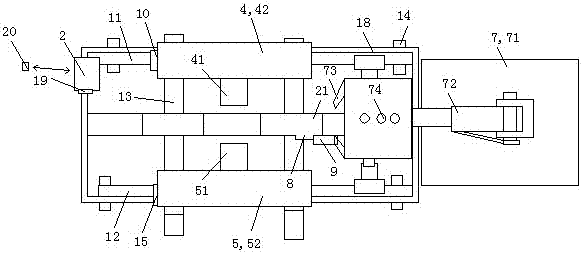

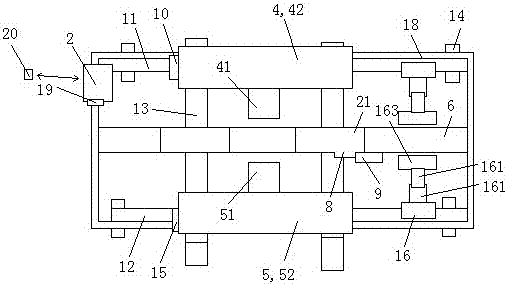

Rapid cutter replacing and automatic clamping type numerically-controlled hydraulic flanging machine

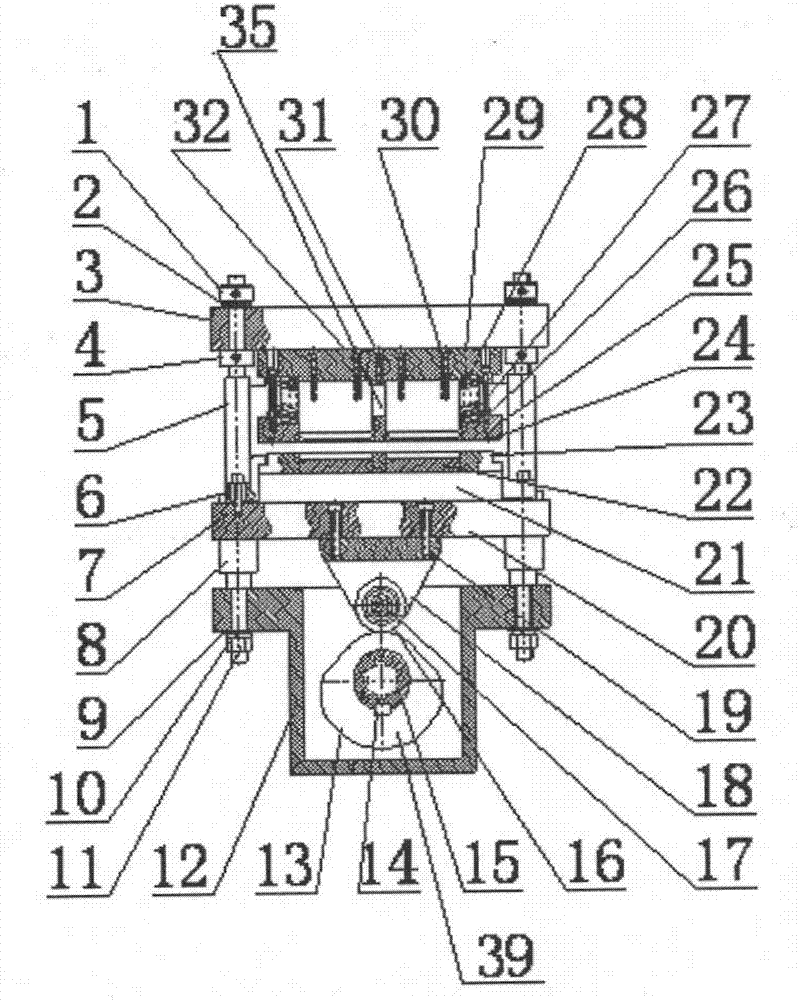

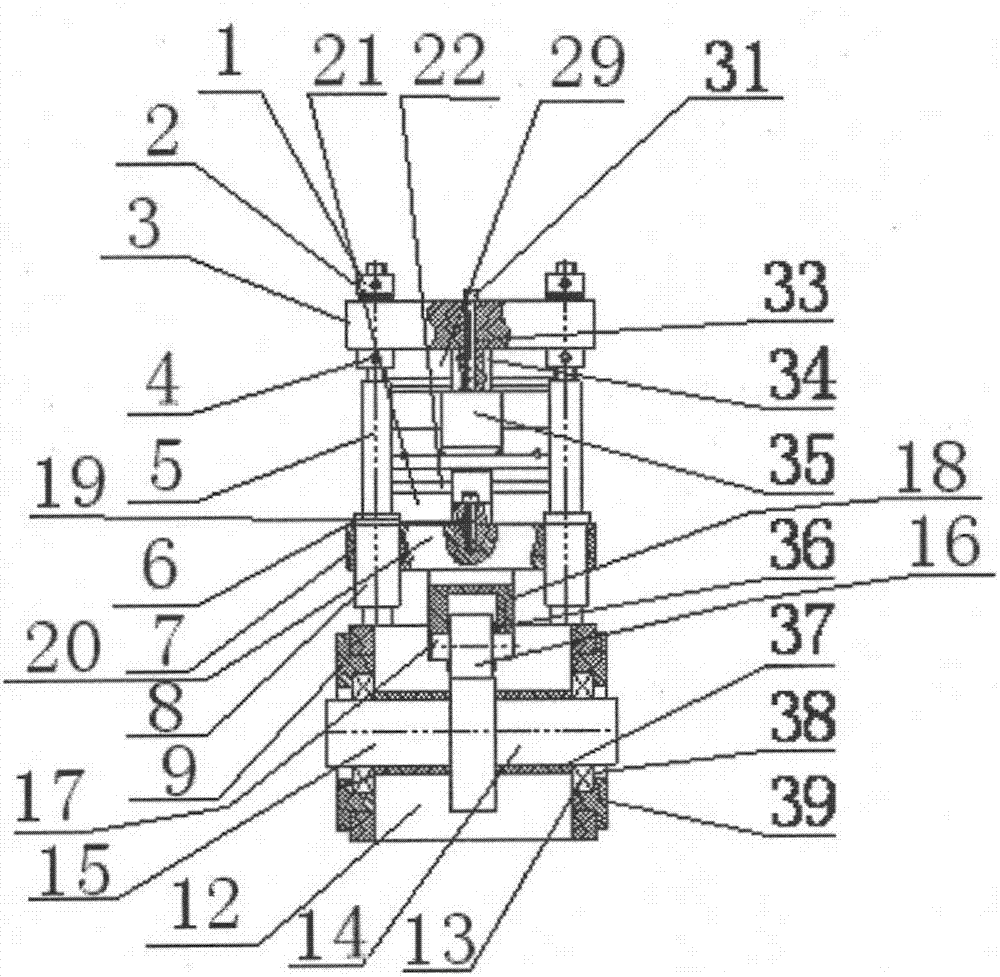

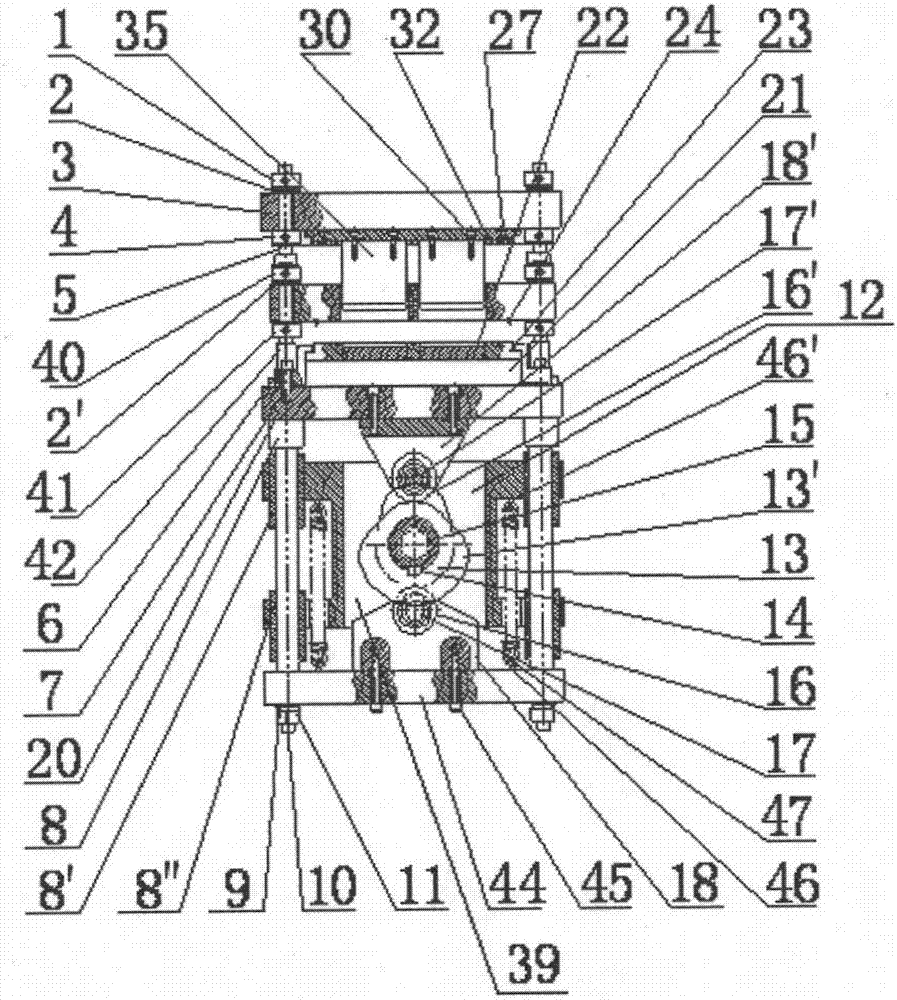

PendingCN107497896AGuaranteed bending distanceImprove securityMetal-working feeding devicesMetal working apparatusEngineeringFlanging

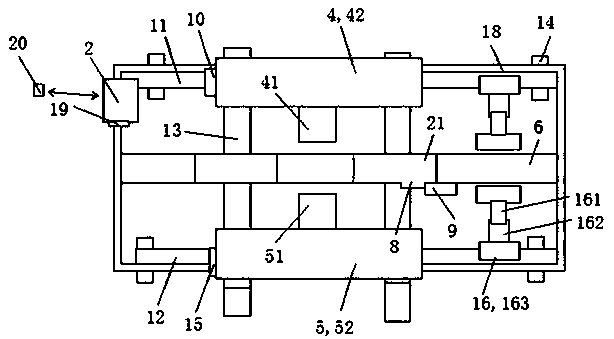

The invention provides a rapid cutter replacing and automatic clamping type numerically-controlled hydraulic flanging machine. The machine comprises a base body, an upper pressing mechanism, a lower pressing mechanism and a flanging mechanism, wherein the upper pressing mechanism, the lower pressing mechanism and the flanging mechanism are arranged on the base body; the upper pressing mechanism is that an upper pressing cutter mechanism is arranged at the upper part between side supports of the base body; the lower surface of the upper pressing cutter mechanism is connected with an upper pressing cutter rack sliding block mechanism which is provided with an upper pressing cutter; the upper pressing mechanism can move up and down along two sides of the base body; the upper pressing cutter mechanism is provided with a rapid cutter replacing and automatic clamping device; the lower pressing mechanism is that a lower pressing cutter fixing rack which is provided with a lower pressing head is arranged between the side supports, below the upper pressing cutter, of the base body; the flanging mechanism is that a flanging angle cutter rotating shaft is arranged above the lower pressing cutter fixing rack and between the side supports, below the upper pressing cutter, of the base body; one end of the shaft is provided with a device capable of controlling the rotating angle of the flanging angle cutter rotating shaft; a flanging angle cutter fixing rack mechanism provided with the flanging angle cutter is arranged on the flanging angle cutter rotating shaft. With the adoption of the machine, workpieces with different width can be flanged to form different flanging shapes; the cutter can be quickly and conveniently replaced; and the accuracy, the efficiency, the quality and the safety are high.

Owner:南阳市百斯特液压机械有限公司

Monitoring device with good convenience of surgical nursing

InactiveCN109965985AImprove maintenance or repair efficiencyMeet the needs of useSurgical furnitureClamping/extracting meansInterior spaceEngineering

