Lithium battery processing and assembling mechanism

A technology for assembling mechanism and lithium battery, which is applied in primary batteries, battery assembling machines, and equipment for manufacturing primary batteries, etc., can solve problems such as low efficiency, and achieve the effect of improving automation and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

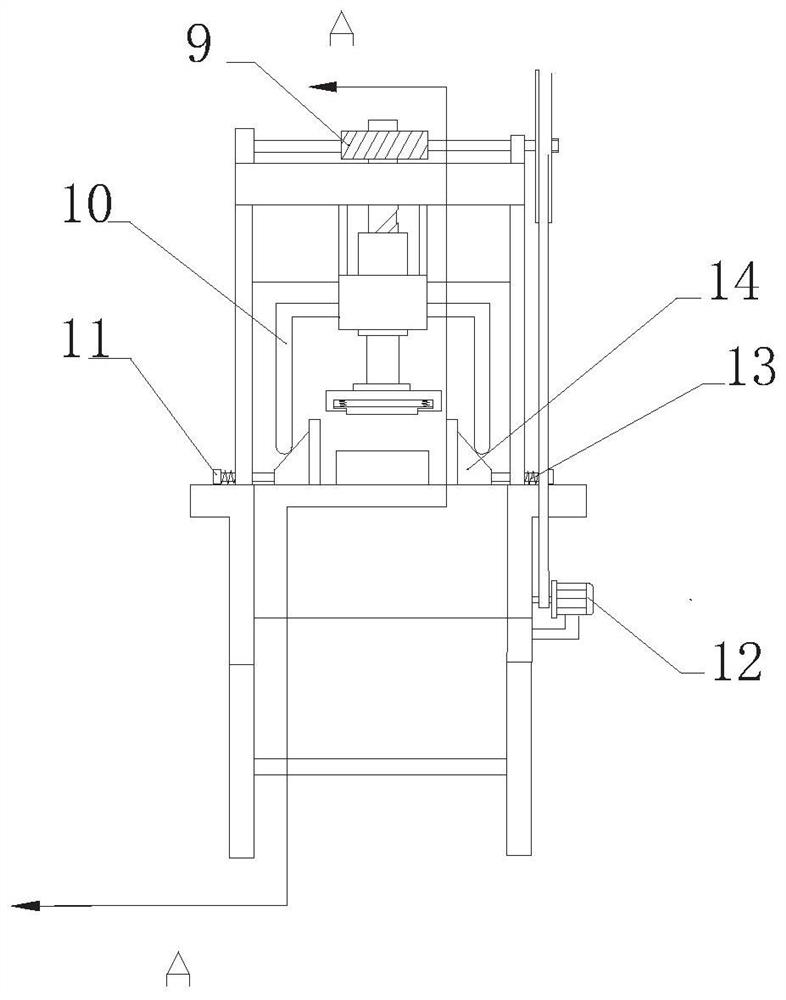

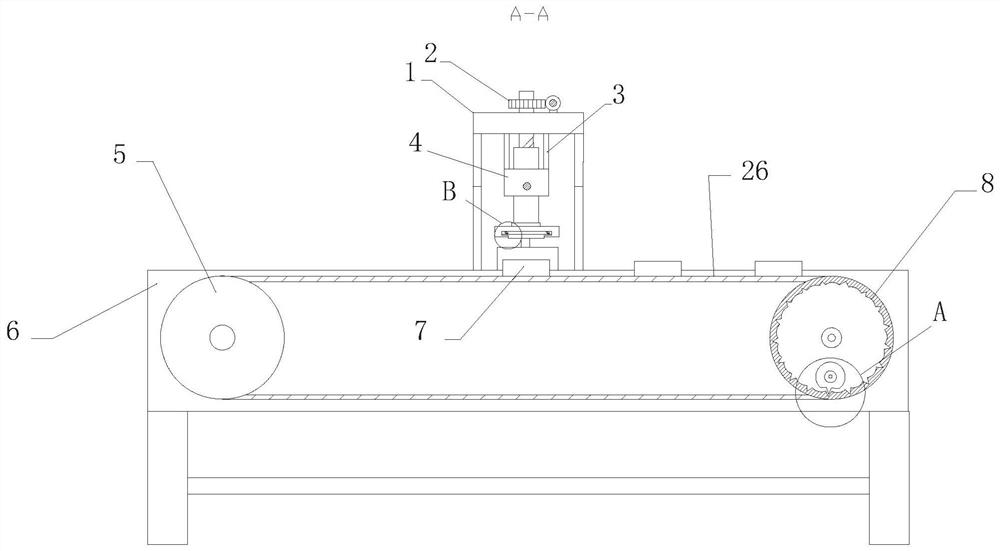

[0026] see Figure 1-6 , which is a schematic structural diagram of a lithium battery processing and assembling mechanism in a preferred embodiment of the present invention. A lithium battery processing and assembling mechanism in this embodiment includes a casing 1, and a pressing mechanism 4 is installed in the casing 1 , the press-down mechanism 4 includes a chute rod 23, the chute rod 23 is provided with a chute 22 that is wave-shaped in the expanded view, and the chute rod 23 is rotatably connected to the top plate of the casing 1, the The chute rod 23 extends above the top plate of the casing 1, and the part above the top board of the casing 1 is provided with a rotating gear 2. 