A multi-station automatic loading and unloading processing equipment

A technology of automatic loading and unloading, processing equipment, applied in metal processing equipment, metal processing, metal processing machinery parts and other directions, can solve the problems of processing equipment can not automatically load and unload, each station can not be connected in series, low work efficiency, etc. The effect of saving labor cost, simple and ingenious structure, and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

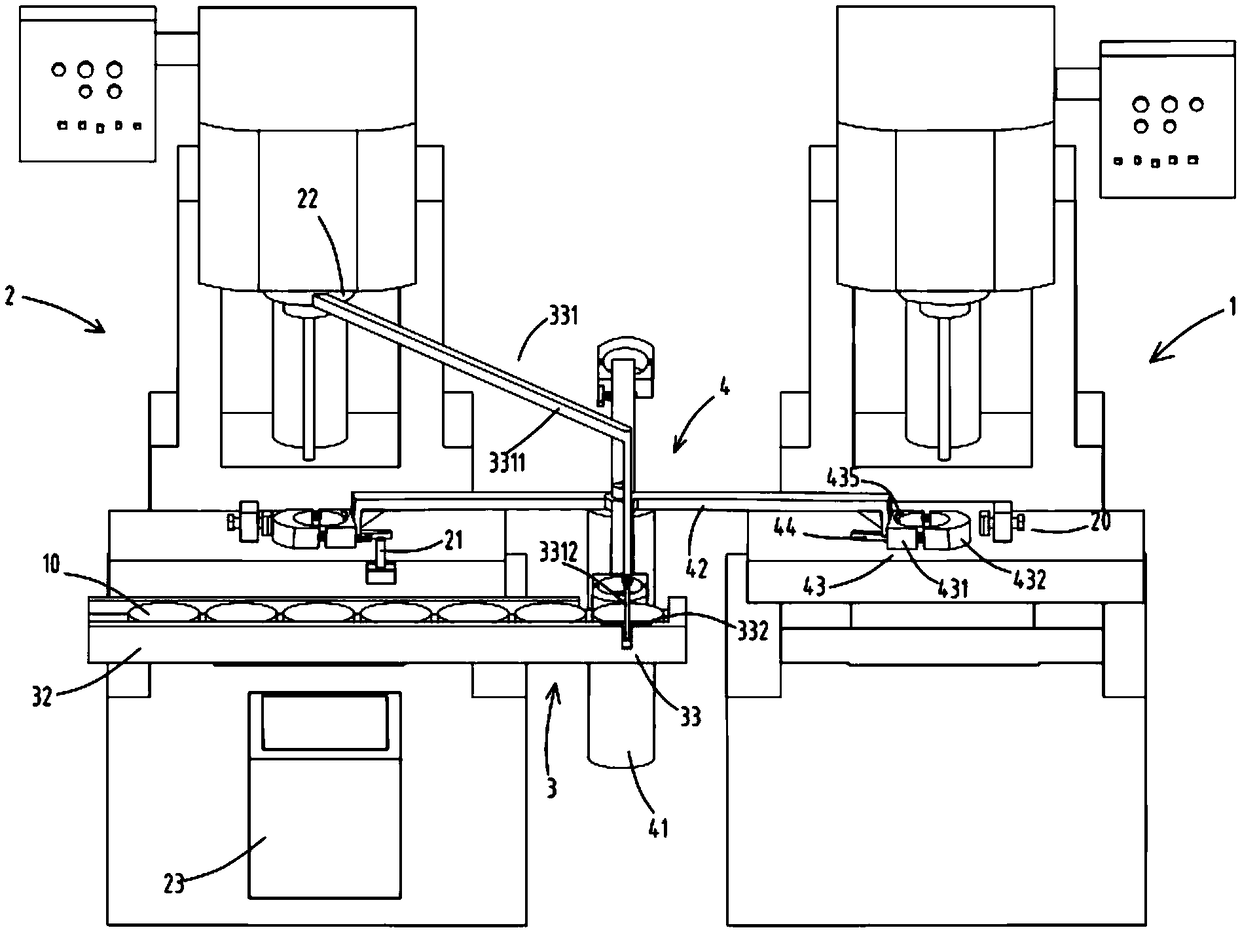

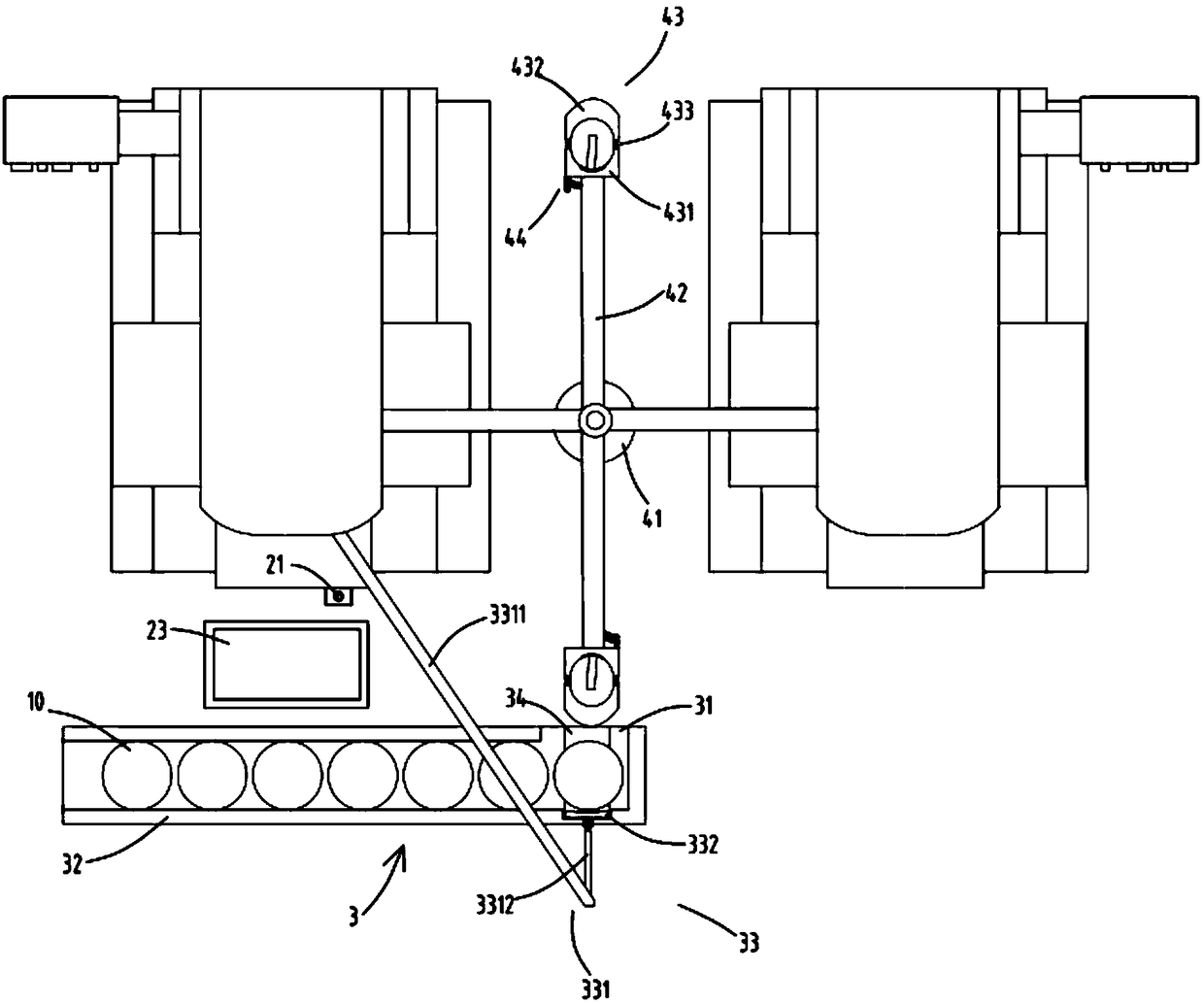

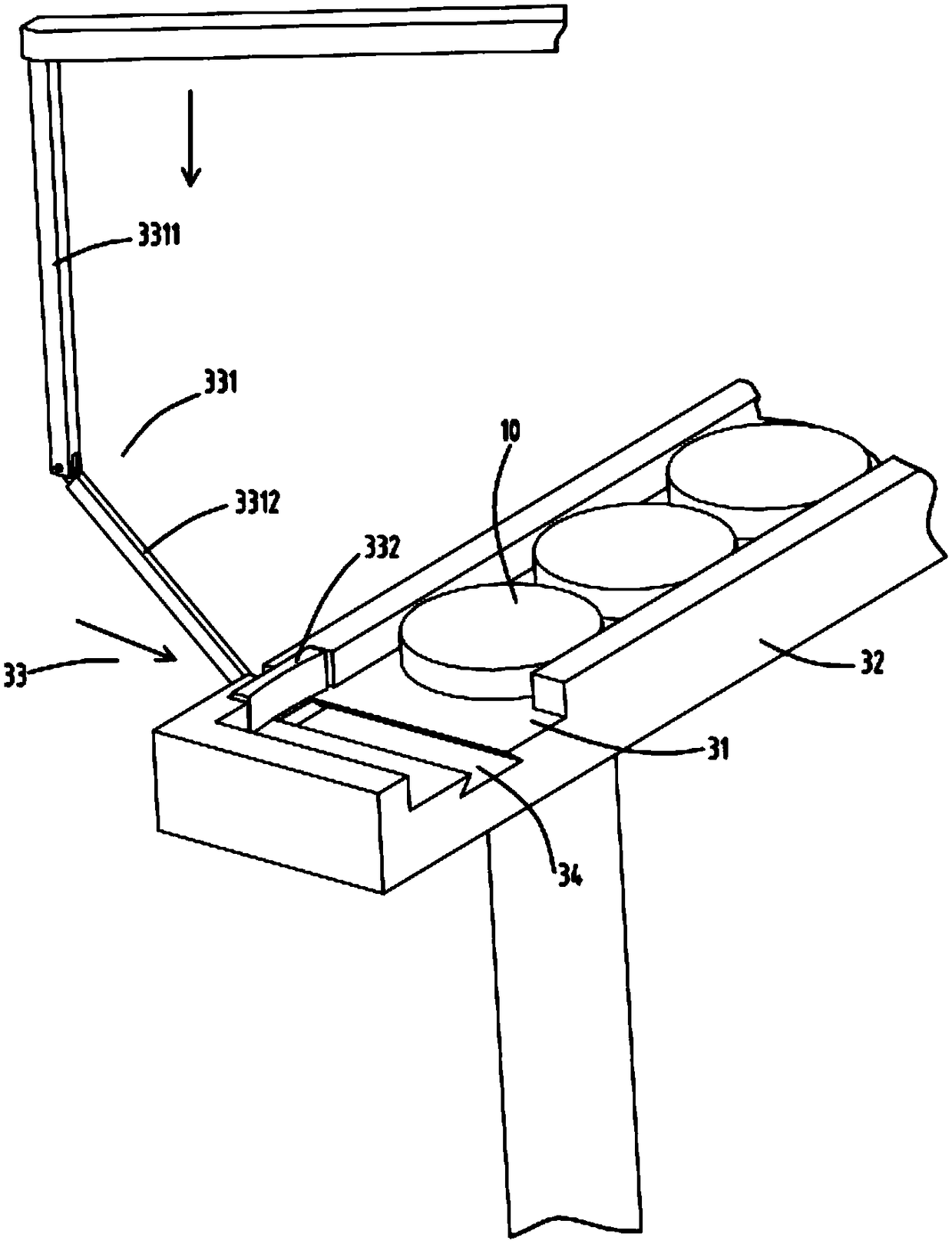

[0035] figure 1 It is a schematic diagram of multi-station automatic loading and unloading processing equipment, figure 2 It is a top view schematic diagram of multi-station automatic loading and unloading processing equipment, image 