Owner:李艾芹

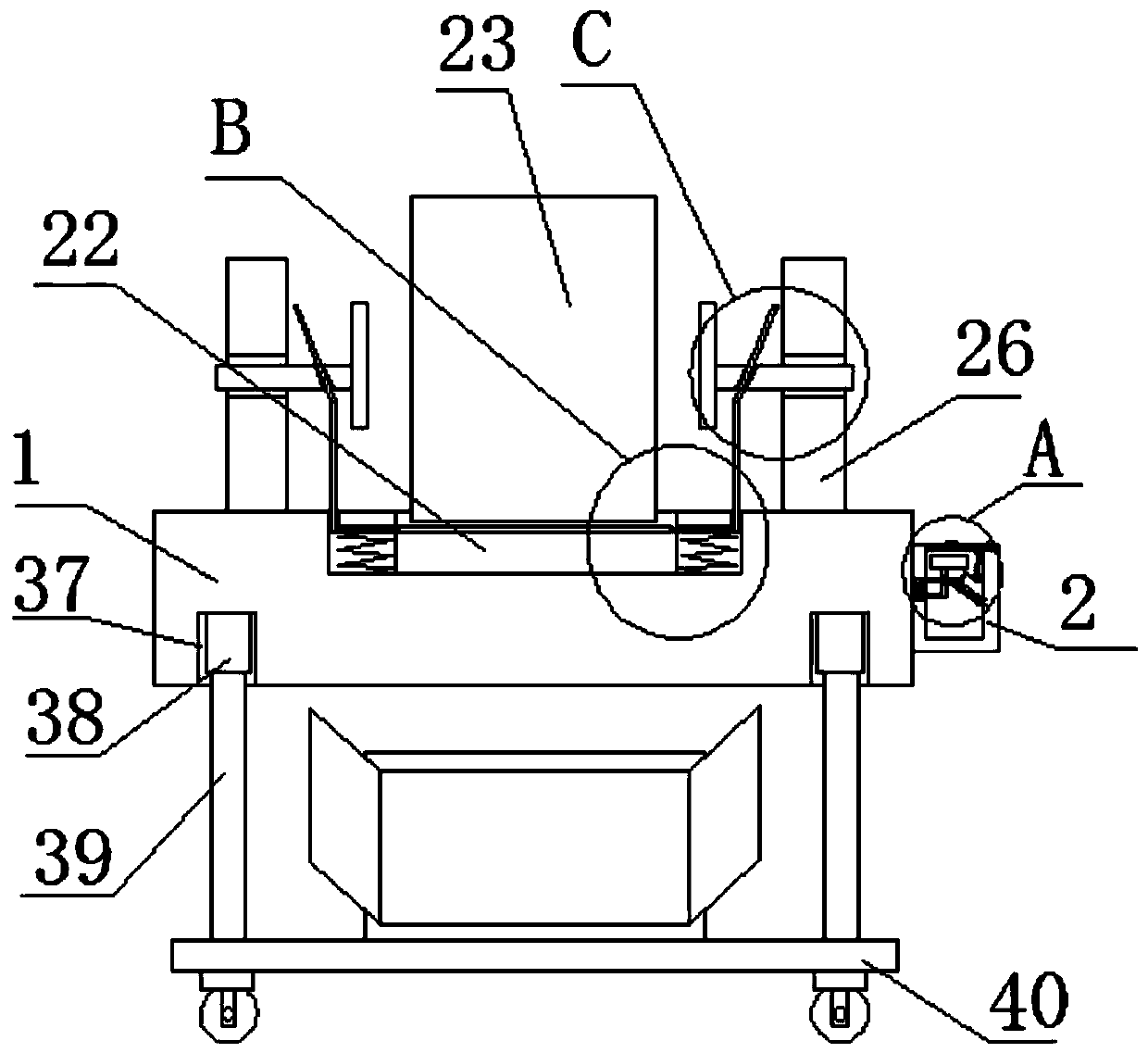

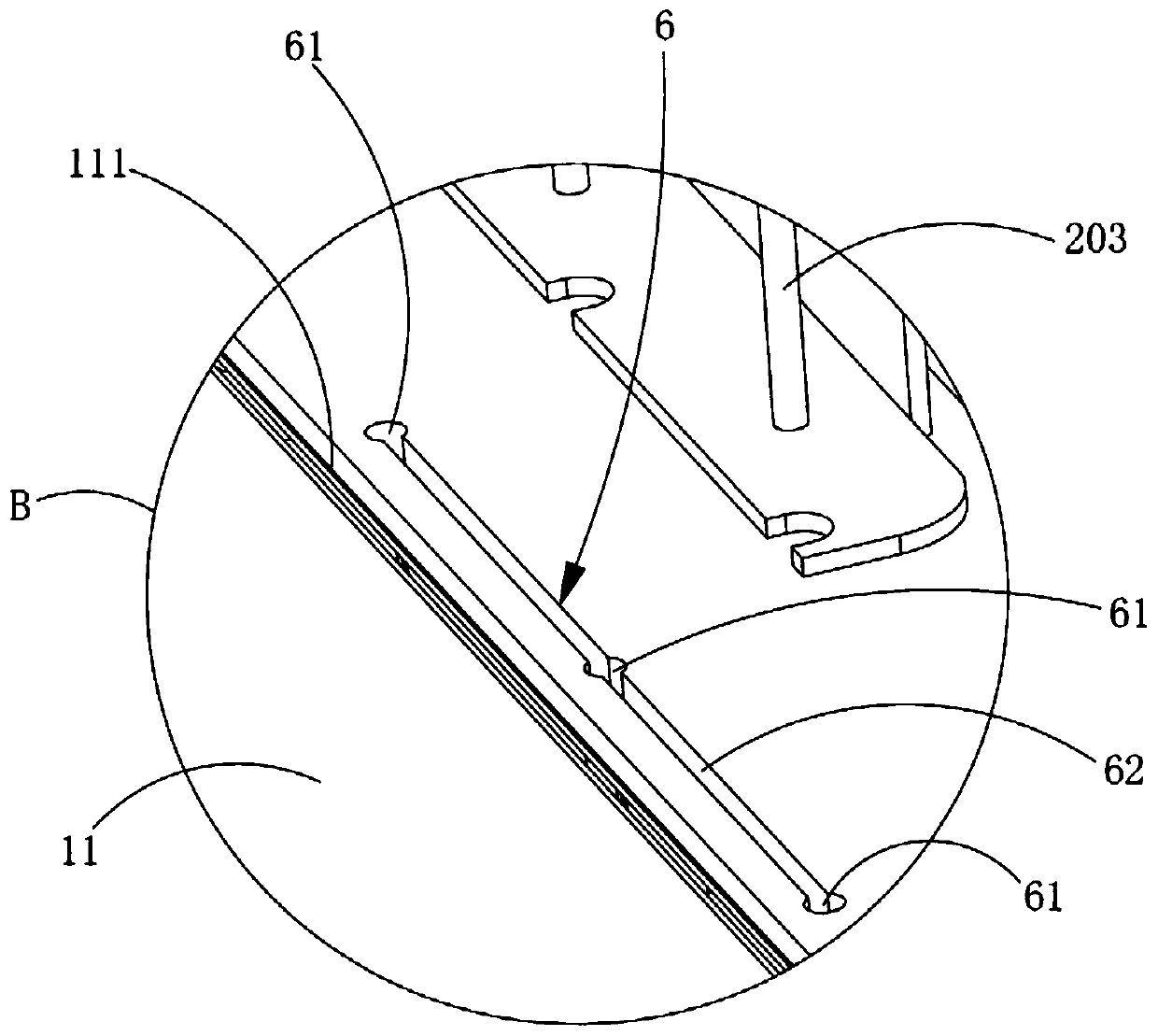

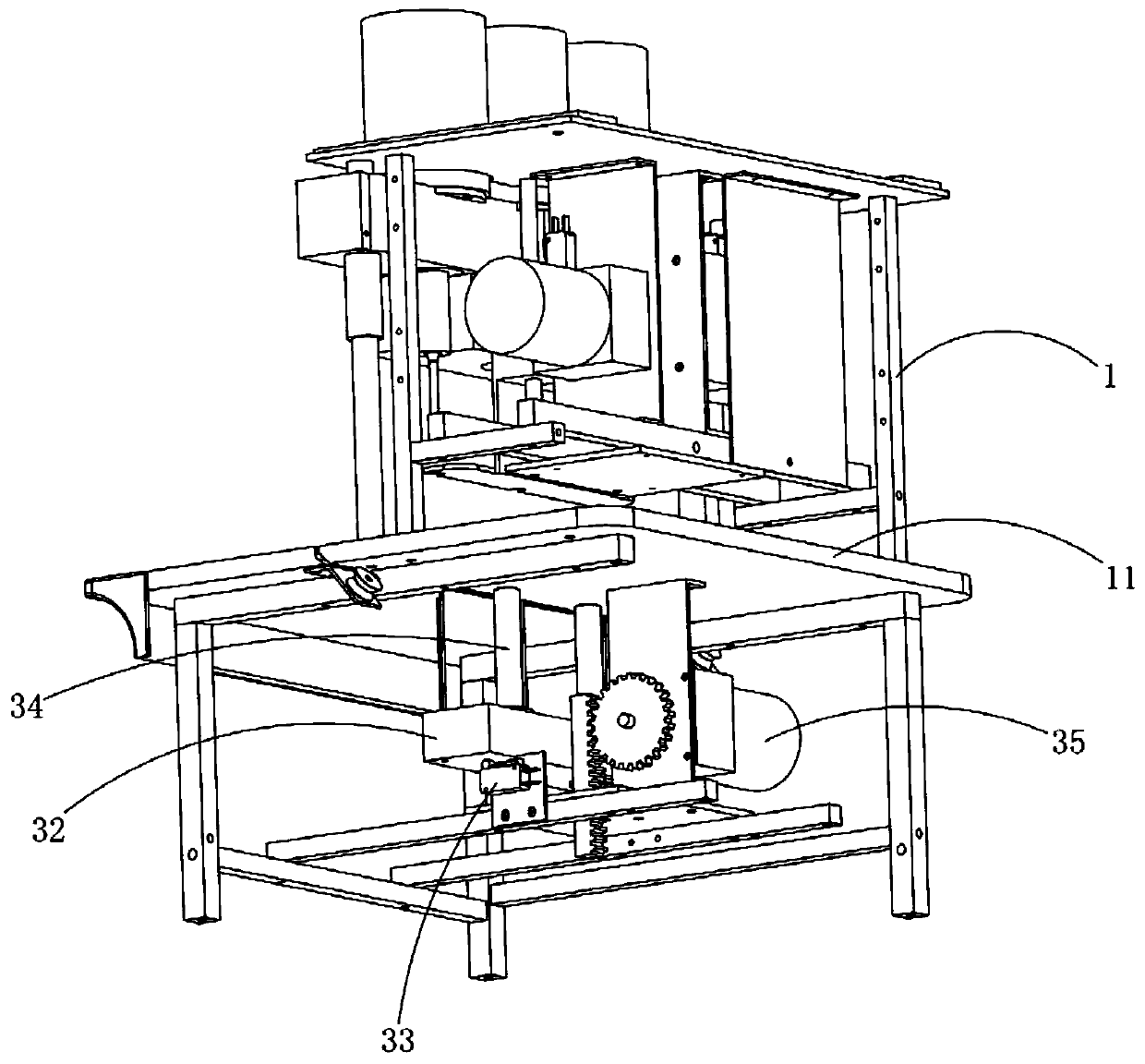

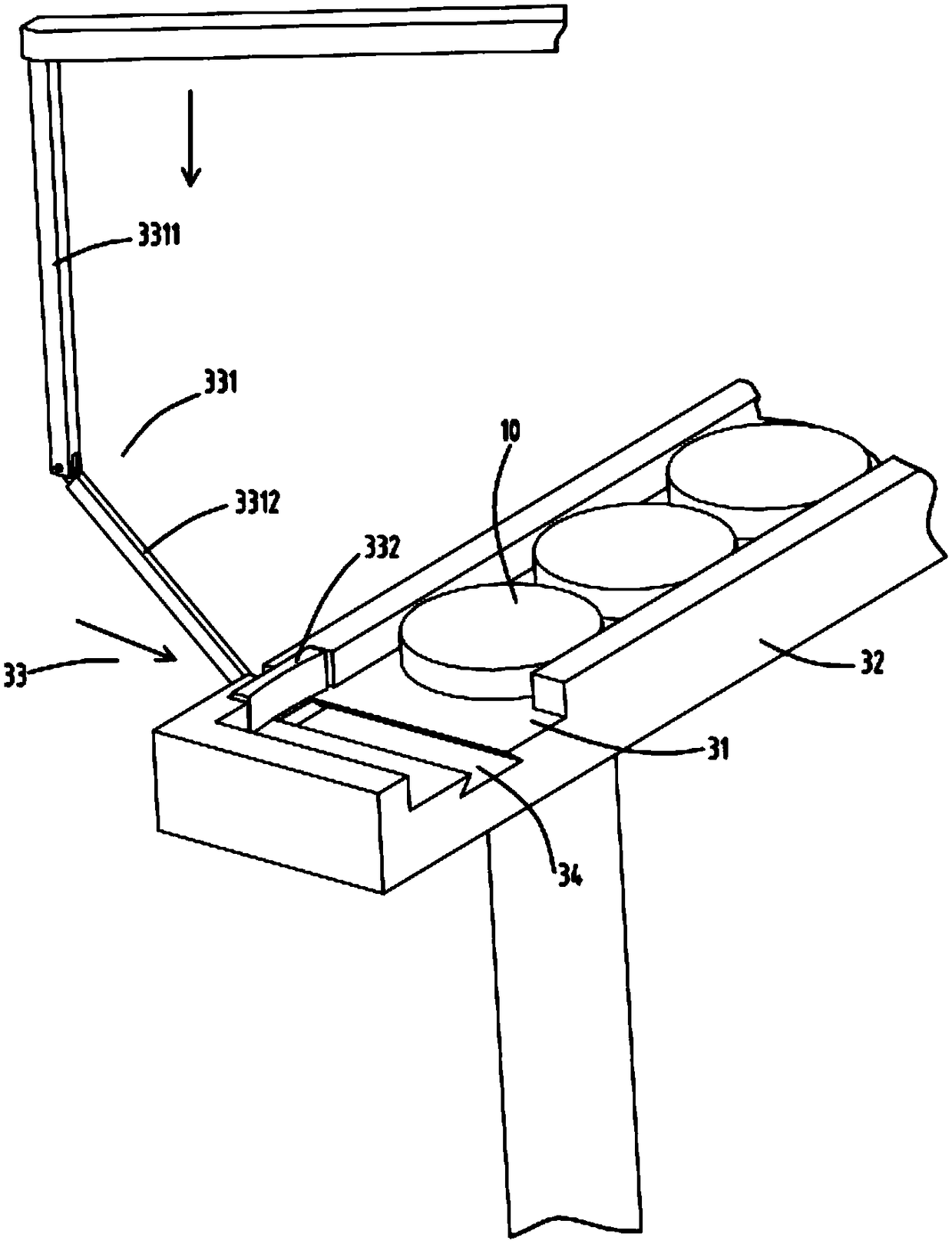

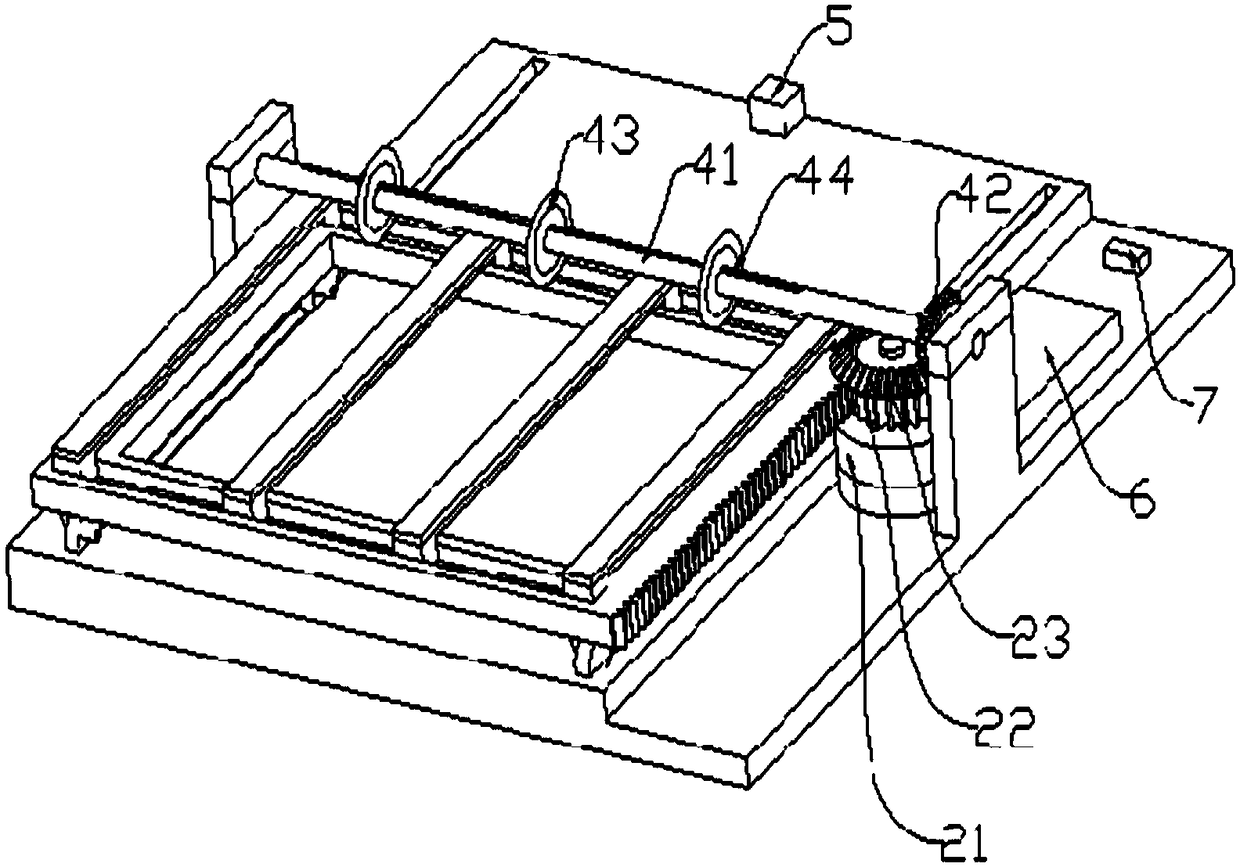

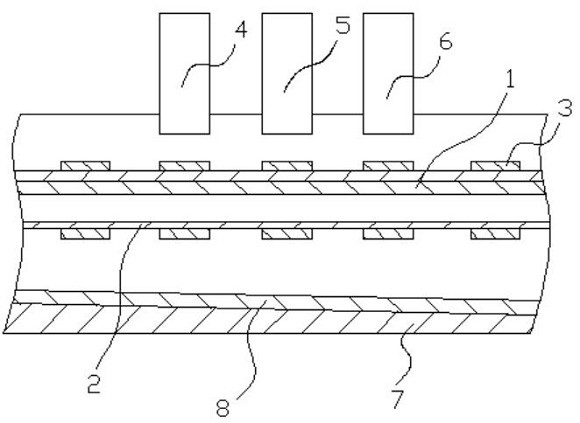

Improved porous wire type binding machine

The invention discloses an improved porous wire type binding machine. The improved porous wire type binding machine comprises a machine frame, a control circuit, a binding platform, a drilling mechanism and a wire feeding mechanism, wherein the binding platform is arranged in the middle of the machine frame; the drilling mechanism is arranged above the binding platform, and the drilling mechanismis provided with three drilling cutters; the wire feeding mechanism is positioned below the binding platform, the wire feeding mechanism is provided with three machine needles, each machine needle isaligned with the corresponding drilling cutter in parallel, a receding groove opening is formed in the binding platform, the binding platform is used for receding the drilling cutters and the machineneedles, the receding groove opening penetrates through the binding platform up and down, the receding groove opening transversely penetrates each drilling cutter and each machine needle, and the width of the receding groove opening is larger than the outer diameter of the drilling cutters and the outer diameter of the machine needles. Compared with the prior art, the binding machine can be used for receding the use of a conductive rubber pad and a rubber pad translation mechanism, receding the drill cutters in the downward drilling process, so that a binding line can be conveyed to penetratethrough the binding platform and a binding hole, and the whole machine is low in cost and good in stability.

