Patents

Literature

117results about How to "Meet feeding needs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

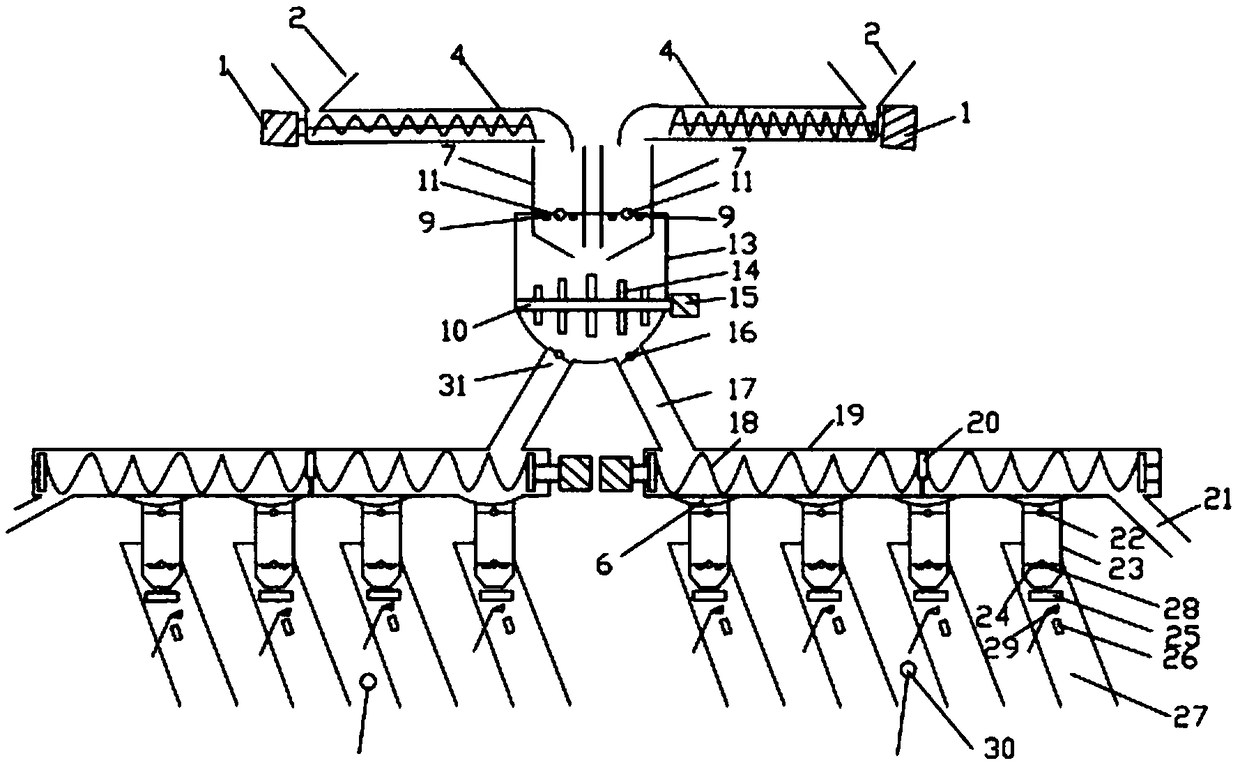

Fine feeding system for pig farm

PendingCN108377924AEfficient recyclingAvoid pollutionAnimal feeding devicesOther apparatusPig farmsEngineering

The invention discloses a fine feeding system for a pig farm. The fine feeding system comprises feed inlet devices, a weighing device, a mixing tank and a distributing device. Input ends of the inletdevices are connected with an input end of the weighing device, an output end of the weighing device is connected with an input end of the mixing tank, an output end of the mixing tank is connected with an input end of the distributing device, and feed can be distributed into feeding troughs in pig raising pigsties by the distributing device via distributing openings of the distributing device. The fine feeding system has the advantages that feed formula proportions can be finely regulated by the aid of the fine feeding system, and feed components can be finely uniformly mixed with one anotherby the fine feeding system; one-time food intake can be set by the aid of RFID (radiofrequency identification) scanning technologies according to individual live pig conditions of live pigs, the one-time feed demand of each single live pig individual can be adjusted in real time, accordingly, refined live pig individual feeding requirements can be met, conditions such as the weights of the live pigs, eating states and epidemic situations can be monitored in real time, and reliable bases can be provided to refined feed feeding; residual feed can be effectively recycled, accordingly, the cost can be saved, and feed contamination can be prevented.

Owner:HUNAN AGRICULTURAL UNIV

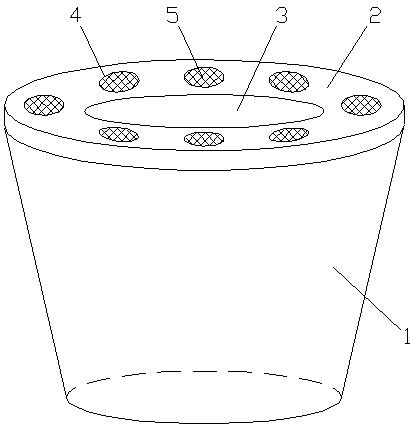

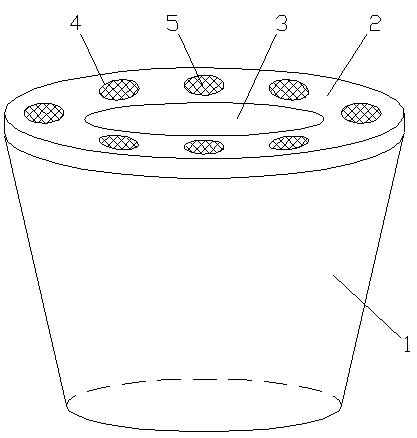

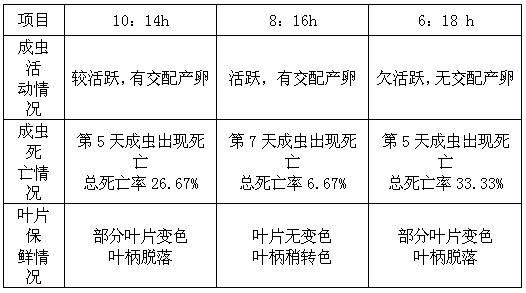

Insect breeding bottom and breeding method of gynaikothrips ficorum

The invention relates to an insect breeding bottom and a breeding method of gynaikothrips ficorum and belongs to the field of insect breeding and insect ecology. A bottom body is in a cone frustum shape with large top and small bottom and is in sealing match with a bottle cover, a magnifying glass is installed at the center of the bottle cover, a plurality of venting holes are evenly distributed on the bottle cover, and a filter screen is installed on the venting holes. The method utilizing the insect breeding bottom to breed the gynaikothrips ficorum comprises (1) collection of eggs, (2) hatching of the eggs, (3) breeding of nymphs and (4) breeding of imagoes. By using the breeding method, the hatching rate, survival rate and eclosion rate of the gynaikothrips ficorum are high, massive thrips of various insect states which are orderly in age and high in vigor can be obtained, and form changes and the whole life history of the gynaikothrips ficorum can be observed in real time.

