Multi-function trolley and construction method thereof

A multi-functional, trolley technology, applied in earthwork drilling, wellbore lining, tunnel lining, etc., can solve the problem of poor welding quality, strength, stiffness and stability of the bench, discontinuous climbing up and down the ladder and platform, and inconvenient up and down operations, etc. problems, to achieve the effect of promoting civilized and safe construction, improving construction efficiency, and reducing operators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

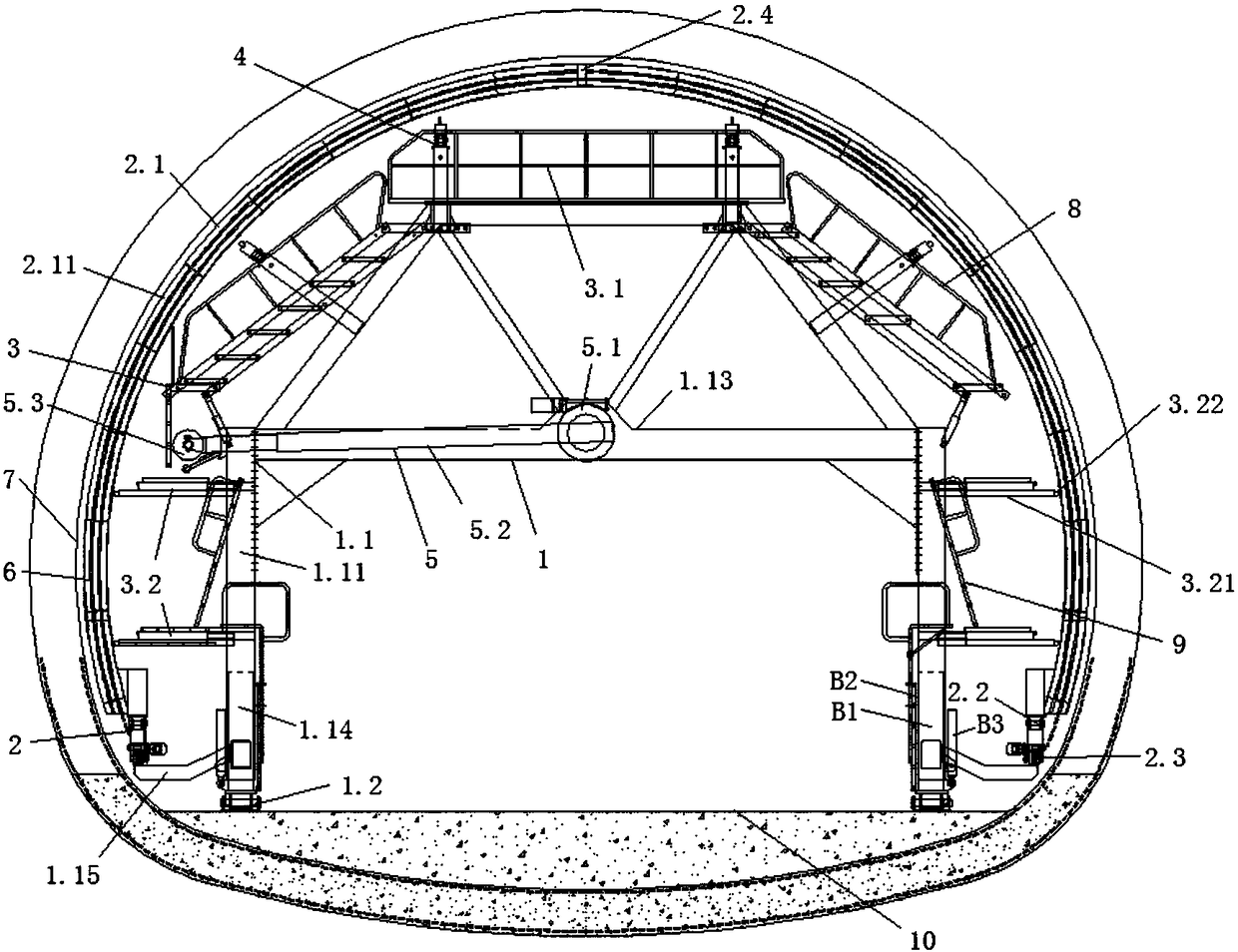

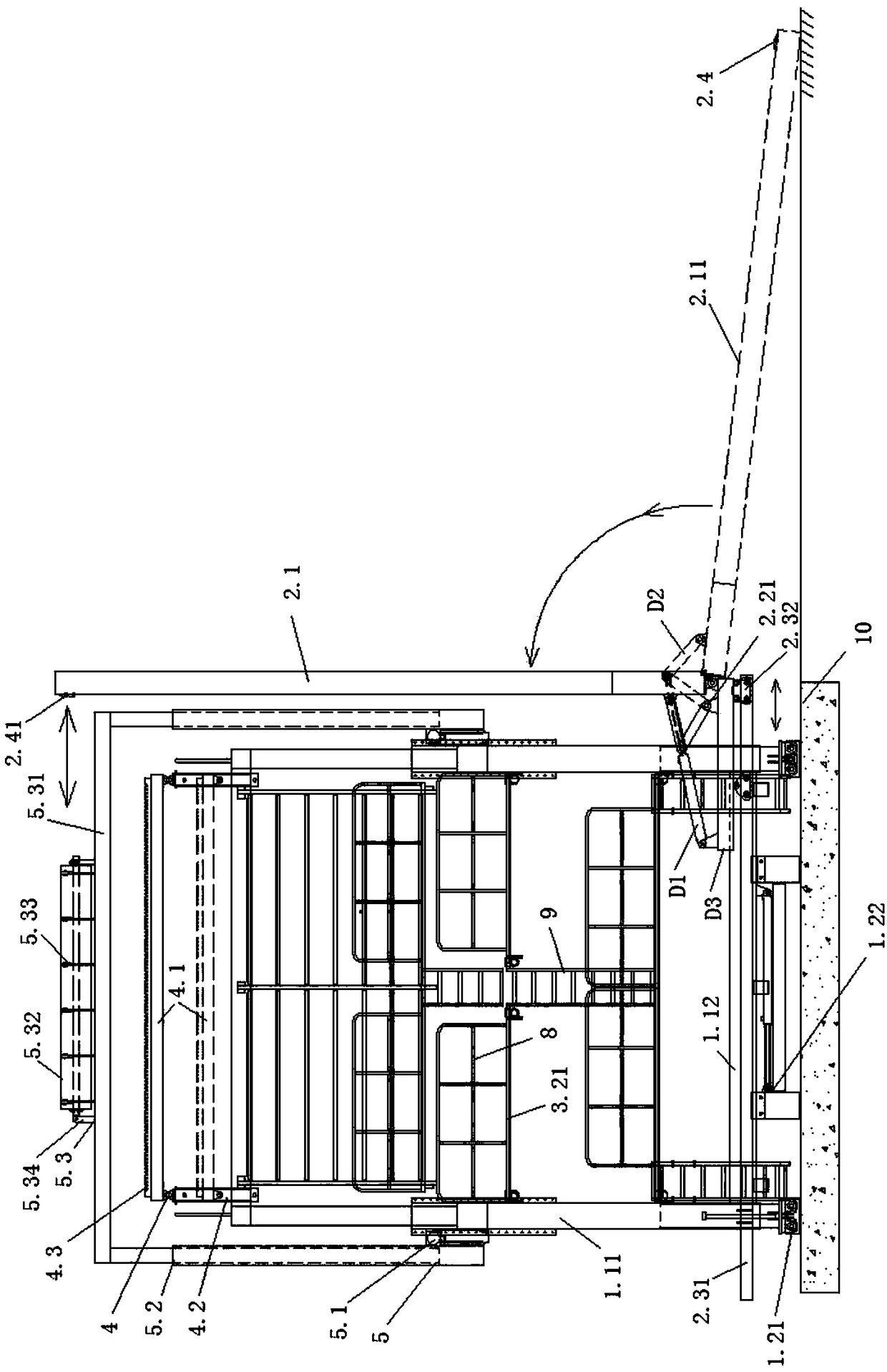

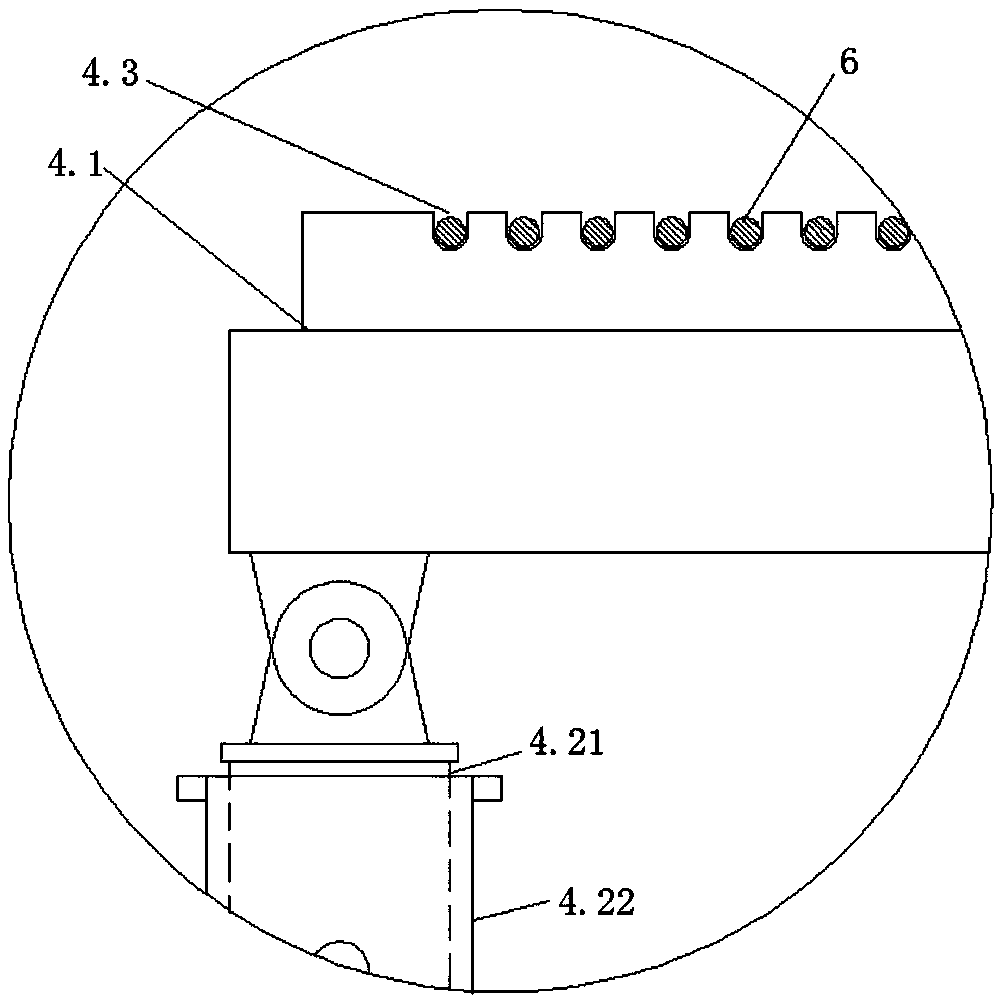

[0053] A multifunctional trolley, see details Figure 1-2 ( figure 2 The upper and lower two-way arrows in the middle represent the horizontal movement direction of the rebar feeding system, and the arc arrows represent the turning