Production equipment for square steel pipe

A technology for producing equipment and square steel pipes, applied in the field of steel pipe processing, can solve the problems of frequent manual operations, low efficiency and poor action time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

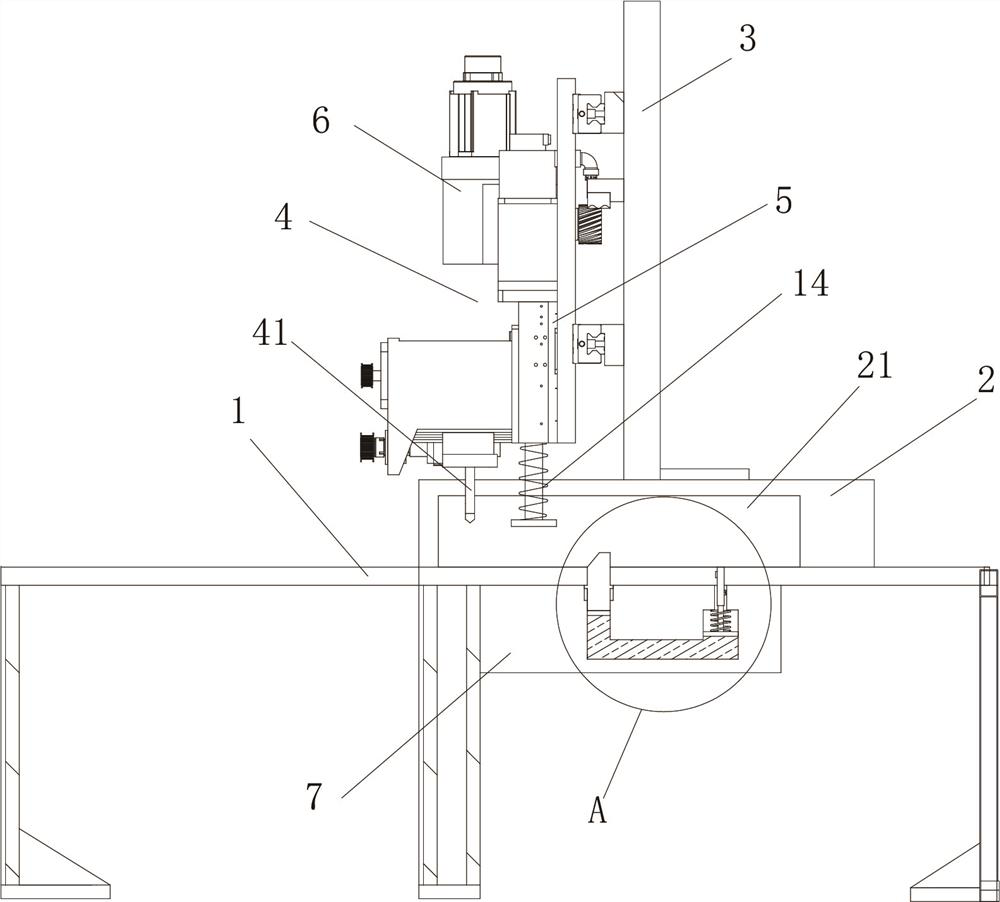

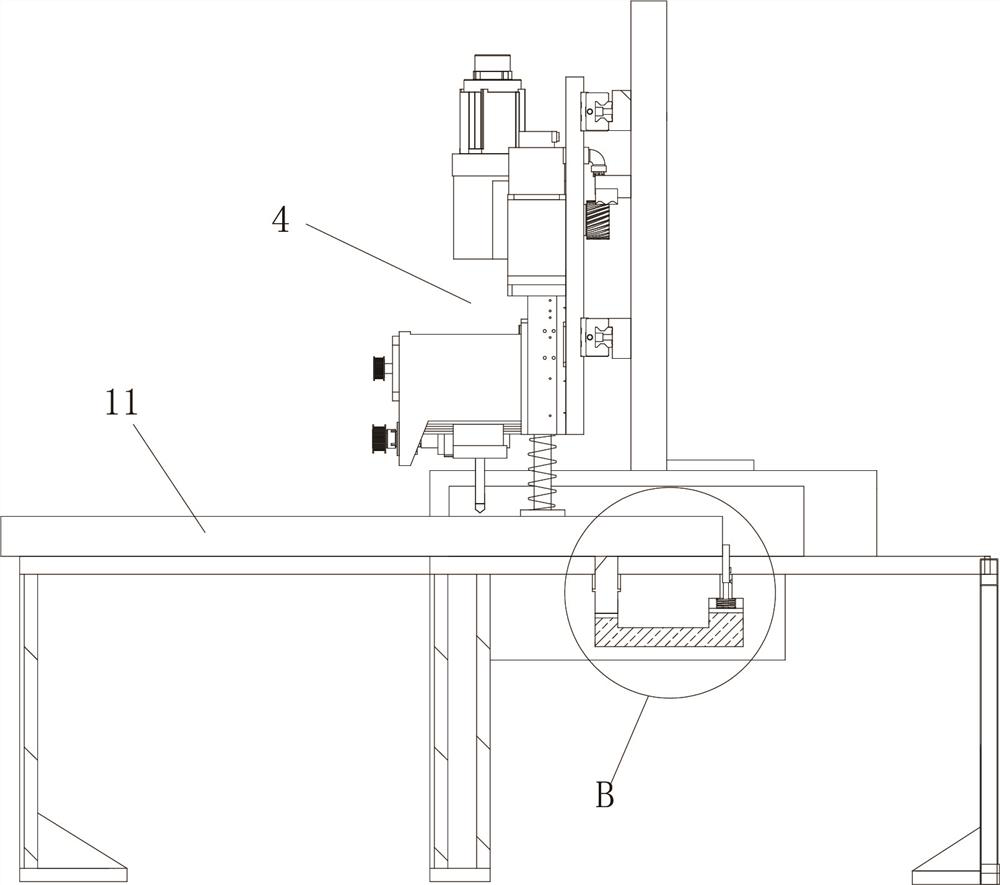

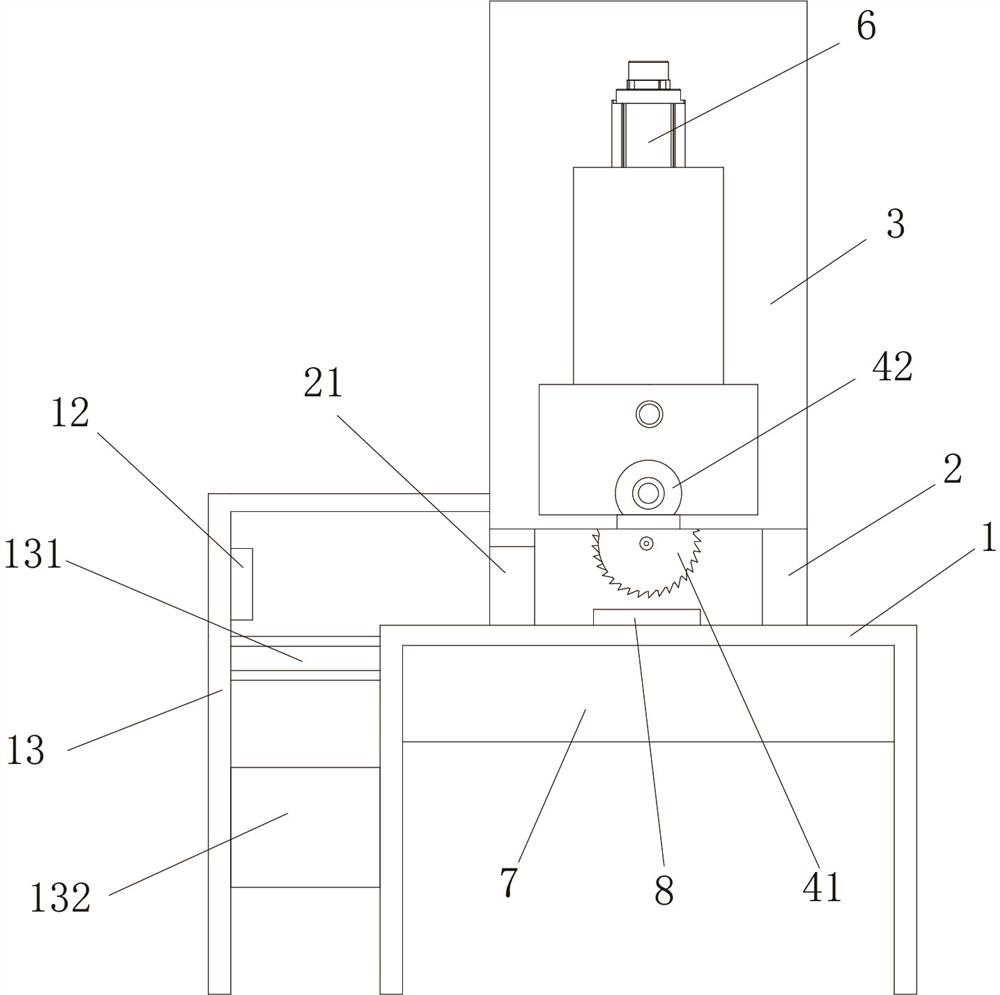

[0027] Reference Figure 1-8 As shown, a specific embodiment of the present invention: a square steel tube production apparatus, comprising: a workbench 1; a support frame 2 and a vertical support plate 3; a cutting head assembly 4, comprising a cutting plate 41 and a drive motor 42 for driving the cutting plate 41, the cutting head assembly 4 is set on the vertical support plate 3 by sliding rail 5, and driven by the second motor 6 its longitudinal activity, specifically, the second motor 6 is selected as a servo motor, the cutting piece 41 may be driven by the drive motor 42 through the belt drive to drive its rotation;

[0028] On the table 1 is provided with a lower support block 7, the lower support block 7 is provided with a trigger ramp 8 and a resistance plate 9 may be operated along the guide groove 71 longitudinally, the trigger ramp 8 and the resistance plate 9 are provided below the moving plate 10, the activity plate 10 is placed in a hydraulic groove 72, the hydraulic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com