Owner:INST OF PLANT PROTECTION FAAS

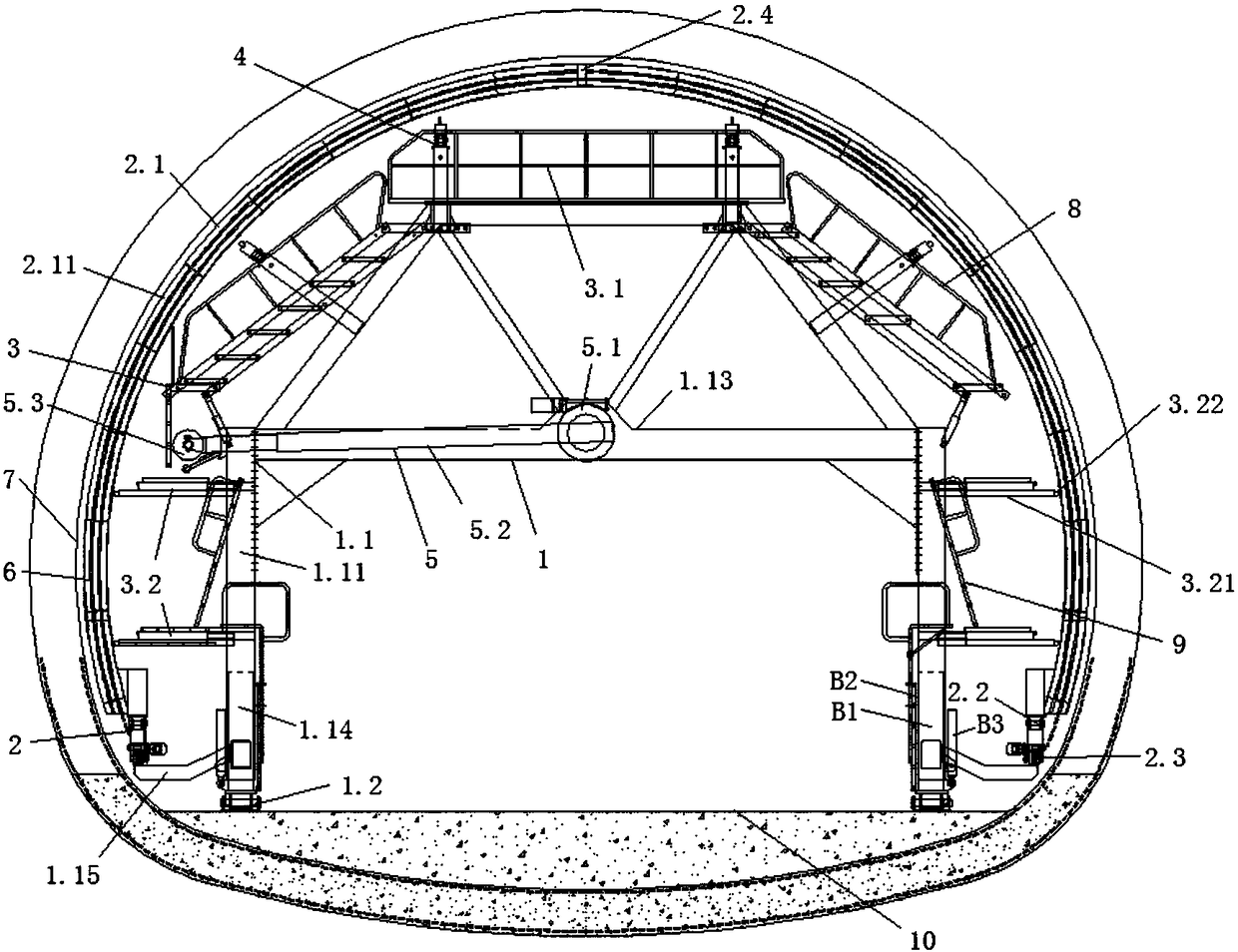

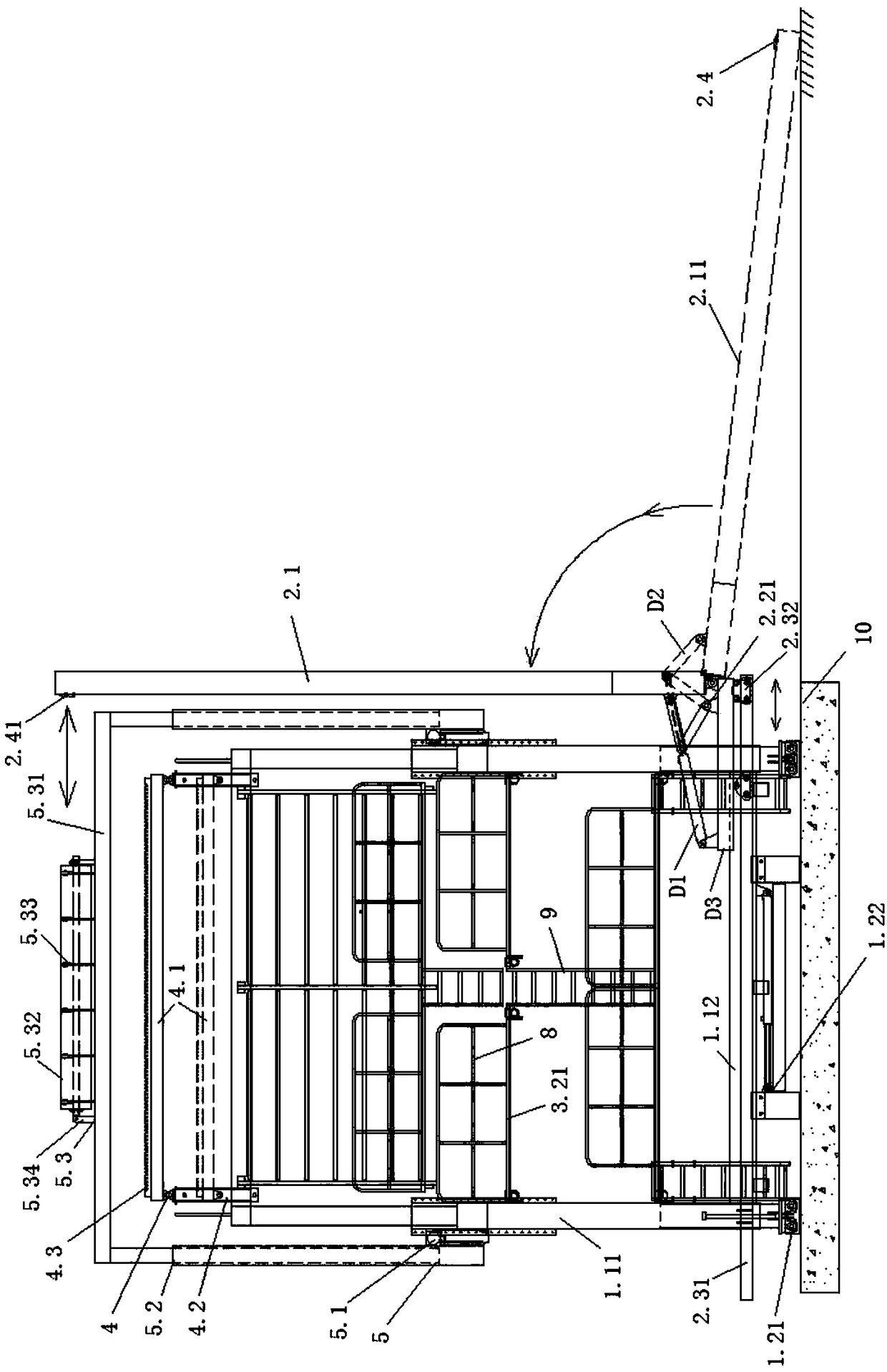

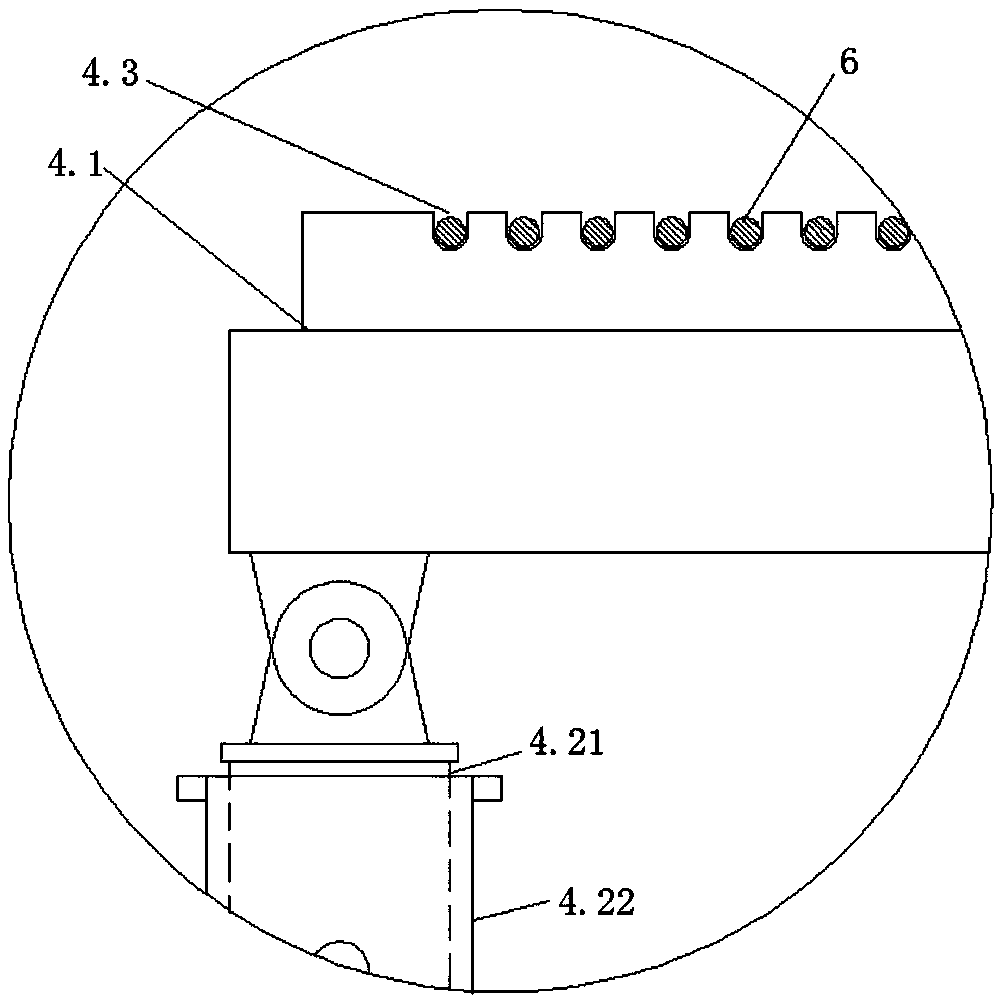

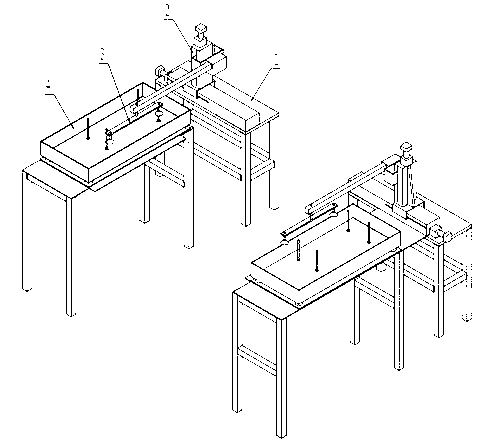

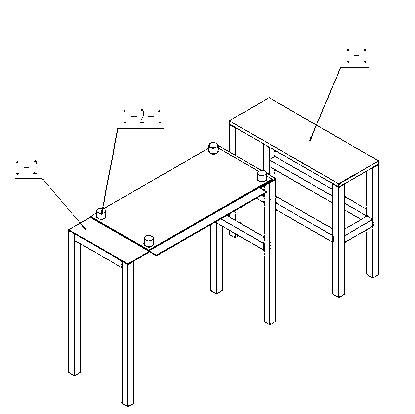

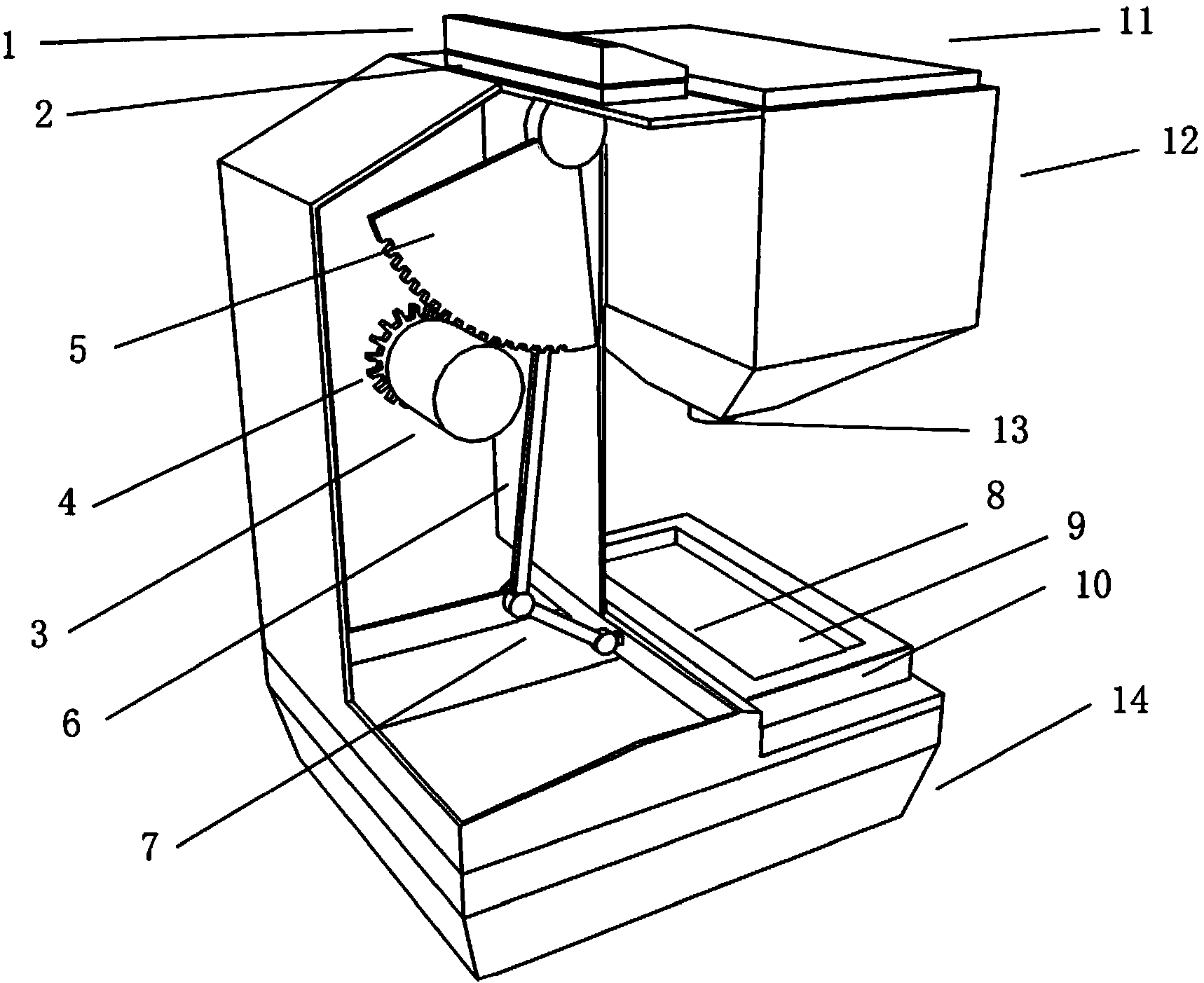

Multi-function trolley and construction method thereof

The invention provides a multi-function trolley. The multi-function trolley comprises a door frame system, a rebar feeding system and a work platform assembly. The rebar feeding system comprises a rebar containing arch frame, a rotating member, a horizontally-moving member and a rebar falling-proof assembly, the rebar containing arch frame comprises a group of arch frame single piece or at least two groups of arch frame single pieces arranged in parallel; and the rotating member comprises at least one group of rotating single piece, and each rotating single piece comprises a power source and arotating connecting piece. The horizontally-moving member comprises a driving source and horizontally-moving single pieces arranged with the rotating single pieces in a one-to-one correspondence mode. The rebar falling-proof assembly comprises at least one group of rebar falling-proof single piece arranged correspondingly with the arch frame single pieces. The work platform assembly comprises a top platform and a side direction platform group. The multi-function trolley can realize quick feeding of circumferential rebar. The invention further discloses a construction method for the multi-function trolley. The construction method comprises the following steps of circumferential rebar construction, longitudinal rebar construction and waterproof material construction, one machine with multiple purposes is realized, and the practicality is high.

Owner:HUNAN WUXIN TUNNEL INTELLIGENT EQUIP CO LTD

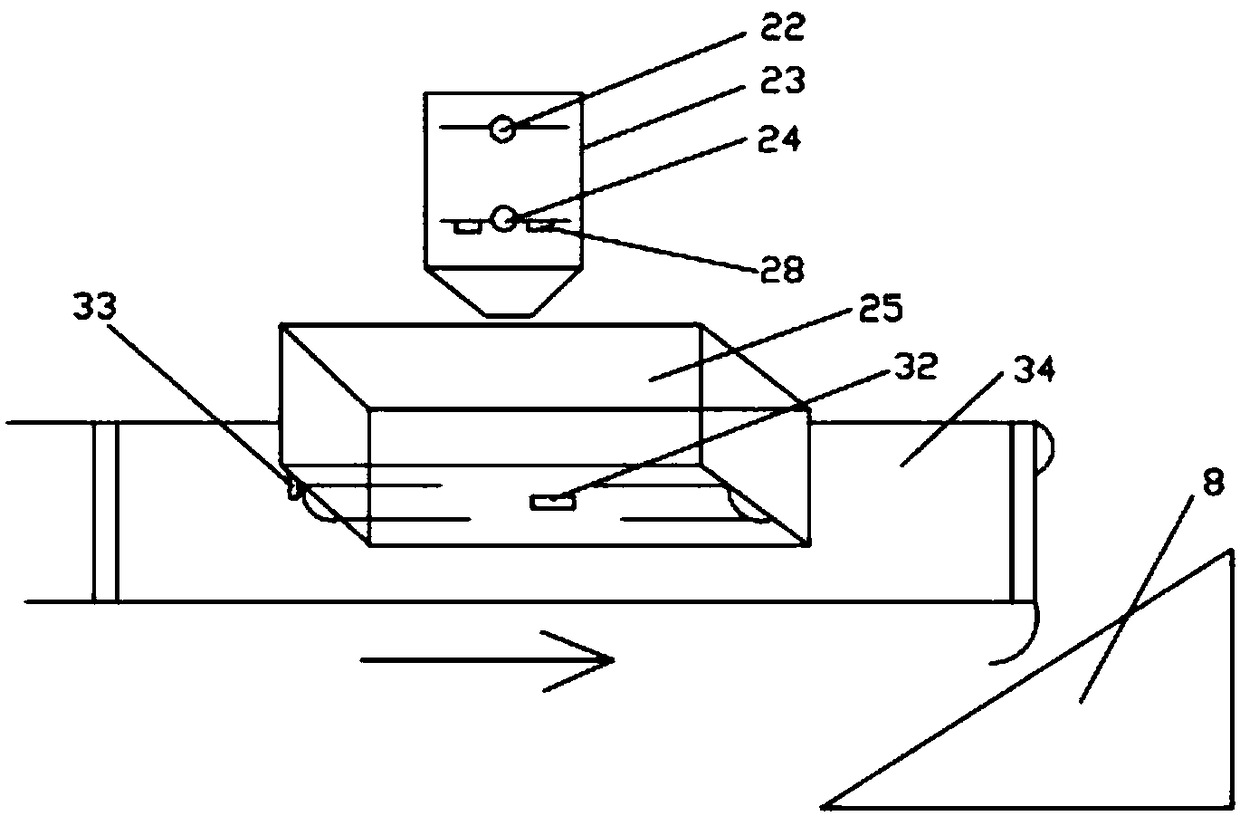

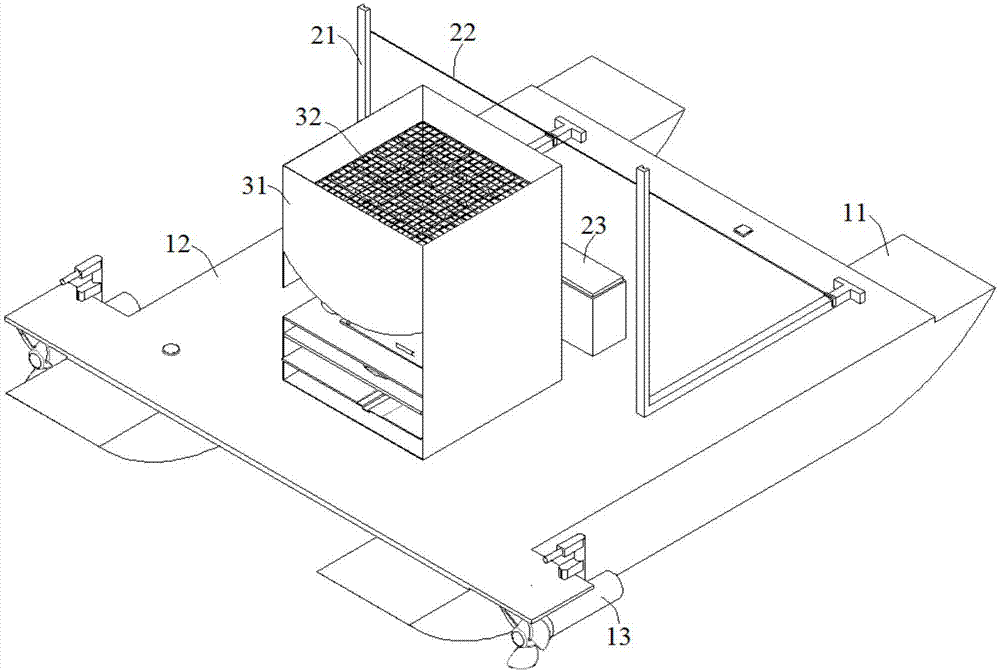

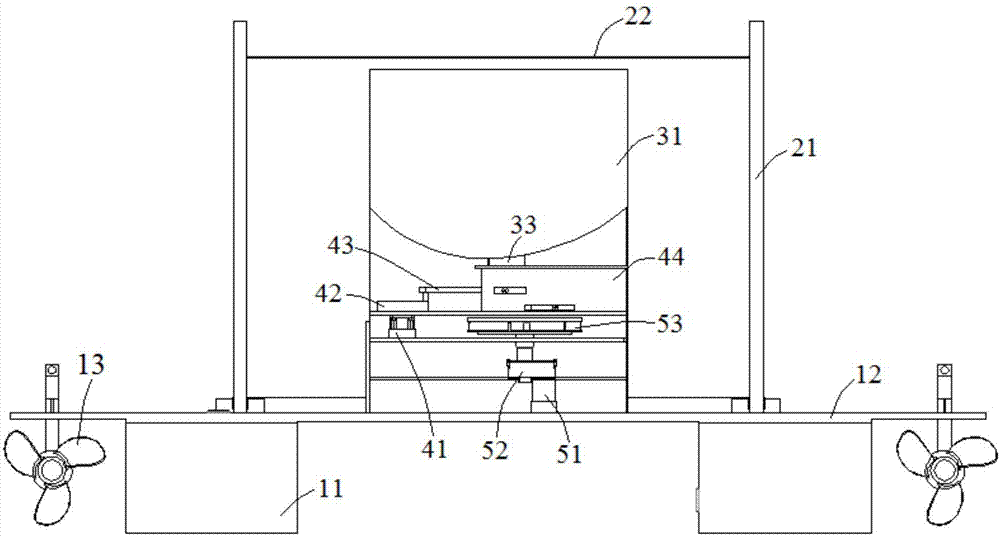

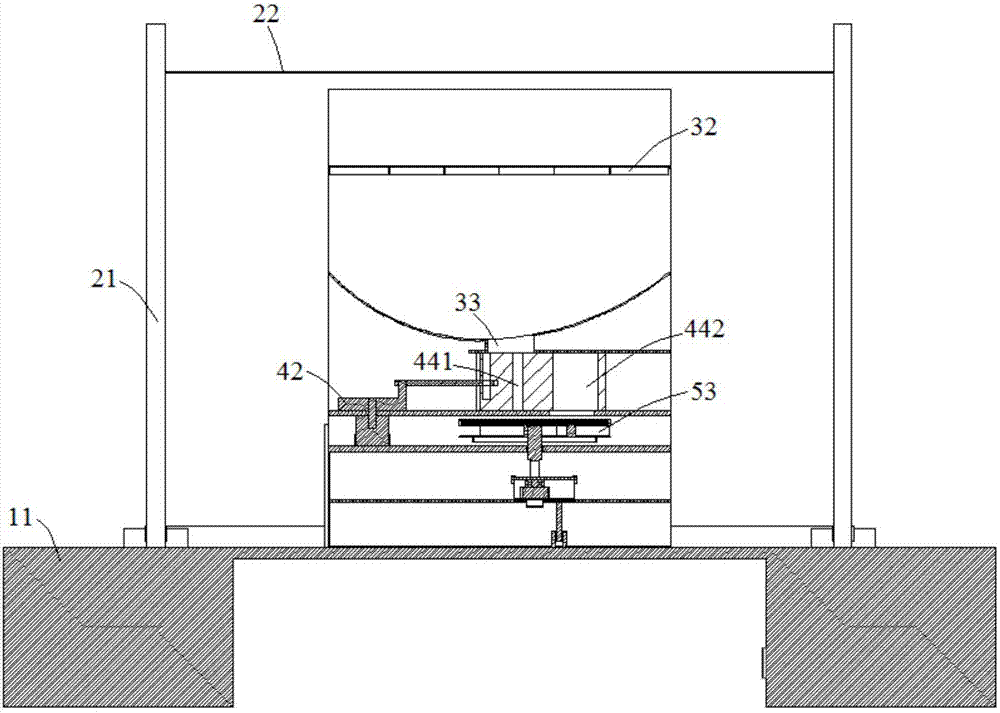

Water-surface automatic cruising-type solar bait casting boat and method

ActiveCN107980685AReduce lossMeet feeding needsWaterborne vesselsGas current separationAquatic productEngineering

The invention discloses a water-surface automatic cruising-type solar bait casting boat and a method, and belongs to the technical field of aquaculture equipment. The boat includes a boat body, a solar battery panel, a storage battery, a feeding device and a putting device, the solar panel is arranged on a supporting plate of the boat body and connected with the storage battery through a solar panel controller, and the storage battery supplies electric power to the boat body for cruising on the water surface and running of the feeding device and the putting device; the putting device is arranged below the feeding device, the feeding device stores baits and conveys the baits to the putting device, and the putting device scatters the baits. The boat solves the problems that traditional baitcasting equipment has difficulty in power supply and cannot move flexibly, achieves feeding at fixed positions, feeding in important areas and complete-coverage mode, can meet the demands of aquaculture farmers, and has high adaptability and movability.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Loading device of automatic spot welding device

ActiveCN103071906AAvoid scratchesEnsure consistencyResistance welding apparatusEngineeringSpot welding

A loading device of an automatic spot welding device is used for solving the automatic loading problem of a welding workpiece. The loading device comprises a left part and a right part, which are symmetrically distributed, wherein each part comprises a working rack, a drive mechanism, an actuation mechanism and a material frame, the working rack consists of a first working rack and a second working rack, the drive mechanism is installed on the first working rack, the material frame is installed on the second working rack, and the actuation mechanism is assembled with the drive mechanism. The loading device has the characteristics of strong practicability, stability in performance, safety and reliability, can greatly alleviate the labor intensity of operators, remarkably improve the working efficiency, meet the welding production requirement and improve the welding production capacity of enterprises.

Owner:长城汽车股份有限公司平湖分公司

Barbus capito fry feed

InactiveCN101926420AMeet feeding needsSolve problems in productionFood processingClimate change adaptationCapitoMortality rate

The invention discloses a Barbus capito fry feed relating to a fish feed. The invention solves the problems of high breeding cost of Barbus capito fry fed by other fish feeds, slow Barbus capito fry weight increment and high death rate. The Barbus capito fry feed is composed of wheat short, bean pulp, fish meal, Subaokang, food meal, cottonseed meal, corn albumen powder, soybean oil, fish oil, multi-vitamin for fishes, composite trace element, choline, MgSO4.7H2O, Yiduo enzyme P8901 and sodium carboxymethylcellulose. The Barbus capito fry feed of the invention has low cost, satisfies the requirement on feeding Barbus capito fry feed, solves the problem existing in Barbus capito fry feed production, avoids the problems of high cost of other fish feeds, slow weight increment and high death rate, improves the growth speed and survival rate of the Barbus capito fry and accelerates the healthy growth of the Barbus capito fry.

Owner:HEILONGJIANG RIVER FISHERY RES INST CHINESE ACADEMY OF FISHERIES SCI

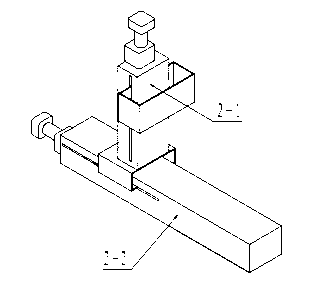

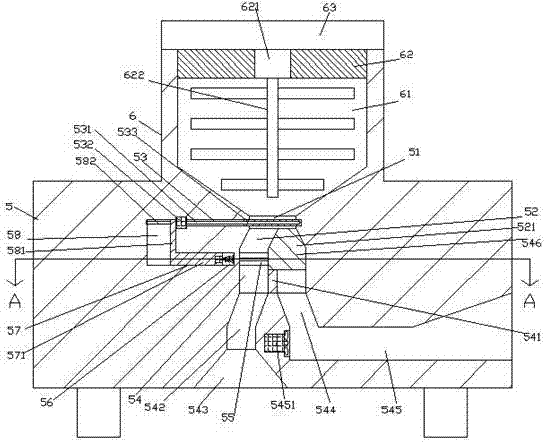

Feedstuff feeding device

ActiveCN107318681AMeet the working needs of feedingImprove work efficiencyAnimal feeding devicesEngineeringFodder

The invention discloses a feedstuff feeding device, comprising a base and a storage tank mounted at the top of the base; a mixing cavity extended down is arranged in the storage tank, the bottom of the mixing cavity is extended into the base, the tail of the of the bottom of the mixing cavity within the base is provided with a discharge port having its top communicated with the mixing cavity, a slide-conveying cavity extended side to side is arranged in the discharge port in through manner, an open operating device is arranged in the slide-conveying cavity, a chamber is arranged in the bottom of the discharge port in a communicated manner, a partition cavity is arranged in the bottom of the chamber in communicated manner, the midpoint of the inside of the bottom of the partition cavity is provided with a partition wallboard fixedly connected to the front and rear inner walls of the partition cavity, the top of the partition wallboard within the partition cavity is in slide-conveying fit connection with a slide-conveying block, and the top of the slide-conveying block is fixedly provided with a conical block in slide-conveying fit connection manner. The feedstuff feeding device is simple in structure and convenient to operate, feedstuff feeding efficiency is improved, feedstuff feeding effect is good, labor intensity is reduced, it takes less time and labor to use, and the requirement for feeding with various feedstuffs can be met.

Owner:蒙城县京徽蒙农业科技发展有限公司

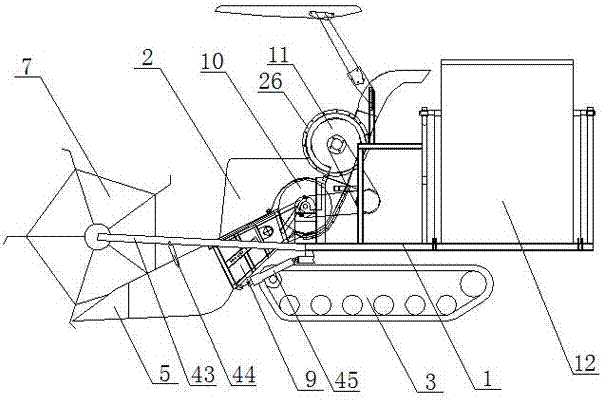

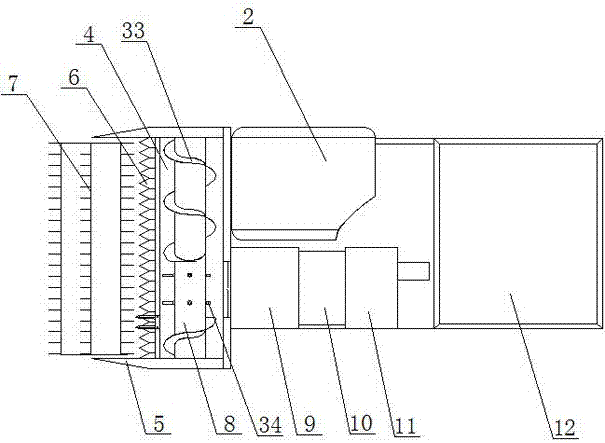

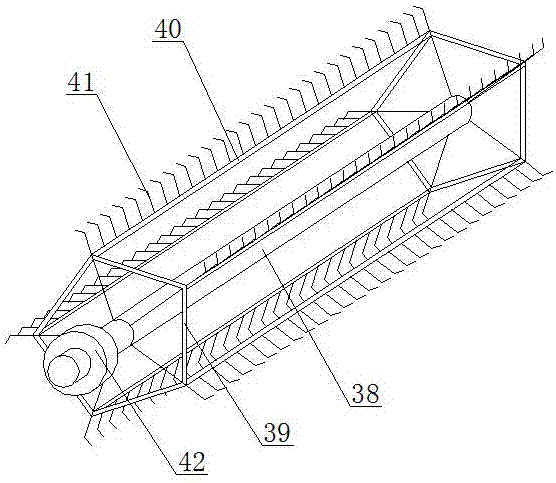

Multifunctional pasture harvester

PendingCN107223400AReduce labor intensityIncrease nutritionMowersAgricultural scienceAgricultural engineering

The invention discloses a multifunctional pasture harvester which is mainly composed of a rack, a driving cab, a hydraulic system, an engine assembly, a track chassis, a header, dividers, a reciprocating cutter, a reel, a helical conveyor, a pasture elevator, a cutting device, a rubbing and throwing device and a pasture storing box. The dividers on two sides of the header separate pasture in a harvesting area from that in other areas, posture entering the harvesting area is supported by the reel to be cut off by the reciprocating cutter at the front end of the header, then conveyed into the pasture elevator by the helical conveyor and conveyed into the cutting device to be cut off, and cut pasture enters the rubbing and throwing device for rubbing and is then thrown into the pasture storing box after being rubbed. The multifunctional pasture harvester can realize whole-process continuous efficient operation of cutting, conveying, cutting, rubbing, throwing and boxing of pasture like sorghum, oat and alfalfa and is high in automation level, time-saving, labor-saving and high in production efficiency, and produced feed is high in palatability and high in nutrient and quality.