Owner:周添星

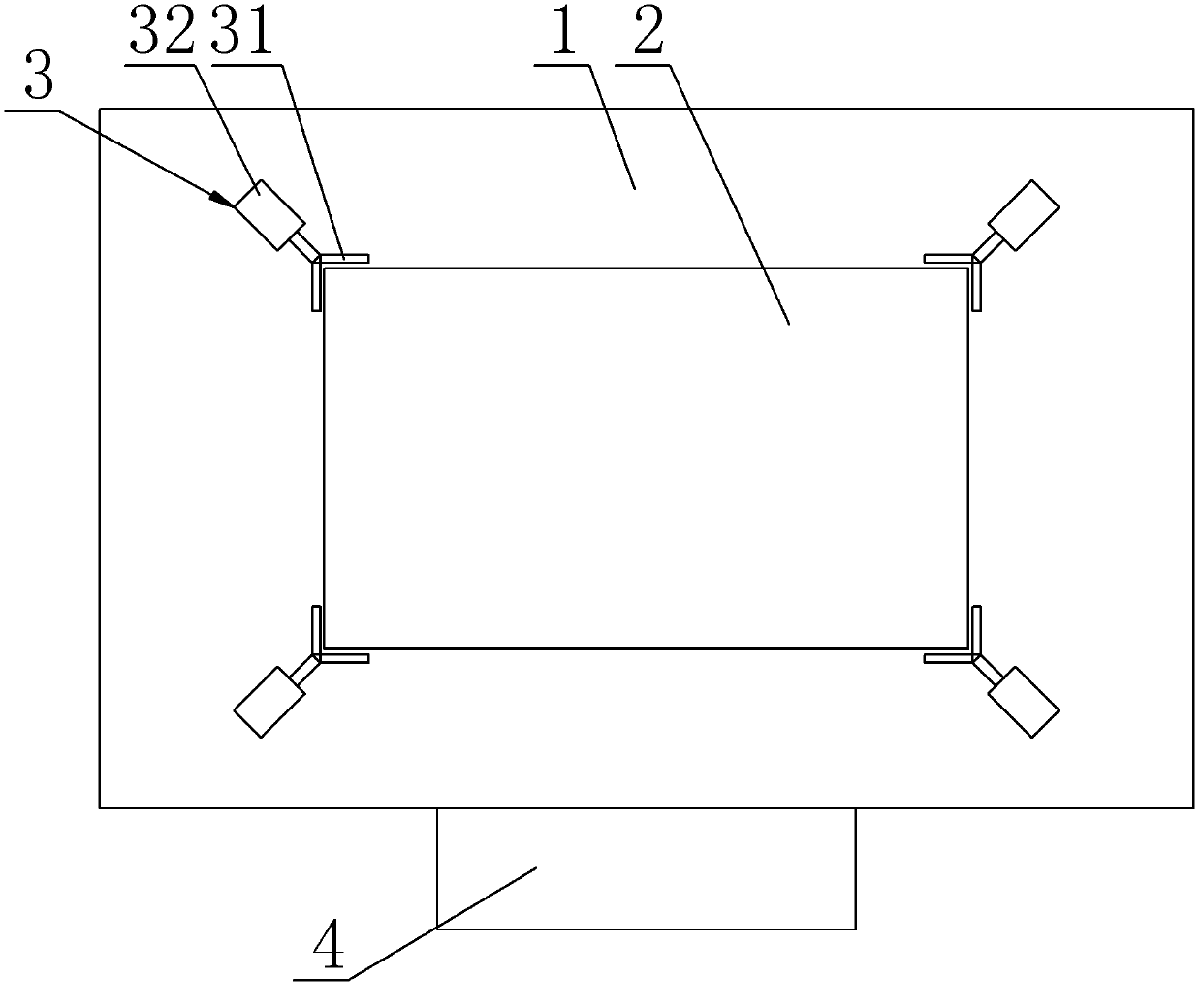

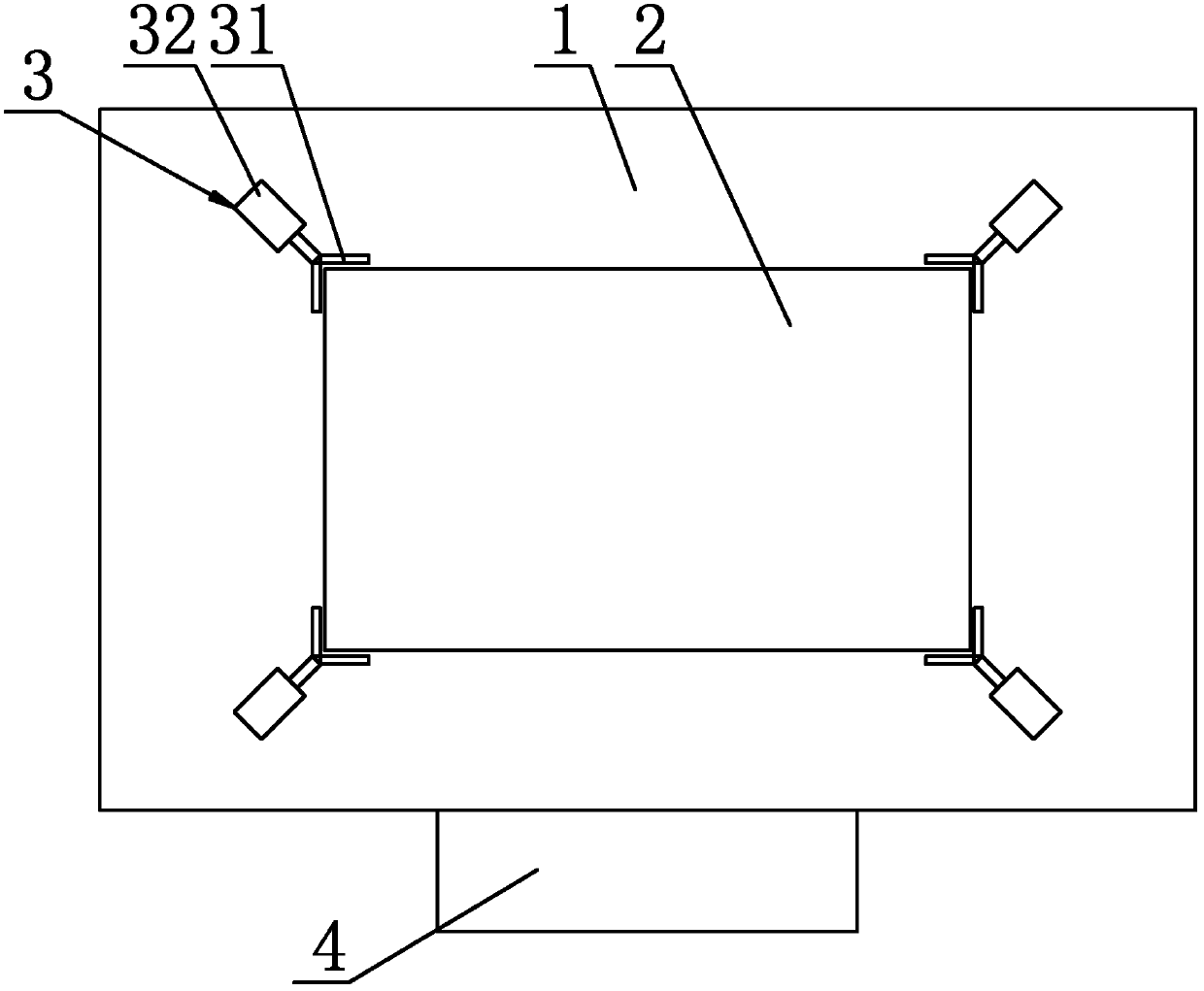

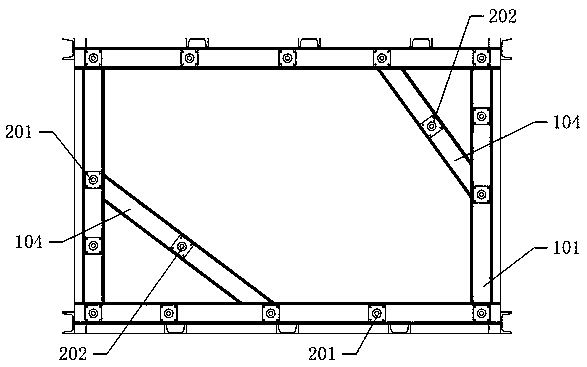

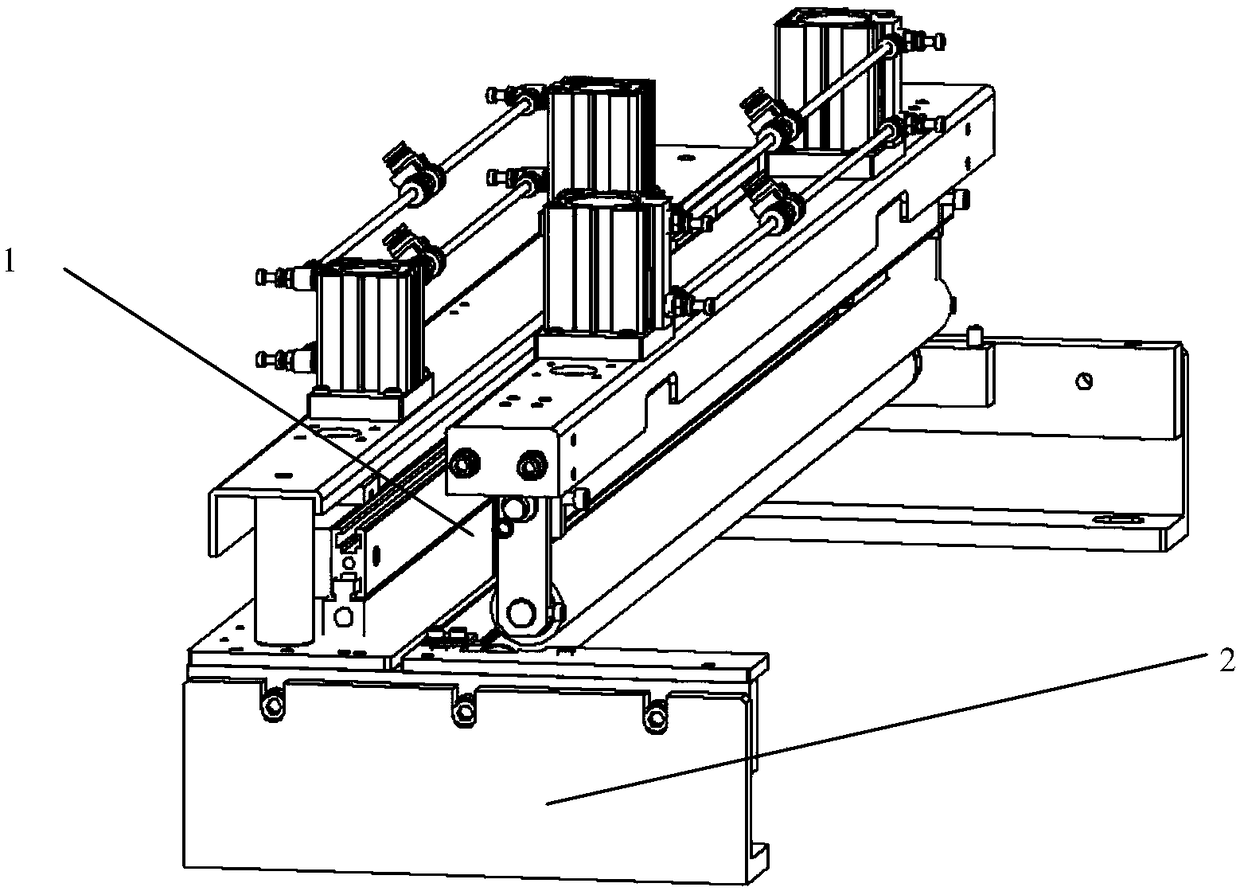

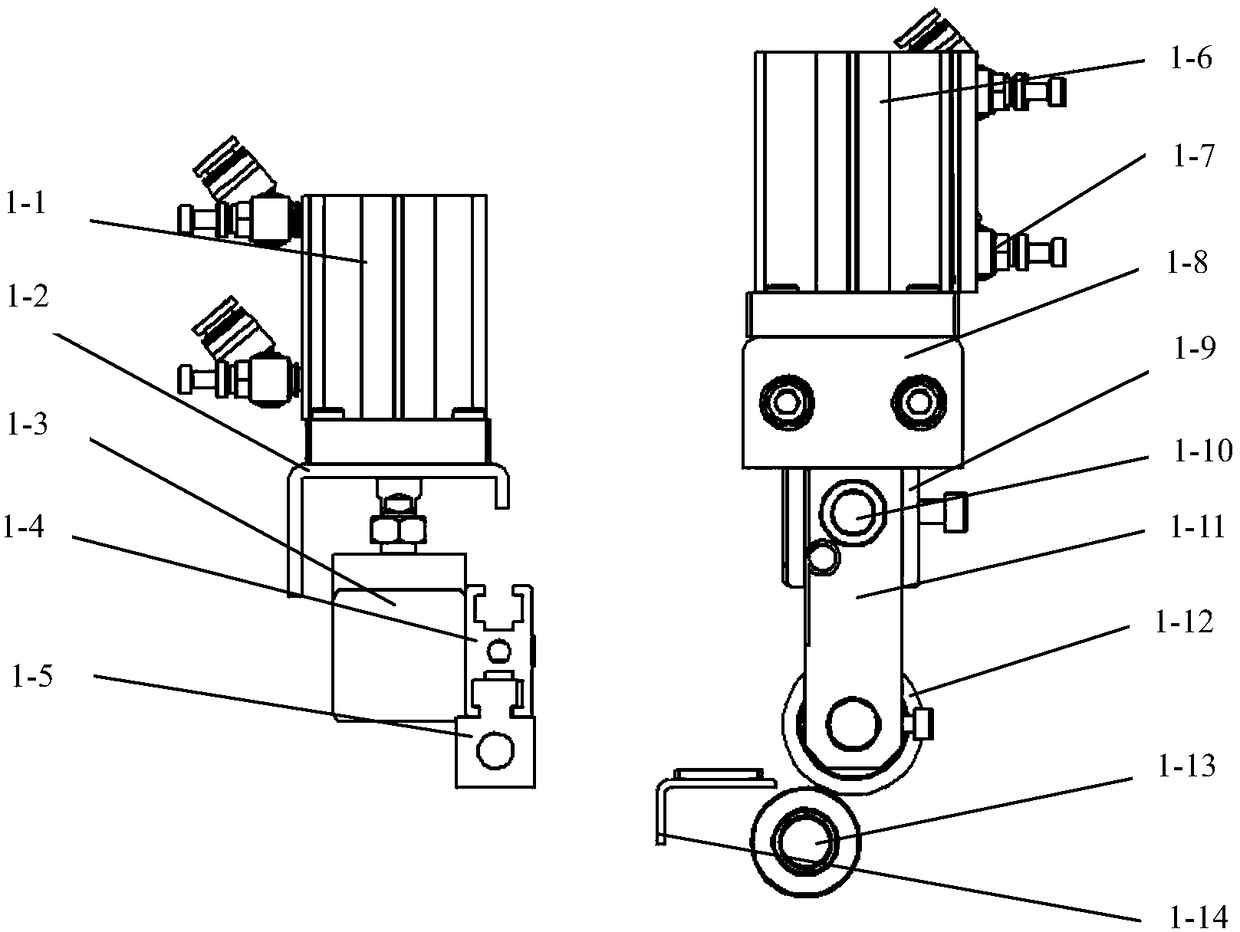

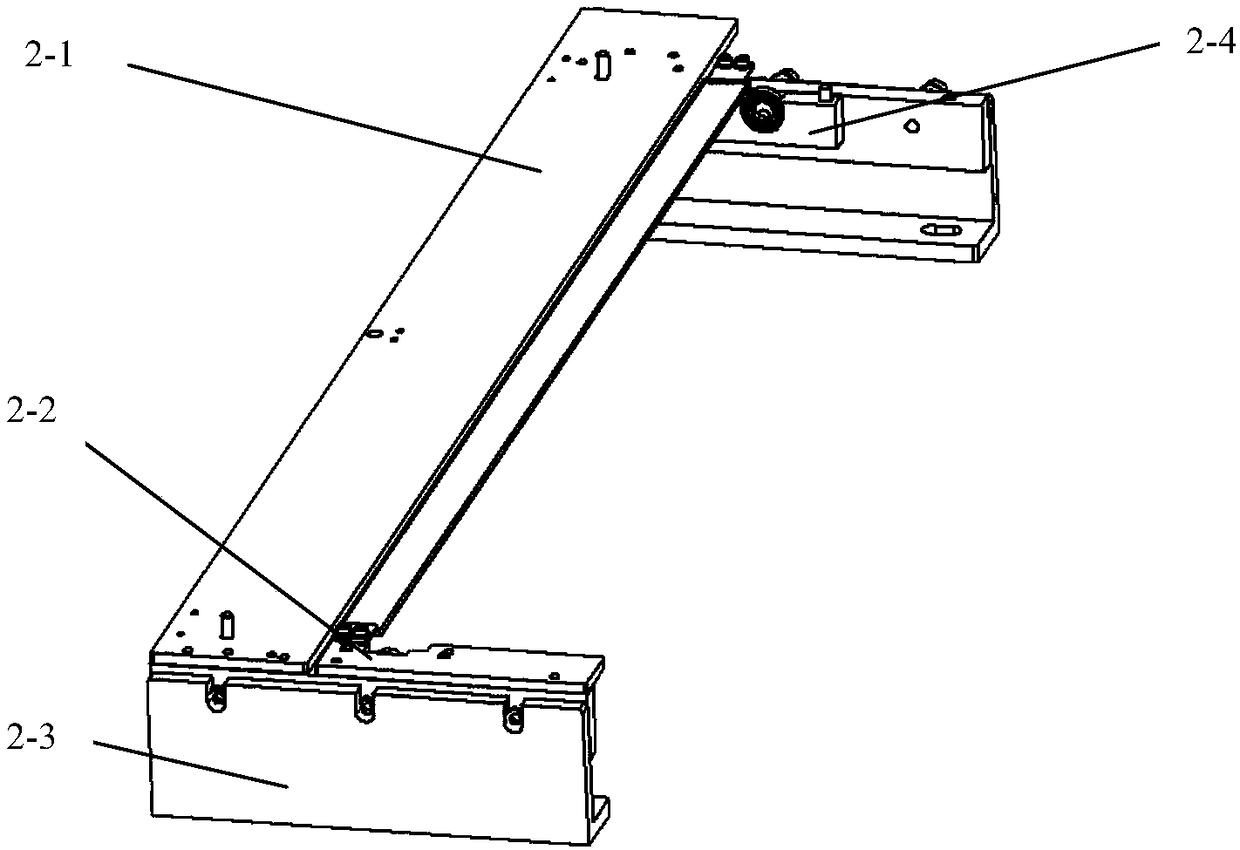

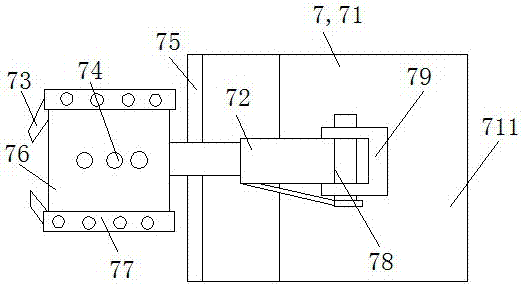

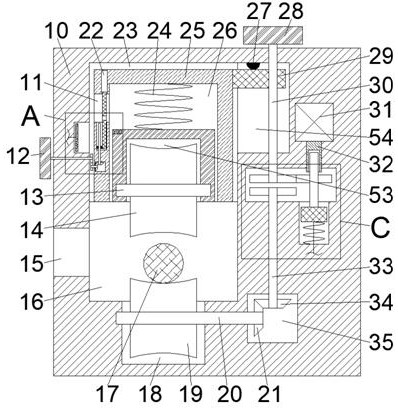

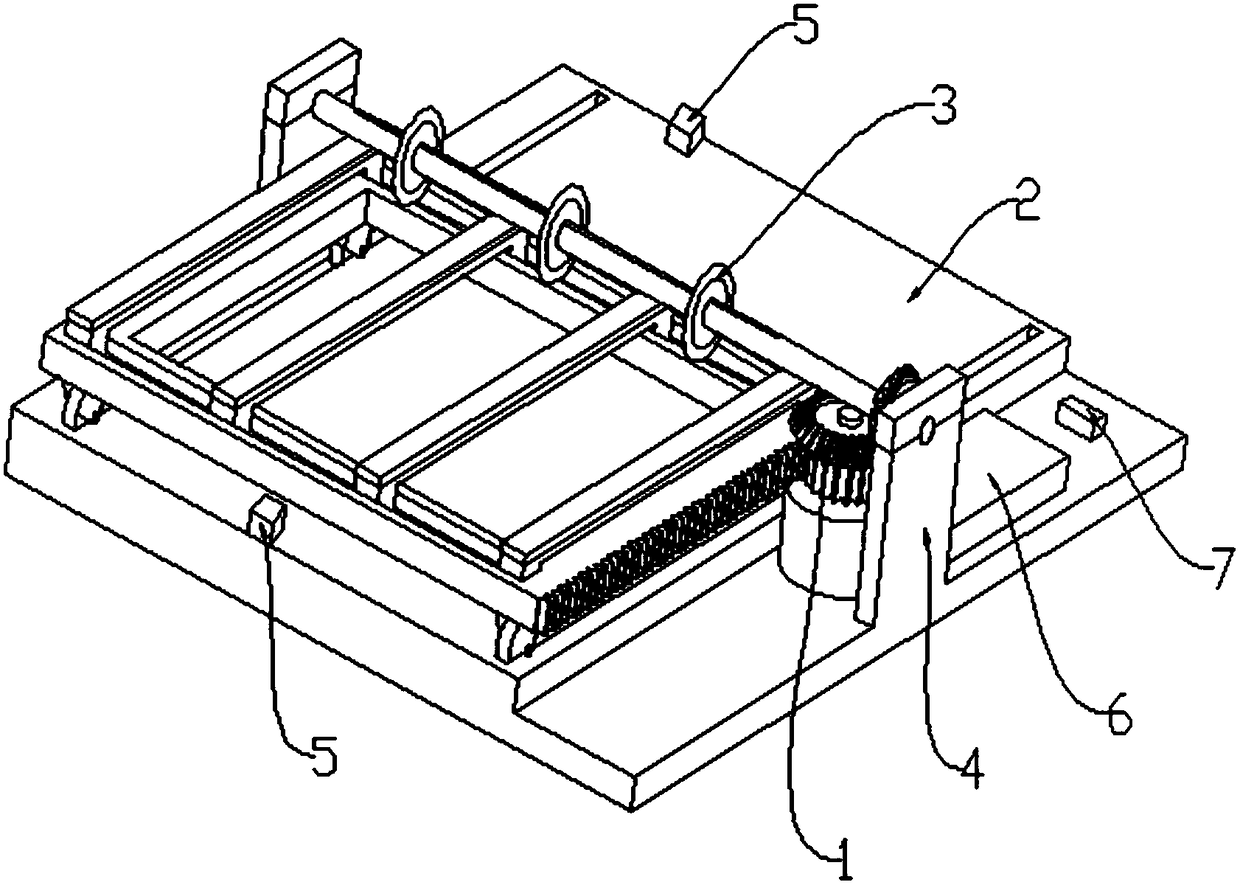

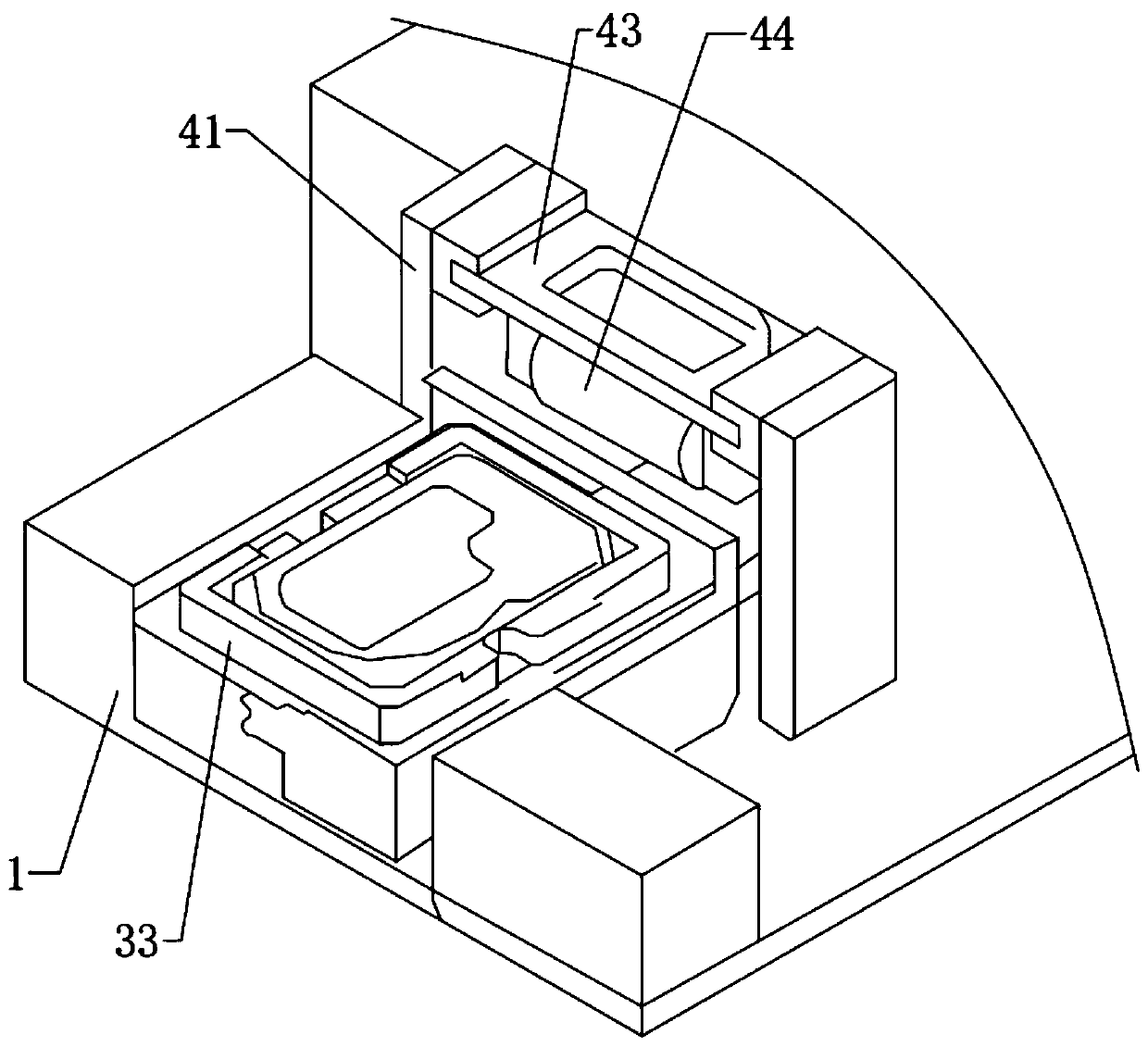

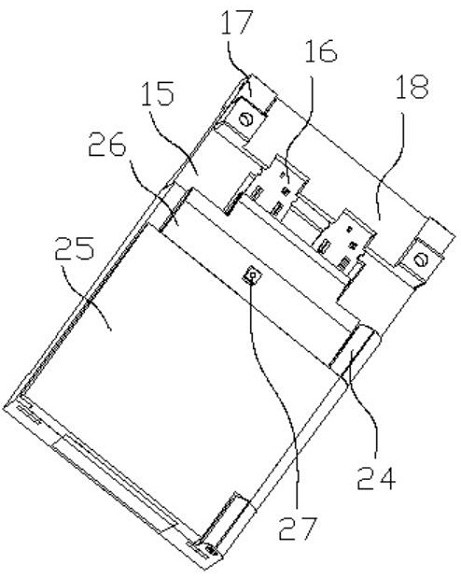

Frame assembling machine of pre-riveted photovoltaic assembly

InactiveCN102437250ARealize automatic compressionImprove compactnessFinal product manufactureSemiconductor devicesMechanical engineeringPhotovoltaics

The invention relates to a frame assembling machine of a pre-riveted photovoltaic assembly, wherein the frame assembling machine comprises an operation platform which is used for placing a photovoltaic assembly which is riveted in advance; the operation platform is provided with a frame pressing device and a control device for controlling the operation of the frame pressing device; the frame pressing device comprises four pressing dies and a driving device, wherein the pressing dies are corresponding to four angles of the frame of the photovoltaic assembly; and the driving device is used for driving the pressing dies to move. According to the frame assembling machine of the pre-riveted photovoltaic assembly provided by the invention, through driving the pressing dies to move by the driving device, the pressing of the frame of the photovoltaic assembly is realized, the tightness is higher, the product quality is improved, the structure is simple, the frame assembling machine is easy to manufacture, and the working efficiency is high.

Owner:CHANGZHOU SKY SOLAR NEW ENERGY INST

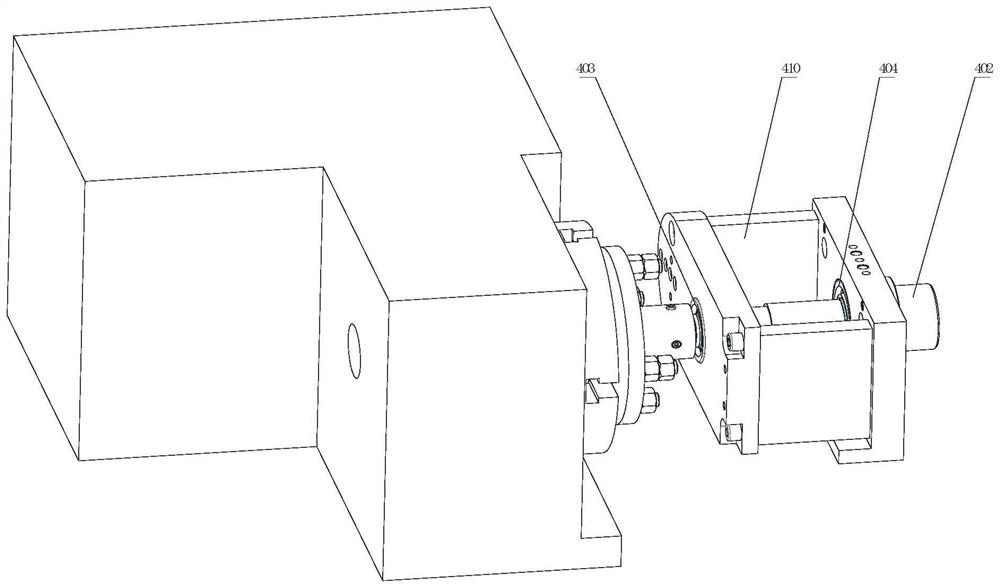

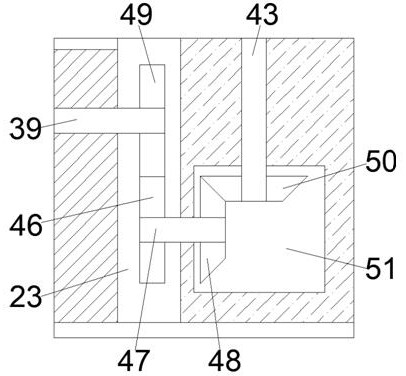

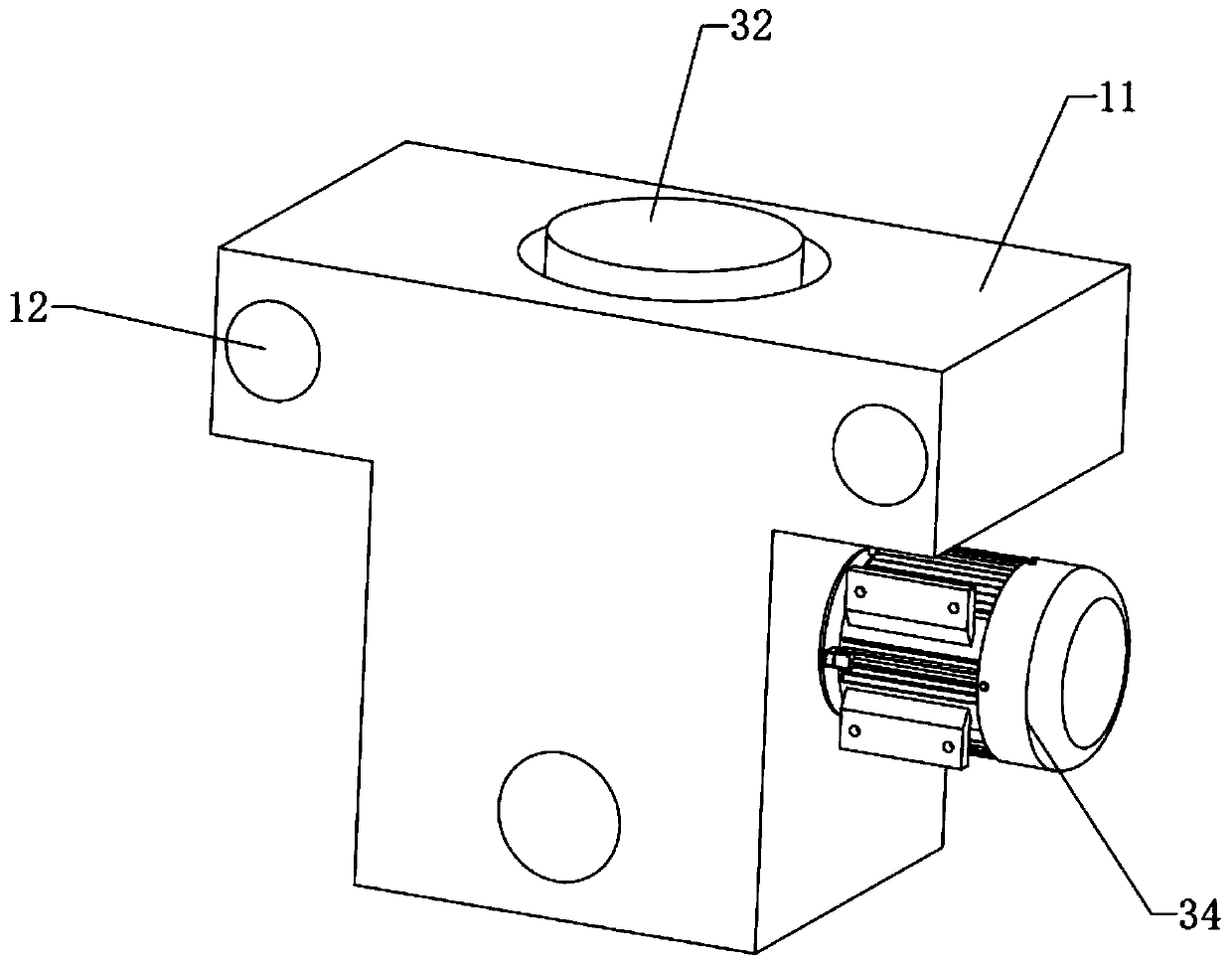

Gas-assisted protection integral impeller trepanning electrolytic machining process and device

ActiveCN114247943AAchieve precise indexingRealize automatic compressionElectrochemical machining apparatusElectrical-based auxillary apparatusElectrolytic agentImpeller

The invention discloses an integral impeller trepanning electrolytic machining process and device with a gas-assisted protection function, and belongs to the field of electrolytic machining. The upper part of the device is provided with a cylindrical cathode seat which is in clamping connection with a main shaft, and the bottom of the cylindrical cathode seat is provided with a pin hole so as to realize the positioning of a cathode; a vent hole is formed in the middle of the device and used for conducting gas-assisted insulation on a machined blade and a blade to be machined. An insulation sealing device is arranged on the lower portion of the device, and the insulation sealing device and the front blade insulation sleeve and the rear blade insulation sleeve inside the device form a closed machining area to achieve closing of an electrolytic machining flow field. In the machining process, the blade sleeved with the blade insulation sleeve is always in the gas auxiliary insulation state, and the stray corrosion degree of the machined blade is effectively reduced. The method solves the problems that the machined blade is subjected to stray corrosion and the flow field open type electrolyte remains in a non-machining area during the trepanning electrolytic machining of the uniform-section blade type integral impeller, and is beneficial to improving the machining precision of the blade and enhancing the stability of the machining process.