23 is covered with an outer cylinder 21, the outer wall of the outer cylinder 21 is provided with a bar-shaped key 29, and the inner wall of the outer cylinder 21 is provided with a block 24, the block 24 is cylindrical and extends to the inside of the chute 22, The outer cylinder 21 is slidably...

Embodiment 2

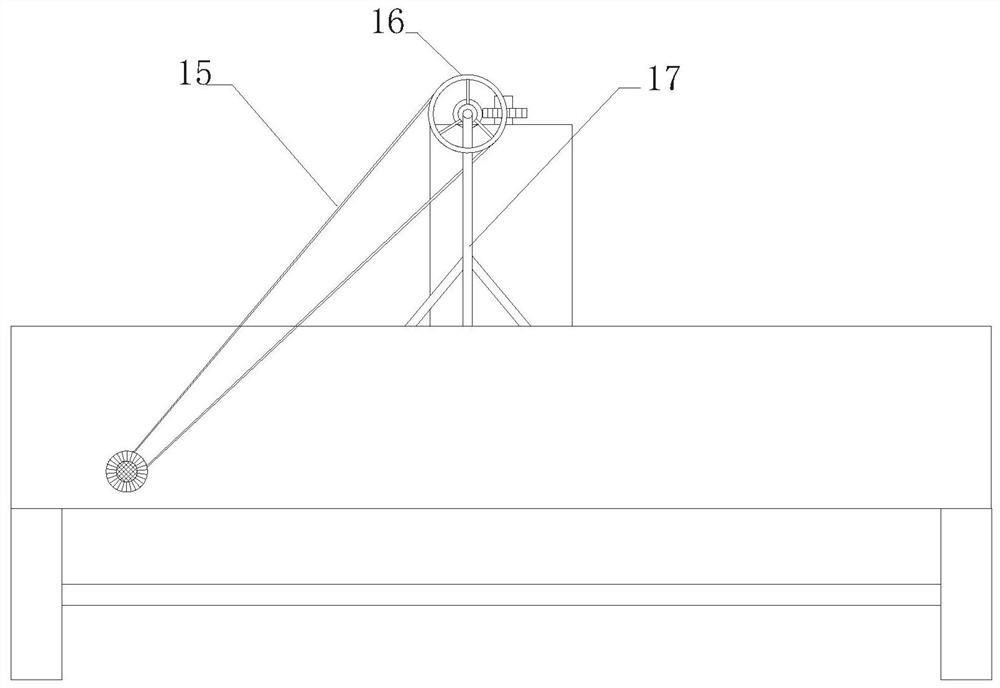

[0030] see Figure 1-6 , a lithium battery processing and assembling mechanism, on the basis of embodiment 1, the motor 12 is fixed on the outer wall of the mounting frame 6, a group of transmission belts 15 are connected to the transmission shaft of the motor 12, and the transmission belt 15 is connected with a group of rotating wheels 16, and the rotating wheels 16 are connected on the mounting frame 6 through a support frame 17, and a group of worms 9 are connected on the central axis of the rotating wheels 16.

[0031] In this lithium battery processing and assembling mechanism, the transmission shaft of the motor 12 drives the rotating wheel 16 to rotate through the transmission belt 15, and the rotating wheel 16 drives the coaxial worm 9 to rotate, and the worm 9 drives the rotating gear 2 to rotate, thus driving the chute rod 23 Rotation makes the lower mechanism work.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com