Pressing and fixing device for paper plastic in cross cutting device

A fixed device, paper-plastic technology, applied in metal processing and other directions, can solve the problems of lack of automation, time-consuming and labor-intensive efficiency, etc., and achieve the effect of simple structure, compact overall structure and strong environmental adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] specific implementation plan

[0015] Preferred embodiments of the present invention are described in detail as follows in conjunction with accompanying drawings:

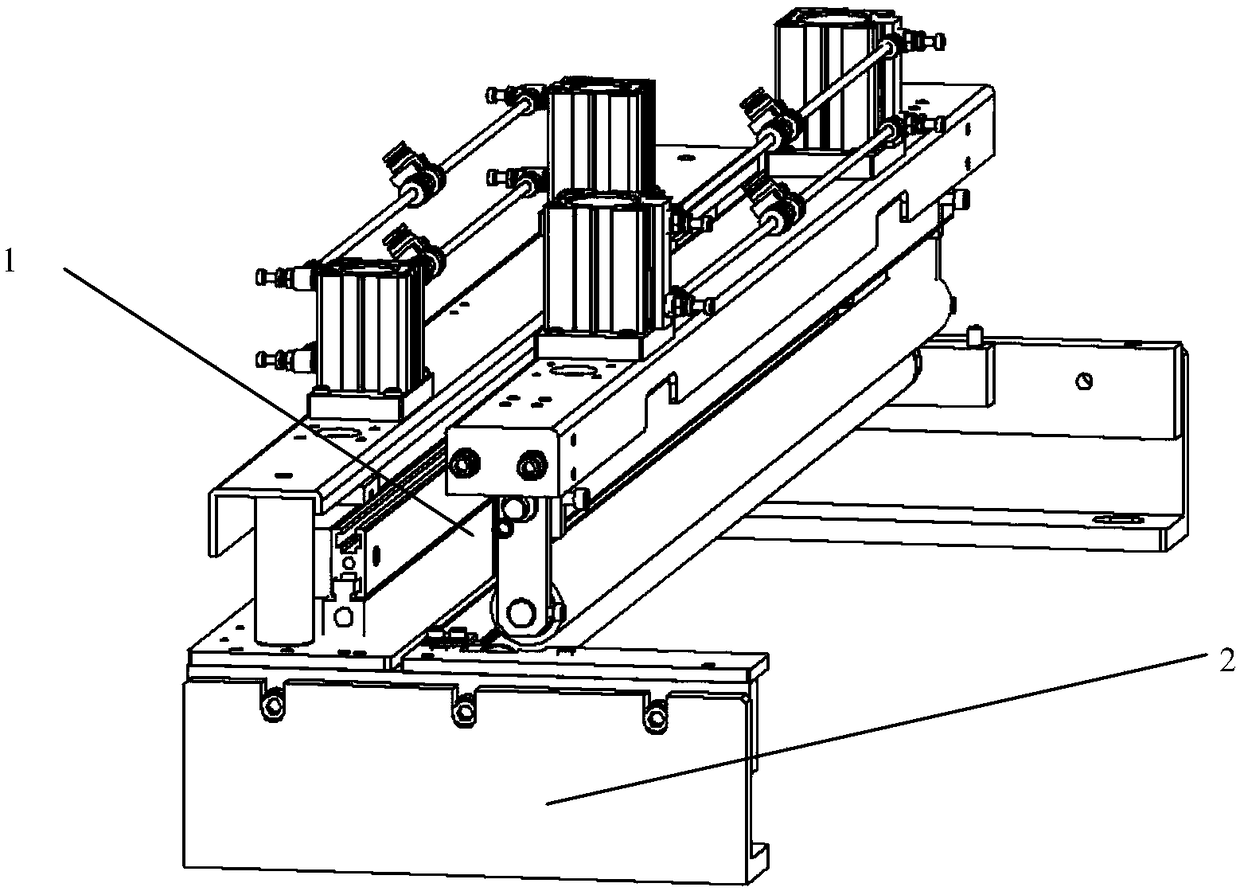

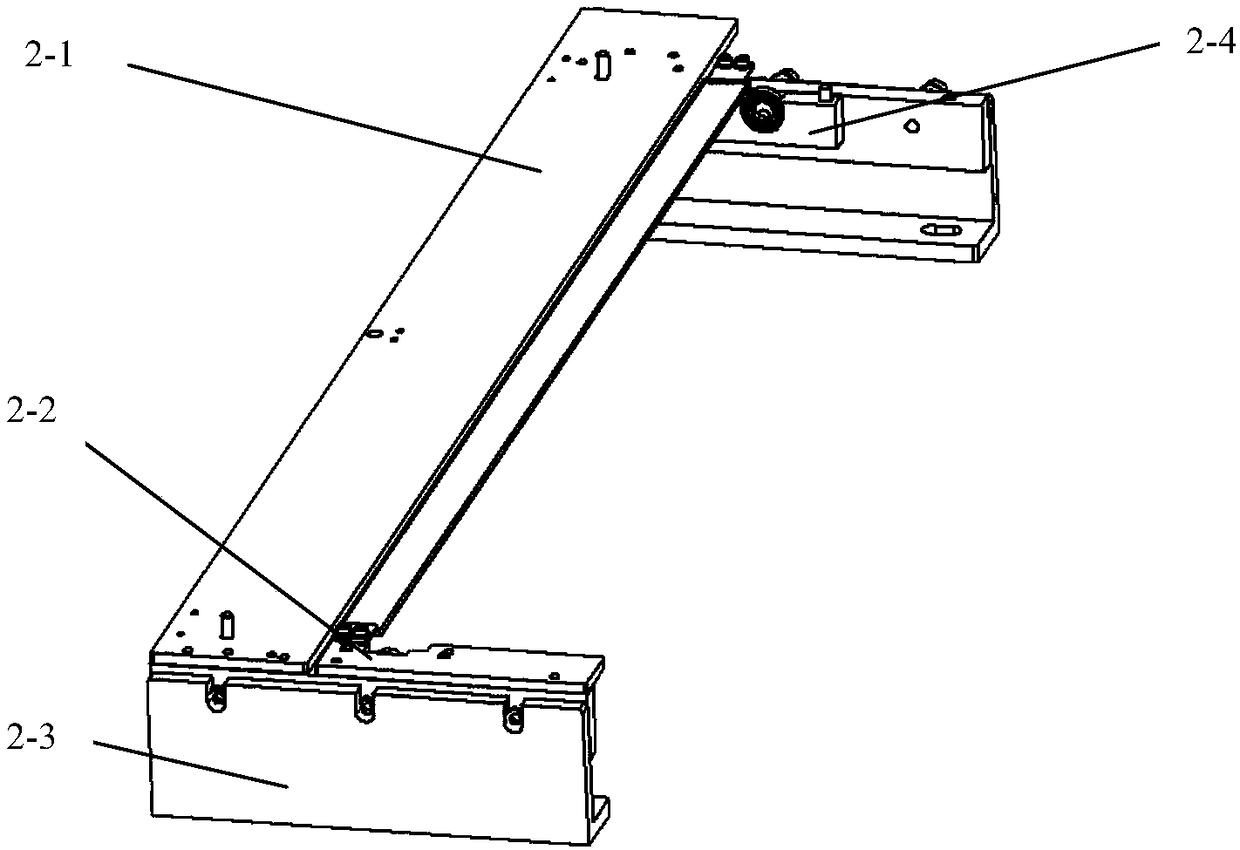

[0016] In this example, see Figure 1-Figure 3 , the pressing and fixing device of paper plastic in the cross-cutting equipment is mainly composed of a pressing and fixing device 1 and an integral base 2 of the pressing and fixing device,