Owner:JITRI INST OF PRECISION MFG

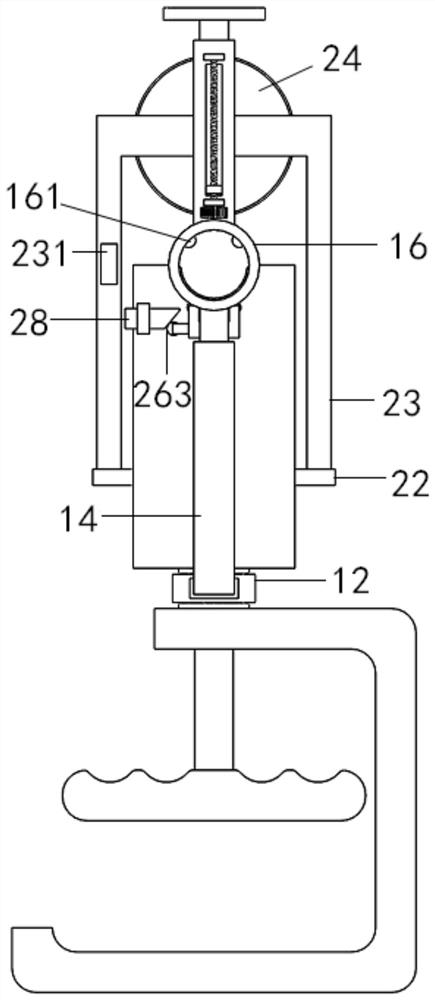

Multifunctional cutting machine capable of conveniently cutting pipeline in wall

InactiveCN112238251ARealize automatic compressionIncrease flexibilityTube shearing machinesShearing machine accessoriesElectric machineryStructural engineering

The invention discloses a multifunctional cutting machine capable of conveniently cutting a pipeline in a wall. The multifunctional cutting machine comprises a handheld frame, a circular base and a cutting main body base are fixed to the handheld frame, an arc-shaped containing groove and a cutting groove are formed in the top face of the cutting main body base, a main driving rod is inserted intothe cutting main body base, a pair of transmission plates arranged on the left side and the right side of the top of the main driving rod extend out of the cutting main body base and are connected with a cutting frame, and a cutting blade and a cutting motor are arranged in a top plate of the cutting frame. The multifunctional cutting machine has the advantages that the cutting blade and a pressing ring can move at the same time by pulling the main driving rod, so that the purpose that the pipeline can be automatically pressed during cutting and can be automatically loosened after cutting isachieved, the cutting efficiency is greatly improved, when the pipeline in the wall is cut, two movable frames can be flexibly attached to the wall, the stability of the whole device is ensured, adjustable limiting roll shafts are arranged on the cutting main body base and the pressing ring, so that the pipeline with a relatively large diameter can be subjected to ring type cutting, and the flexibility is high.

Owner:王祎颖

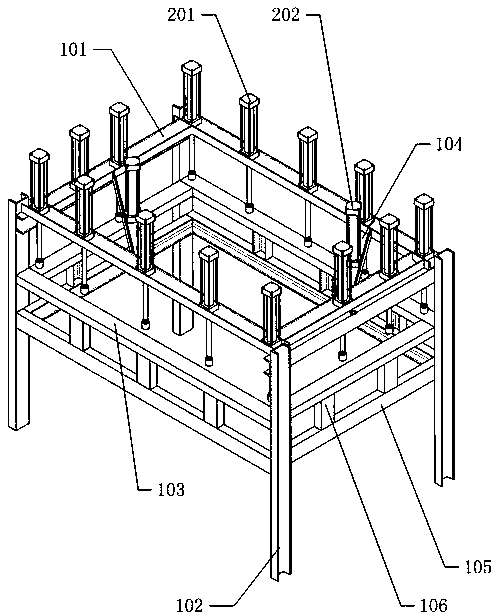

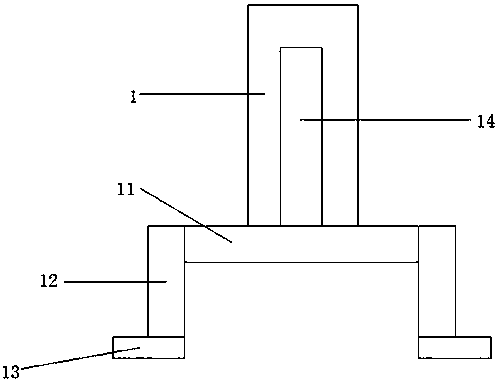

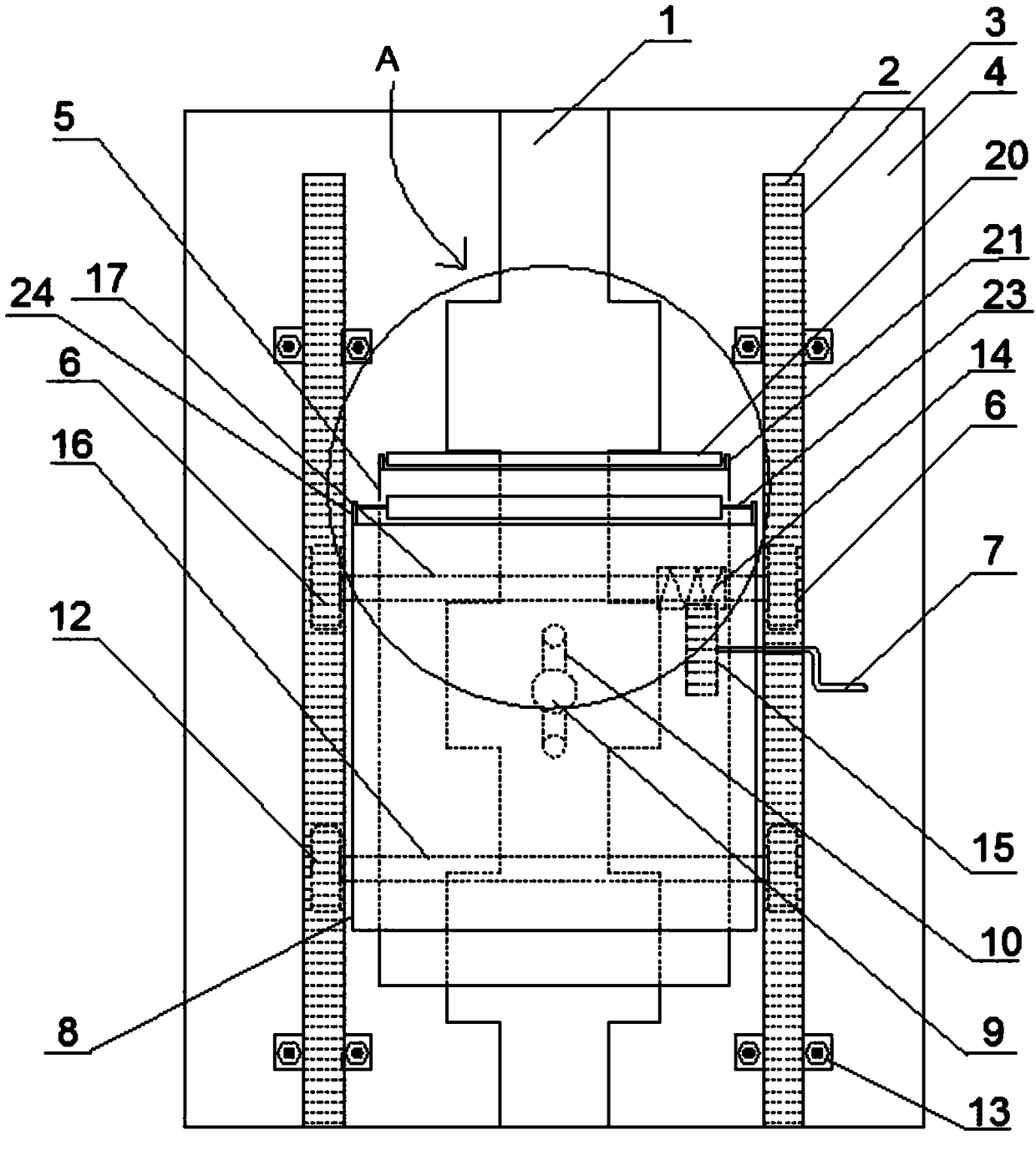

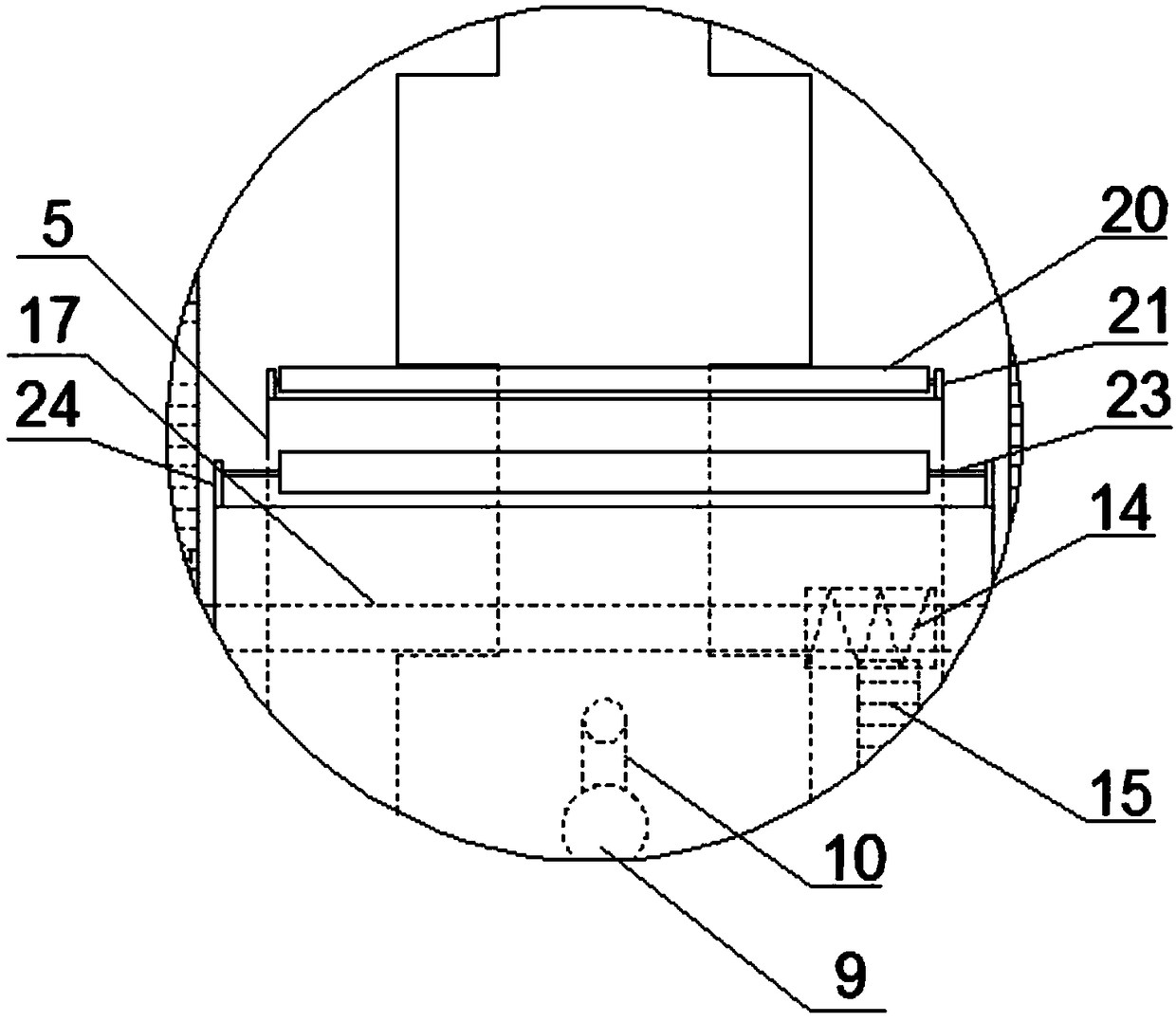

Pressing machine of piano sound board frame

The invention discloses a pressing machine of a piano sound board frame. The pressing machine includes a rectangular top frame, four supporting legs arranged at the four corners of the rectangular frame correspondingly, and a worktable connected with the four supporting legs and located on the lower portion of the rectangular top frame. The four edges of the rectangular top frame are provided witha plurality of first cylinders correspondingly, and piston rods of the first cylinders pass vertically downward through the rectangular top frame and are used for compressing a resonant board and a sound board frame placed on the worktable. According to the pressing machine of the piano sound board frame, the sound board frame and the resonant board of a piano are automatically compressed, the working efficiency is improved, and the labor intensity of workers is lowered.

Owner:黄雪侨

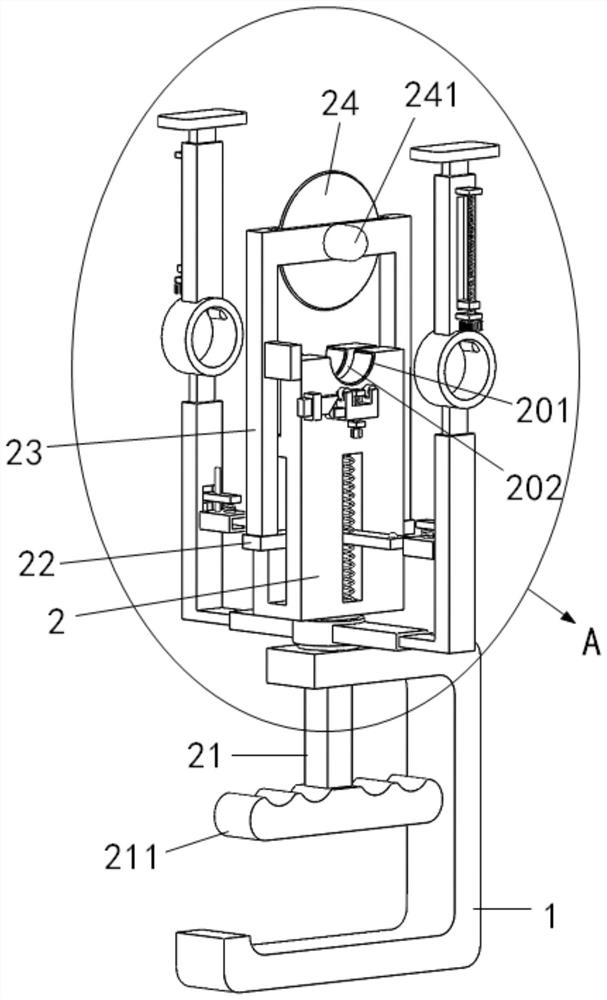

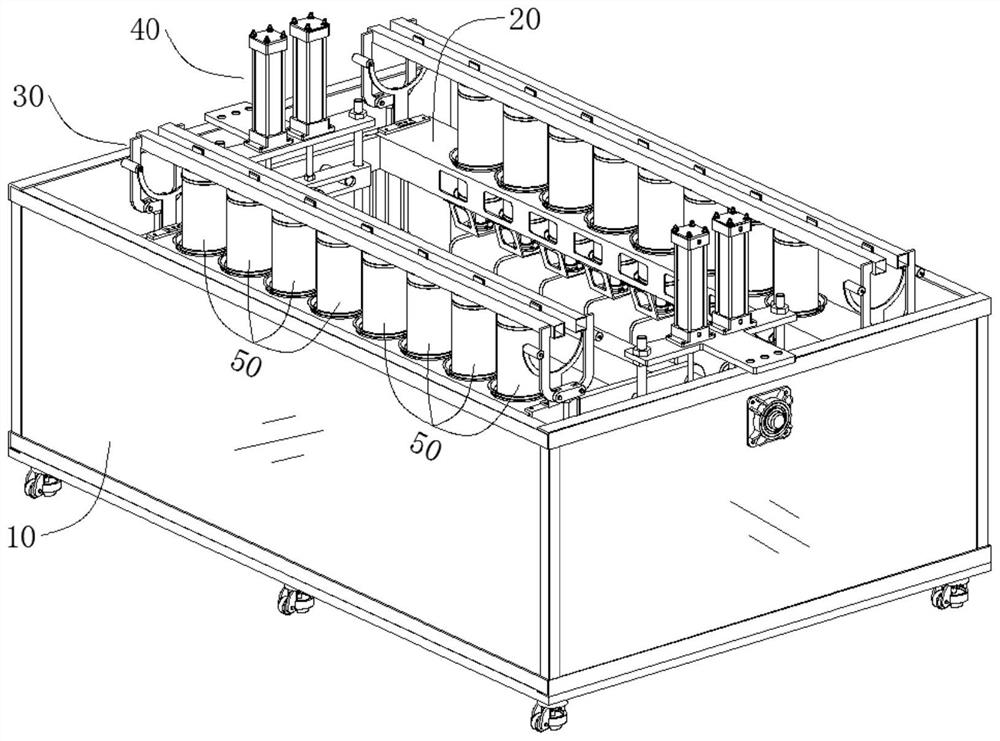

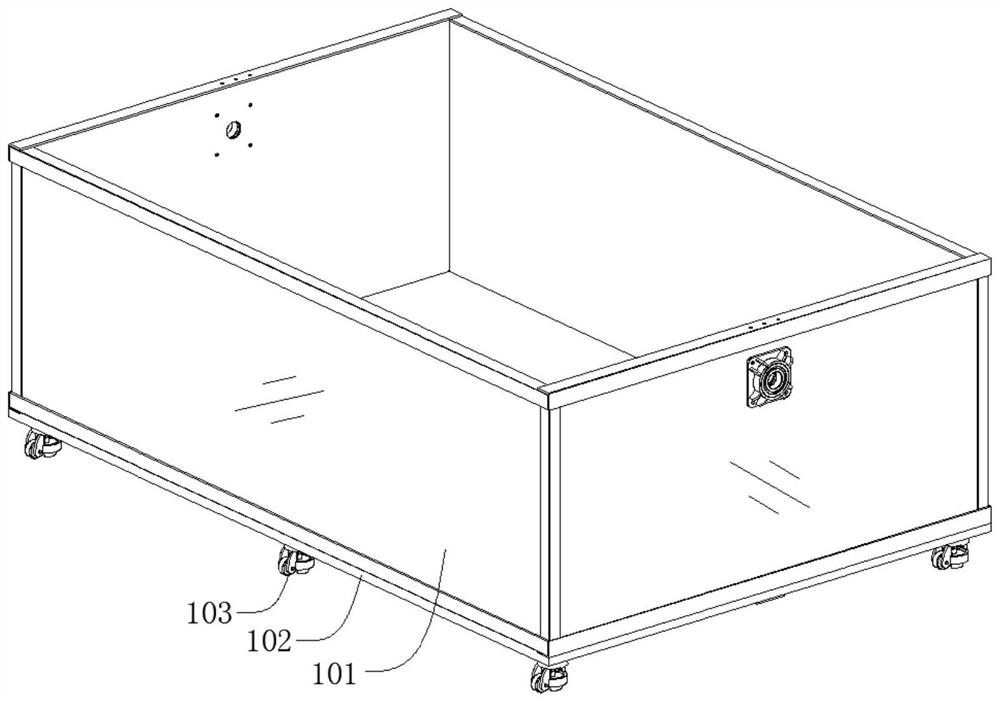

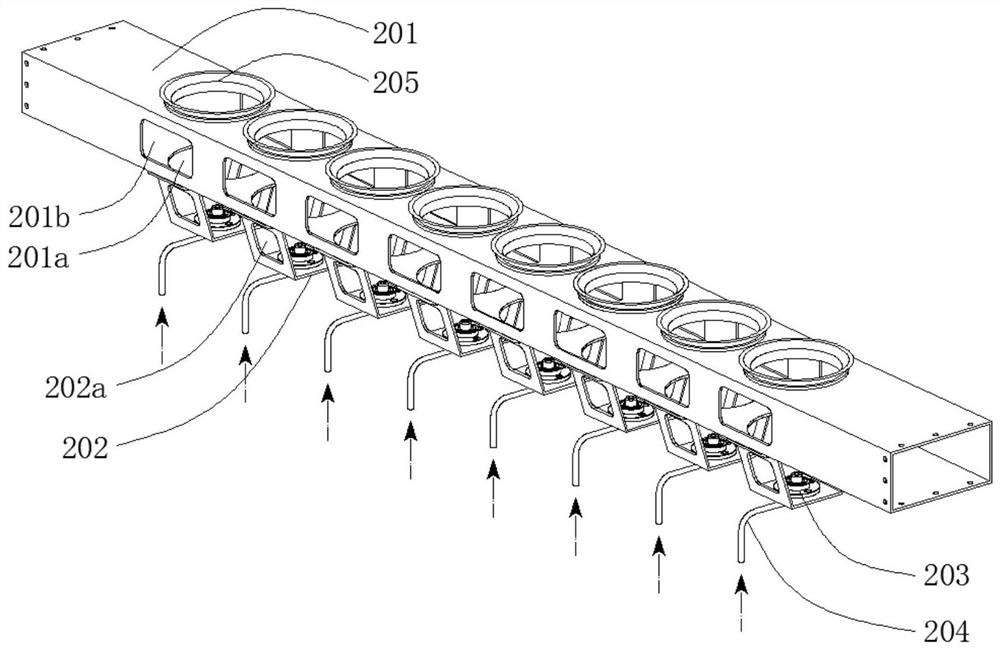

Semi-automatic fire extinguisher bottle body airtightness detection system

InactiveCN113280982ARealize automatic positioningEfficient detectionDetection of fluid at leakage pointHydraulic cylinderWater storage

The invention discloses a semi-automatic fire extinguisher bottle airtightness detection system, and belongs to the technical field of fire extinguisher detection. The semi-automatic fire extinguisher bottle airtightness detection system comprises a water storage assembly, positioning assemblies, pressing assemblies and soaking assemblies; the water storage assembly comprises a water storage pond, a supporting plate and footmaster casters. the two positioning assemblies comprise a front positioning assembly and a rear positioning assembly and are used for automatically positioning front and rear rows of fire extinguisher bottle bodies, and each positioning assembly comprise positioning pipe, positioning plates and positioning blocks; the pressing assemblies comprise a front pressing assembly and a rear pressing assembly and are used for automatically pressing the fire extinguisher bottle bodies in the front row and the rear row, each pressing assembly comprises a fixed plate I, a hydraulic cylinder I, a hinge block, a hinge rod and a pressing pipe; and the soaking assemblies comprises a left soaking assembly and a right soaking assembly and are used for automatically soaking the fire extinguisher bottle bodies in the front row and the rear row, each soaking assembly comprises a mounting shaft, a mounting strip, a fixing plate II and a hydraulic cylinder II. In conclusion, the system has the advantages of being ingenious in design, reasonable in structure, convenient to detect and efficient.