Owner:甘肃华岭农业科技开发有限责任公司

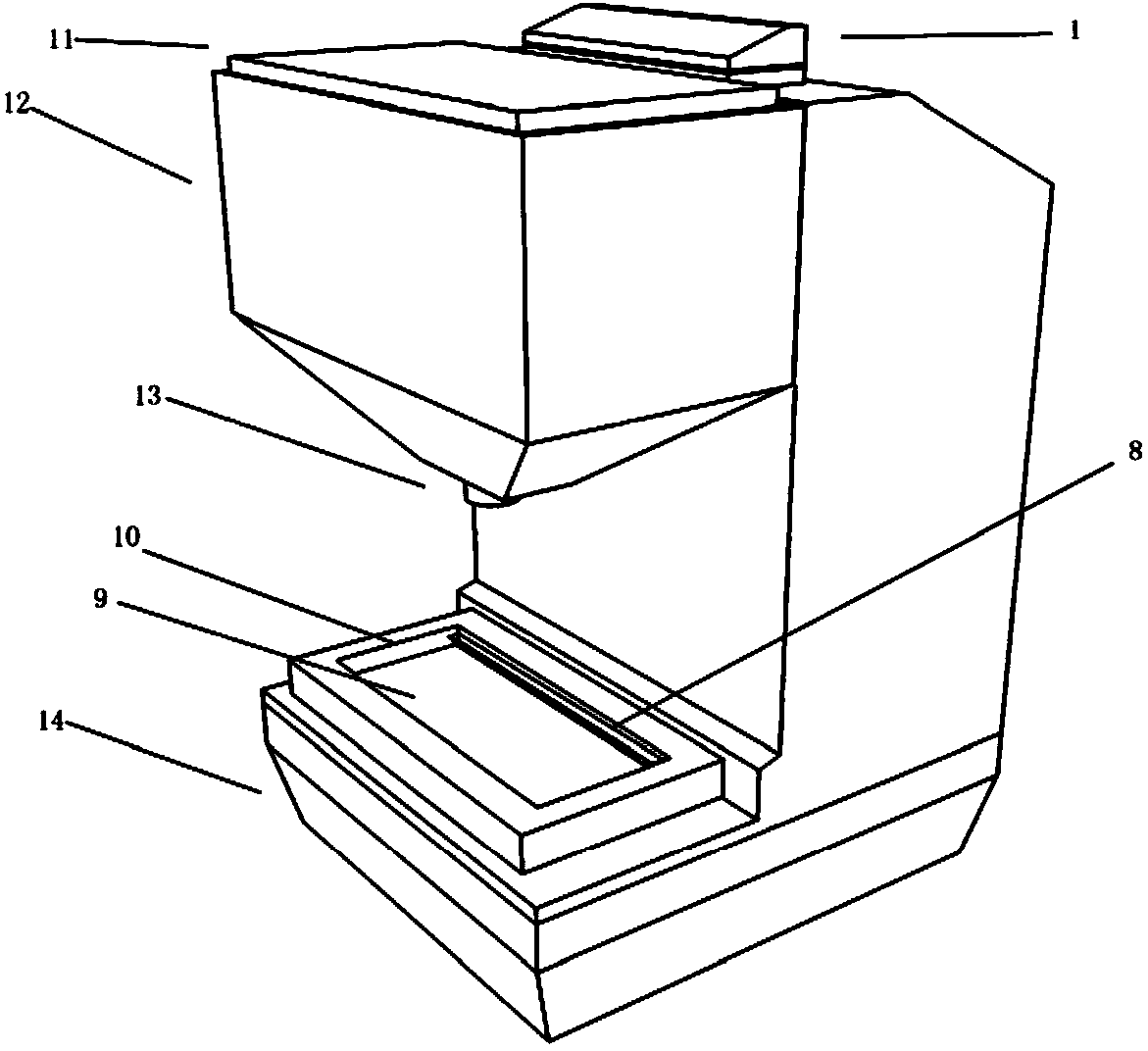

Automatic welding equipment for plastic barrel cover and oil nozzle

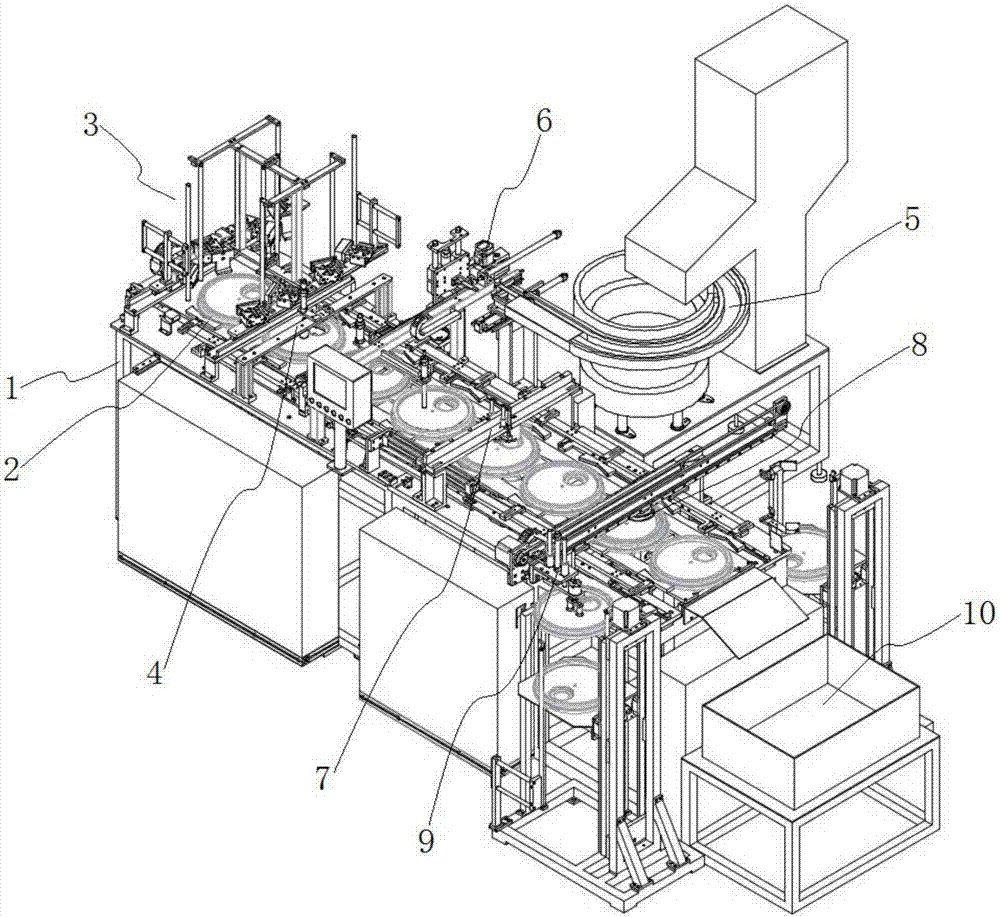

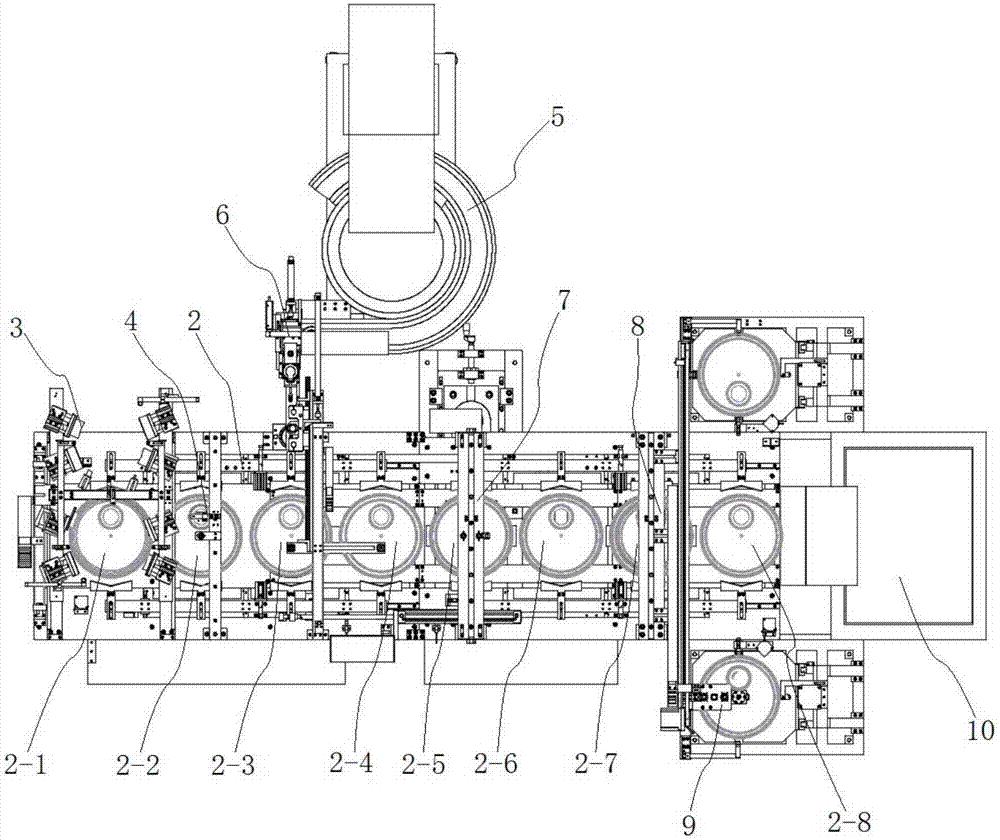

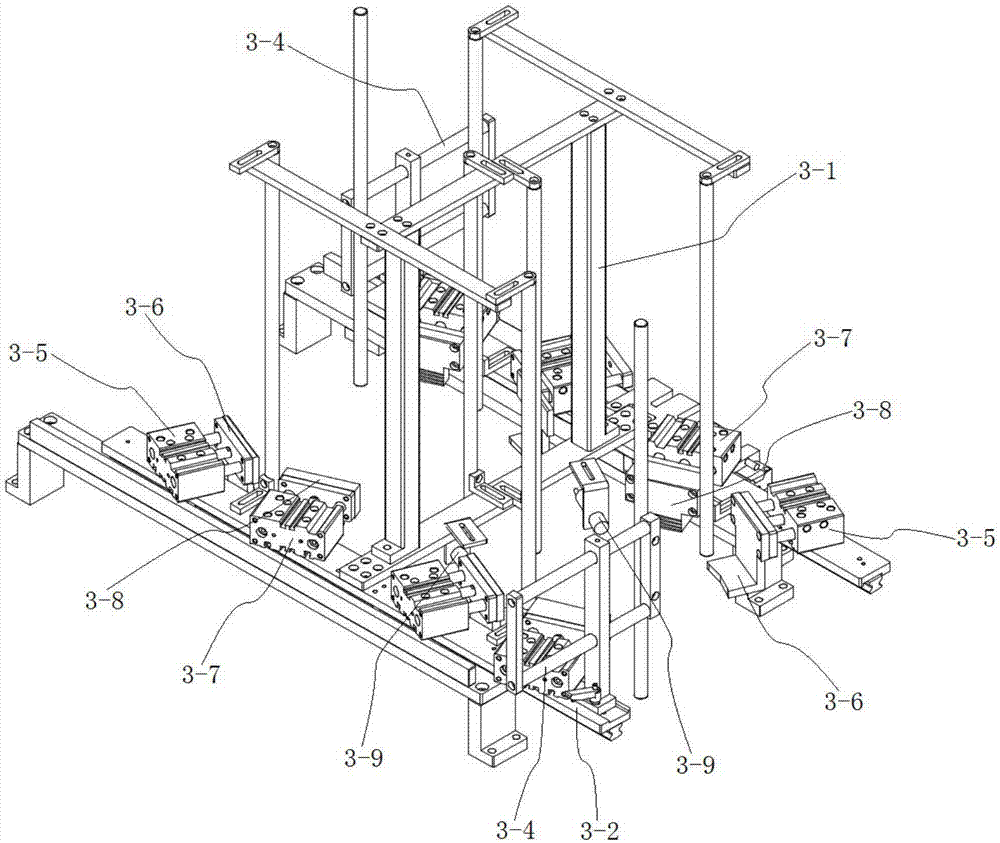

ActiveCN107139488ARealize continuous automatic welding productionCompact structureStacking articlesDe-stacking articlesUltrasonic weldingStructural engineering

The invention discloses automatic welding equipment for a plastic barrel cover and an oil nozzle and belongs to the field of automatic equipment. The automatic welding equipment disclosed by the invention comprises a frame and a barrel cover clamping and conveying device; a barrel cover feeding station, a barrel cover positioning station, an oil nozzle mounting station, a welding station, a detecting station and a discharging station are arranged in sequence on the barrel cover clamping and conveying device and along a rectilinear direction; a barrel cover feeding device is arranged at the barrel cover feeding station; a barrel cover rotary positioning device is arranged at the barrel cover positioning station; an oil nozzle positioning and mounting device is arranged at the oil nozzle mounting station; an ultrasonic welding device is arranged at the welding station; an air tightness detecting device is arranged at the detecting station; and a discharged material stacking device and an inferior-quality product recycling device are arranged at the discharging station. The automatic welding equipment disclosed by the invention can sequentially automatically accomplish the work of barrel cover feeding, barrel cover positioning, oil nozzle positioning and mounting, welding, air tightness detection and discharged material stacking, and is simple and compact in structure, stable and reliable in operation, flexible and convenient to control, high in production efficiency and good in welding quality.