direction of the rebar accommodating arch), including the gantry system 1, the rebar feeding system 2, the working platform assembly 3, the rebar support Lifting device 4 and rotating telescopic arm assembly 5, the details are as follows:

[0054] The gantry system 1 includes a gantry frame 1.1 and a traveling mechanism 1.2 arranged on the gantry frame and used to drive the entire trolley to move. The gantry frame 1.1 includes a gantry column 1.11 (shown here). Four gantry uprights), gantry longitudinal beam 1.12 and upper frame 1.13, the specific structure can be designed based on the structure of the existing lining trolley. The walking mechanism 1.2 includes a walking part 1.21 for driving the trolley to walk and a traverse part 1.22 for drivi...

Embodiment 2

[0071] The difference from Example 1 is that:

[0072] The rotating connector 2.21 includes a balance beam D3, a tie rod D4, a pulley D5 and a wire rope D6, see details for details Image 6 , the balance beam is arranged horizontally and the length direction of the balance beam is the same as the turning direction of the arch frame, the moving part is arranged on the balance beam; the end of the single piece of the arch frame is hinged on the balance beam The two ends of the tie rod are respectively connected with the end of the single piece of the arch frame and the balance beam; the pulley is fixed on the upper door frame 1.13 of the trolley through the pulley support seat D7, and the pulley is used for Play a guiding role for the wire rope; one end of the wire rope is connected to the power source, and the other end is detachably connected to the dome position of the single piece of the arch connect).

[0073] The said steel bar anti-falling single piece includes the ear ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com