A device for cutting photocopied paper

A technology for photocopying paper and paper carrier, which is applied in metal processing and other directions, can solve the problems of high operating skills requirements of cutting workers, low efficiency of photocopying paper cutting work, and easy changes in displacement, so as to ensure cutting accuracy and solve easy wrinkles. , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

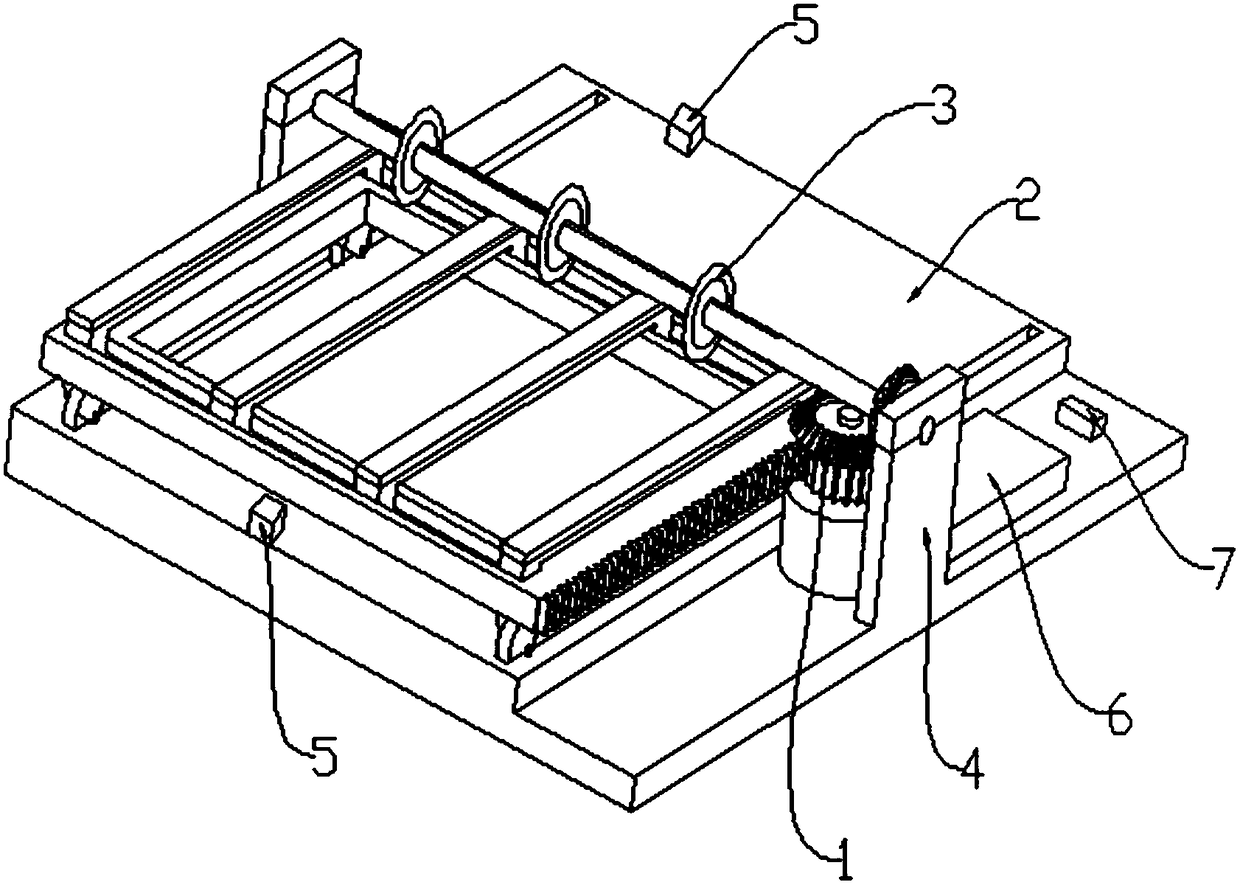

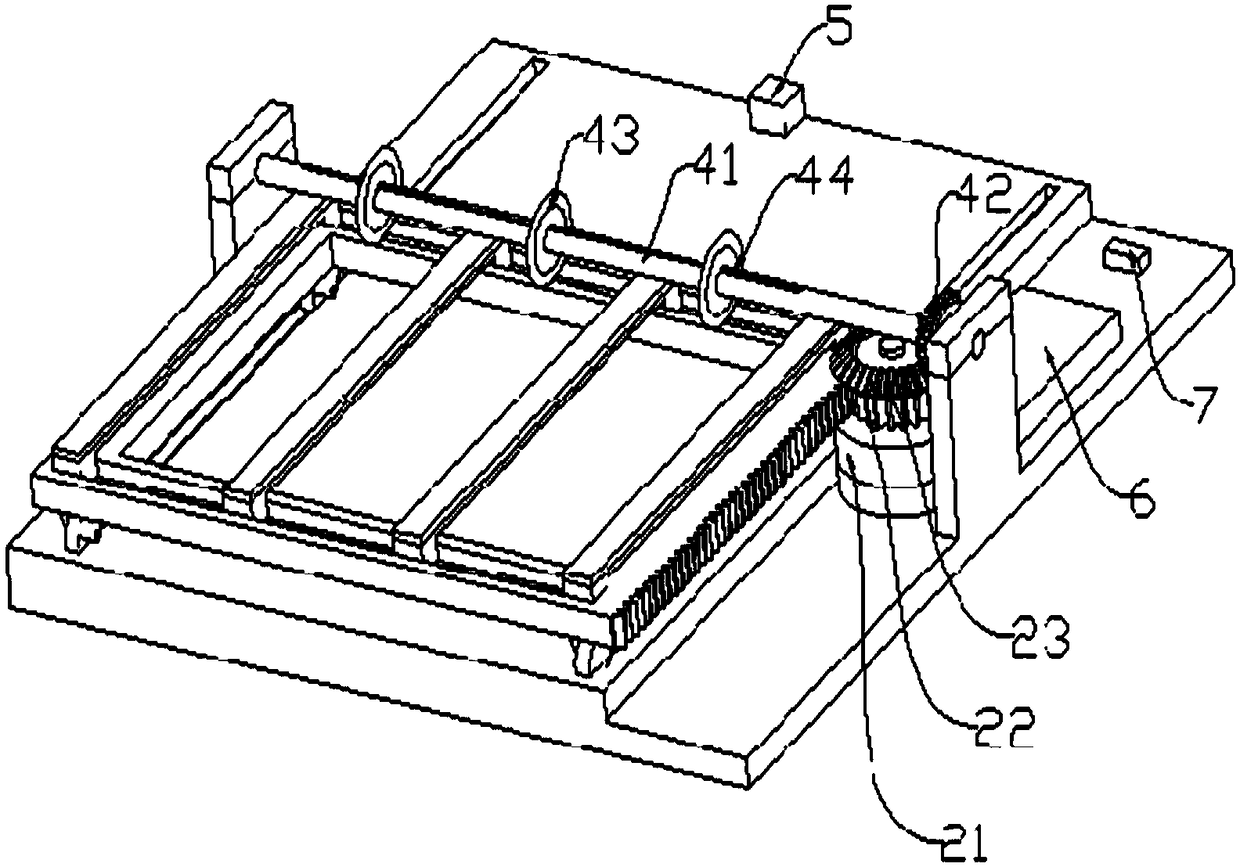

[0036] The invention discloses a device for cutting photocopied paper. The photocopied paper is fixed through the pressing bar and the paper carrier. Multi-edge automatic cutting of photocopied paper not only improves the work efficiency of cutting, but also ensures the precision of photocopied paper cutting.