Owner:CHANGZHOU CENTRWAY PLASTICS

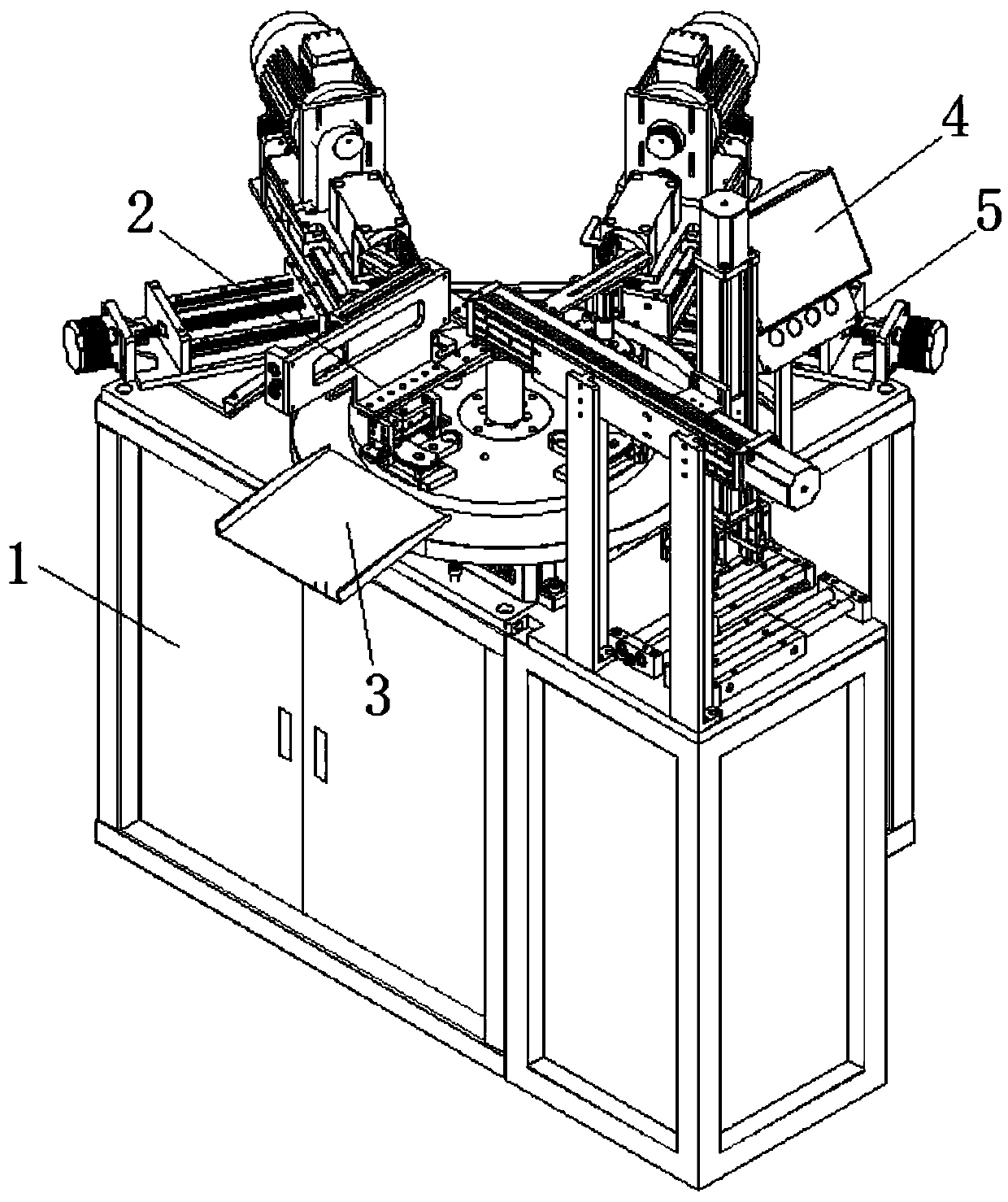

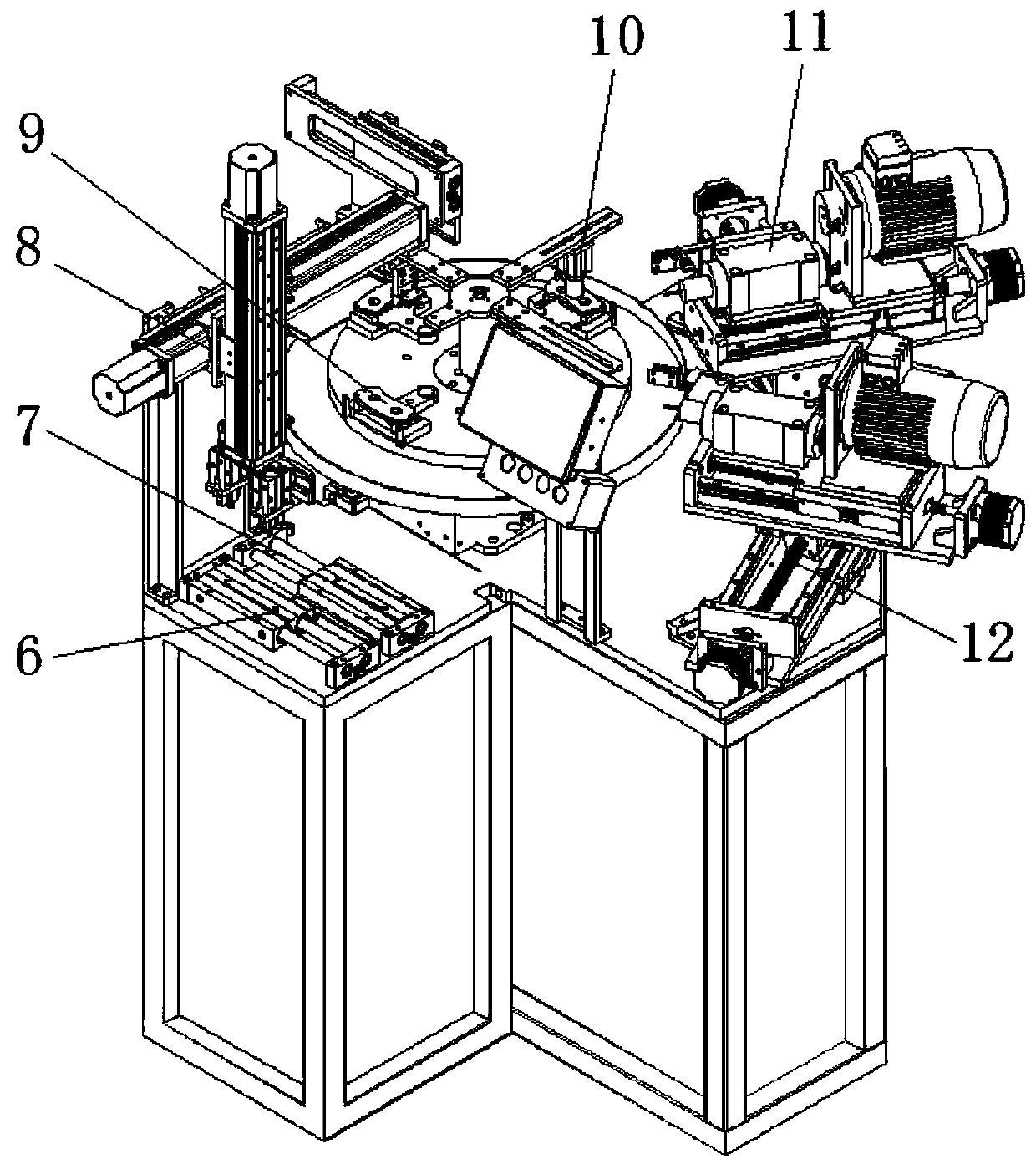

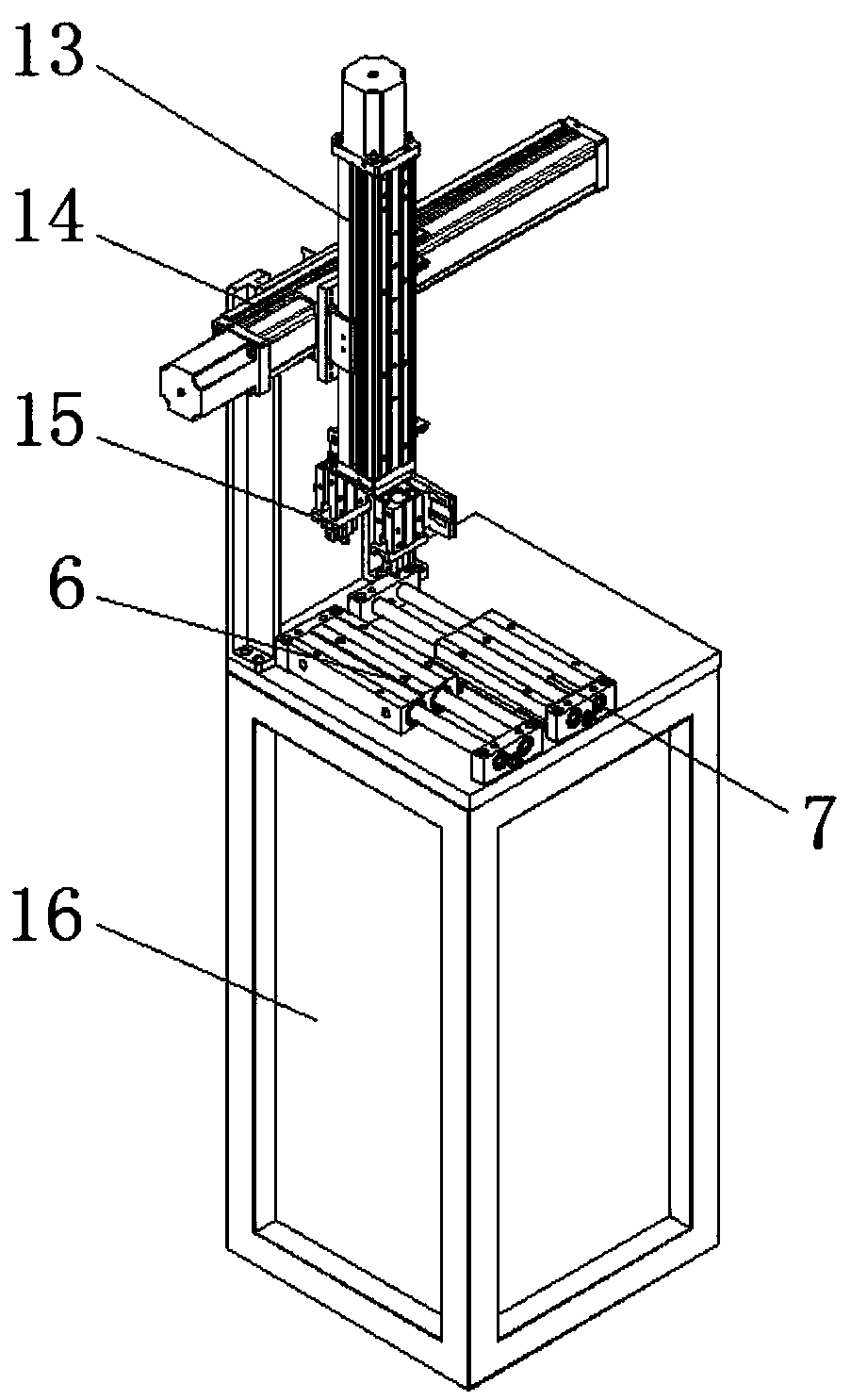

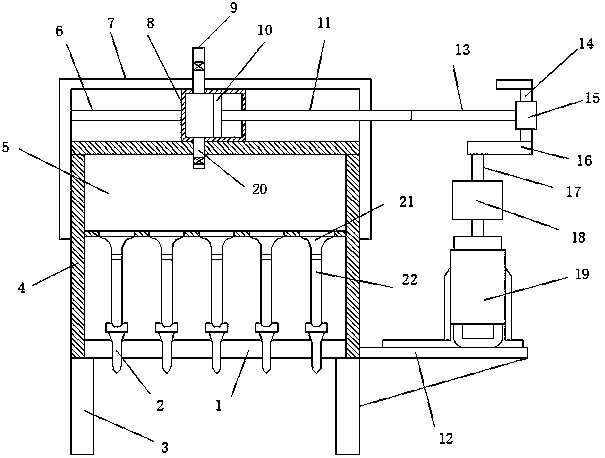

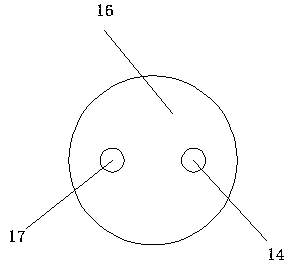

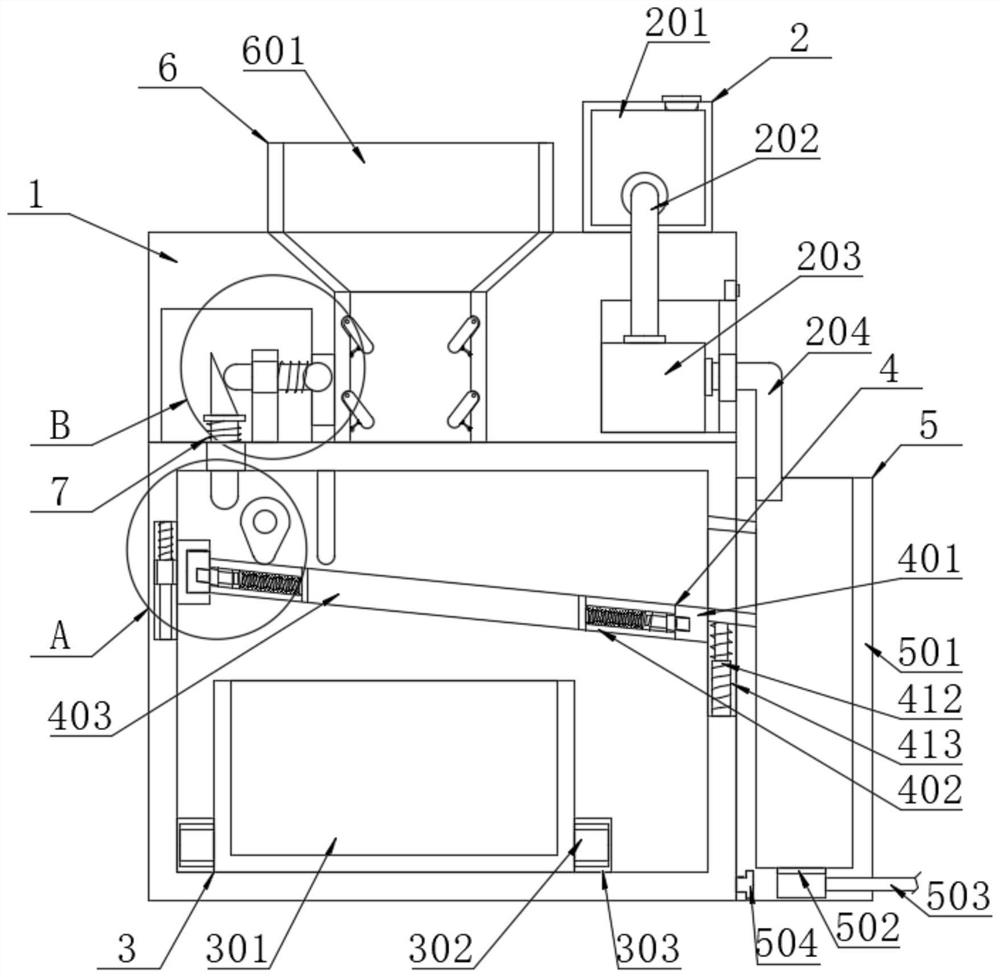

Friction plate steel backing full-automatic drilling machine

InactiveCN109551002AReasonable structural designShorten the processing cycleLarge fixed membersMetal working apparatusHuman–machine interfaceEngineering

The invention discloses a friction plate steel backing full-automatic drilling machine. The friction plate steel backing full-automatic drilling machine comprises a machine frame, an automatic discharging device, a trough, a human-computer interface controller, a system supporting frame, a first tray assembly, a second tray assembly, an automatic feeding device, a multi-station rotation disc device, product pressing blocks, drilling power devices, an angle adjusting device and a sliding table Z shaft. The friction plate steel backing full-automatic drilling machine is a horizontal multi-station drilling machine, a multi-station rotation disc system is adopted so that feeding, drilling machining and discharging can be conducted at the same time, the structural design is more reasonable, small-size friction plate steel backings and small-included-angle friction plate steel backings can be machined, in addition, a friction plate steel backing of which the two holes are parallel is machined, the two holes are machined at the same time, mutual noninterference is achieved, the machining cycle is shortened, and the production efficiency is greatly improved from 25s / pcs to smaller than orequal to 10s / pcs; and through the scheme, the product automatic feeding function is achieved, the labor intensity of workers is greatly relieved, and the equipment automation degree is improved.

Owner:杭州众享机械技术有限公司

Automatic pet feeding machine

InactiveCN103461161AMeet feeding needsAnimal feeding devicesAvicultureIntelligent control systemControl parameters

The invention belongs to animal feeding devices and provides an automatic pet feeding machine which is intelligently controlled by adopting a PLC (Programmable Logic Controller) circuit. According to the automatic pet feeding machine, a PLC intelligent control system is used, control parameters are input through a control panel so as to set feeding starting time, feeding ending time and a feeding quantity, and finally, a PLC controller drives a stepping motor and a feed box valve to complete the actions of feeding and cleaning according to settings, so that the needs of pet feeding during business trip or long-term leaving are met; a motor is driven to rotate through a PLC driver so as to clean a feed box, and thus, diseases cannot be caused due to excessive food accumulation or pollution while a pet can obtain food of a set quantity; the feeding and residual food residue removal can be carried out in a timed manner according to user or system settings.

Owner:张覃婧

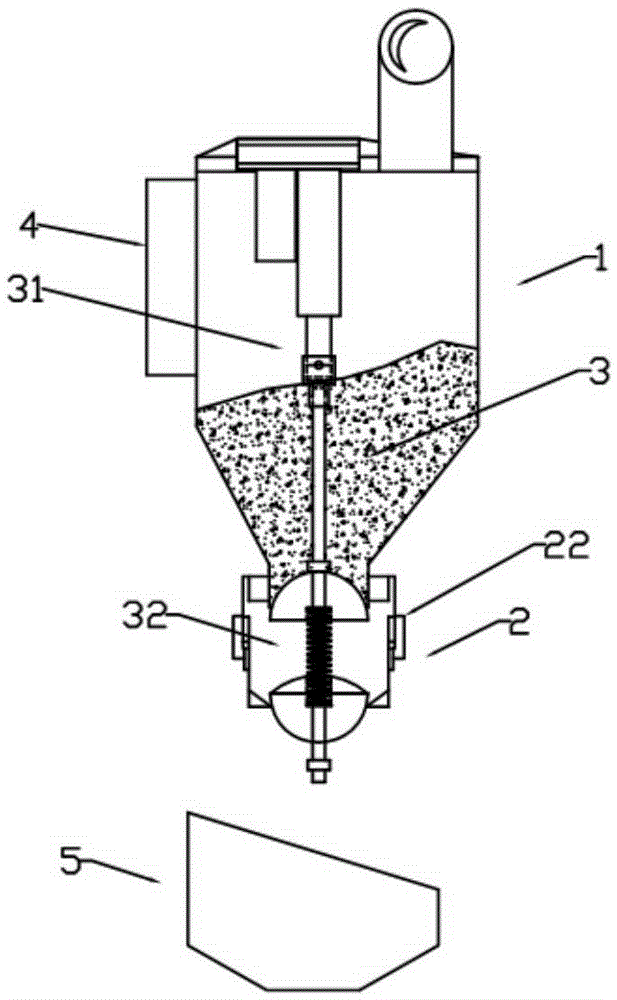

Cub feeding device for animal husbandry

InactiveCN107912323AReasonable structureInnovative designAnimal feeding devicesReduction driveEngineering

The invention discloses a baby feeding device for animal husbandry, which comprises a support plate, a fixing plate is installed on the right side of the support plate, a driving motor is installed on the upper end of the fixing plate, a speed reducer is connected to the upper end of the drive motor, and a speed reduction shaft is connected to the upper end of the speed reducer , An eccentric wheel is installed at the upper end of the reduction shaft, an eccentric column is installed at the upper end of the eccentric wheel, a sliding sleeve is installed in the middle of the eccentric column, a moving rod is installed at the left end of the sliding sleeve, a piston rod is hinged at the left end of the moving rod, and a piston plate is installed at the left end of the piston rod. A milk tank is installed on the outer side of the plate, and a support frame is installed on both sides of the upper end of the support plate. The top of the support frame is provided with a milk output box. A pacifier is connected to the lower end of the milk tube. The present invention realizes the replenishment of the milk in the milking box, and then meets the feeding needs of multiple cubs.

Owner:陈守谦

Springtime high-yield freshwater shrimp breeding method

ActiveCN105941232AImprove qualityGuaranteed qualityFood processingClimate change adaptationWater sourceFishing

The invention discloses a springtime high-yield freshwater shrimp breeding method. The springtime high-yield freshwater shrimp breeding method comprises the steps that a pond free of silt at the bottom is selected, pond water is complete pumped out in the first ten-day period of January, then the pond is exposed to the sun, and quick lime is evenly scattered at the bottom of the pond; after water injection is performed in first ten-day period of February, hydrilla verticillata is sowed and planted at the bottom of the pond, water injection is performed, then alternanthera philoxeroides are planted in a shallow water zone of the pond, and water injection is performed; a summer flower net is arranged in the middle of the pond; shrimp larvae are put in the pond in the early morning of fine days in the first ten-day period of March for a period of time, and then silver carps are put in the pond; after putting, a fine-grain feed is put for one time in the morning and afternoon every day; fishing is performed the last ten-day period of May, water at the bottom of the pond is pumped for one every week to make the water level in the pond lowered, then fresh water is supplemented to reach the previous water level before water pumping, and meanwhile air is pumped into the pond; fishing is performed in the afternoons of cloudy days after a period of time after putting.

Owner:周玉春

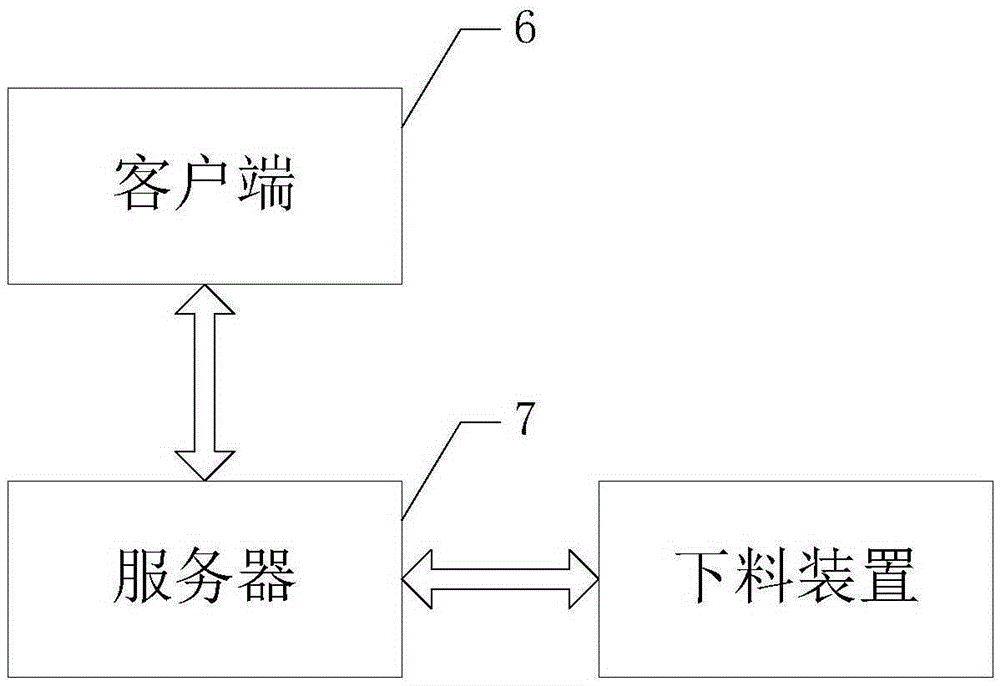

Precise feeding system for nursing sow

ActiveCN105325310AMeet feeding needsImprove feeding accuracyAnimal feeding devicesClient-sideWeaning weight

The invention discloses a precise feeding system for a nursing sow. The precise feeding system comprises a client side, a server and a feeding device, wherein the client side is used for receiving feeding information which comprises feeding times, feeding time and feeding amount, and is also used for sending the feeding information to the server; the server is used for receiving and storing the feeding information and controlling the feeding device to feed according to the feeding information. According to the precise feeding system for the nursing sow provided by the invention, feed of predetermined volume can be released according to preset time points, the feed needs of the nursing sow can be met, and the feeding accurate level and the feeding efficiency can be improved, so that the nutritional status of the nursing sow is improved, the weaning weight and the survival rate of weaned piglets are improved, and the uniformity of the piglets is ensured to reach an expected standard.

