Gas-assisted protection integral impeller trepanning electrolytic machining process and device

An integral impeller and gas-assisted technology, applied in the direction of electric processing equipment, electrochemical processing equipment, auxiliary devices, etc., can solve the problems of unstable open flow field and the blades cannot be fully insulated and protected, so as to reduce machine tool corrosion and improve The service life of the machine tool and the effect of stable processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The above-mentioned content of the present invention will be described in further detail below by the form of the embodiment, but this should not be interpreted as the scope of the above-mentioned theme of the present invention being limited to the following embodiments, all technologies realized based on the above-mentioned content of the present invention belong to scope of the invention.

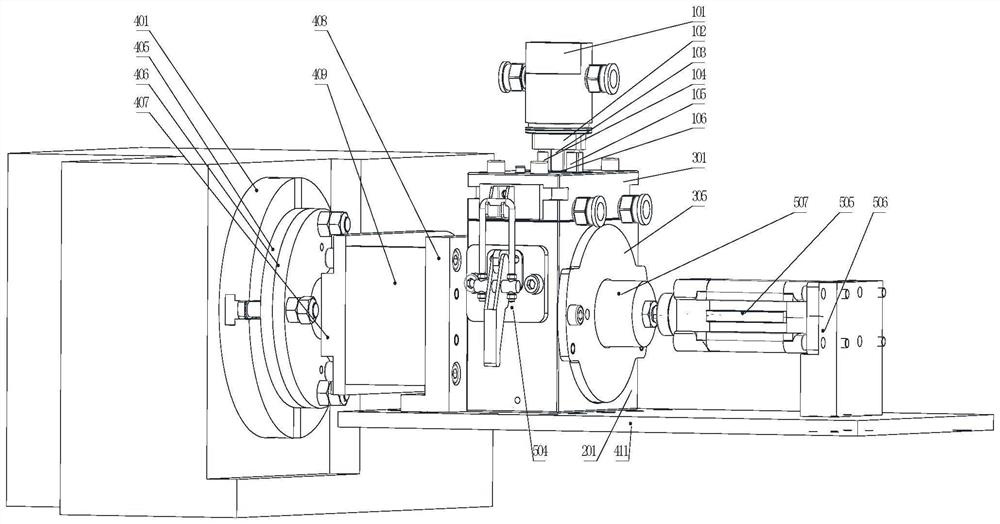

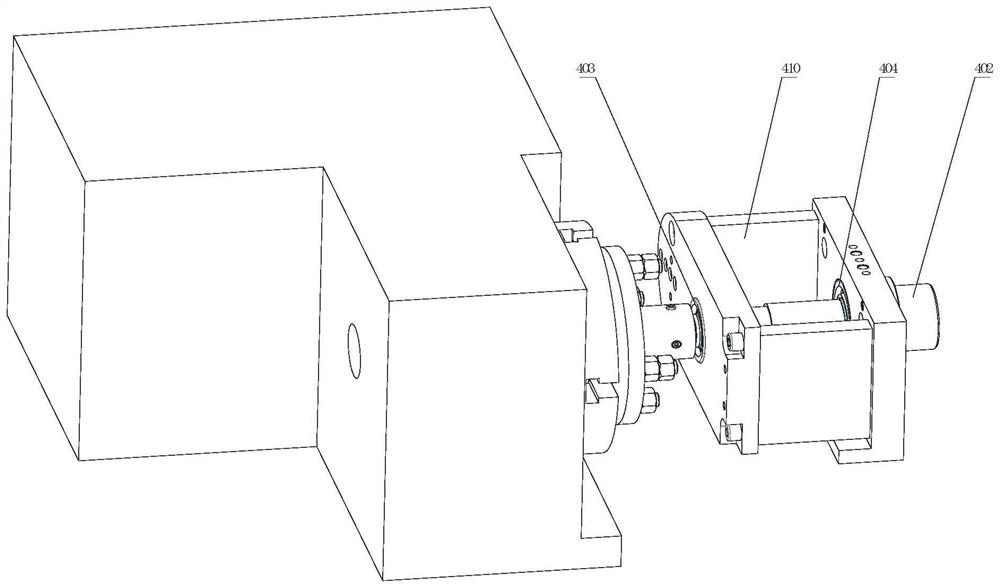

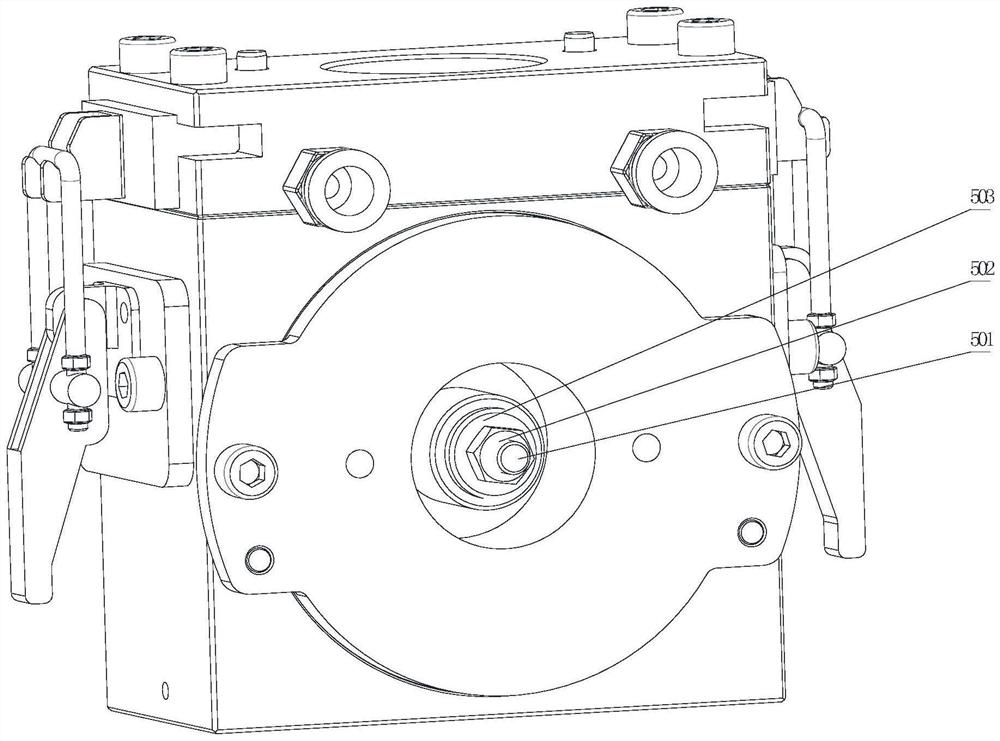

[0034] The invention provides a gas-assisted protective integral impeller casing electrolytic processing device, such as figure 1 As shown, it includes a cathode clamping device 1 , a gas mixing device 2 , an insulating sealing device 3 , an indexing device 4 and a workpiece clamping device 5 . The cathode holding device 1 includes a cylindrical cathode holder 101, a cathode holder insulating block 102, a cathode insulating block 103, a left insulating shell 104, a right insulating shell 105, and an arched bridge-shaped cathode 106; the gas mixing device 2 includes an insulating ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com