Owner:来安县誉强消防科技有限公司

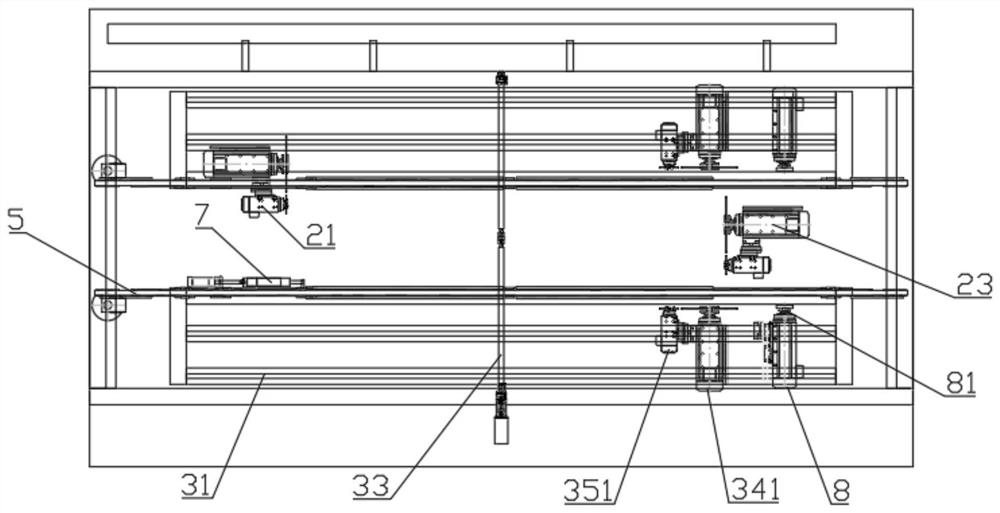

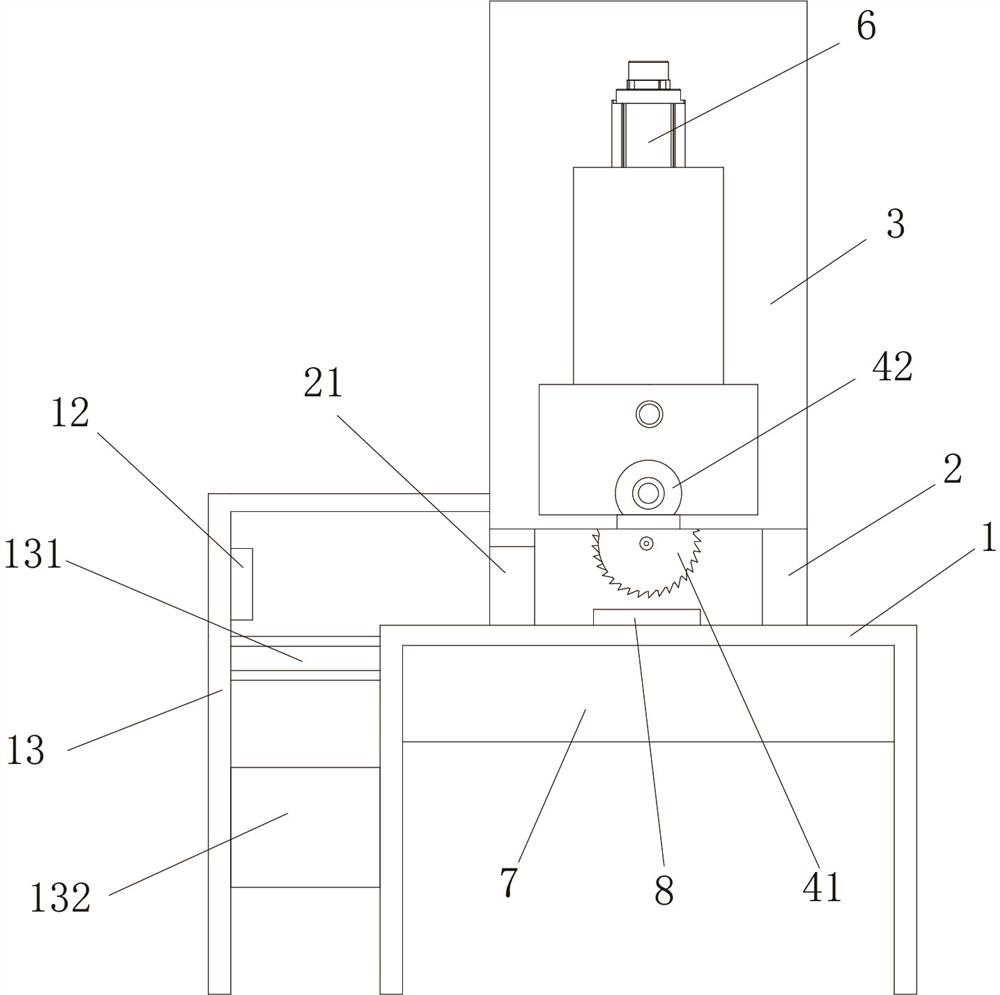

Wooden door four-side saw with groove-shaped workbenches and sawing method of wooden door four-side saw

ActiveCN112677244ASuitable for processingConsistent thicknessCircular sawsStructural engineeringWorkbench

The invention provides a wooden door four-edge saw with groove-shaped workbenches and a sawing method of the wooden door four-edge saw. The wooden door four-edge saw comprises a rack, a door length sawing group, a door width sawing group and the two groove-shaped workbenches which are arranged on two bases; each groove-shaped workbench comprises two narrow-edge workbench surfaces; the workbench surfaces are arranged on the bases; a lifting type conveying belt is arranged between the two workbench surfaces of each groove-shaped workbench; and the lifting type conveying belts are arranged on the bases. According to the wooden door four-edge saw with the groove-shaped workbenches and the saw cutting method of the wooden door four-edge saw, the groove-shaped workbenches are adopted, the lifting type conveying belts are arranged between the two workbench surfaces of each groove-shaped workbench, when a narrow door is machined, the two groove-shaped workbenches are driven by a left threaded lead screw and a right threaded lead screw to get close to the middle at the same time, blocking of the lifting type conveying belts is avoided, and the limiting distance can be achieved, so that the width of the narrow door capable of being machined can reach the minimum value, and the saw is suitable for machining of a child door of a child-mother door.

Owner:JIANGSU GUOQUAN AUTOMATION TECH CO LTD

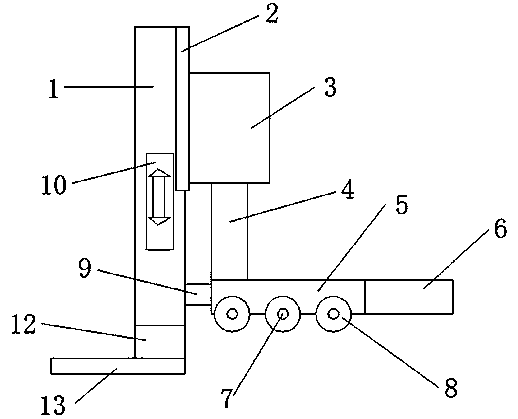

Pressure foot device for sewing machine

InactiveCN108950893AImprove work efficiencyHold down for convenienceWork-feeding meansPressersEngineeringControl switch

The invention relates to a pressure foot device for a sewing machine. The device comprises a vertical plate, a fixing plate is fixedly connected to the right end of the vertical plate, and an electricpush rod is fixedly installed on the fixing plate; a retractable rod is installed on the electric push rod, a pressure foot plate is fixedly connected to the bottom of the retractable rod, and a working plate is fixedly connected to the right end of the pressure foot plate; a rectangular through hole is formed in the working plate, pressure foot idler wheels are movably connected to the bottom ofthe pressure foot plate through rotation shafts, and a connection rod is fixedly connected to the left end of the pressure foot plate; a slide block is fixedly connected to the left end of the connection rod, a slide groove is formed in the right end face of the vertical plate, and a first supporting plate is fixedly connected to the bottom of the vertical plate; second supporting plates are fixedly connected to the two ends of the first supporting plate respectively, mounting bases are fixedly connected to the bottoms of the second supporting plates, and a control switch is further arrangedon the vertical plate and connected with the electric push rod through a wire. The whole device is convenient to use, cloth is conveniently pressed and conveyed, and the working efficiency of the sewing machine is improved.

Owner:SUZHOU KAICHENG SEWING EQUIP

Pressing and fixing device for paper plastic in cross cutting device

ActiveCN109015836ARealize automatic compressionAchieve fixationMetal working apparatusEngineeringWork flow

The invention provides a pressing and fixing device for paper plastic in a cross cutting device. The pressing and fixing device is mainly formed by air cylinders, U steel, a stand column, a base, a square pipe, an aluminum profile, a rubber bumper strip, an upper pressing rod, a lower pressing rod, a rotary shaft, an upper pressing rod support and another square pipe. The working flow of the wholedevice is characterized in that one air cylinder stretches out to push one square pipe to move downwards so as to drive the rubber bumper strip to move downwards until pressing one end of the paper plastic; after the rubber bumper strip presses one end of the paper plastic, the other air cylinder stretches out to push the other square pipe to move downwards so as to drive the rotary shaft to movedownwards and rotate; and the push rod moves downwards and swings forwards, and the upper pressing rod is stressed by forward force so as to move downwards and swing forwards, so that the paper plastic is tightened, the other end of the paper plastic is pressed, and the paper plastic is fixed onto the base. According to the pressing and fixing device for the paper plastic in the cross cutting device provided by the invention, the problem of automatic pressing and fixing after film coating is solved, the automatic flow is realized, the structure is simple, the mechanical structure is mainly adopted, and redundant external control is avoided, so that the device is compact in overall structure, high in environment adaptability and high in working stability.

Owner:SHANGHAI GENIE ROBOT AUTOMATIC

Two-way movement cam shaping mechanism

The invention discloses a two-way movement cam shaping mechanism. The two-way movement cam shaping mechanism comprises a cam case, a cam spline housing is arranged in the cam case, a punch assembly is arranged above the cam case and comprises a cover plate, and the cover plate is fixedly connected with the cam case through guide columns. A punch bottom plate is arranged below the cover plate, a duralumin punch and pressing plate dies are arranged below the punch bottom plate, the punch bottom plate is connected with a lower module through a punch locating plate, lower duralumin dies are arranged outside the lower module, the lower duralumin dies are fixedly connected with a guide plate through a lower duralumin die pressing plate, a first roller base is arranged below the guide plate, and a first roller is arranged on the first roller base. The two-way movement cam shaping mechanism is characterized in that another punch assembly is arranged below the cam case and comprises a bottom plate, a second roller base is arranged on the bottom plate, and a second roller is arranged on the second roller base; the second roller is tangent to a first cam; the first roller is tangent to a second cam. The two-way movement cam shaping mechanism can realize compacting and shaping of packing materials when a bubble cap machine runs, compaction force can be freely adjusted, and insufficient pressure or excessive pressure is avoided.