Owner:COFCO BEIJING FEED TECH

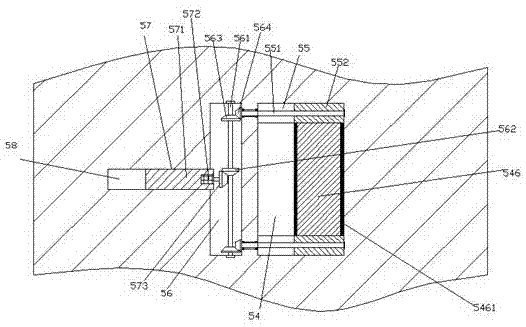

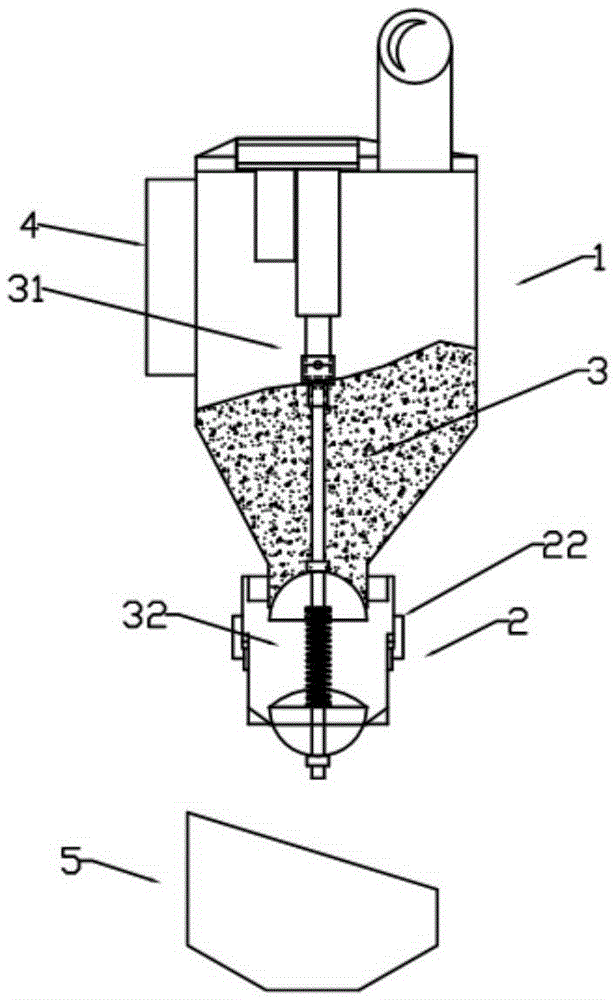

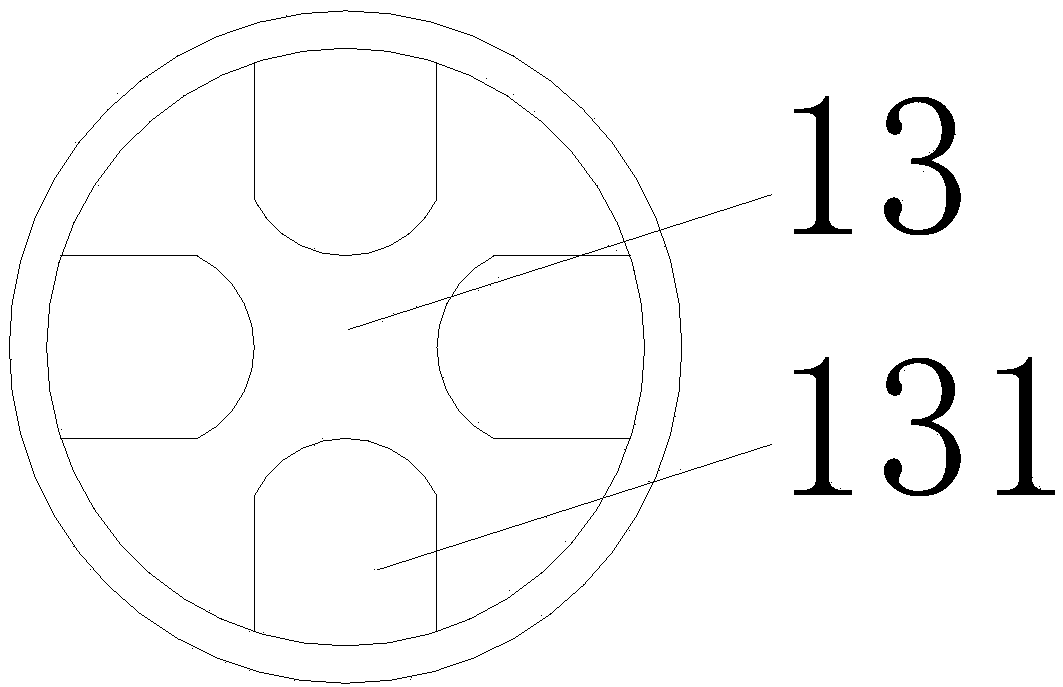

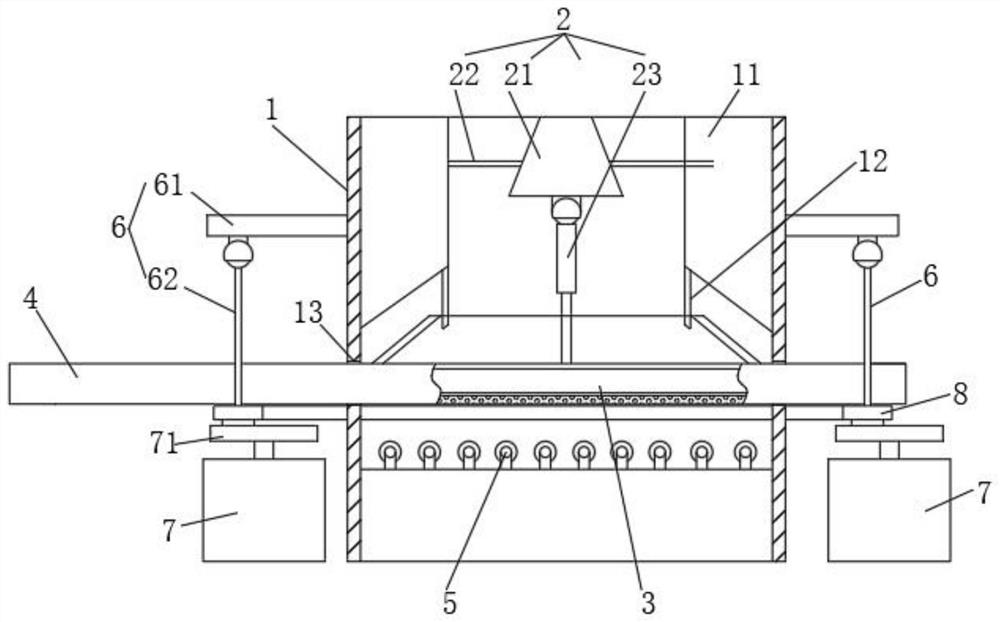

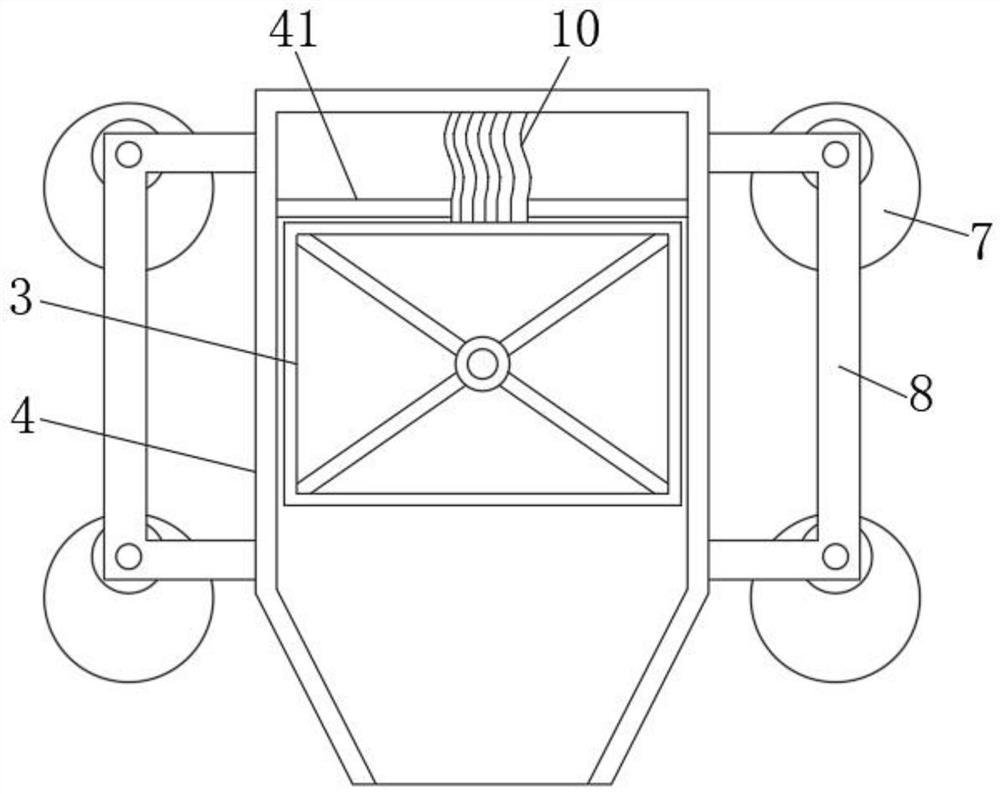

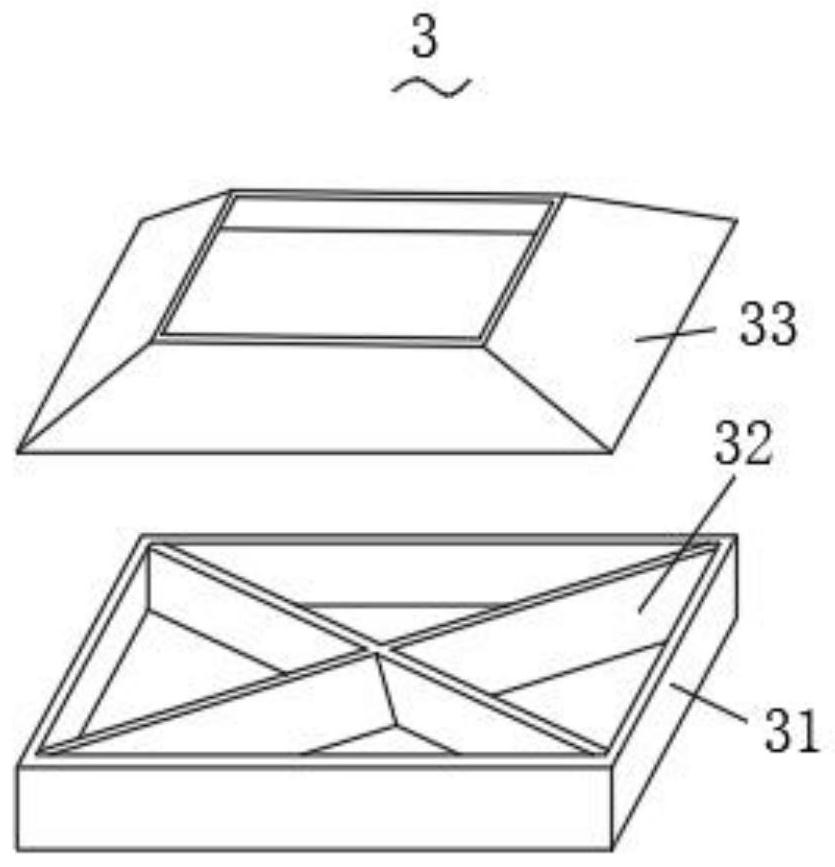

Rod pin type bifrustum-shaped sand mill device

ActiveCN107626395ACompact structureReasonable structureGrain treatmentsSurface mountingElectric machinery

The invention relates to a rod pin type bifrustum-shaped sand mill device. The rod pin type bifrustum-shaped sand mill device comprises a rack, wherein a motor is arranged on the upper surface of therack; the output end of the motor is connected with a spindle component through a driving component; one end of the spindle component is supported by a bearing base component; a sand mill barrel bodycomponent is arranged at the outer end of the bearing base component through a sealing device; a stirrer connected with the spindle component is arranged inside the sand mill barrel body; rollers arearranged on two sides of the sand mill barrel body component; a guide rail bracket for the rollers to run is arranged on the upper surface of the rack. The rod pin type bifrustum-shaped sand mill device disclosed by the invention has the advantages of compact and reasonable structure and convenience in operation; a barrel body with a conical structure is adopted, and the inner part of the barrel body is matched with the pin rod type stirrer for grinding materials, so that good milling effect and high working efficiency are realized.

Owner:WUXI HOPE LIGHT IND EQUIP TECH

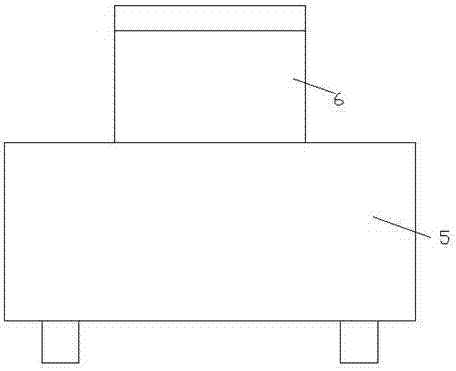

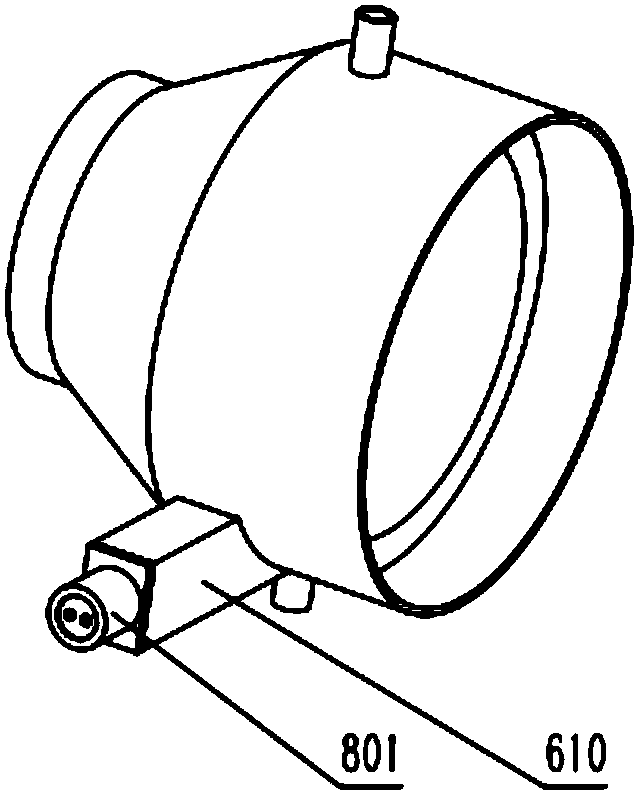

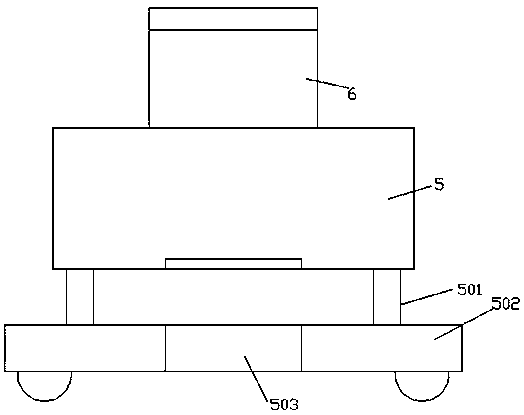

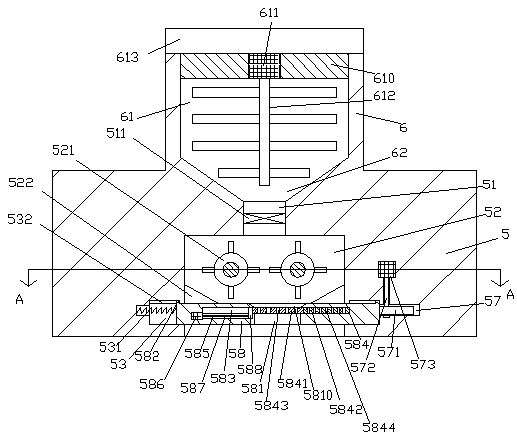

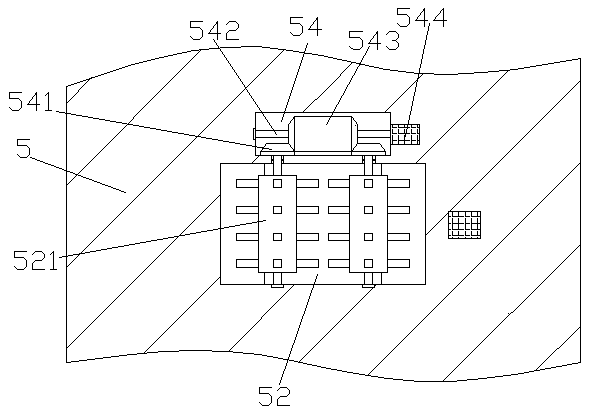

Feed feeding vehicle

InactiveCN109380132AContinuously manage left and right mobile workFall quicklyAnimal feeding devicesAvicultureConical cavityEngineering

The invention discloses a feed feeding vehicle, which comprises a feed feeding machine body and a mixing box arranged at the top of the feed feeding machine body, wherein a mixing cavity is formed inthe mixing box; a conical cavity which is formed in a downward extending way is formed at the bottom of the mixing cavity in a penetrating way; an extending part at the bottom of the conical cavity extends into the feed feeding machine body; a discharge port is formed at the tail part of the bottom of the conical cavity in a penetrating way; a discharge groove with the top part and the tail part of the bottom of the discharge port in a penetrating way is formed in the bottom surface of the feed feeding machine body; sliding conveying grooves are correspondingly formed in the inner walls of theleft side and the right side of the discharge groove; a guiding groove is formed on the top wall of each sliding conveying groove; a feed feeding device, which is communicated with the discharge groove and is in sliding fit connection, is arranged between the left side and the right side of the sliding conveying grooves; the tops of the tail parts of the left side and the right side of the feed feeding device in the left side and the right side of the sliding conveying grooves are respectively provided with guiding blocks which extend into the left side and the right side of the guiding groove and are in sliding fit connection; the feed feeding device has the advantages of simple in structure and convenient to operate, thereby automatically controlling different feed feeding amounts, andimproving the feed feeding working efficiency.

Owner:广西领测科技有限公司

Method for raising first instar crab fingerlings

InactiveCN102550456AImprove survival rateMeet feeding needsClimate change adaptationPisciculture and aquariaDiseaseSecondary stage

The invention discloses a method for raising first instar crab fingerlings, which is characterized by including a primary stage and a secondary stage. The method comprises the following steps: preparing in an early stage, raising crab larvae, transferring crab larvae out of culture boxes, raising crab larvae in open facilities, feeding baits, performing water quality management, and treating crab diseases. The method of the invention is advantageous in that the conditions are simple and feasible, superiority of the method is obvious, the technical scheme is reasonable, yield of crab fingerlings by culturing crab larvae is improved, and the method lays foundation for river carb industry structural regulation.

