Feedstuff feeding device

A feed and storage box technology, applied in the field of breeding, can solve the problems of low efficiency, easy agglomeration of feed, and small amount of feeding, so as to achieve the effect of improving the degree of automation, reducing labor costs, and reducing manual operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

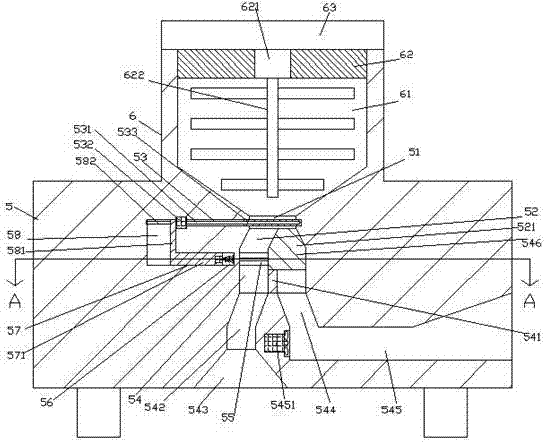

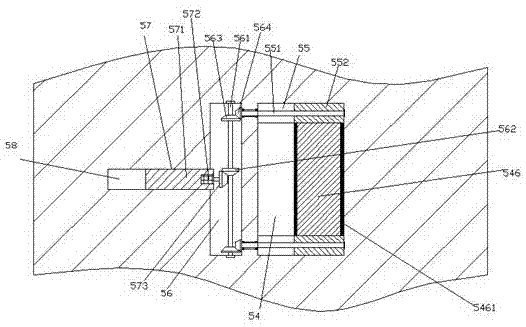

[0025] like Figure 1-Figure 7 As shown, a feed feeding device of the present invention includes a base body 5 and a material storage box 6 installed on the top of the base body 5, and the material storage box 6 is provided with a mixing cavity 61 extended downwards. , the extension of the bottom of the mixing chamber 61 extends into the seat 5, and the bottom of the base 5 at the bottom of the mixing chamber 61 is provided with a lower outlet that communicates with the mixing chamber 61 at the top 51, the lower discharge port 51 is provided with a sliding chamber 53 extending left and right, the sliding chamber 53 is provided with an opening manipulation device, and the bottom of the lower discharge port 51 communicates with the chamber 52, so The bottom of the chamber 52 communicates with a partition chamber 54, and the midpoint in the bottom of the partition chamber 54 is provided with a partition wall plate 541 fixedly connected to the front and rear inner walls of the par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com