Owner:上海江南制药机械有限公司

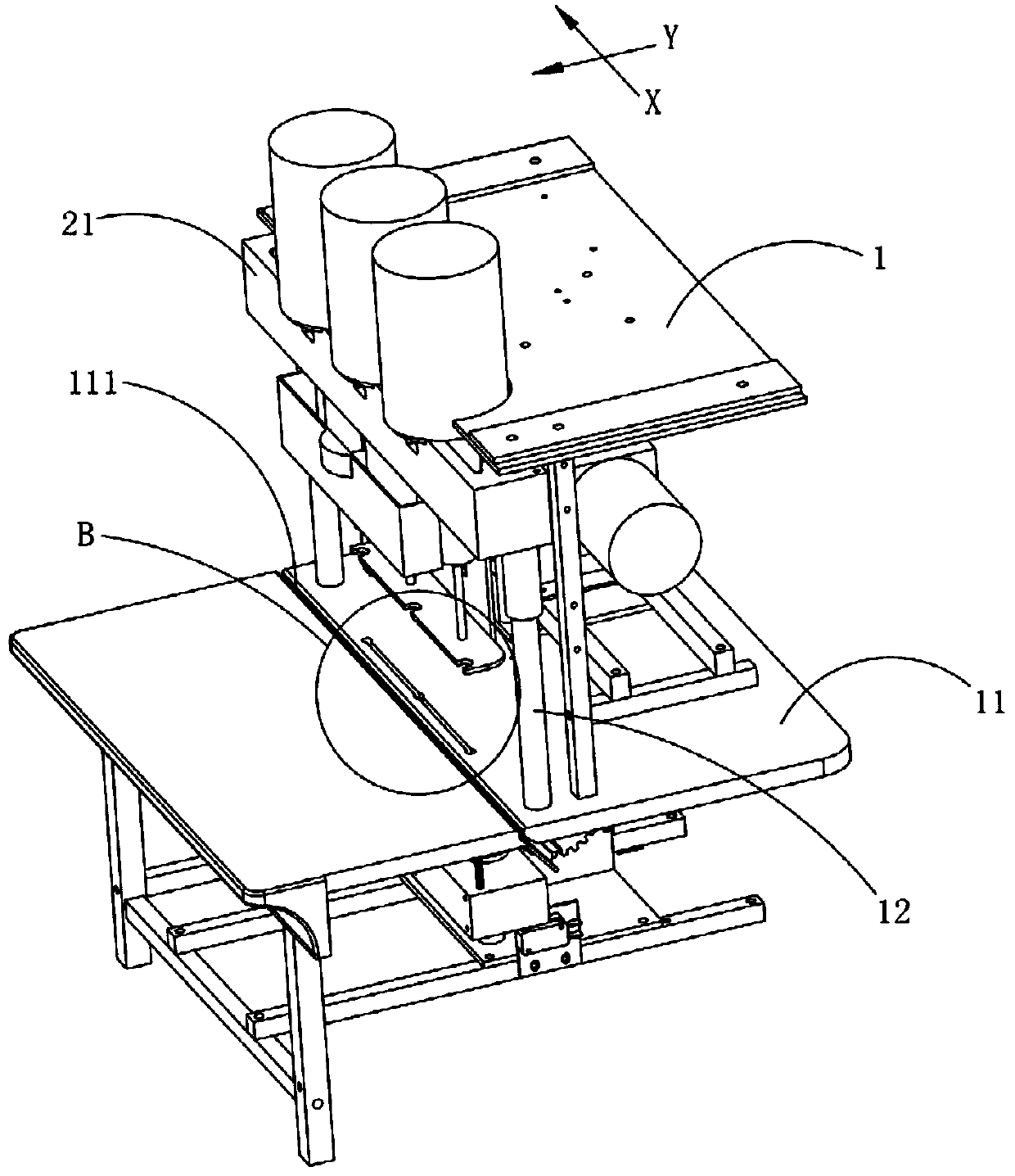

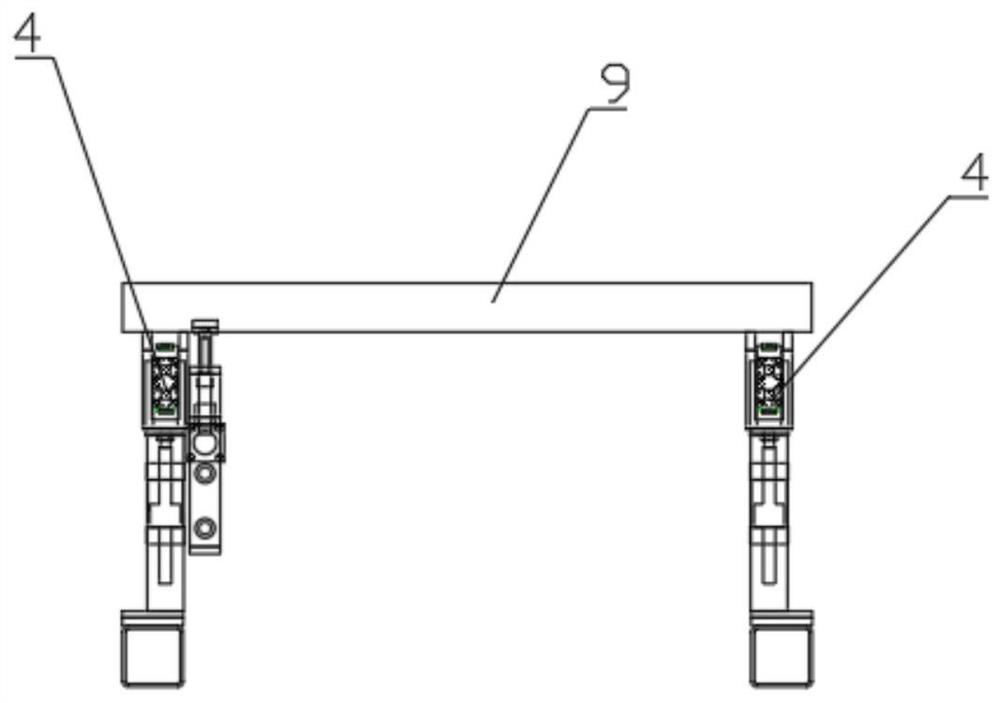

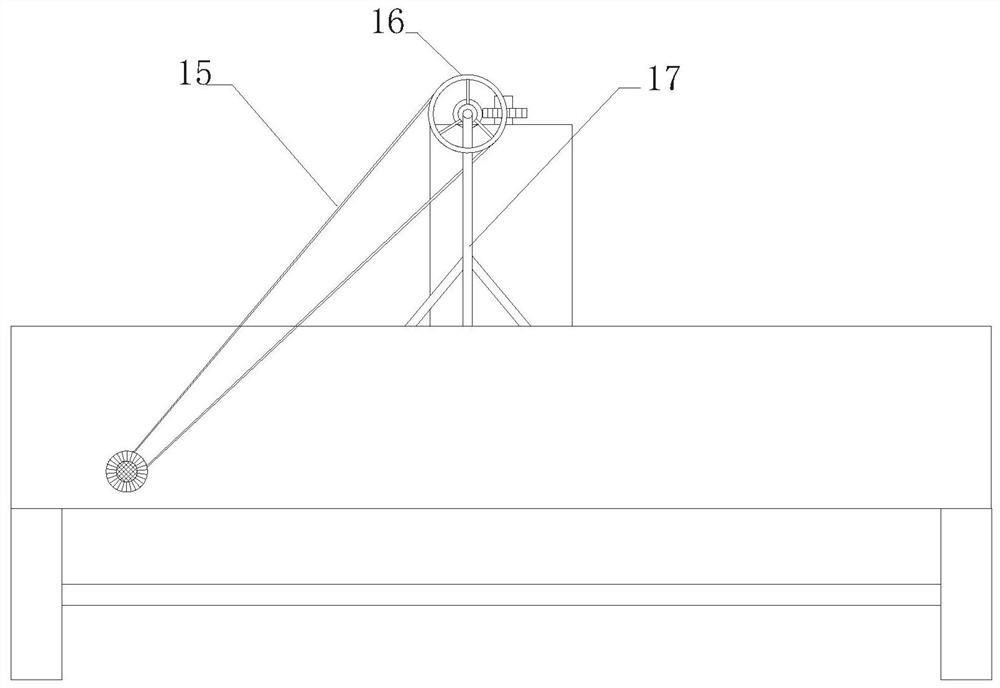

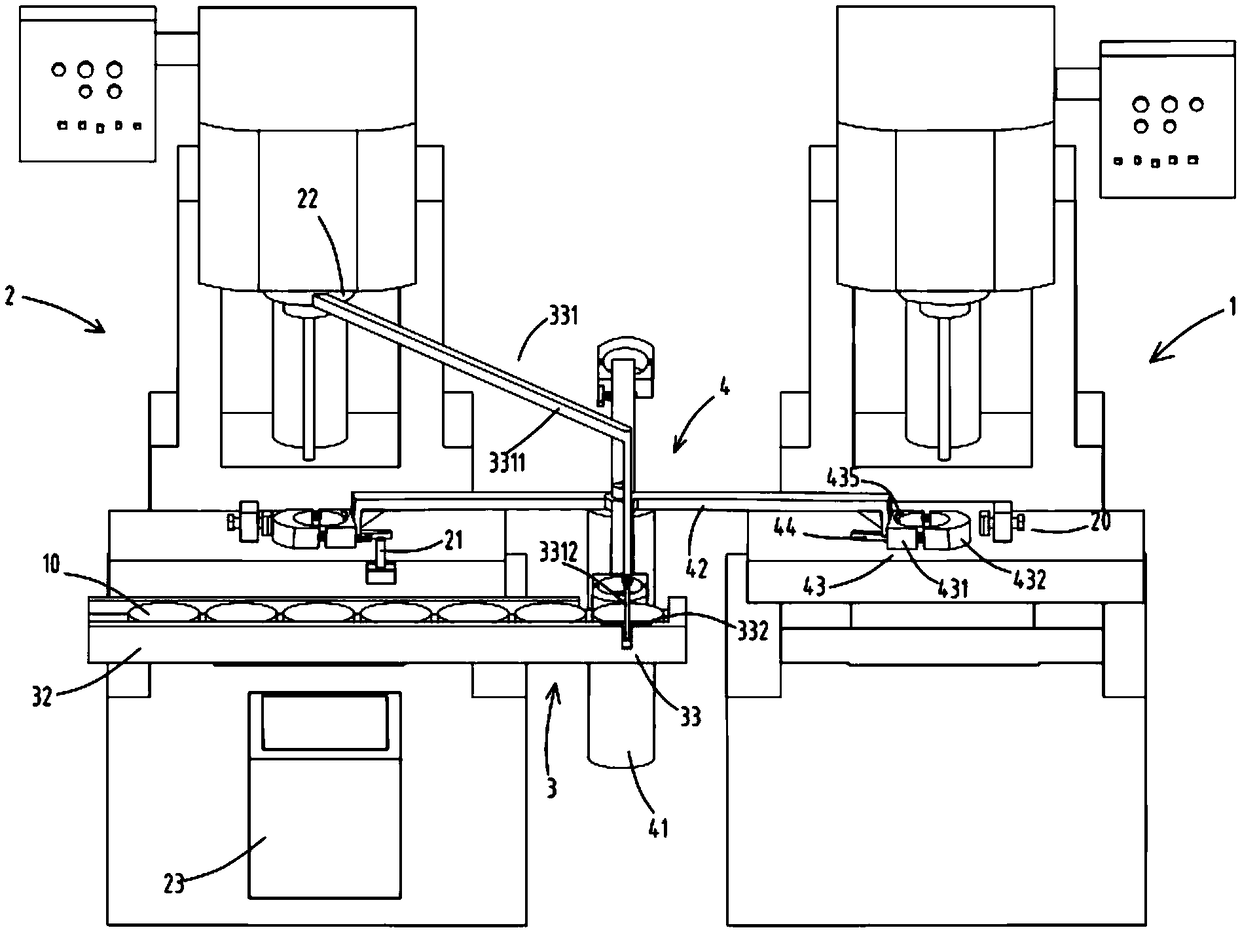

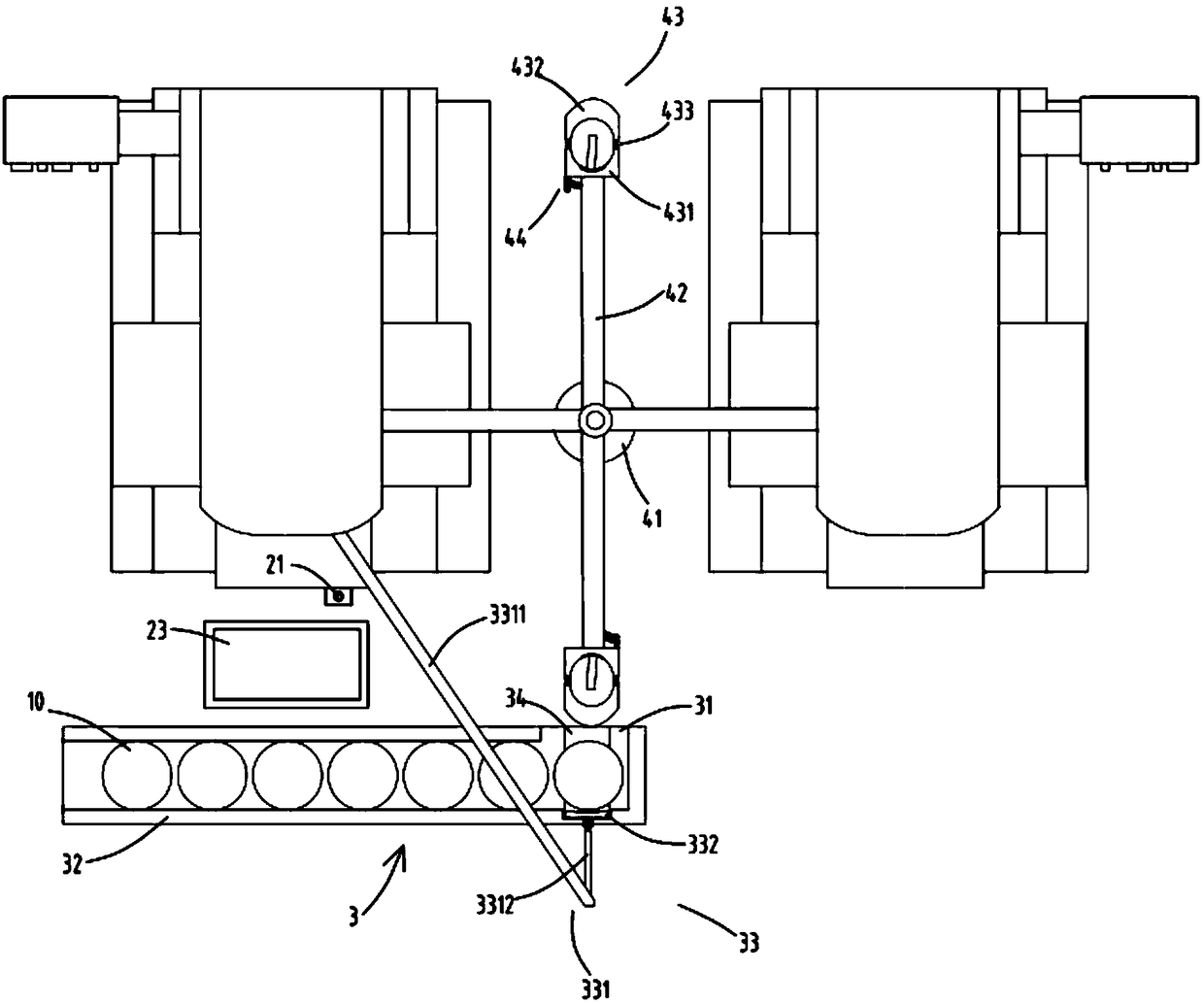

Hoisted feeding device for horizontal double-linkage bending machine

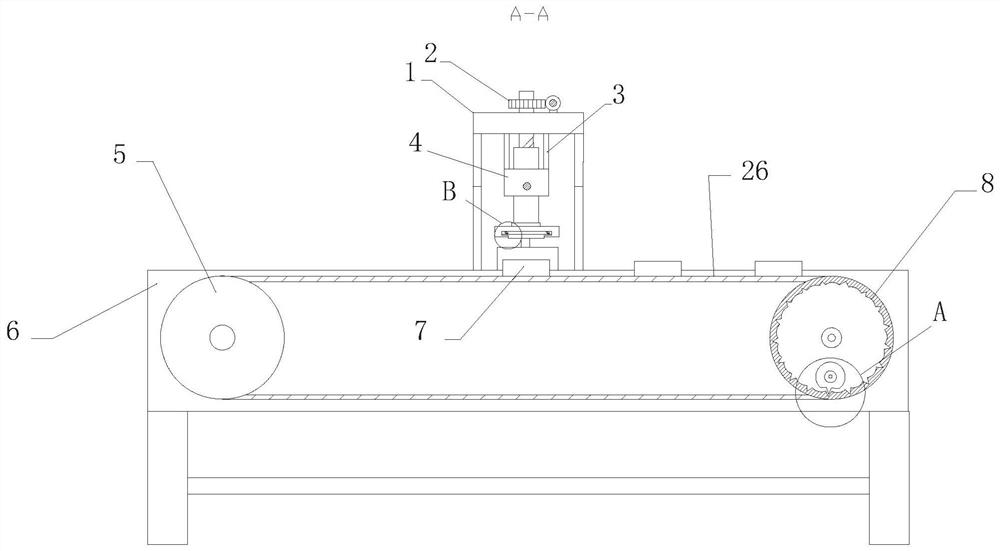

ActiveCN106964712AShorten the processing cycleRealize integrated processingMetal-working feeding devicesPositioning devicesDual functionMechanical engineering

The invention discloses a hoisted feeding device for a horizontal double-linkage bending machine. The hoisted feeding device is used by being connected to the double-linkage bending machine with a workbench, a PLC device, a mould base, a left bending device and a right bending device. The hoisted feeding device is arranged over the workbench and the mould base and comprises a conveying platform and a robot crane jib, and the robot crane jib conveys plates prepared on the conveying platform to the top of the mould base through a plurality of grippers arranged at the bottom of the robot crane jib; a plurality of pneumatic compressing devices are arranged on the tops of the grippers of the robot crane jib and connected with the PLC device to achieve synchronous coordinative control; the end, close to the workbench, of the conveying platform is provided with a flexible material blocking plate, and the flexible material blocking plate is of a half-I-shaped structure. According to the hoisted feeding device special for the horizontal double-linkage bending machine, the dual functions of hoisted feeding and compressing bending are achieved.

Owner:JIANGSU JIANGHAI MACHINE TOOLS GROUP

Bead grinding and polishing device for glass product processing

InactiveCN112405199ARealize the pressing actionReduce compaction operationsEdge grinding machinesGrinding drivesPolishingEngineering

Owner:日照市睿尔泽新材料科技有限公司

Lithium battery processing and assembling mechanism

PendingCN113193224ARealize automatic compressionImprove automationPrimary cell manufactureAssembling battery machinesStructural engineeringBattery pack

The invention provides a lithium battery processing and assembling mechanism, and belongs to the technical field of lithium battery assembling. The mechanism includes a cover shell and a sliding groove rod, the sliding groove rod is rotationally connected to a top plate of the cover shell, the sliding groove rod extends to the position above the top plate of the cover shell, a rotating gear is arranged on the portion, located above the top plate of the cover shell, of the sliding groove rod, the rotating gear is connected with a worm in an engaged mode, and a downward pressing mechanism is installed in the cover shell and comprises the sliding groove rod. A sliding groove with a wavy unfolded drawing is formed in the sliding groove rod, the sliding groove rod is rotationally connected to a top plate of the housing, the sliding groove rod is sleeved with an outer barrel, a strip-shaped key is arranged on the outer wall of the outer barrel, an abutting block is arranged on the inner wall of the outer barrel, the abutting block is cylindrical and extends into the sliding groove, and the outer barrel is slidably connected with a limiting block. A sliding hole matched with the outer barrel is formed in the limiting block; automatic pressing of the blank cover plate is achieved through the pressing mechanism and the trapezoidal sliding block, and deviation is avoided in the pressing process.

