Two-way movement cam shaping mechanism

A technology of forming mechanism and cam, applied in the direction of packing/bundling items, packaging, wrapping items, etc., can solve the problems of unadjustable pressing force, too small or too large pressing force, etc., to avoid insufficient pressure and avoid wrinkling The effect of overloading the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

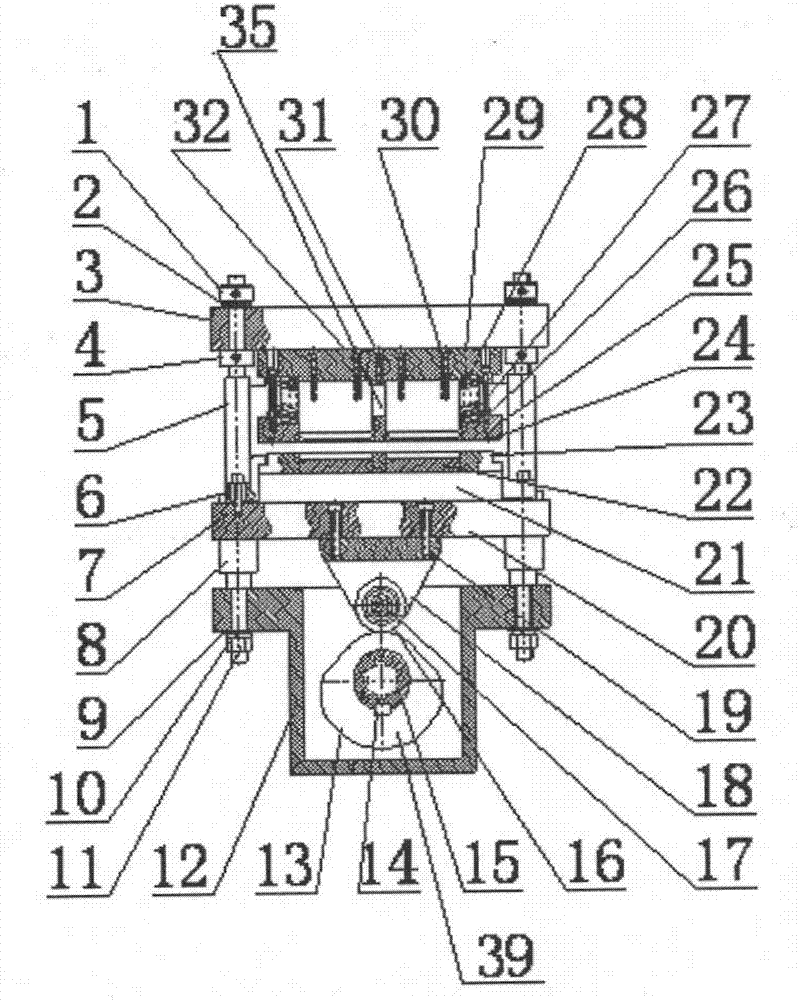

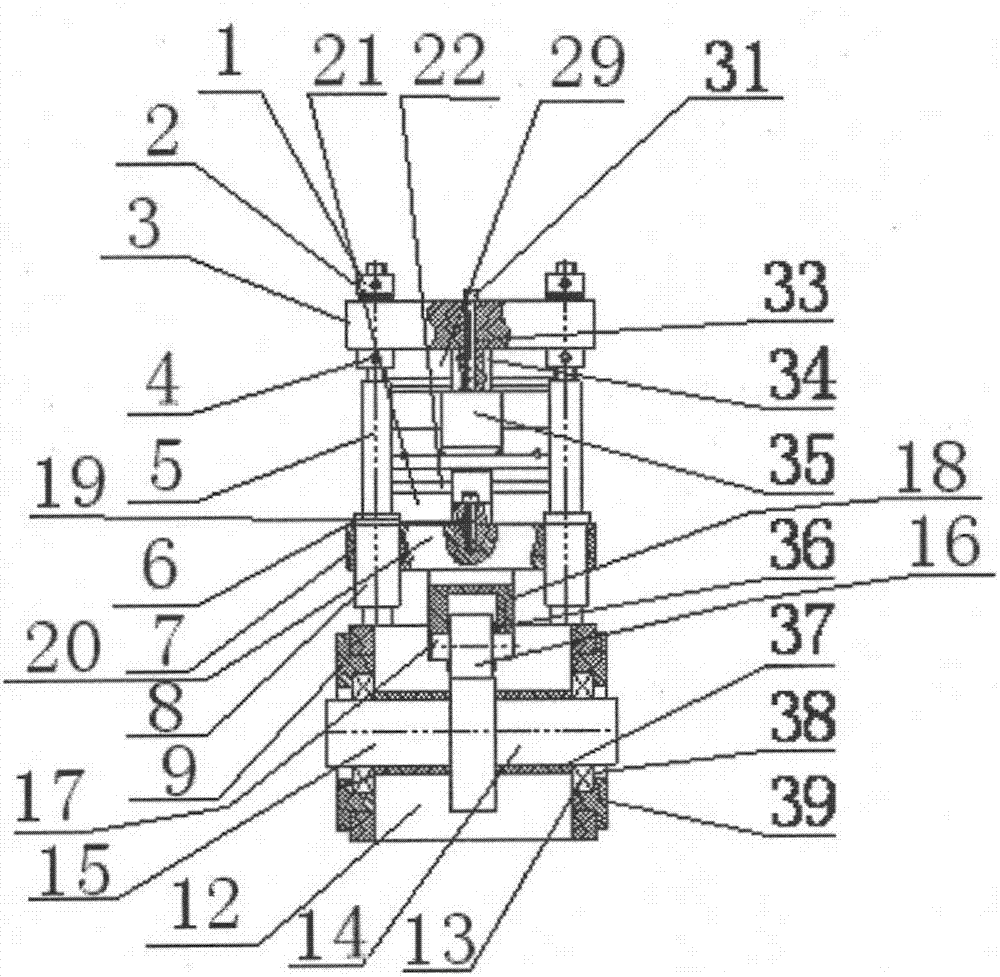

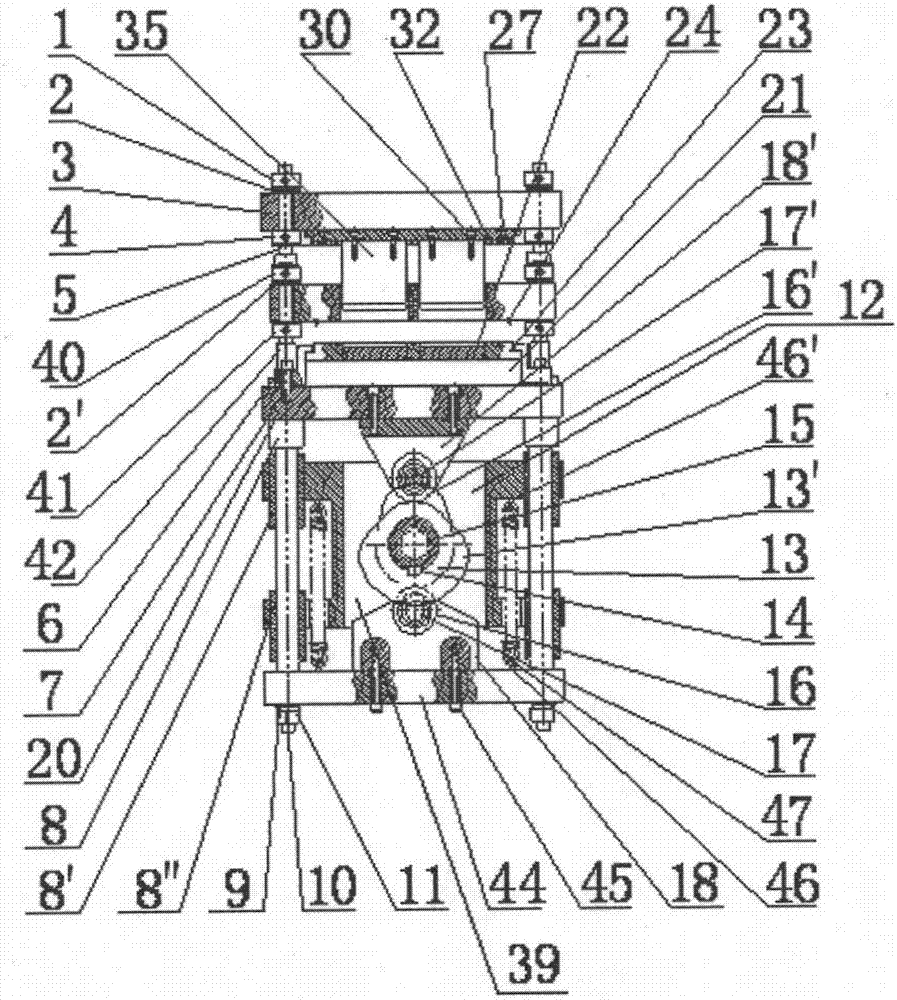

[0025] Such as image 3 , 4 As shown, it is a two-way action cam forming mechanism provided by the present invention. The first cam 13 and the two second cams 13' are installed on the cam spline sleeve 15 according to the relative positions in the figure, and additional cams are installed between adjacent cams. Cam spacer one 37, put cam spacer two 37' on the outer sides of the cams on both sides, separate cam one 13 and cam two 13, then press flat key 14 into the keyway of cam spline sleeve 15, cam The spline sleeve 15 is installed on the cam box 12 through the bearing 38 and the bearing cover 39; the first roller 16 and the second roller 16' are respectively installed on the roller seat through the first roller mandrel 17 and the second roller mandrel 17' One 18, Roller seat 2 18', Roller spacer 136 / Roller spacer 2 is installed between Roller 16 / Roller 2 16' and Roller seat 18 / Roller seat 2 18' 36'; adjust the position of the roller 2 16' to be tangent to the cam 13, insta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com