High-speed and high-accuracy driving device for rotary table

A technology of rotary table and driving device, which is applied in the direction of transmission device, transmission device parts, manufacturing tools, etc. It can solve the problems of inability to achieve precise speed control, inability to achieve precise indexing, high gear precision requirements, etc., and achieve simple structure, gear The effect of low accuracy requirements and high repeat positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with accompanying drawing, the utility model is further described:

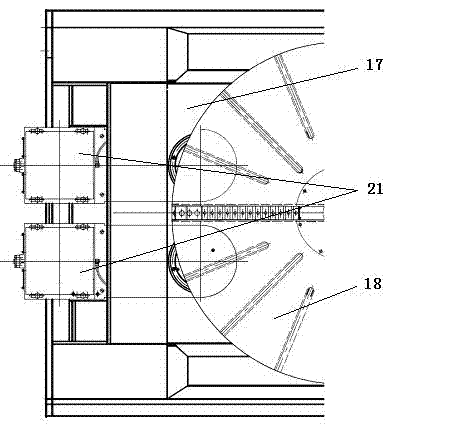

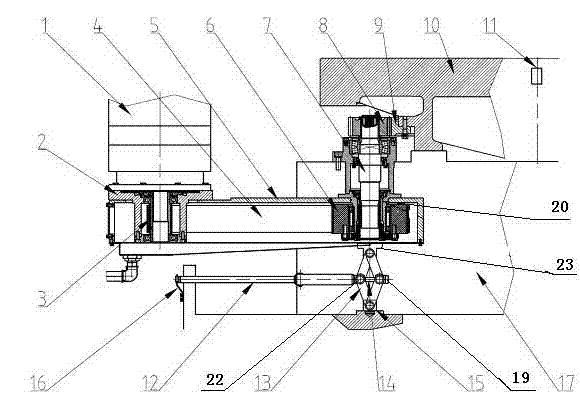

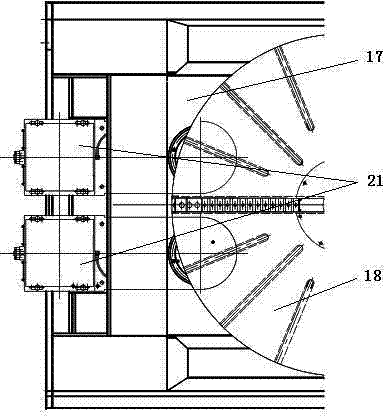

[0015] A high-speed, high-precision rotary workbench driving device is provided with a workbench 1, a base 17 and a control system. Two sets of rotary drive devices 21 are arranged side by side. An angle encoder 11 is provided at the center of the workbench 10. The rotary drive device 21 includes a box body 5, a servo motor 1, an adjustment seat 2, a main drive gear 3, a drive shaft 7, and a drive sprocket. 3 and the driven sprocket 6, the encoder 11 is connected with the control system, the box body 5 is fixed on the base 17, one end of the box body 5 is provided with a positioning sleeve 20, and the other end is provided with an adjustment seat 2, and the inner wall of the positioning sleeve 20 is passed through the bearing It is fixedly connected with the driving shaft 7, the outer wall is fixedly connected with the driven sprocket 6, the driven sprocket 6 is meshed with the syn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com