Owner:永州聚力新能源科技有限公司

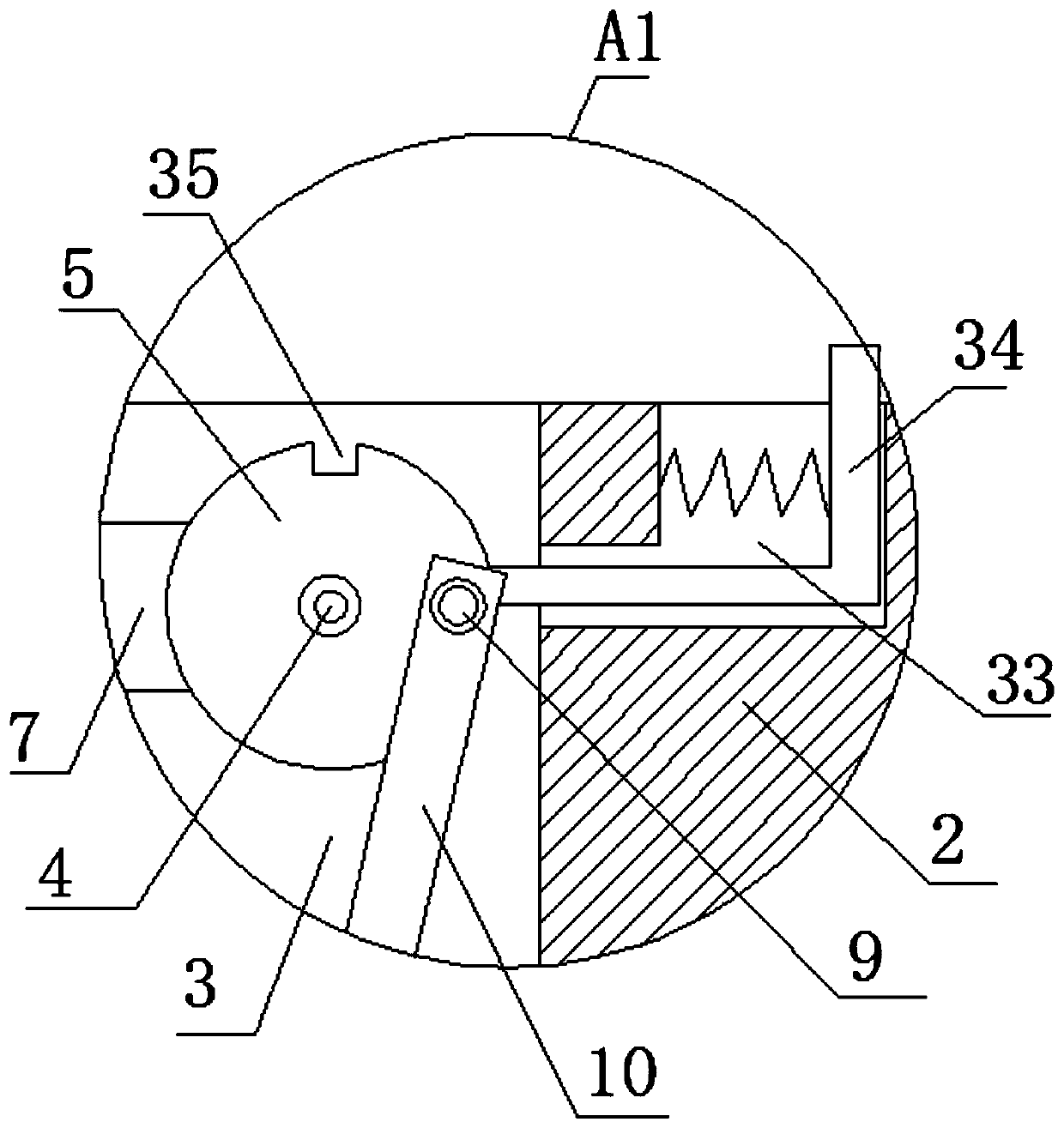

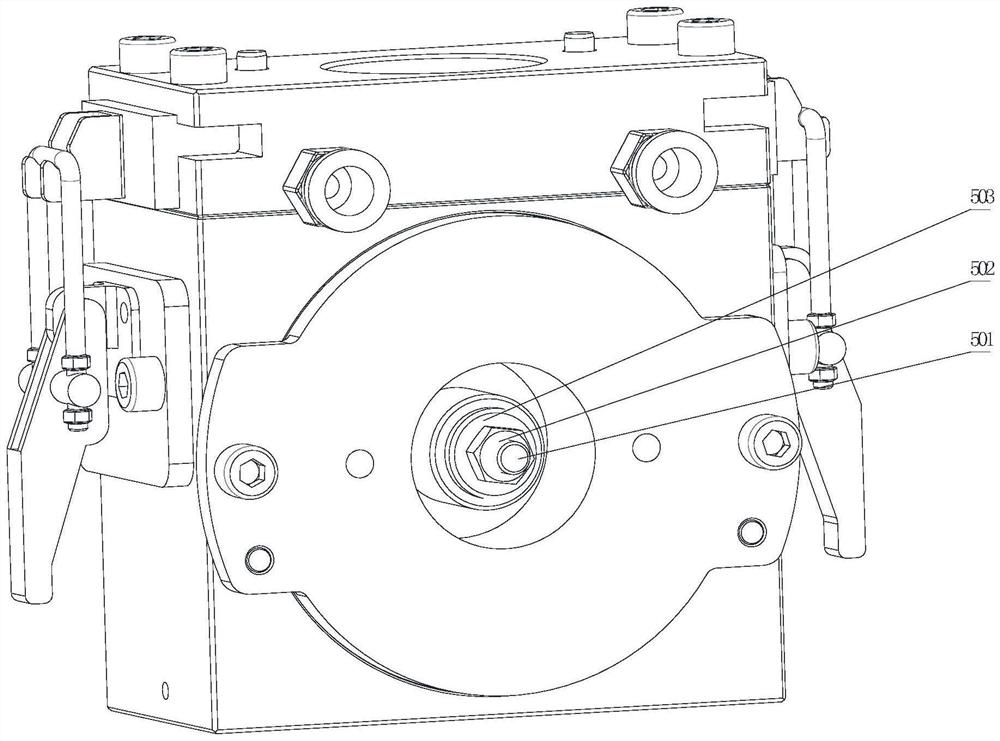

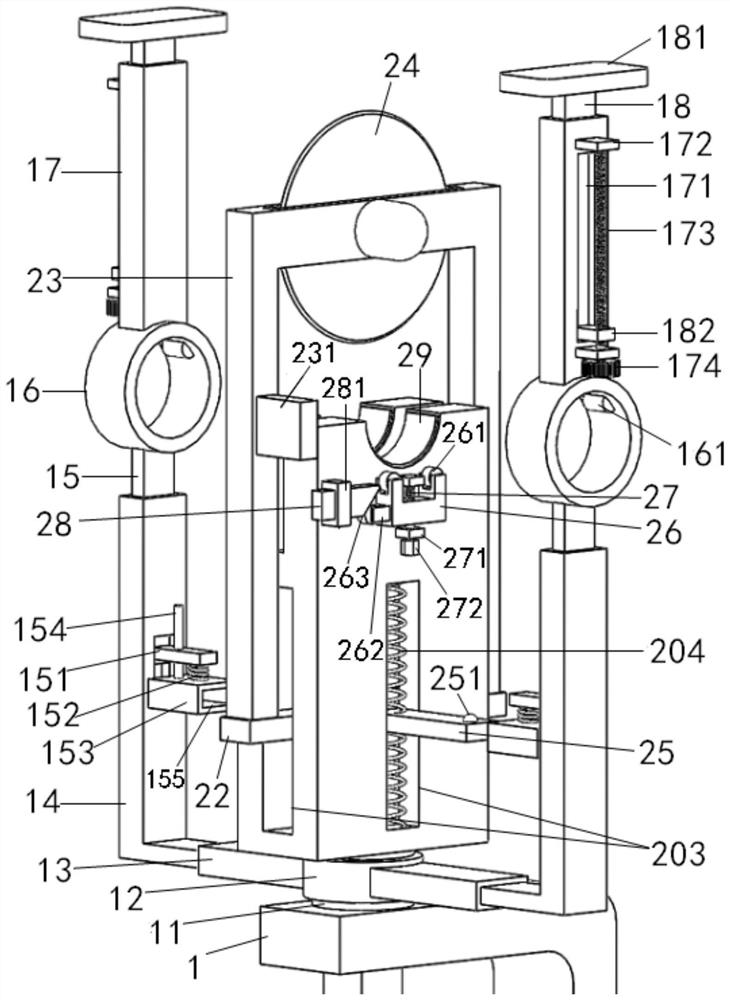

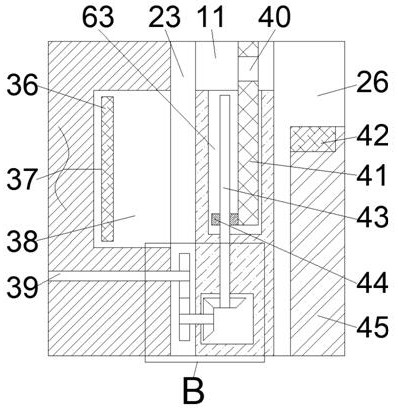

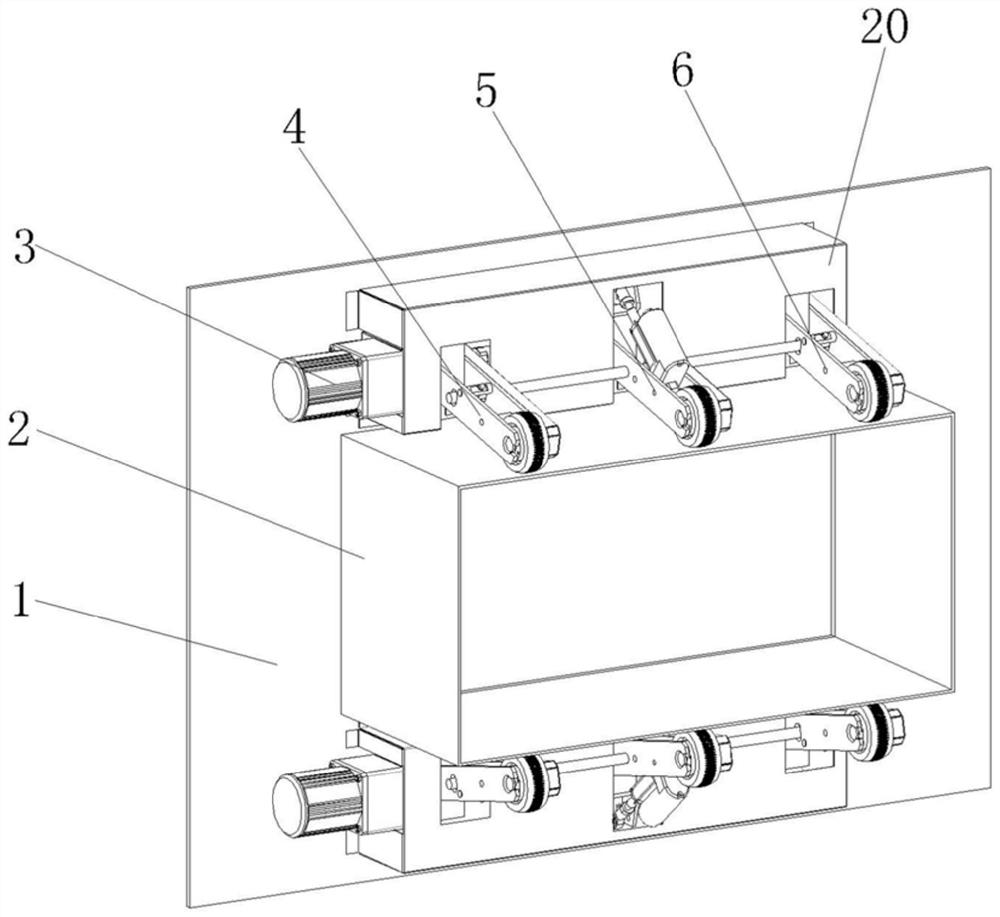

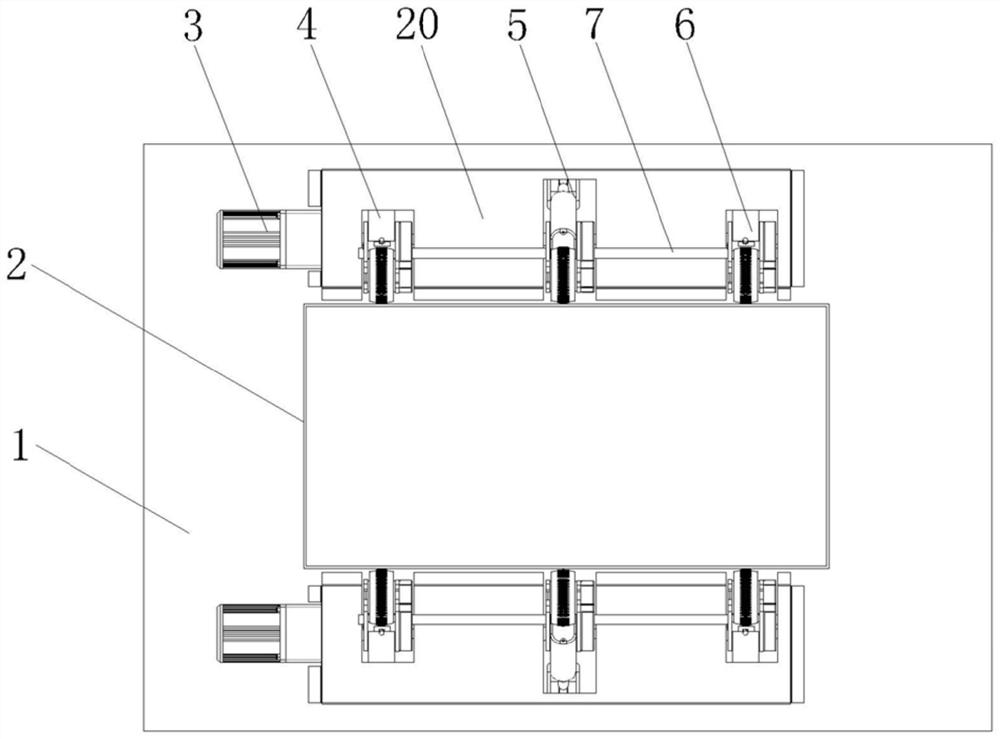

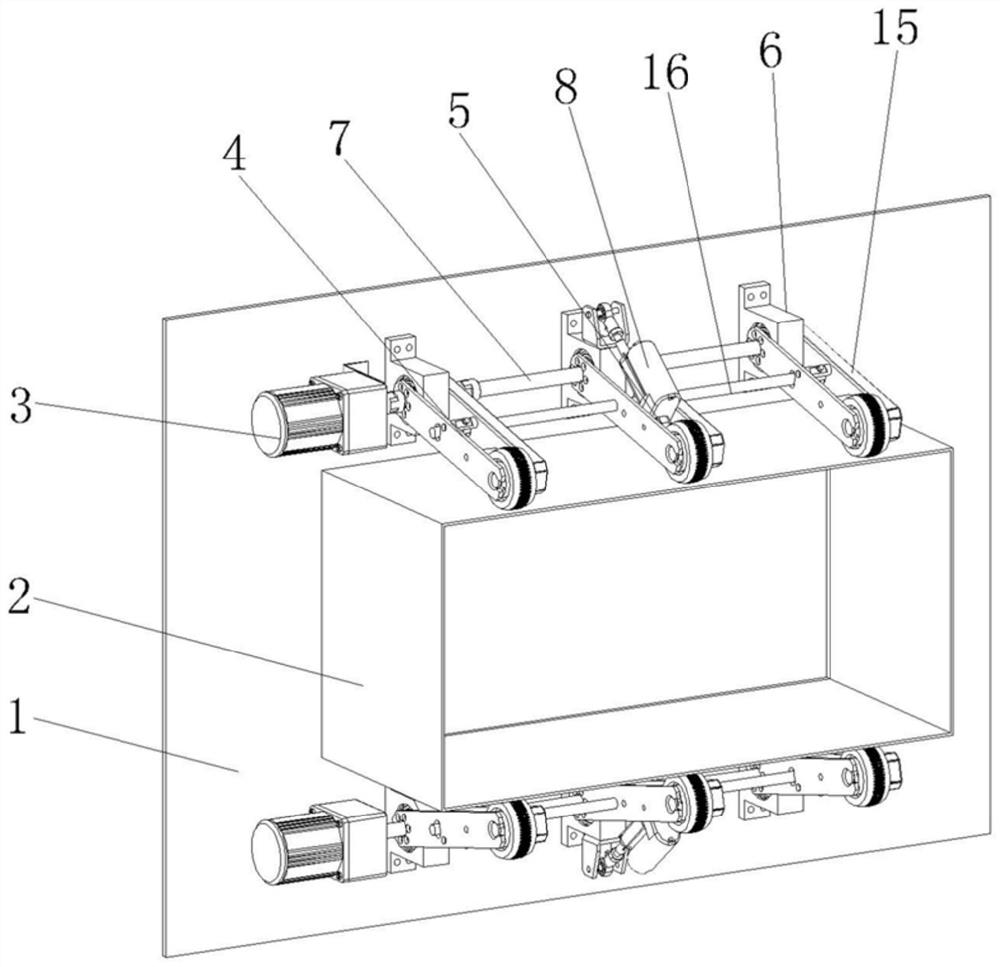

Optical cable traction machine suitable for optical cables of different specifications and capable of automatically compressing

InactiveCN112596185ARealize automatic compressionAvoid situations that damage fiber optic cablesOptical fibre/cable installationMechanical engineeringElectrical and Electronics engineering

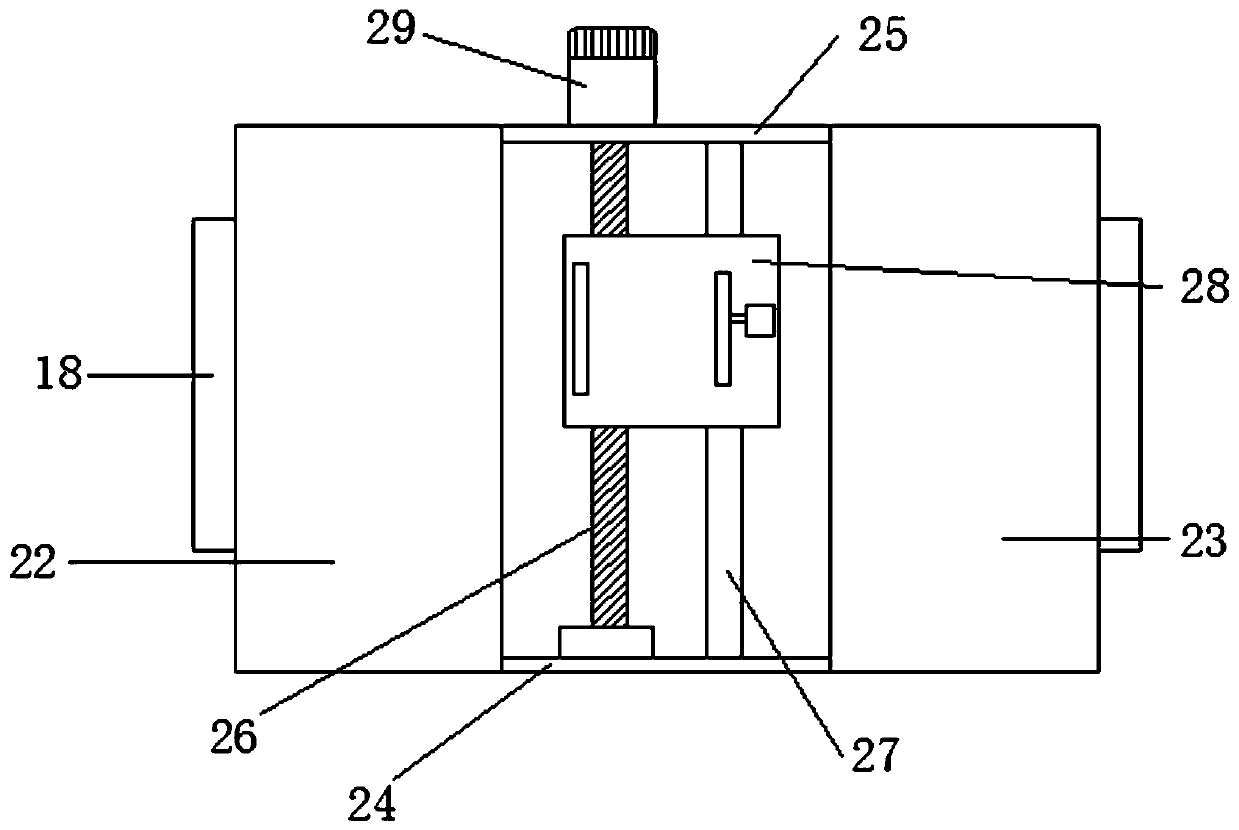

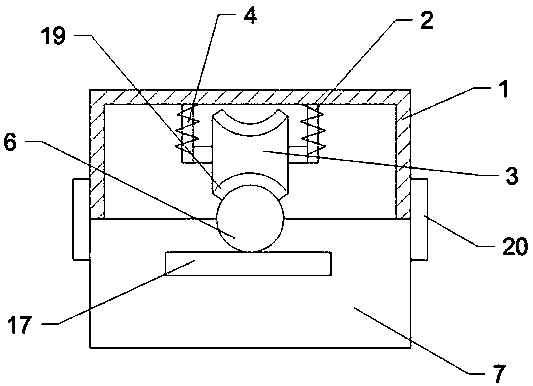

The invention relates to the related field of optical cables, and discloses an optical cable traction machine suitable for optical cables of different specifications and capable of automatically compressing. The optical cable traction machine comprises a main body box, a front-back through main traction cavity is arranged in the main body box, the left end wall of the main traction cavity is communicated with an optical cable inlet cavity with a leftward opening, and the upper end wall of the main traction cavity is communicated with a main compressing block cavity, the lower end wall of the main traction cavity is communicated with a lower friction roller cavity; according to the device, proper pressure values of cables of different specifications can be set in a user-defined mode throughthe pressure adjusting knob, the upper friction roller capable of moving downwards is matched with the pressing spring at the same time, and thus the device can automatically compress the optical cable according to the pressure values set in advance; on one hand, the trouble of manually and frequently adjusting the pressure is saved, on the other hand, the pressure borne by the optical cable is ensured to be constant, and slipping caused by too small pressure or damage to the optical cable due to too large pressure is avoided.

Owner:成都沁域网络科技有限公司

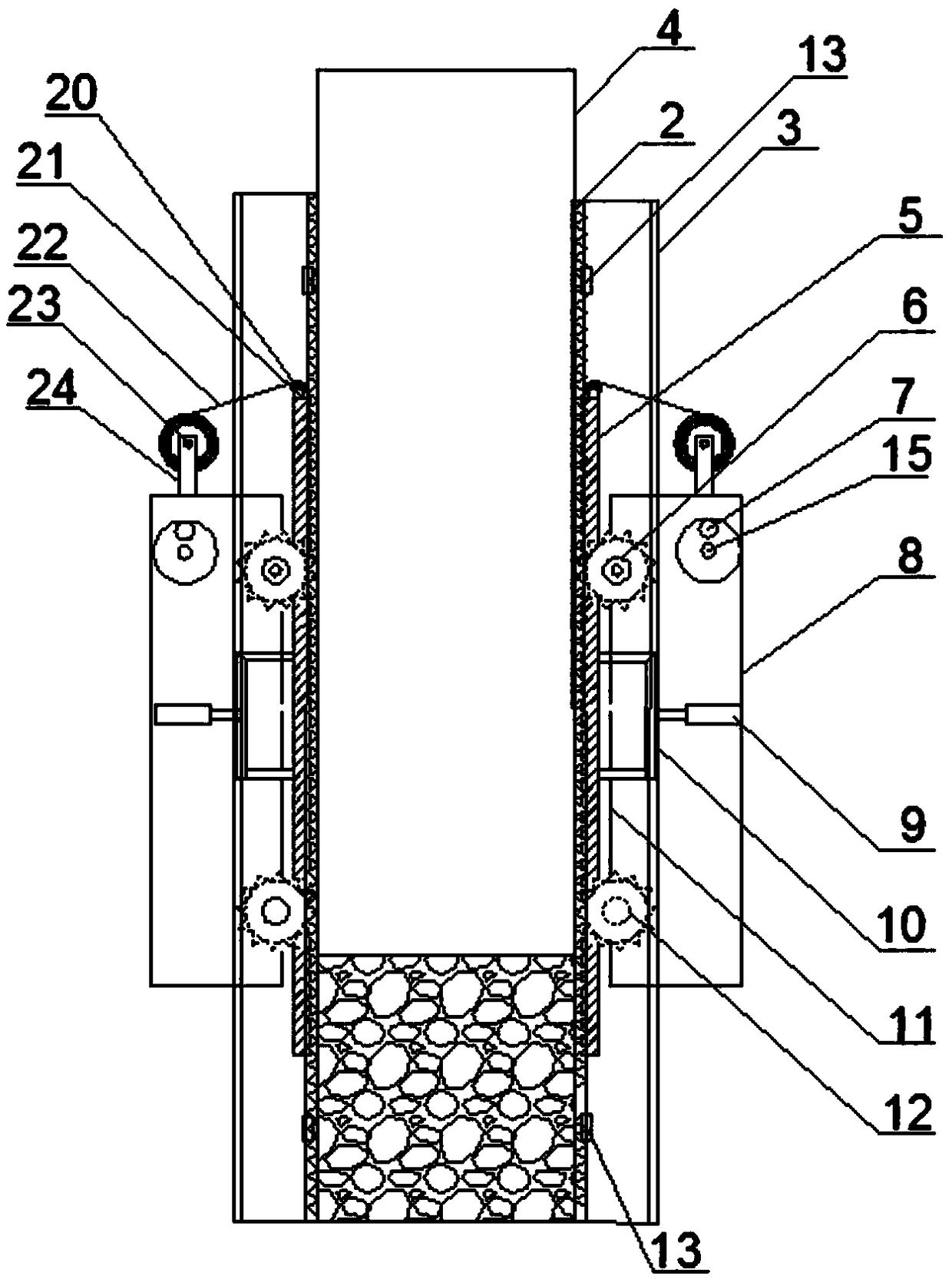

Straight-type wall body constructional column construction device

ActiveCN108547453AWon't fall offLow pouring heightBuilding material handlingMechanical engineeringBuilding construction

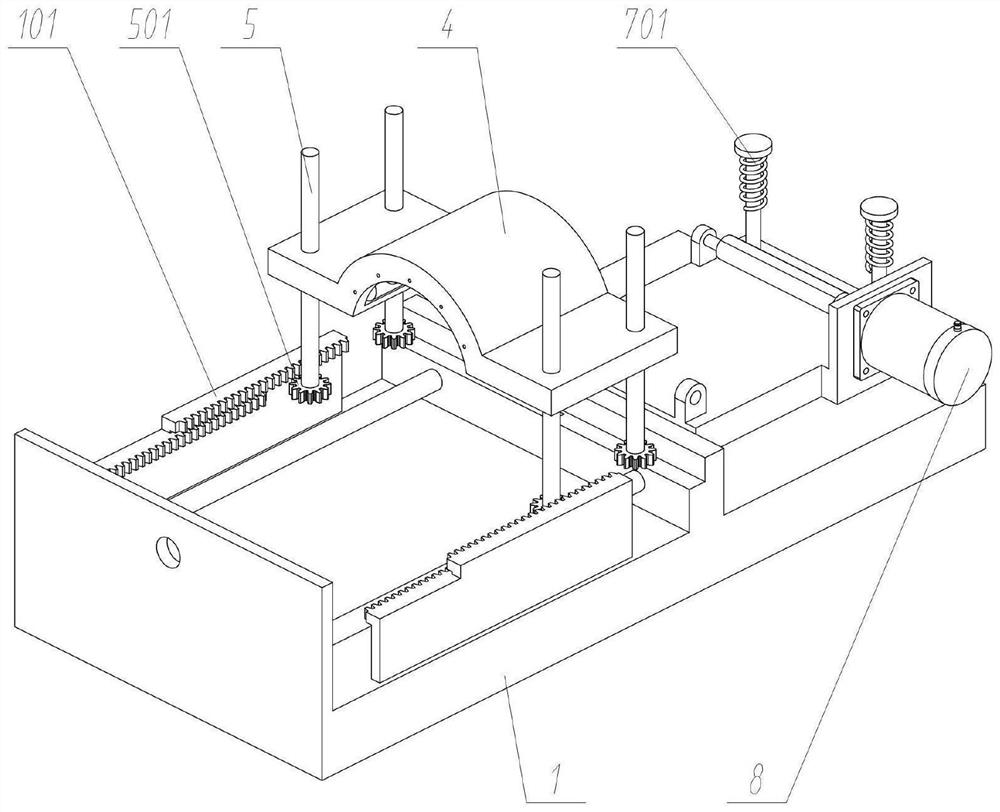

A straight-type wall body constructional column construction device comprises a rail mechanism and a tackle mechanism which are arranged on wall bodies on the two sides in a left-right symmetrical mode. The rail mechanism comprises two rails arranged in a front-rear spaced mode, wherein racks are evenly distributed on the rails. The outer ends of an outer end plate and an inner end plate of each rail are connected through side end plates, and the inner end faces of the outer end plate and the inner end plate of each rail are connected with an outer extending baffle and an inner extending baffle correspondingly. A strip-shaped notch is formed between each outer extending baffle and the corresponding inner extending baffle. The tackle mechanism comprises a box body internally provided with apressing device. One end of the pressing device is connected with an outer side plate, and the other end of the pressing device penetrates through a hole formed in an inner side plate to be connectedwith a formwork. The inner side of the inner side plate is sequentially connected with a lower axle and an upper axle from bottom to top. The axles extend from the strip-shaped notches into the rails, gears at the two ends of the axles are located in the rails, and the lower gears and the upper gears are matched with the racks. A worm wheel and a worm connected in a mutually engaged mode are arranged on one side of the upper axle. A rocking handle is connected to the eccentric position of the worm wheel. According to the straight-type wall body constructional column construction device, the construction period can be shortened, the pouring quality is good, and the construction efficiency is high.

Owner:江苏数链建筑科学研究院有限公司

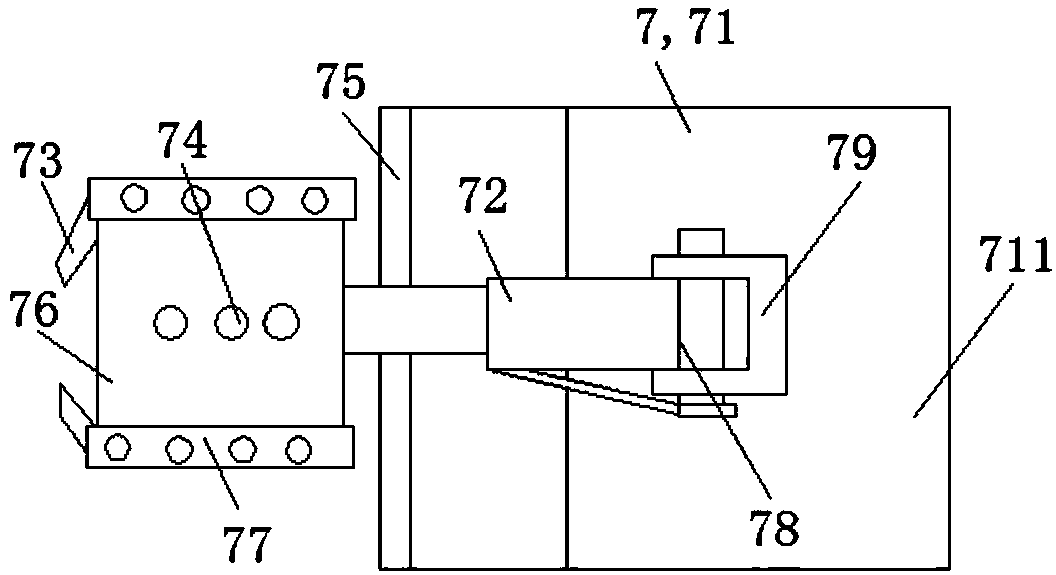

A multi-station automatic loading and unloading processing equipment

ActiveCN106736802BSimple structureImprove work efficiencyMetal working apparatusPositioning apparatusEngineeringMachining

Owner:山东辛丁管理咨询有限公司

Hanging feeding device for horizontal double linkage bending machine

ActiveCN106964712BShorten the processing cycleRealize integrated processingMetal-working feeding devicesPositioning devicesEngineeringMechanical engineering

The invention discloses a hoisted feeding device for a horizontal double-linkage bending machine. The hoisted feeding device is used by being connected to the double-linkage bending machine with a workbench, a PLC device, a mould base, a left bending device and a right bending device. The hoisted feeding device is arranged over the workbench and the mould base and comprises a conveying platform and a robot crane jib, and the robot crane jib conveys plates prepared on the conveying platform to the top of the mould base through a plurality of grippers arranged at the bottom of the robot crane jib; a plurality of pneumatic compressing devices are arranged on the tops of the grippers of the robot crane jib and connected with the PLC device to achieve synchronous coordinative control; the end, close to the workbench, of the conveying platform is provided with a flexible material blocking plate, and the flexible material blocking plate is of a half-I-shaped structure. According to the hoisted feeding device special for the horizontal double-linkage bending machine, the dual functions of hoisted feeding and compressing bending are achieved.