Owner:顾宏兵

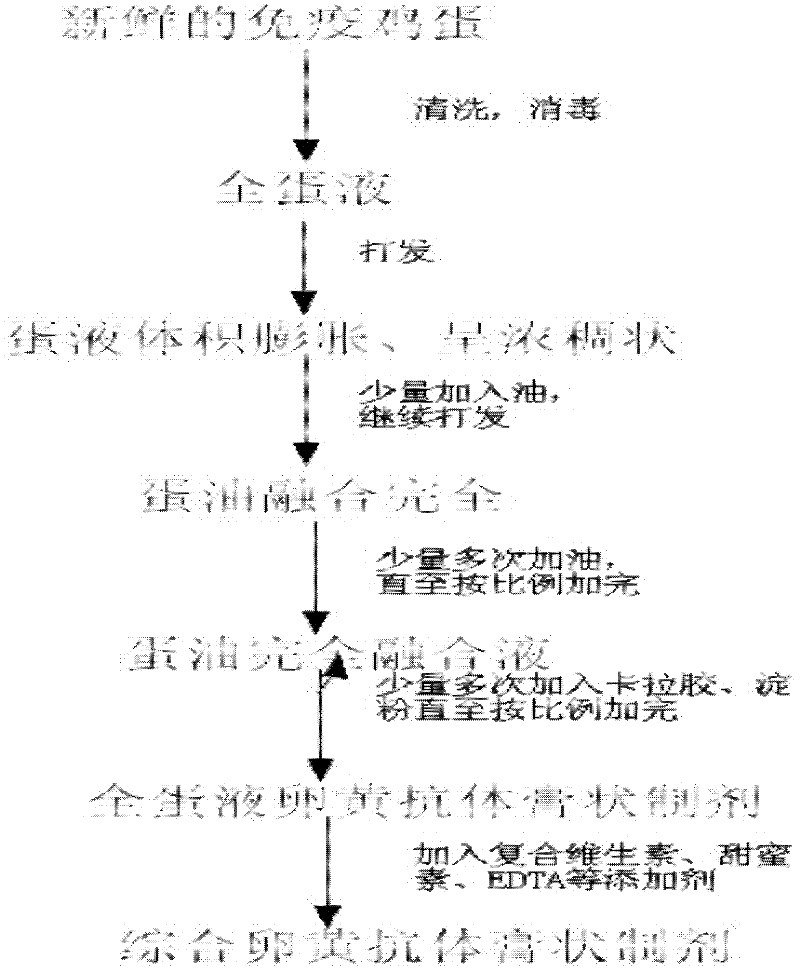

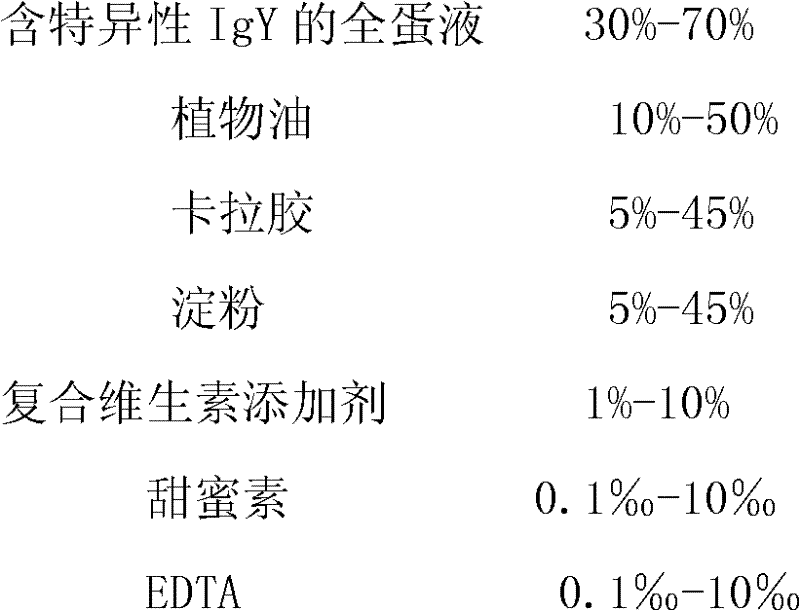

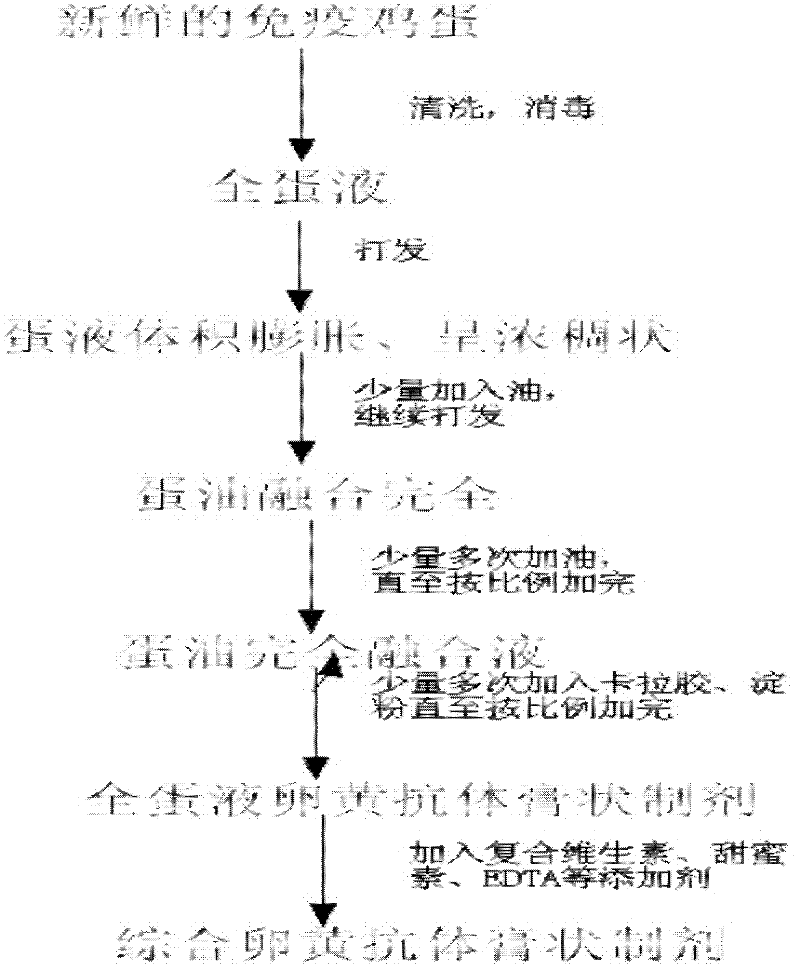

Animal dietotherapy IgY whole egg pulp paste preparation and its preparation method

ActiveCN102308914AReduce lossesEasy to feedAnimal feeding stuffAccessory food factorsDiseaseAnimal science

The invention relates to an animal dietotherapy IgY whole egg pulp paste preparation, which comprises the following ingredients by mass percentage: 30%-70% of egg liquid, 10%-50% of plant oil, 5%-45% of carragheenan, 5%-45% of starch, 1%-10% of composite vitamin additive, 0.01%-1% of sodium cyclamate and 0.01%-1% of EDTA. The paste preparation of the invention is suitable for directly feeding animal baby, is capable of preventing diarrhoea of animal baby or other immunization diseases and substantially raising the survival rate of the animal baby, simultaneously the paste dosage form enables a convenient and effective eating for animal babies which solves the problem of edible mode of animal baby. Further, the production technology of the invention can be simplified to a larger extent, the production cost can be substantially reduced, so that the paste preparation of the invention is suitable for large scale production.

Owner:DALIAN SEM BIOLOGICAL ENG TECH

Sandstone separator for construction machinery

ActiveCN112570257AEasy to separateReduce the difficulty of screeningSievingScreeningClassical mechanicsStructural engineering

The invention discloses a sandstone separator for construction machinery, and belongs to the technical field of sandstone separation. The sandstone separator comprises a box body, a liquid spraying mechanism is arranged on one side of the top of the box body, a screening mechanism is arranged in an inner cavity of the box body, a transmission mechanism is attached to one side of the screening mechanism, a storage mechanism is movably connected to the position, corresponding to the screening mechanism, of the other side of the inner cavity of the box body; discharging holes are formed between the box body and the screening mechanism and between the box body and the storage mechanism; a discharging mechanism is arranged at the bottom of the inner cavity of the box body; and a feeding mechanism is arranged at the top of the box body. According to the sandstone separator, when a screen plate vibrates through reciprocating extrusion of polarization blocks, the screen plate vibrates to enable silt in mortar to fall into a bottom sand box, and at the moment, the screened-out sandstone can move through the inclined screen plate to fall into the discharging holes on one side and a stone boxon one side, so that the sandstone can be quickly separated, and then the screening difficulty can be reduced; and the screening efficiency is remarkably improved through reciprocating vibration, andthe discharging difficulty is effectively reduced.

Owner:浙江绩丰机械有限公司

Method for preparing integral small-diameter aquatic hard-particle feed

InactiveCN101103778ASmall size differenceRegular shapeAnimal feeding stuffWorking-up animal fodderNutrientWater quality

The invention discloses a production method for a complete minor diameter hard particle aquatic feed, which comprises the following steps: 1. the raw materials is mixed and crushed into 0.02 to 0.30mm in proportion; 2. the flour with a weight content of 18% to 30 percent is added into the mixed powder lot; 3. a steam softening materials is added into the mixed powder lot so as to make the weight content of moisture reach 12 percent to 18 percent, thereby the moist heat materials is formed; 4. a die mold with the ratio between the depth and the diameter of die hole of 20:1-28:1 is adopted; 5.the moist heat materials is delivered into a forming machine to produce the particles with a diameter of 0.8 to 1.2 mm; 6. after the heat preservation for 20 to 50 min, the particles are cooled to 28 DEG C to 40 DEG C by cold wind; 7. the crushed grain and powder of cooling particle feed are filtered by a grading screen; 8. the complete minor diameter hard particle aquatic feed is packed and stored. The minor diameter hard particle aquatic feed which is made by the method of the invention has the advantages that: the utilization rate is high; the need of feed of the fish and shrimp larvae can be met, and the waste of feed can be reduced; furthermore, the pollution of the quality of the cultivation is reduced, and the balance of nutriment for the fish and shrimp larvae is improved.

Owner:何金林 +1

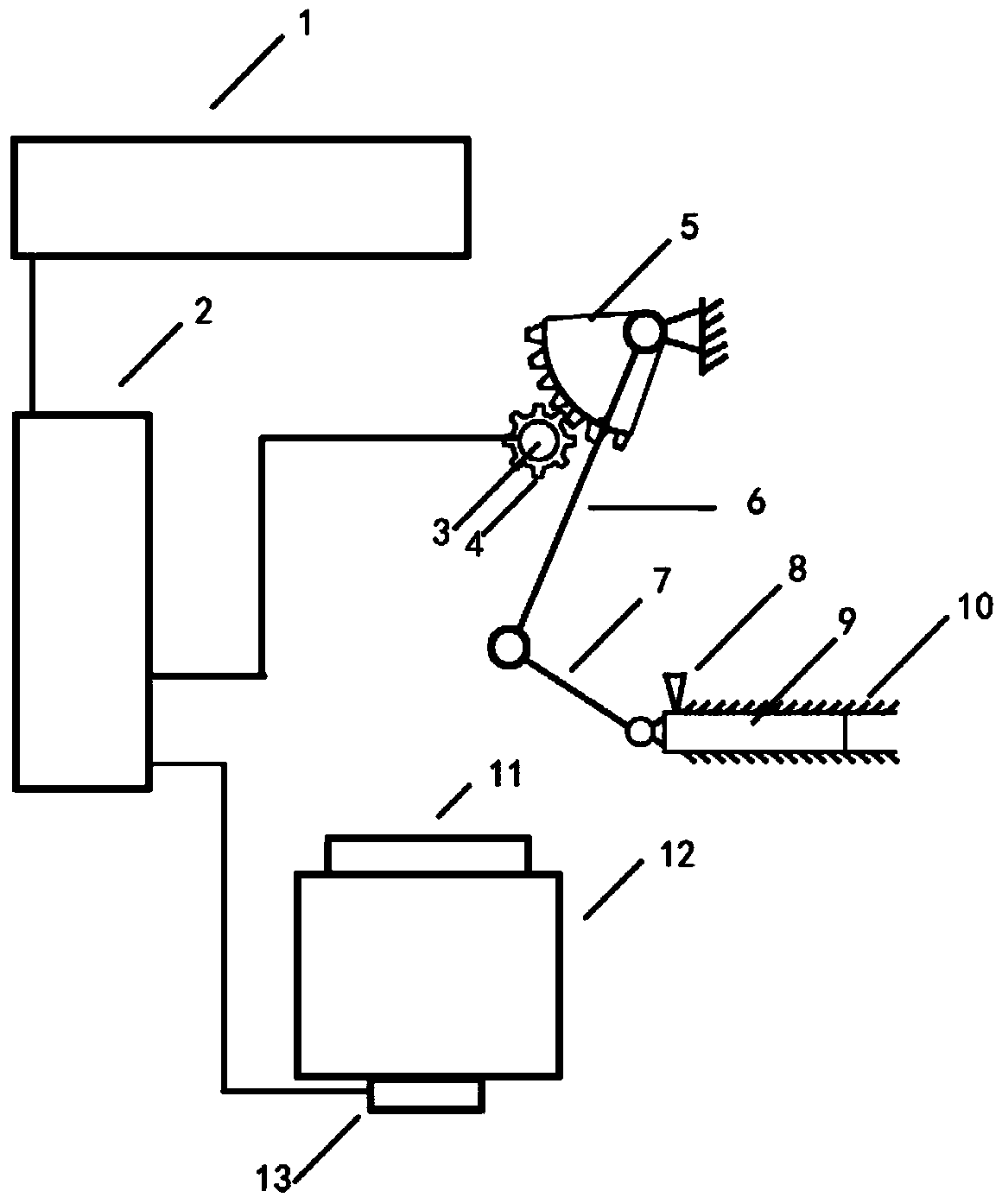

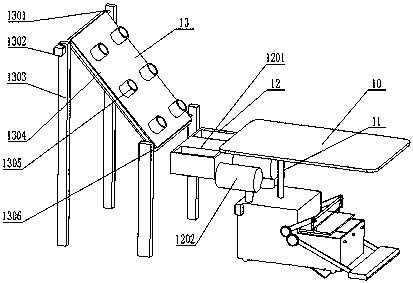

Automatic art frame stretching machine

ActiveCN111361345AImprove processing efficiencySave human effortSpecial ornamental structuresStructural engineeringMechanical engineering

The invention relates to frame stretching machines, in particular to an automatic art frame stretching machine. The machine comprises a canvas feeding frame. The canvas feeding frame is rotationally connected with a canvas feeding rotary shaft through a bearing. A frame feeding frame is arranged at a discharging end of the canvas feeding frame. A nailing frame is arranged at the discharging end ofthe canvas feeding frame. A traction base plate is arranged in the center of the nailing frame in the width direction. An upper end face of the traction base plate is connected with a clamping assembly. Two ends of a toothed synchronous belt are connected to the upper end face of the traction base plate by the clamping assembly in a tight pressing manner. A lower end face of the traction base plate is fixedly connected with a traction support. The traction support is connected with the middle of a traction shaft in a holding manner. Two ends of the traction shaft are connected with linear bearings respectively. The linear bearings are detachably connected with a canvas stretching frame through connecting pieces. The lower part of the canvas stretching frame is connected with a canvas pressing assembly. The automatic art frame stretching machine can automatically complete several steps of processing of art frames including canvas and frame conveying, canvas stretching on the frames, nailing and canvas cutting, the processing efficiency is greatly improved, and manpower is saved.