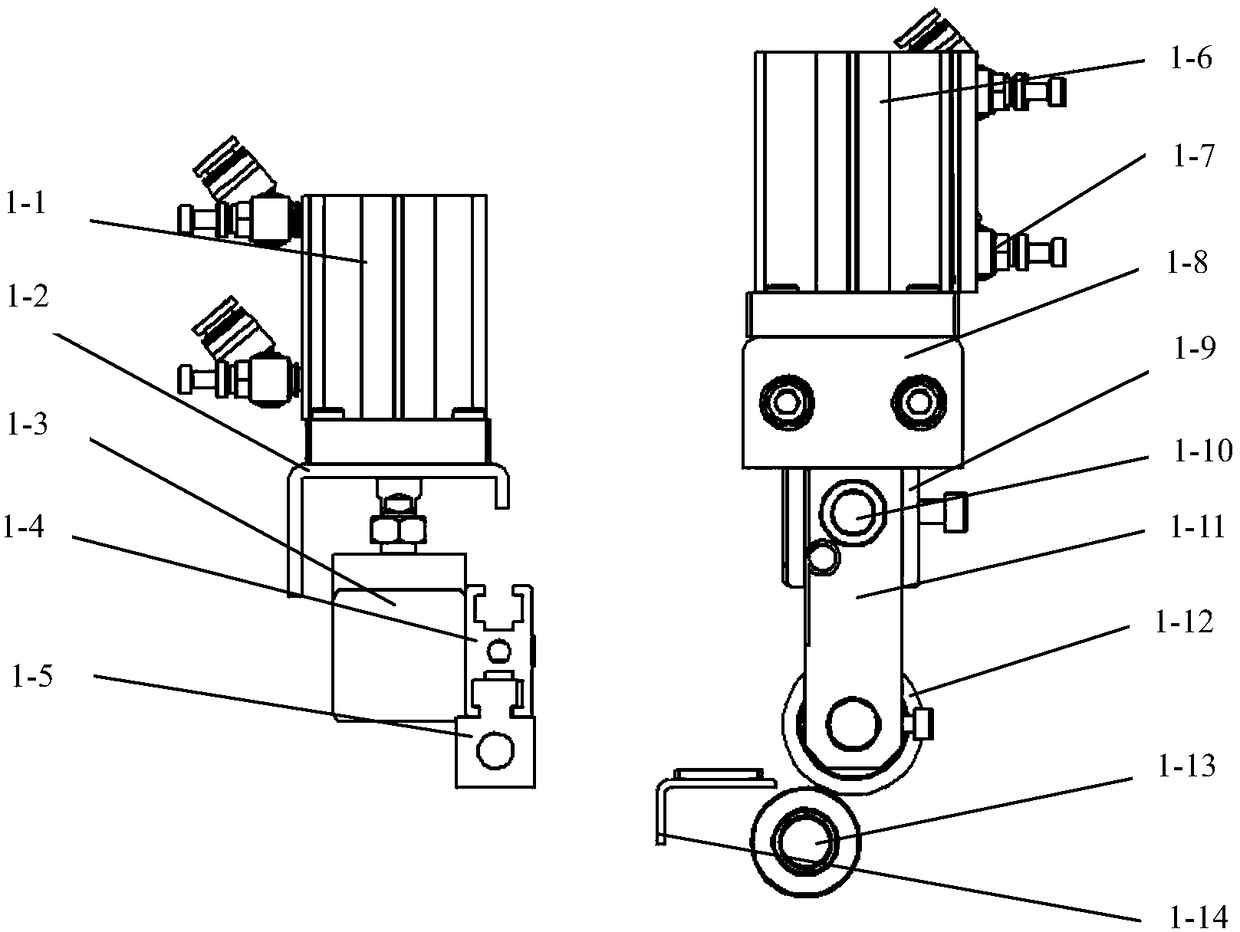

[0017] Compression fixing device 1 is mainly composed of cylinder 1-1, channel steel 1-2, square pipe 1-3, aluminum profile 1-4, rubber anti-collision strip 1-5, cylinder 1-6, air pipe connector 1-7, Channel steel 1-8, square pipe 1-9, rotating shaft 1-10, swing bar 1-11, upper pressing bar 1-12, lower pressing bar 1-13, material pallet 1-14 form. The overall base 2 of the pressing and fixing device is mainly composed of the base 2-1, the tool holder support 2-2, the tool holder support seat 2-3 and the bearing seat 2-4, and the cylinder 1-1 is fixed on the channel stee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com