3 It is a schematic diagram of the structure of the feeding equipment, Figure 4 It is a partial structural schematic diagram of the feeding device, Figure 5 It is a schematic diagram of the pressing device when pressing the clamping device. Such as figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 As shown, what is provided in this embodiment is a multi-station automatic loading and unloading processing equipment, including

[0036] The processing equipment a1 is used to process the workpiece 10 in the first process;

[0037] The processing equipment b2 is used to process the workpiece 10 in the second process;

[0038] It should be noted that the processing equipment a1 and the processing equipment b2 are only set for this e...

Embodiment 2

[0052] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, the components that are the same as or corresponding to those in the first embodiment are marked with the corresponding reference numerals in the first embodiment. For the sake of simplicity, only the differences from the first embodiment will be described below. The difference between the second embodiment and the first embodiment is that a guide rod 434 is also provided between the fixed clamp block 431 and the movable clamp block 432, one end of the guide rod 434 is fixed on the fixed clamp block 431, and the other end is relatively movable. The guide groove 4321 provided on the clamp block 432 slides; the elastic member 433 is sleeved on the guide rod 434, and the guide rod 434 guides the movement of the movable clamp block 432, preventing the movable clamp block 432 from being squeezed and A large offset angle affects the effect of clamping.

[0053] Working process: multiple material ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com