Optimized structure of rolling tool

A technology for optimizing structure and tooling, applied in the direction of connecting components, material gluing, mechanical equipment, etc., can solve the problems of wrist influence, fit effect and pass rate decline, wrist soreness, etc., to increase firmness, reduce labor consumption, The effect of increasing diversity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

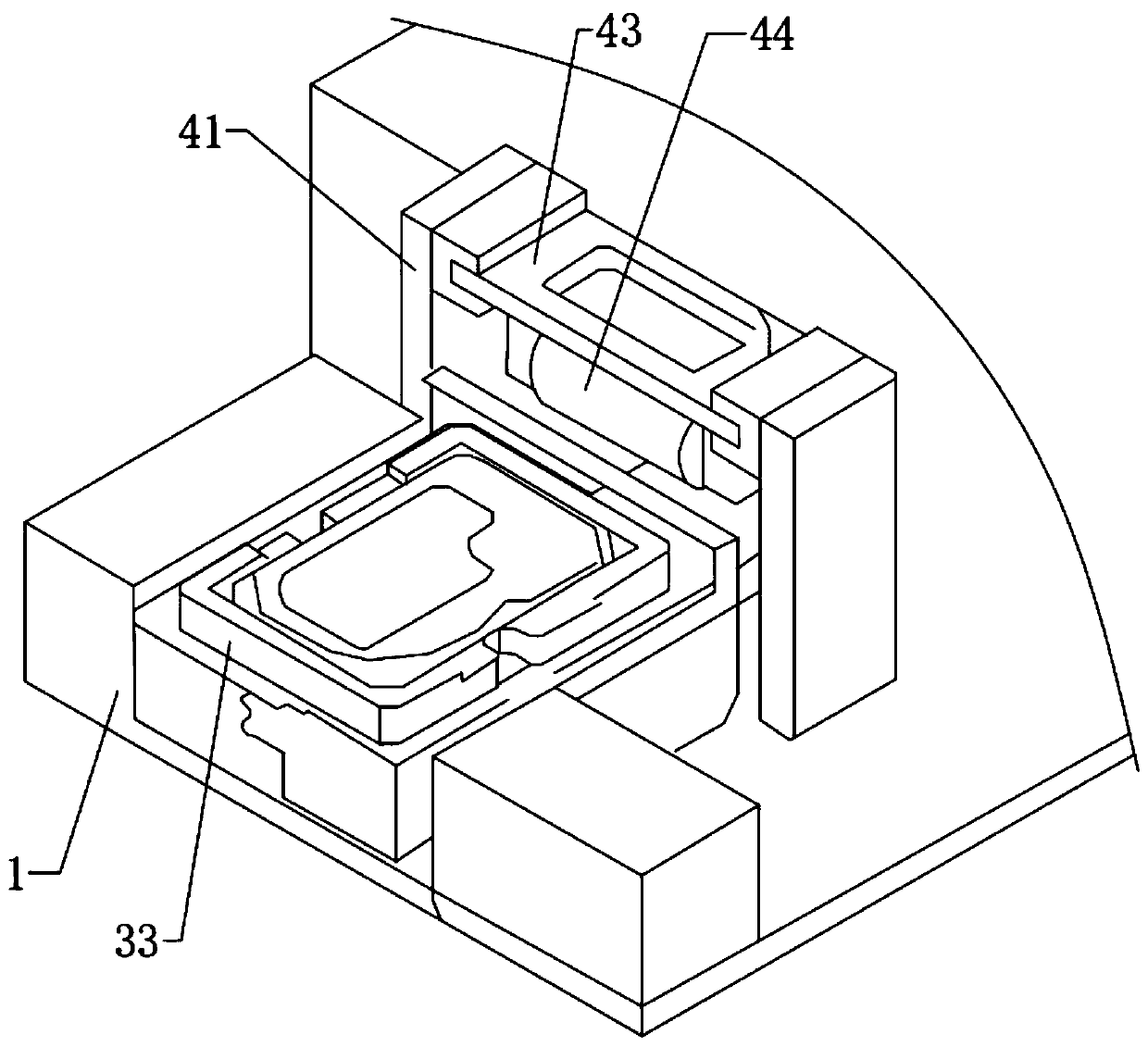

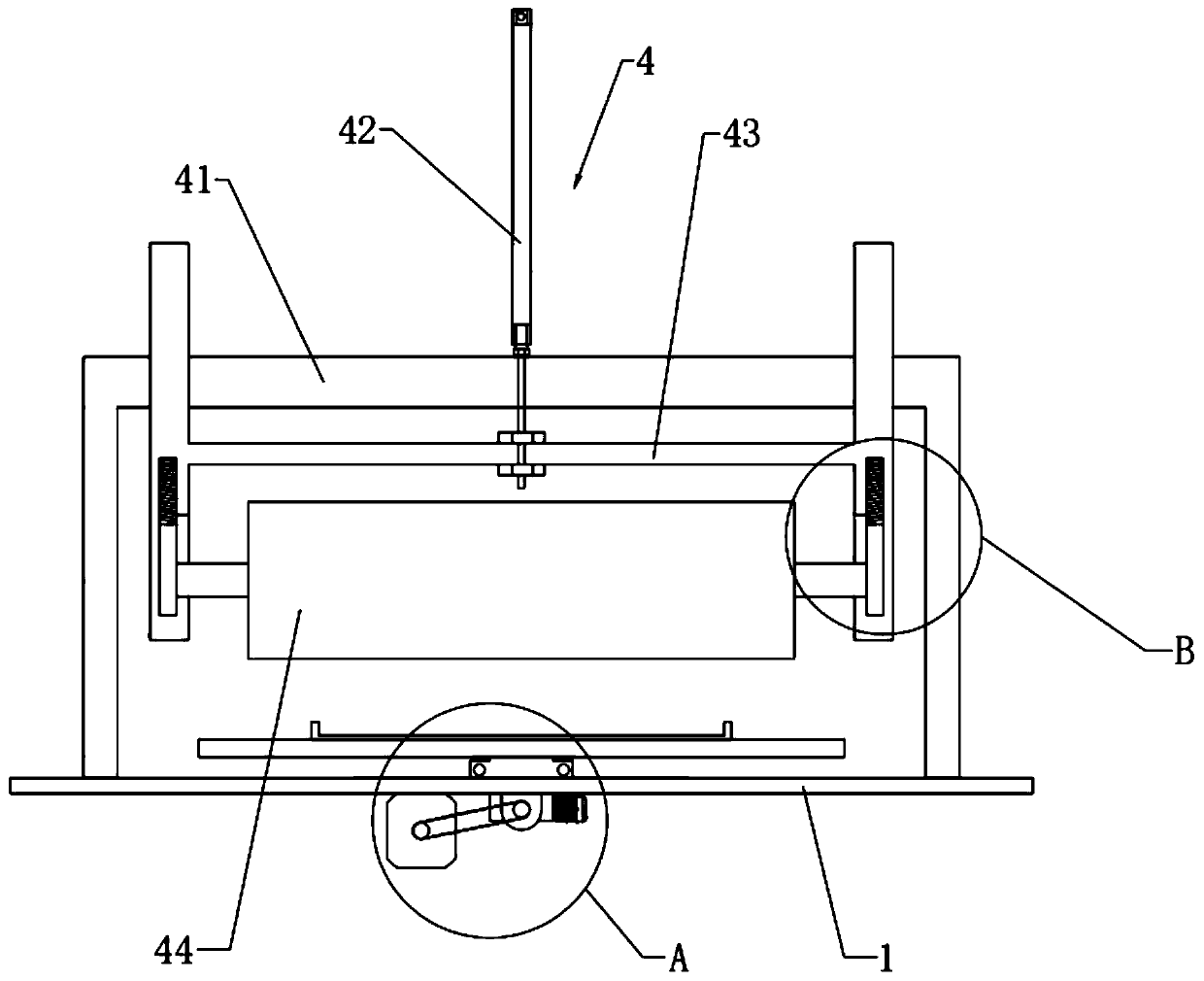

[0022] Example: such as figure 1 and figure 2 As shown, the optimized structure of the rolling tooling includes a machine 1 on which a driving device 2 , a holding device 3 and a rolling device 4 are arranged.