Owner:无锡市云帆工业控制有限公司

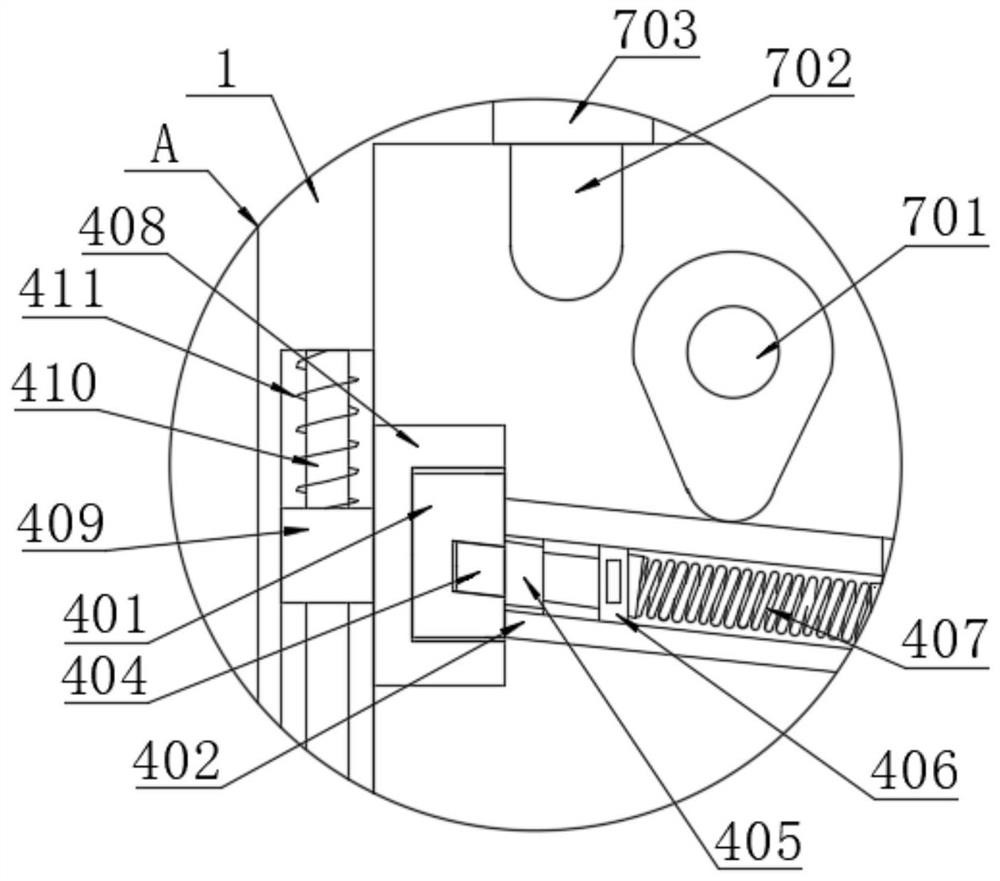

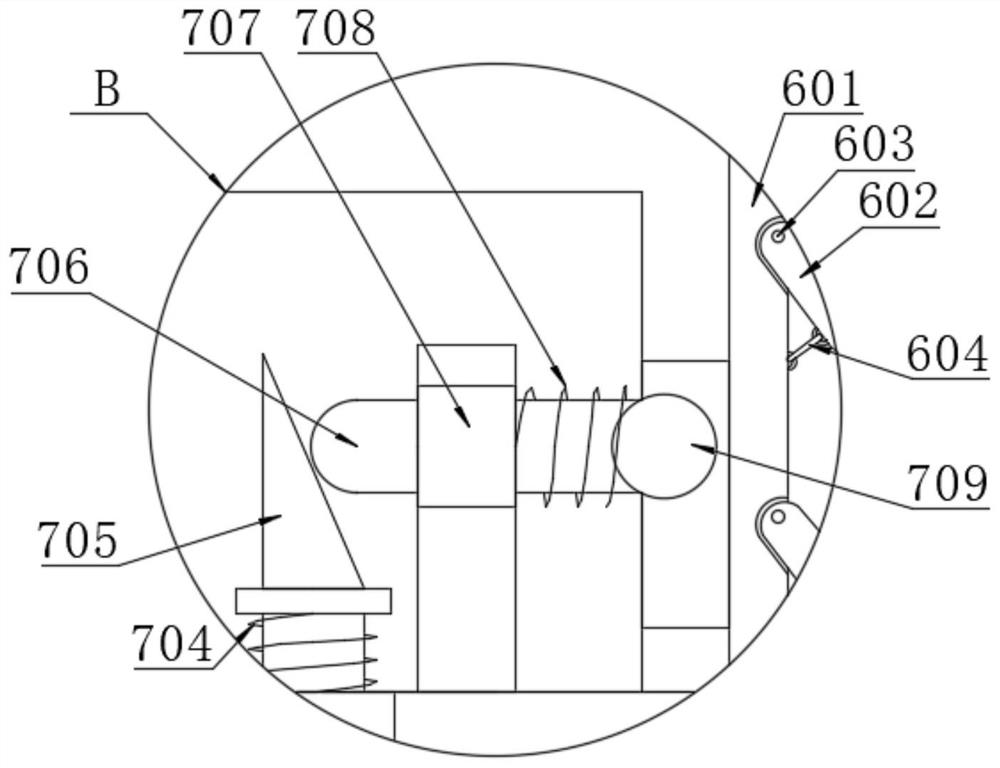

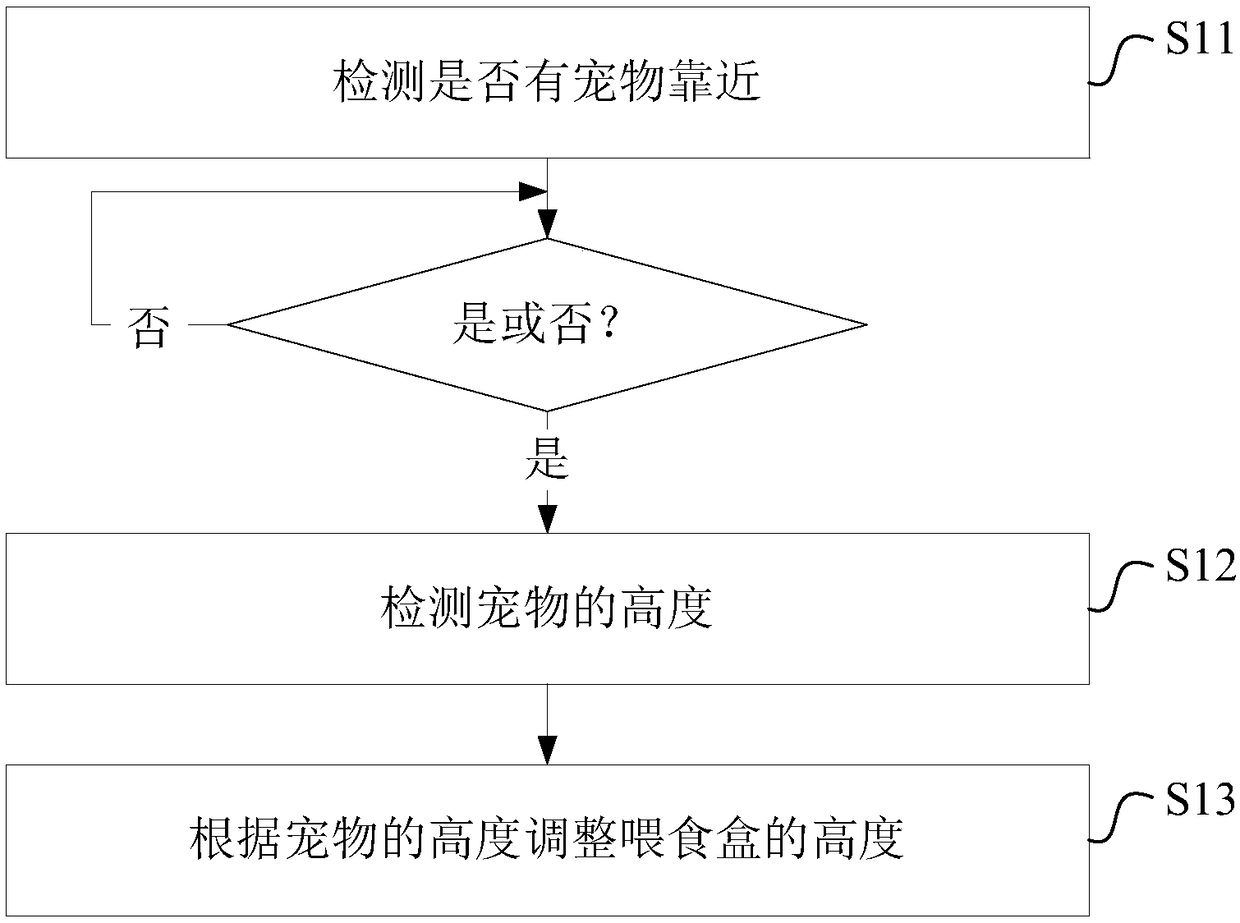

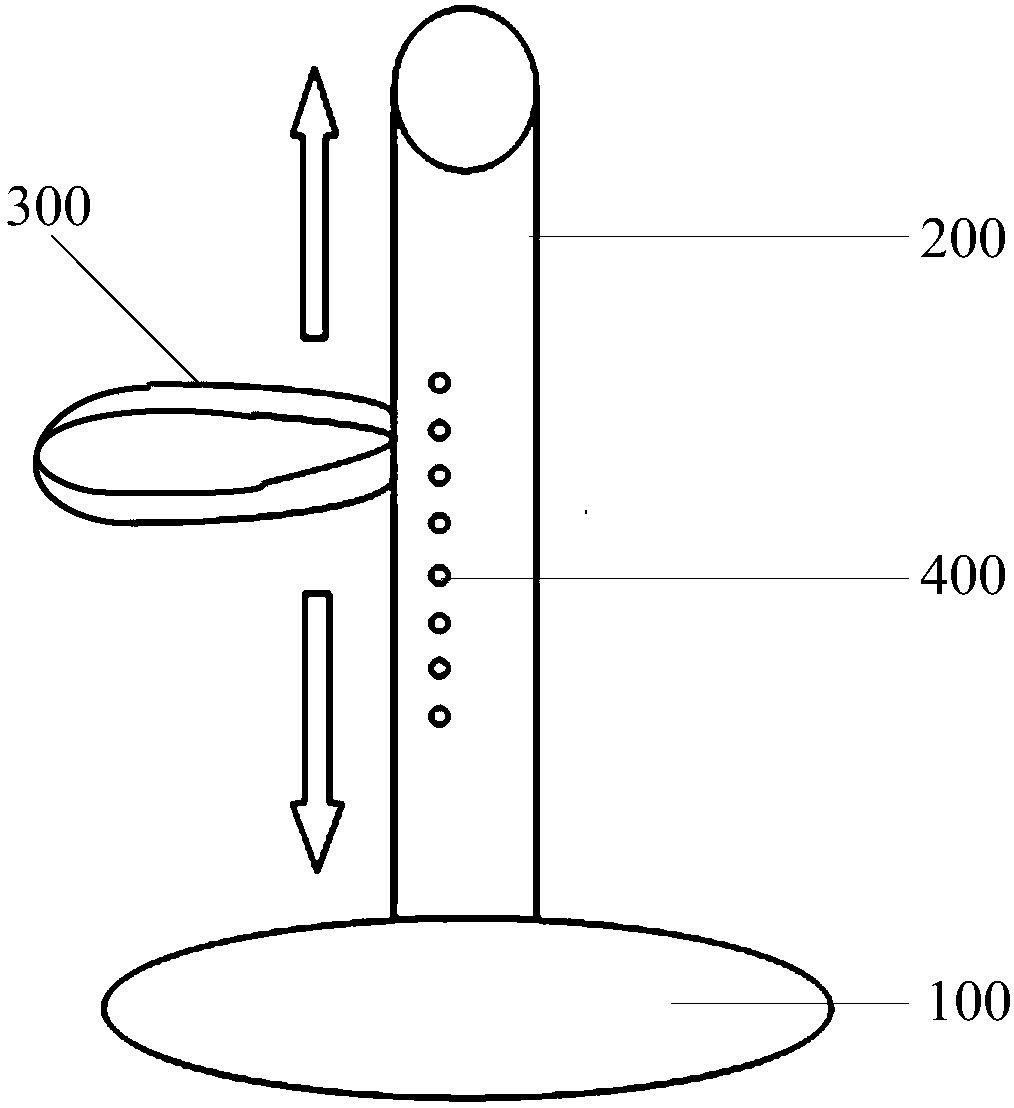

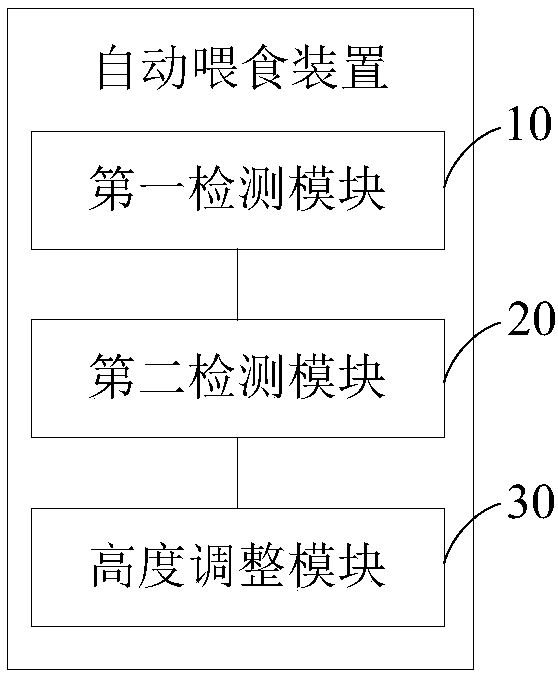

Automatic feeding method and device

InactiveCN108552070AEasy and comfortable to eatConvenience and refined careAnimal feeding devicesAvicultureEngineeringCompanion animal

The invention discloses an automatic feeding method and device. The method comprises the following steps that whether or not a pet approaches the device is detected; if yes, the height of the pet is detected; the height of a feeding box is adjusted according to the height of the pet. According to the automatic feeding method, by detecting the height of the pet which approaches the device, the height of the feeding box is automatically adjusted according to the height of the pet, and accordingly the height of the feeding box is matched with that of the pet; therefore, the pet eats feed more conveniently and comfortably, the eating requirements of pets different in body type are met, and convenience is provided for refinement care and management for the pet.

Owner:SHENZHEN WATER WORLD CO LTD

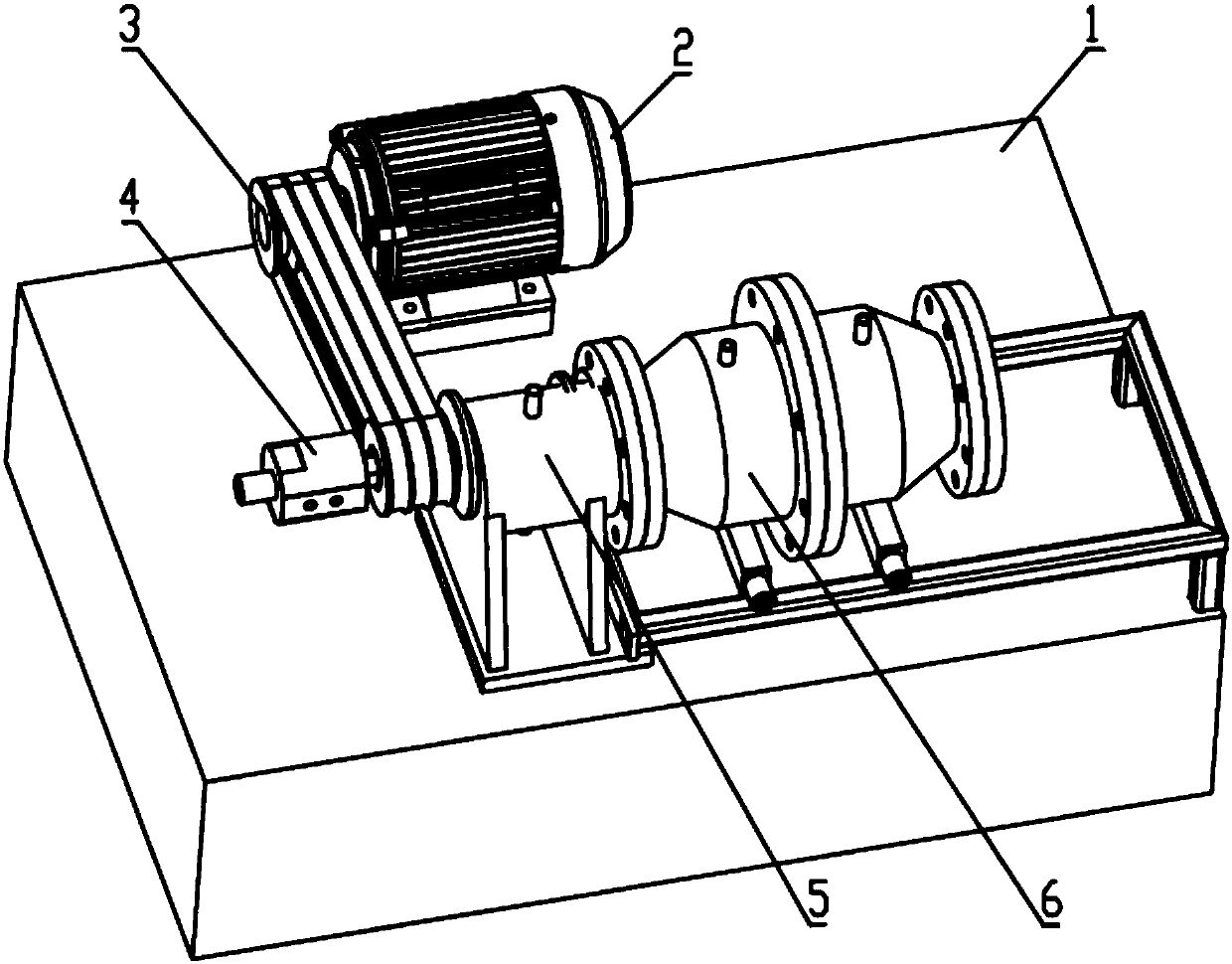

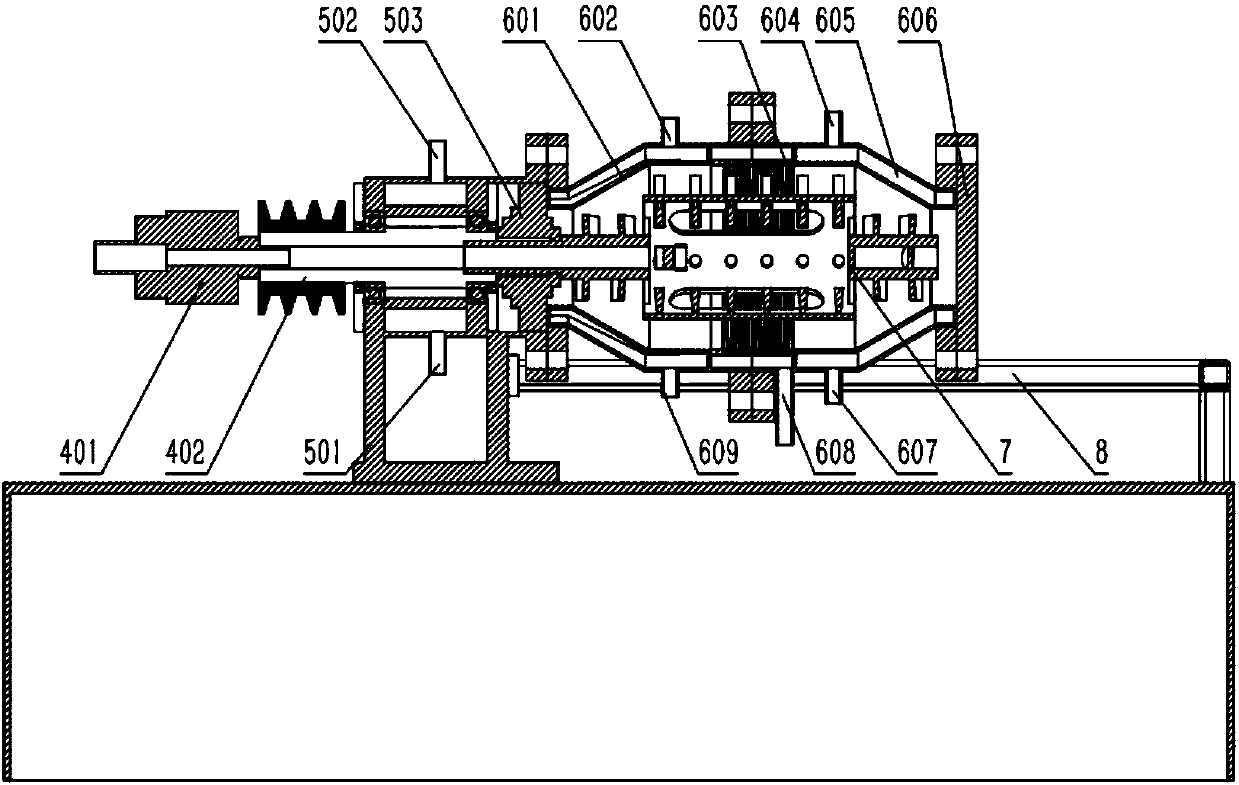

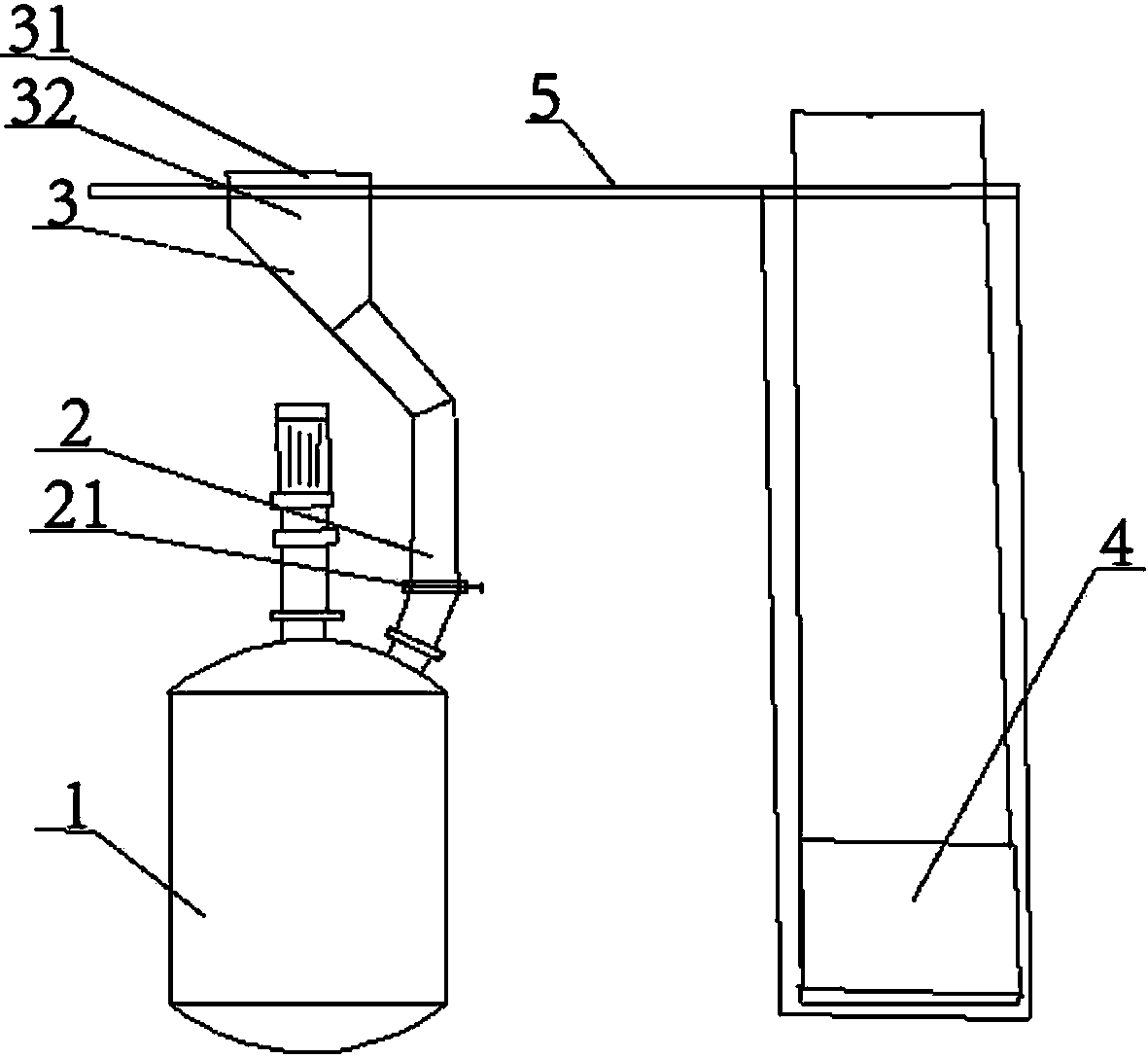

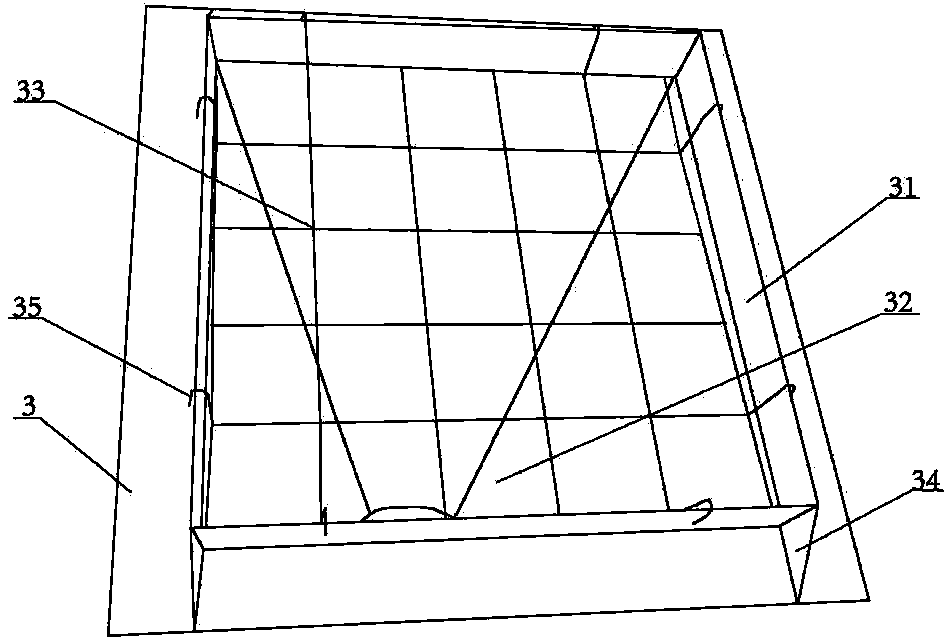

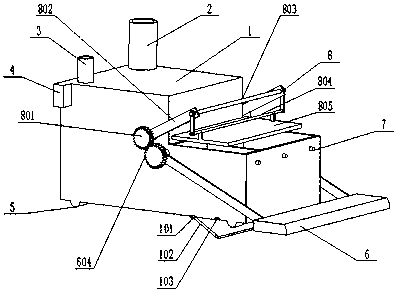

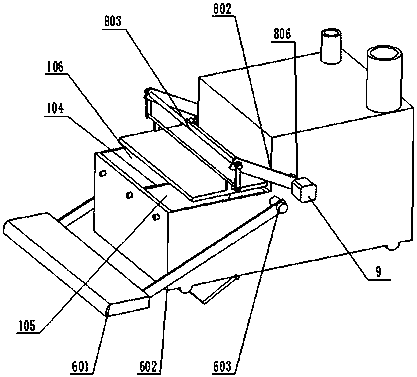

Imidazolidine feeding device

The invention relates to the field of imidazolidine feeding, in particular to an imidazolidine feeding device. The imidazolidine feeding device comprises a reaction kettle, a material adding pipe, a material adding hopper, a material conveying and lifting mechanism and a feeding frame, wherein the material adding pipe is arranged at a manhole position at the upper end of the reaction kettle; the material adding hopper is arranged at the upper end of the material adding pipe and is fixed on the feeding frame; the feeding frame is arranged above and at one side of the reaction kettle; the material conveying and lifting mechanism is arranged on the feeding frame and is positioned at one side of the reaction kettle. The imidazolidine feeding device has the advantages of simple design and convenience in use; by the arrangement of the material adding pipe, the distance between the material adding pipe and the reaction kettle is prolonged; meanwhile, an insertion plate is arranged on the material adding pipe, so that harm by gas volatilized from the reaction kettle to personnel during material adding is prevented; the material conveying and lifting mechanism is used for conveying large-package materials to a position above the feeding frame; an electric hoist above the feeding frame is used for feeding the large-package materials into the material adding hopper, so that a feeding requirement can be met at a time, and the time and the labor are saved; the imidazolidine feeding device is safe and reliable, and the working efficiency is greatly improved.