Owner:JIANGSU JIANGHAI MACHINE TOOLS GROUP

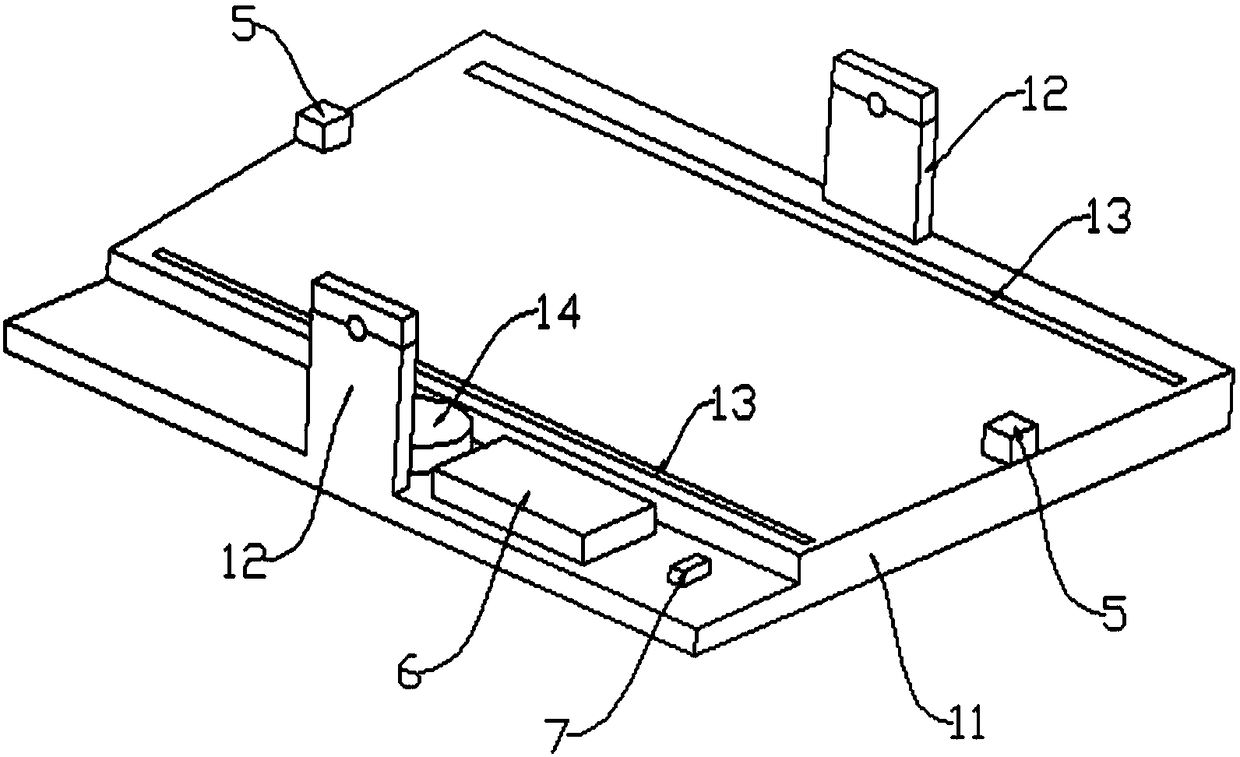

Telescopic screed overlap welding die jig

InactiveCN109736172AInhibit sheddingRealize automatic positioningRoads maintainenceScreedElectric machinery

The invention relates to the technical field of jigs, in particular to a telescopic screed overlap welding die jig, which comprises a bottom plate, a positioning barrel is arranged on the bottom plate, a positioning column is arranged in the positioning barrel, a push block is arranged below the positioning column, the push block is fixedly connected with a rack, and gears are meshed with the twosides of the rack. A supporting rod is arranged on the bottom plate, and the top of the supporting rod is rotationally connected with a U-shaped frame. A pressing block is further arranged on the bottom plate and fixedly connected with a connecting rod, the connecting rod is inserted into a sleeve, and a stud is arranged in the sleeve and fixedly connected with an output shaft of an air cylinder.According to the jig, a workpiece is coarsely positioned by moving the supporting rod to ensure that the positioning column can smoothly extend into the positioning hole, a motor drives the gears andthe rack to drive the positioning column to extend out, automatic positioning is achieved, the workpiece can be prevented from falling off the positioning column, the workpiece is pressed through theair cylinder, in this way, automatic pressing can be achieved, the pressing force of the pressing block on the workpiece can be adjusted by rotating the sleeve, and therefore the situations that pressing is not firm and the workpiece is damaged due to too large pressing force can be avoided.

Owner:合肥佳恩特机械制造有限公司

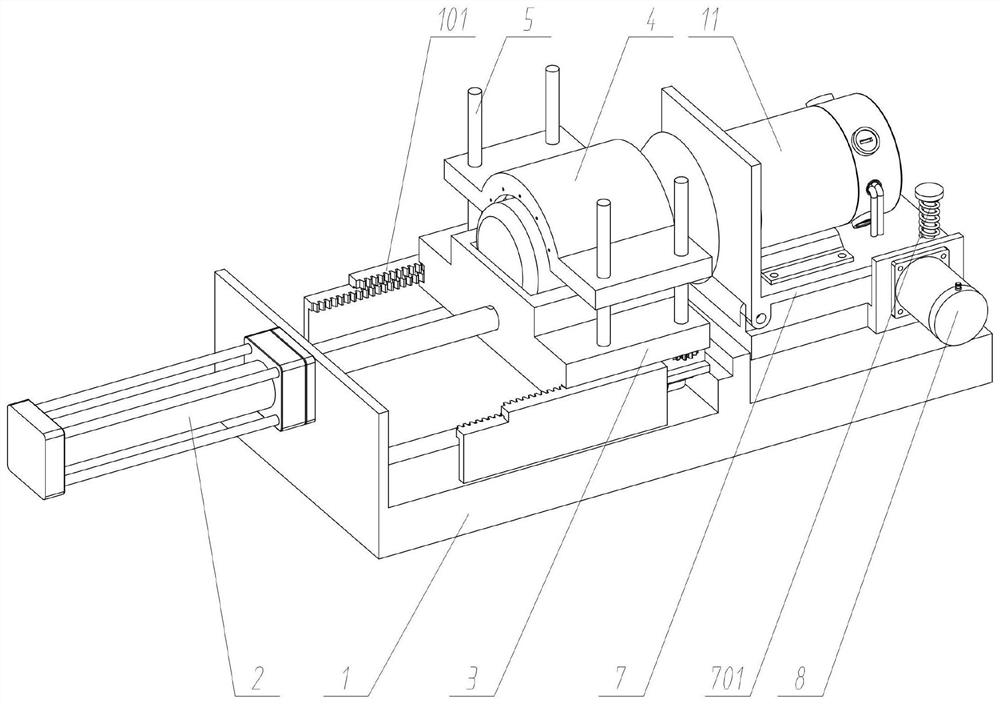

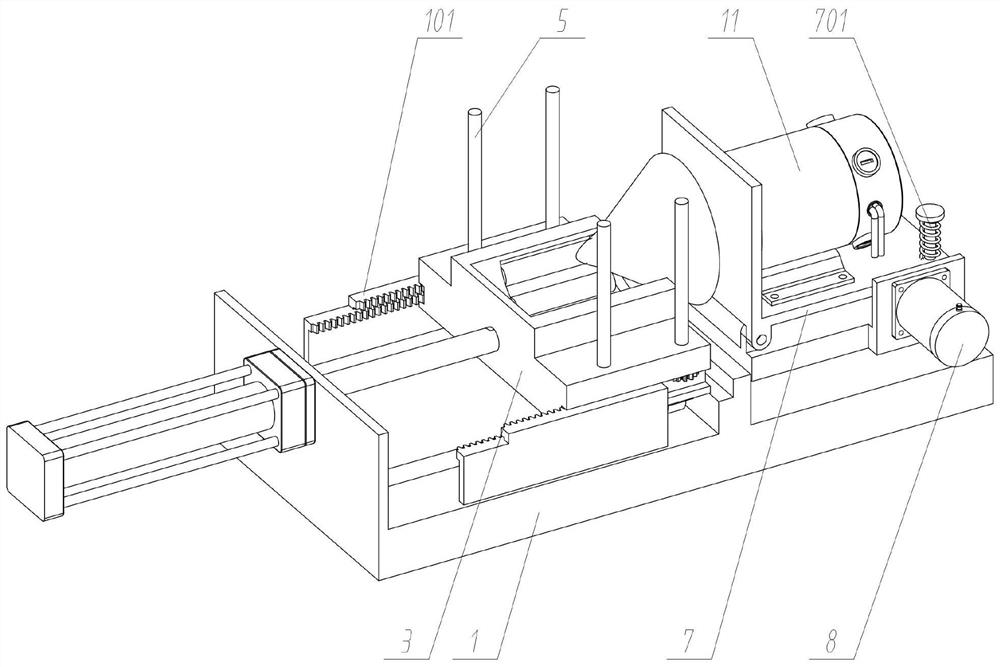

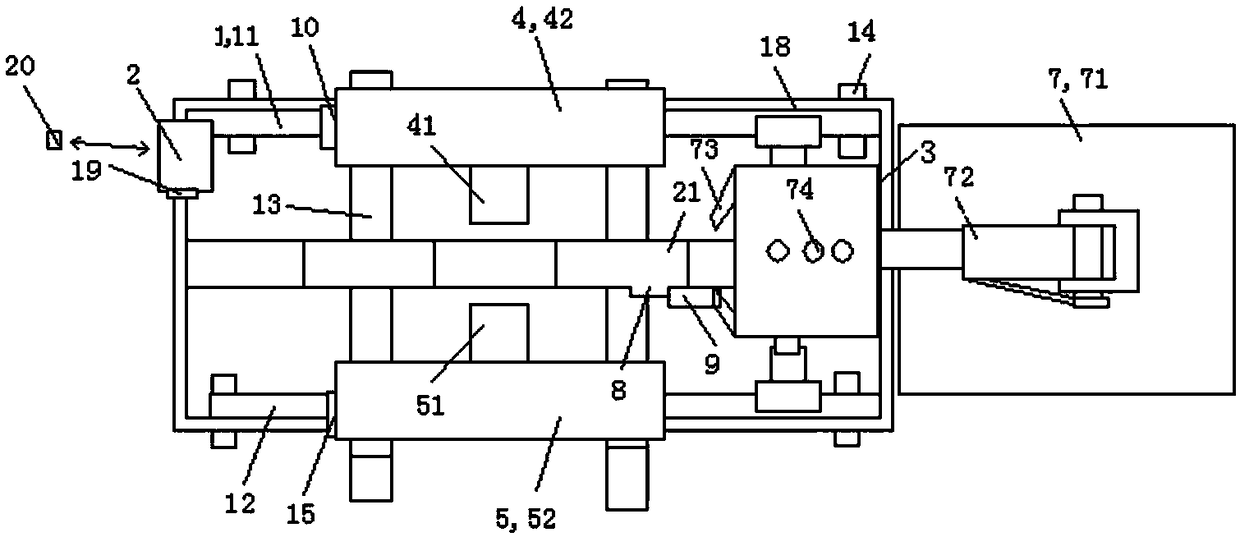

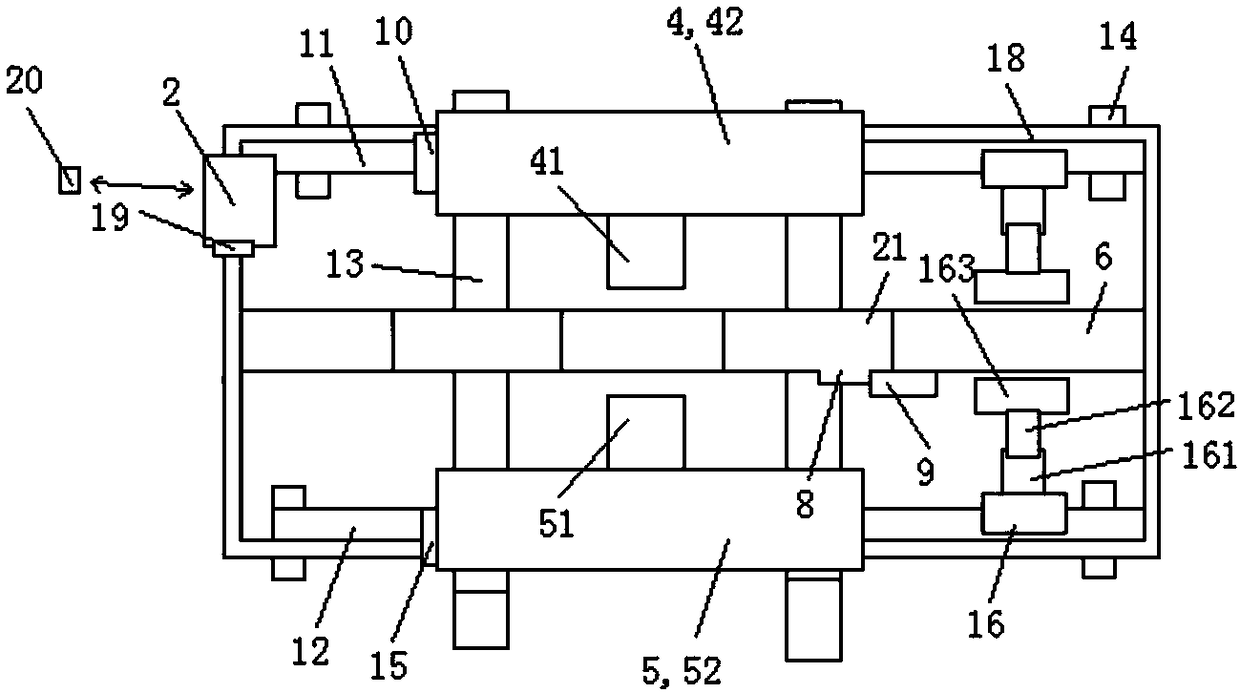

A horizontal double linkage bending machine

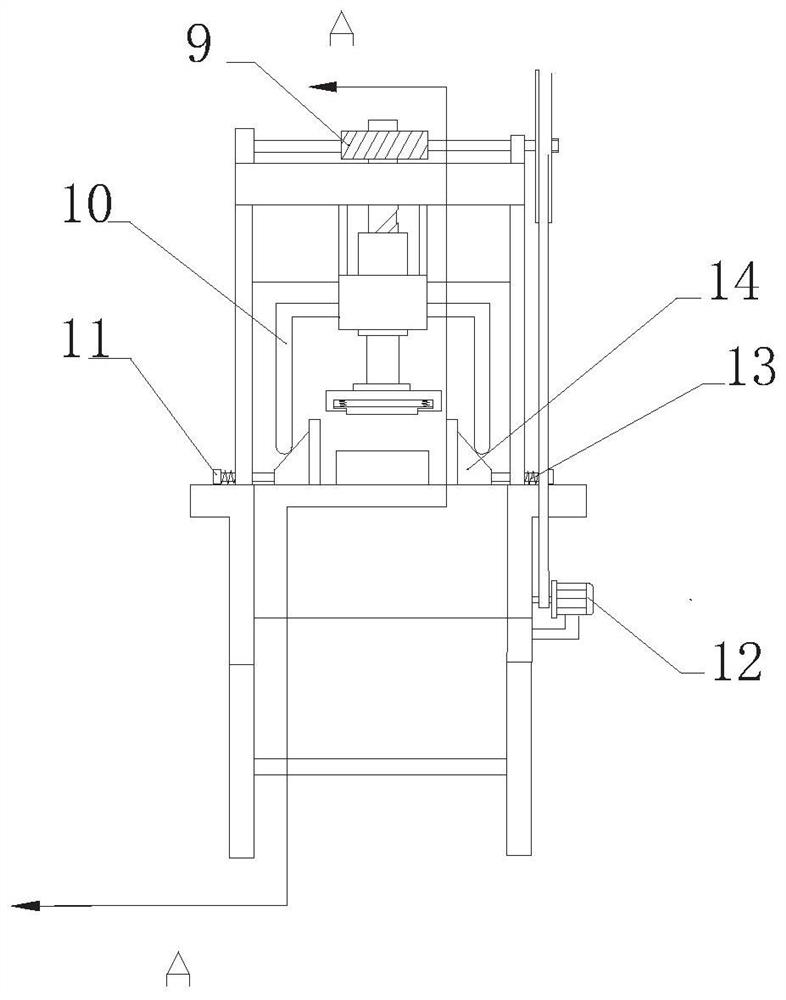

ActiveCN107052098BShorten the processing cycleRealize integrated processingMetal-working feeding devicesPositioning devicesEngineeringCantilever

The invention discloses a horizontal double-linkage bending machine. The machine comprises a worktable, a PLC device, a die seat, a left bending device and a right bending device, wherein the worktable comprises a front cross beam, a rear cross beam, and at least two guide columns which are fixed in parallel between the front cross beam and the rear cross beam; a die seat rail is fixed among the plurality of guide columns; a plurality of dies with different shape and structure are sequentially connected to the die seat rail; at least one compressing device is arranged at each of the left side and the right side of the die seat rail, and each compressing device is connected to the front cross beam or the rear cross beam through a cantilever, a telescoping compressing shaft and a telescoping power source; the left bending device and the right bending device are correspondingly driven through a left sliding device and a right sliding device to move toward the die seat rail; a left bending servo power source and a right bending servo power source are synchronously connected to the PLC device so as to coordinately control the bending. The horizontal double-linkage bending machine is a double-linkage bending machine which is compact in structure, efficient in bending and applicable to wide boards.

Owner:JIANGSU JIANGHAI MACHINE TOOLS GROUP

A semi-automatic sack setting mechanism

ActiveCN112960161BRealize automatic compressionRealize mechanical automation operationFinal product manufactureIndividual articlesElectric machineSemi automatic

Owner:农芯(南京)智慧农业研究院有限公司 +1

A device for cutting photocopied paper

ActiveCN106737953BAvoid fixationGuaranteed accuracyMetal working apparatusProximity sensorPulp and paper industry

The invention discloses a device for tailoring autotype paper and belongs to the field of autotype paper tailoring. The device comprises a transmission mechanism, a paper carrying table, a tailoring mechanism, a body base, a proximity sensor, a micro-processor module and an alarm; the transmission mechanism, the paper carrying table, the tailoring mechanism, the proximity sensor, the micro-processor module and the alarm are arranged on the body base; the micro-processor module is connected to the motor, the proximity sensor and the alarm; the transmission mechanism comprises a motor, a straight gear and a first bevel gear; the paper carrying table comprises a paper carrying table body, a side rack and a compression bar; the tailoring mechanism comprises a transmission main shaft, a second bevel gear and a tailoring disc; the body base comprises a base body, a supporting plate, a track and a motor base. The device provided by the invention automatically tailor the autotype paper in different dimensions through the paper carrying table, the tailoring mechanism and the micro-computer, so that not only is the work efficiency of tailoring improved, but also the tailoring precision of the autotype paper is ensured.

Owner:GUANGXI UNIV

Optimized structure of rolling tool

The invention discloses an optimized structure of a rolling tool. The optimized structure of the rolling tool comprises a machine table, wherein the machine table is provided with following several parts of a driving device, a containing device and a rolling device, the driving device comprises a driving motor installed and fixed on the bottom side of the machine table, a driving screw is rotatably connected with the bottom of the machine table, a belt is arranged between the driving motor and the driving screw, the belt respectively sleeves the outer side of the peripheral wall of a rotationshaft of the driving motor and the outer side of the peripheral wall of the driving screw, the containing device comprises a sliding bottom connected with the machine table in a sliding mode, the sliding seat is connected with the driving screw in a threaded mode, a steering column is rotatably connected in the sliding seat, a mold plate is fixedly connected with the steering column, a steering motor which drives the steering column to rotate is fixed on the sliding seat, the rolling device comprises a placing frame fixedly connected onto the machine table, an air cylinder is fixedly connectedonto the placing frame, an abutting frame is slidably connected onto the placing frame, an abutting wheel is rotatably connected onto the abutting frame, and a piston rod of the air cylinder is fixedly connected with the abutting frame. The optimized structure of the rolling tool can perform automatic rolling and attachment on a damper on a hard disk.

Owner:SEKSUN TECH SUZHOU

Large plate double linkage bending machine

ActiveCN106862325BShorten the processing cycleRealize integrated processingShaping toolsMetal working apparatusWorkbenchPress brake

Owner:JIANGSU JIANGHAI MACHINE TOOLS GROUP

Production equipment for square steel pipe

InactiveCN114406343ARealize automatic cuttingRealize automatic positioningFeeding apparatusTube shearing machinesSteel tubeElectric machinery

The square steel pipe production equipment comprises a workbench and a cutting head assembly, a lower supporting block is arranged on the workbench, a triggering inclined block and a blocking plate which can move in the longitudinal direction of a guide groove are arranged in the lower supporting block, movable plates are arranged below the triggering inclined block and the blocking plate correspondingly, and the cutting head assembly is arranged on the workbench. The movable plate is arranged in a hydraulic groove, the hydraulic groove is filled with hydraulic oil, the guide groove is further internally provided with a first spring exerting downward acting force on the blocking plate, and the blocking plate is further provided with two switches for controlling the motor and the discharging mechanism respectively. The relative positions of the triggering inclined block and the baffle plate are changed in the feeding process of the steel pipe, and then automatic positioning, automatic pressing, automatic cutting and automatic discharging of the steel pipe during machining are controlled.

Owner:ZHEJIANG CHUANBOZHE METAL DECOUATION MATERIAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com