[0023] like figure 2 and Figure 5 As shown, the driving device 2 includes a driving motor 21 fixed on the bottom side of the machine platform 1, the rotating shaft of the driving motor 21 is arranged in the front and rear directions, and two screw seats are fixedly connected to the front and rear sides of the bottom of the machine platform 1, and the two screw seats have a common A driving screw rod 22 is connected in rotation, a belt 23 is provided between the driving motor 21 rotating shaft and the driving screw rod 22, and the inner ring of the belt 23 is enclosed within the peripheral wall of the rotating shaft of the driving motor 21 and the peripheral wall of the driving screw rod 22 simultaneously.

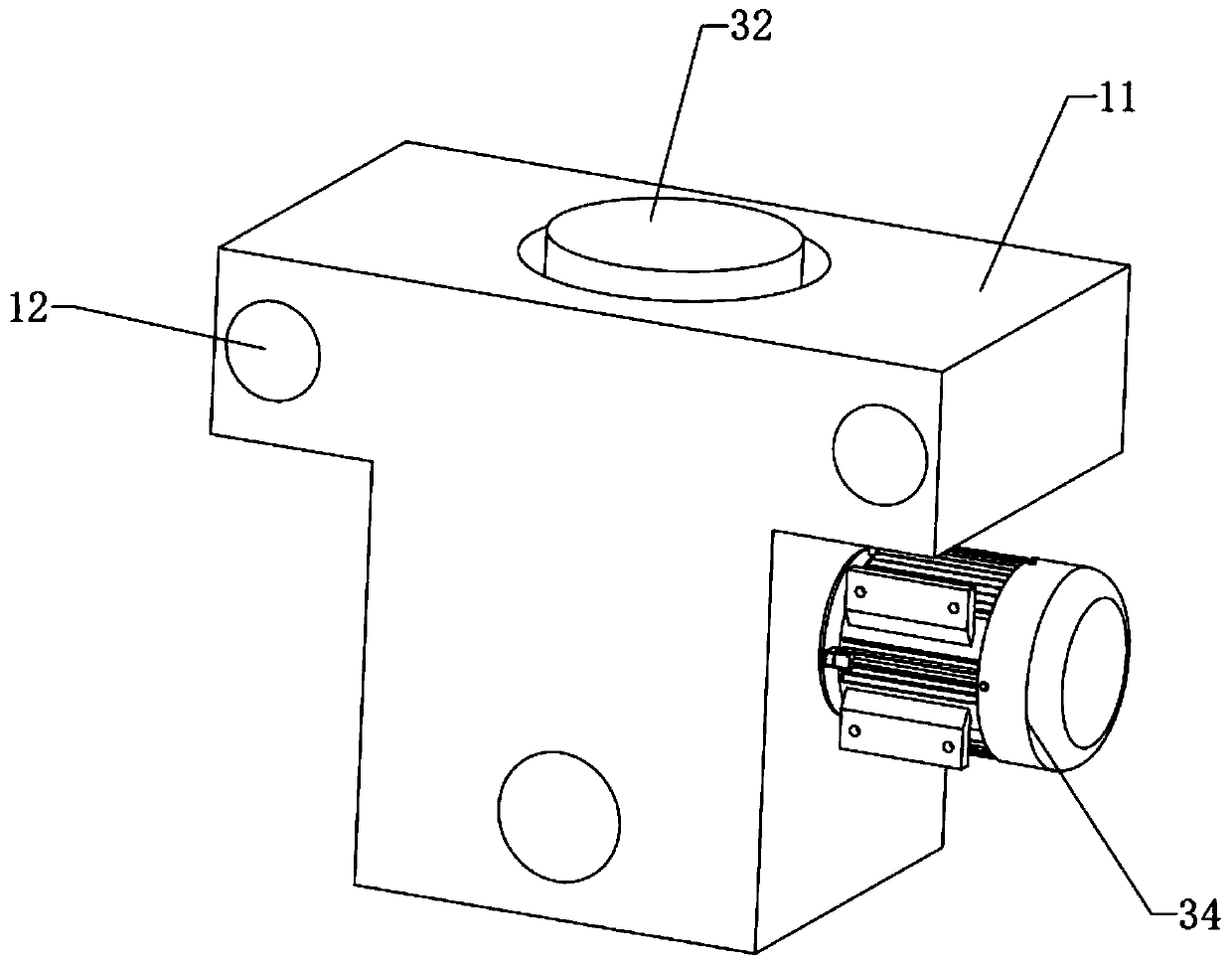

[0024] like image 3 and Figure 5 As shown, the holdi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com