Owner:NANTONG TENDENCI CHEM

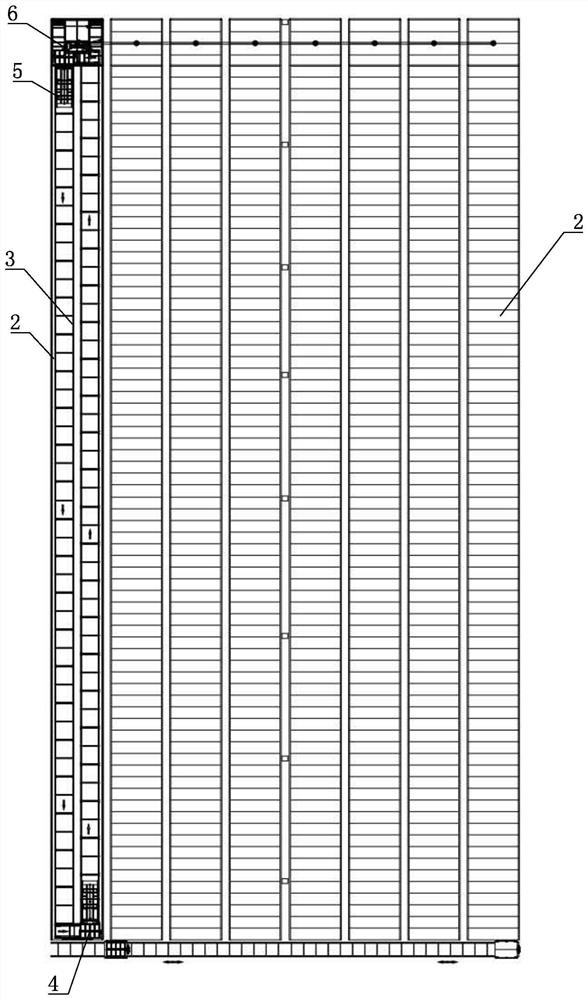

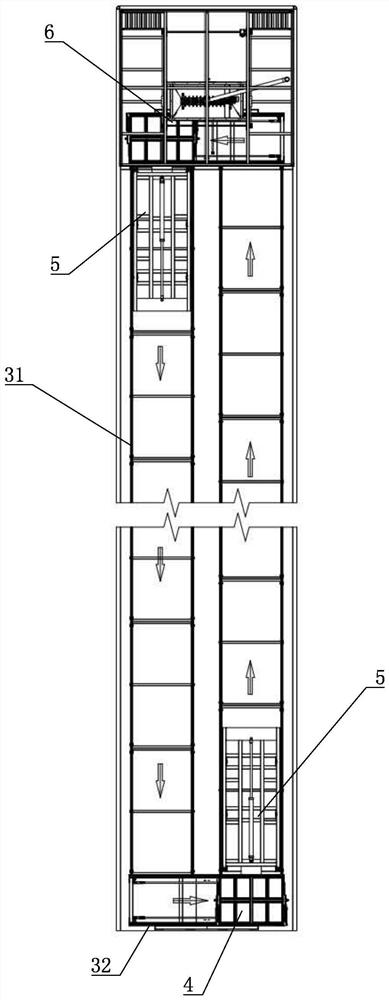

Roadway type hermetia illucens automatic feeding system

PendingCN112335612AGood feeding effectRealize industrial automation farmingTransportation and packagingRotary stirring mixersAnimal scienceTrackway

The invention discloses a roadway type hermetia illucens automatic breeding system. The system comprises a breeding frame circulating track, the breeding frame circulating track is in a hollow squareshape, and the breeding frame circulating track comprises a longitudinal circulating track body and a transverse circulating track body arranged at the end of the longitudinal circulating track body.A breeding frame conveying device for a roadway is arranged on the longitudinal circulating track body, and a breeding frame transverse moving device is arranged on the transverse circulating track body. A foodstuff feeding machine is arranged at the position, located at one end of the longitudinal circulating track body, of the transverse circulating track body. According to the roadway type hermetia illucens automatic feeding system, large-scale hermetia illucens breeding can be achieved, hermetia illucens bred on a large scale can be automatically, regularly and quantitatively fed, industrial automatic breeding is achieved, the feeding effect is good, the work efficiency is high, the environment in the breeding process can be effectively controlled, and the waste organic matter conversion efficiency is high.

Owner:潍坊星美生物科技股份有限公司

High-yield breeding method of freshwater shrimps in pond in summer

ActiveCN105918186ASatisfy the high oxygen demandMeet the characteristicsFood processingClimate change adaptationFresh water organismPrawn

The invention discloses a high-yield breeding method of freshwater shrimps in a pond in summer. The high-yield breeding method includes: selecting a pond without sludge at the bottom, draining water in the pond in late June, exposing the pond under blazing sun, and uniformly scattering quicklime at the bottom of the pond; injecting water into the pond at early July, uniformly sowing and planting Hydrilla varticillata, planting Alternanthera philoxeroides in a shallow region of the pond, and injecting water; arranging summer flower net in the middle of the pond; in an early morning of a sunny day in late July, placing young shrimps into the pond, and then placing silver carps into the pond; after the young shrimps and the silver carps are placed into the pond, feeding fine granulated feed a time every morning and every afternoon; after a period of time, feeding rough granulated feed a time every morning and every afternoon; putting quicklime and a copper sulfate water solution into the pond every other period of time; from later August to time of fishing, extracting water at the bottom of the pond a time every week, supplementing fresh water to reach a water level before extraction, and regularly pumping air into the pond every day; after a period of time, selecting the afternoon of a cloudy day for fishing.

Owner:河北鑫海水产生物技术有限公司

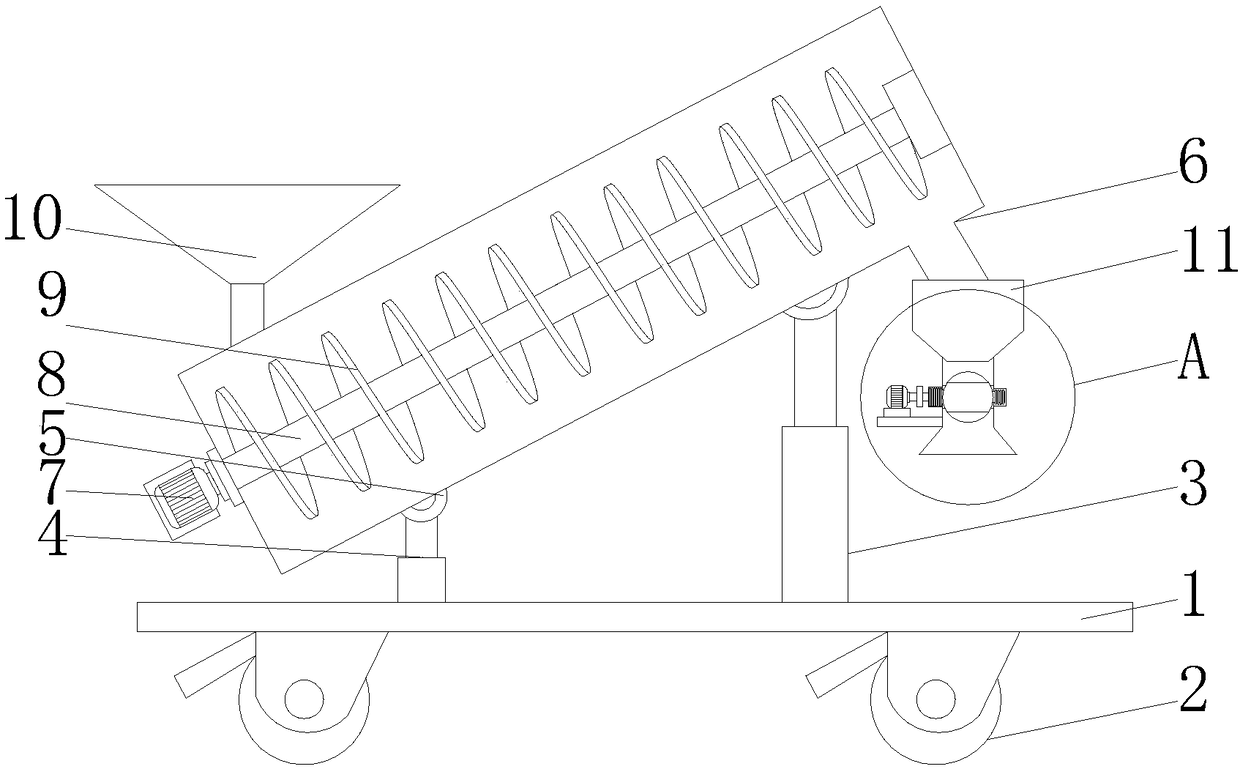

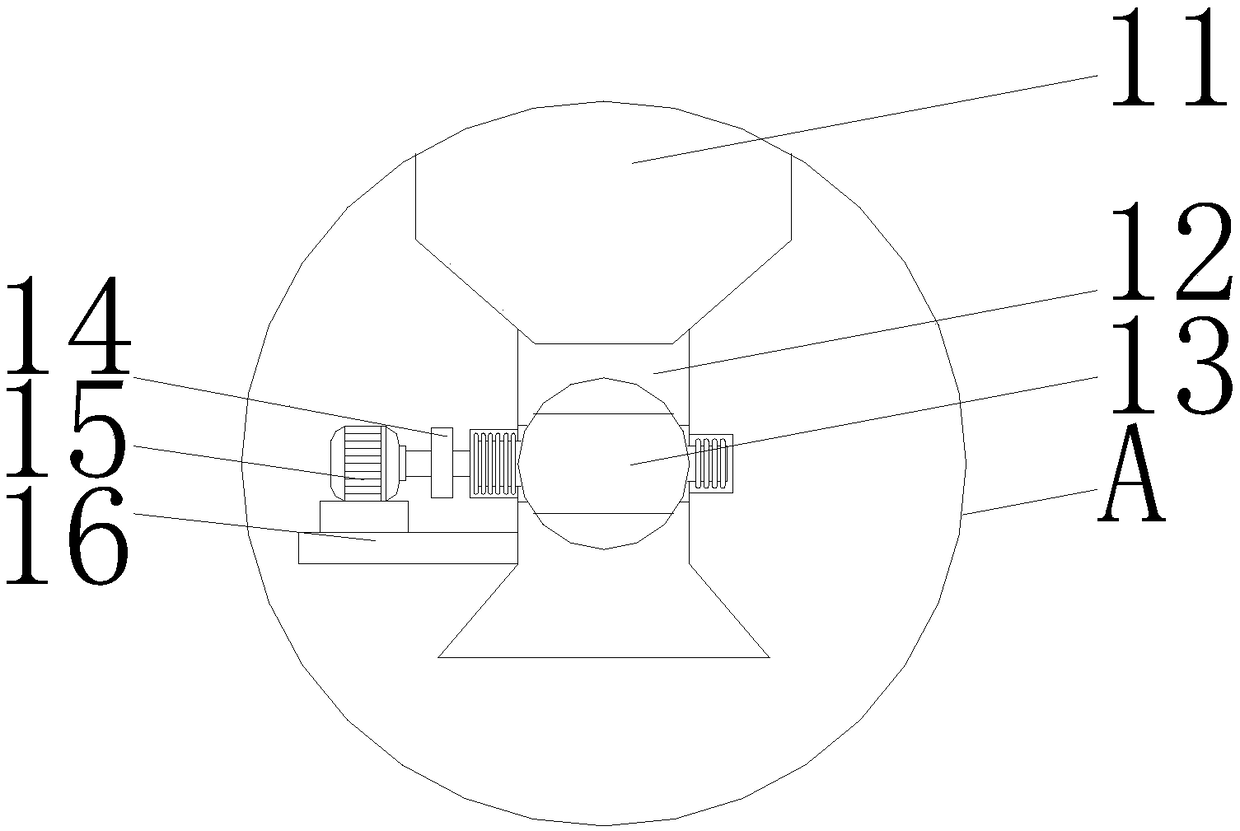

High-precision continuous feeding automatic weighing and metering device

InactiveCN109178807AEasy to moveMeet feeding needsPackagingSpecial purpose weighing apparatusSpiral bladeEngineering

The invention discloses a high-precision continuous feeding automatic weighing and metering device. The high-precision continuous feeding automatic weighing and metering device comprises a bottom plate. Universal wheels are arranged at the bottom end of the bottom plate. The top end of the bottom plate is fixedly connected with an electric push rod. The top end of the bottom plate is fixedly connected with a mounting rod positioned on one side of the electric push rod. The top end of the mounting rod is rotatably connected with a conveying box through a rotary knob. One side wall of the conveying box is fixedly connected with a servo motor, and an output end of the servo motor is fixedly connected with a rotary rod. A spiral blade is fixedly connected to the surface of the rotary rod in asleeving mode, and one end of the conveying box communicates with a discharging hopper. The universal wheels are arranged, so that the whole device is conveniently moved; and the electric push rod andthe mounting rod are arranged, so that when the electric push rod is lifted and fallen, the rotary knob is rotated, one end of the conveying box is lifted and fallen, then one end of a discharging pipe is lifted and fallen, the feeding requirements with different heights are met, and meanwhile, the labor intensity is reduced.

Owner:芜湖佩林郁松计量科技有限公司

Production method of coated nut meat

A production method of coated nut meat comprises the steps of S1, preparing coating formula powder; S2, coating; S3, baking: a rocking furnace comprises a furnace body, rectangular penetrating openings are formed in the two sides of the furnace body, a tray vertically penetrates through the penetrating openings, a rocking supporting mechanism is arranged at the bottom of the tray, the rocking supporting mechanism is used for driving the tray to swing in a reciprocating mode, the outer end of the bottom surface of the tray is rotationally connected with a swinging support mechanism, and the inner end of the bottom surface is connected with the swinging support mechanism through a retracting mechanism; s4, seasoning; and S5, drying. In the production process of the coated nut meat, the coating is easier to form, so that the coating forms a support structure similar to a spider web shape, and the coating is looser, tastes crisp and good and is not easy to shell; the wrapped nut meat is good in mouth melting property, and the fragrant taste of the nut meat can be reserved.

Owner:安徽山里仁休闲食品有限责任公司

Animal feeding device

InactiveCN107787860AAvoid getting dirtyRealize automatic deliveryAnimal watering devicesAnimal feeding devicesWater sourceElectric machinery

The invention discloses an animal feeding device. The device comprises a shell, a feeding pipe, a water inlet pipe, a control switch, wheels, a treading mechanism, an induction sensor, a cover closingmechanism, a motor, a rain shielding plate, a supporting column, a material transferring box and a material transferring device, wherein the feeding pipe, the water inlet pipe and the supporting column are arranged on the top of the shell, the supporting column is provided with the rain shielding plate, and the feeding pipe and the water inlet pipe are connected with the material transferring box; one side of the material transferring box is provided with the material transferring device, and the side edge of the material transferring box is provided with the control switch; the induction sensor is installed at the front end of the material transferring box, and the four wheels are installed at the low end of the material transferring box; the cover closing mechanism and the treading mechanism are arranged on the two sides of the shell, the cover closing mechanism is matched with the treading mechanism for transmission, and the motor is installed on the cover closing mechanism. Food and water sources in the device cannot be contaminated on rainy days, and the food in the feeding box is prevented from being wetted or contaminated by the influence of natural weather.

Owner:公晨阳

Cartilage fish feed

InactiveCN107296174ANutrient composition ratio scienceWith slow sinkingFood processingClimate change adaptationAdditive ingredientPotato starch

The invention provides cartilage fish feed, which is prepared from the following ingredients in parts by weight: 23 to 34 parts of peanut meal, 15 to 22 parts of bean meal, 4 to 7 parts of cuttlefish paste, 3 to 7 parts of Chinese herbal medicine additives, 8 to 16 parts of fish meal, 15 to 24 parts of algae compounds, 3 to 5 parts of potato starch, 1 to 4 parts of antioxidants, 10 to 20 parts of shrimp shell powder, 9 to 16 parts of wheat flour, 17 to 26 parts of sargassum pallidum, 0.6 to 1.2 parts of complex vitamin and 3 to 8 parts of sweet potato stems and leaves. The feed has the advantages that the nutrition proportioning ratio is reasonable; the requirements of the cartilage fish growth can be met; the immunological competence and the strain resistance capability of the cartilage fish can be effectively improved; the palatability is good; the stability in the water is good; the bait coefficient is low; the growth of the cartilage fish can be effectively promoted; the feed cost is low; the preparation method is simple; the water quality cannot be influenced after the feed throwing; no toxic and harmful substances are contained; green and environment-friendly effects are achieved.

Owner:兰溪市酉泽饲料技术服务有限公司

Ecological culturing method of young octopus variabilis

InactiveCN108293926AEasy to observeConvenient farming managementClimate change adaptationAnimal feeding stuffCladophoraObserved Survival

The invention discloses an ecological culturing method of young octopus variabilis. The ecological culturing method comprises the following steps of 1, putting a net cage into an indoor cement pool, putting cladophora into the net cage and uniformly spreading the cladophora; 2, putting large corophium into the net cage and uniformly spreading the large corophium; 3, putting the hatched young octopus variabilis into the net cage to be cultured; 4, after culturing for a certain period of time, putting eogammarus possjeticus into the net cage and uniformly spreading the eogammarus possjeticus; 5,transferring the successfully cultured young octopus variabilis into a new breeding pool. Selection of feed and shelters has the advantages that the materials are convenient to take, and the cost islow; meanwhile, a habitat which has sufficient nutrients and energetic feed and is environmentally friendly and close to a natural environment can be provided for culturing the young octopus variabilis, after 30-40 days of raising, the cultured young octopus variabilis can reach the survival rate of 90% or above, and the average body length and the fresh weight can reach 1 cm and 1 g respectively.

Owner:OCEAN UNIV OF CHINA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com