[0037] The specific implementation of the invention will be further described below in conjunction with the accompanying drawings.

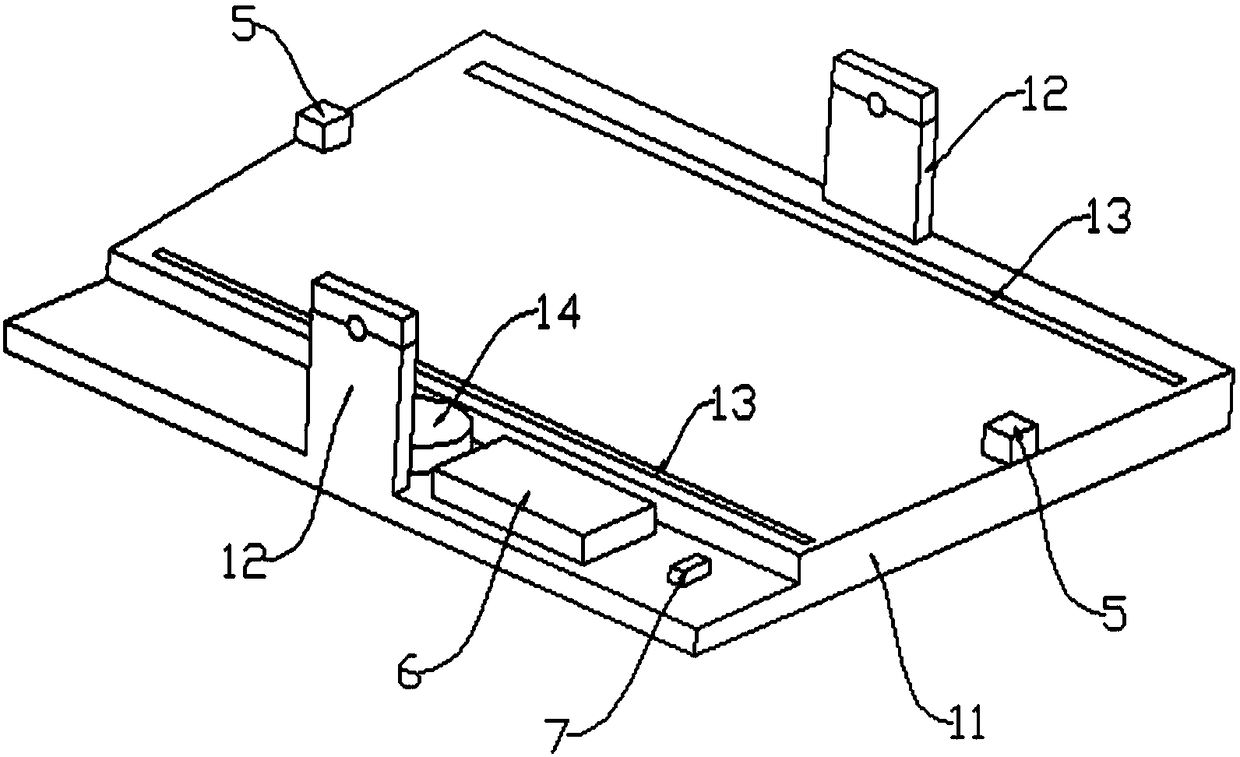

[0038] see figure 1 , figure 2 , image 3 and Figure 4 , a device for cutting photocopied paper, comprising a body base 1, a transmission mechanism 2, a paper loading platform 3 and a cutting mechanism 4; the transmission mechanism 2, the paper loading platform 3 and the cutting mechanism 4 are all arranged on the body base 1 on.

[0039] The body base 1 includes a base body 11, two support plates 12 arranged in the middle of both sides of the upper end surface of the base body 11 and perpendicular to the base body 11, and arranged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com