Method for binding high-layer shear force wall reinforcing steel bar

A technology of steel bar binding and shear wall, which is applied in the direction of structural elements, building components, building reinforcements, etc., can solve problems such as difficult acceptance of main part engineering quality, large thickness deviation of steel bar protection layer, and large mesh spacing deviation , to achieve the effect of being beneficial to environmental protection, improving the quality of binding, and reducing the ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] 1. General idea:

[0011] Steps: binding vertical ladder reinforcement, binding horizontal ladder reinforcement, binding vertical wall reinforcement, binding wall horizontal reinforcement.

[0012] The vertical ladder reinforcement is composed of two vertical reinforcements one level larger than the vertical reinforcement of the wall and several transverse reinforcements, and the horizontal ladder reinforcement is composed of two longitudinal reinforcements and several horizontal reinforcements.

[0013] Remove the horizontal ladder bars after pouring the concrete.

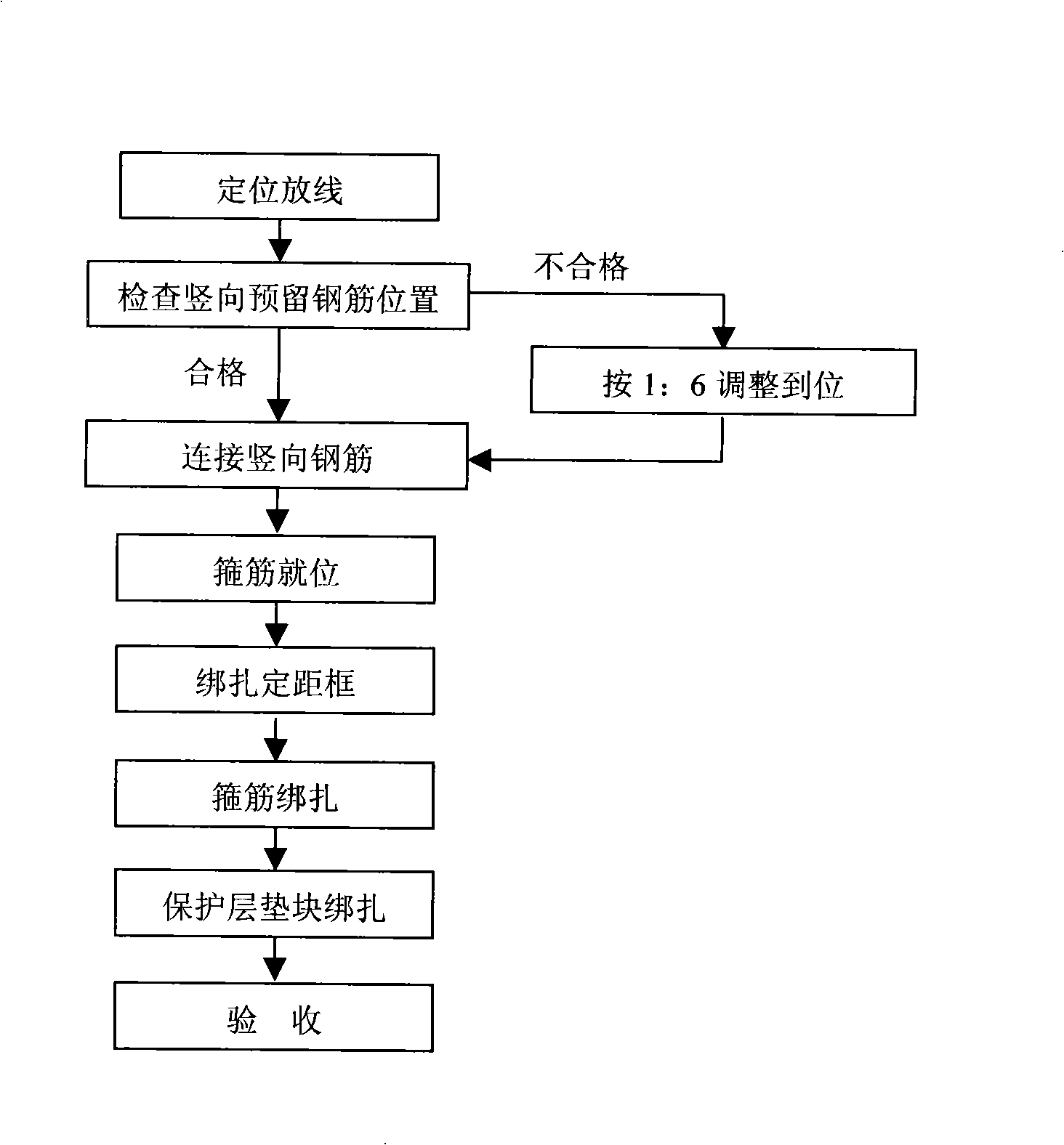

[0014] 2. The steel bar binding process is as follows: figure 1 shown.

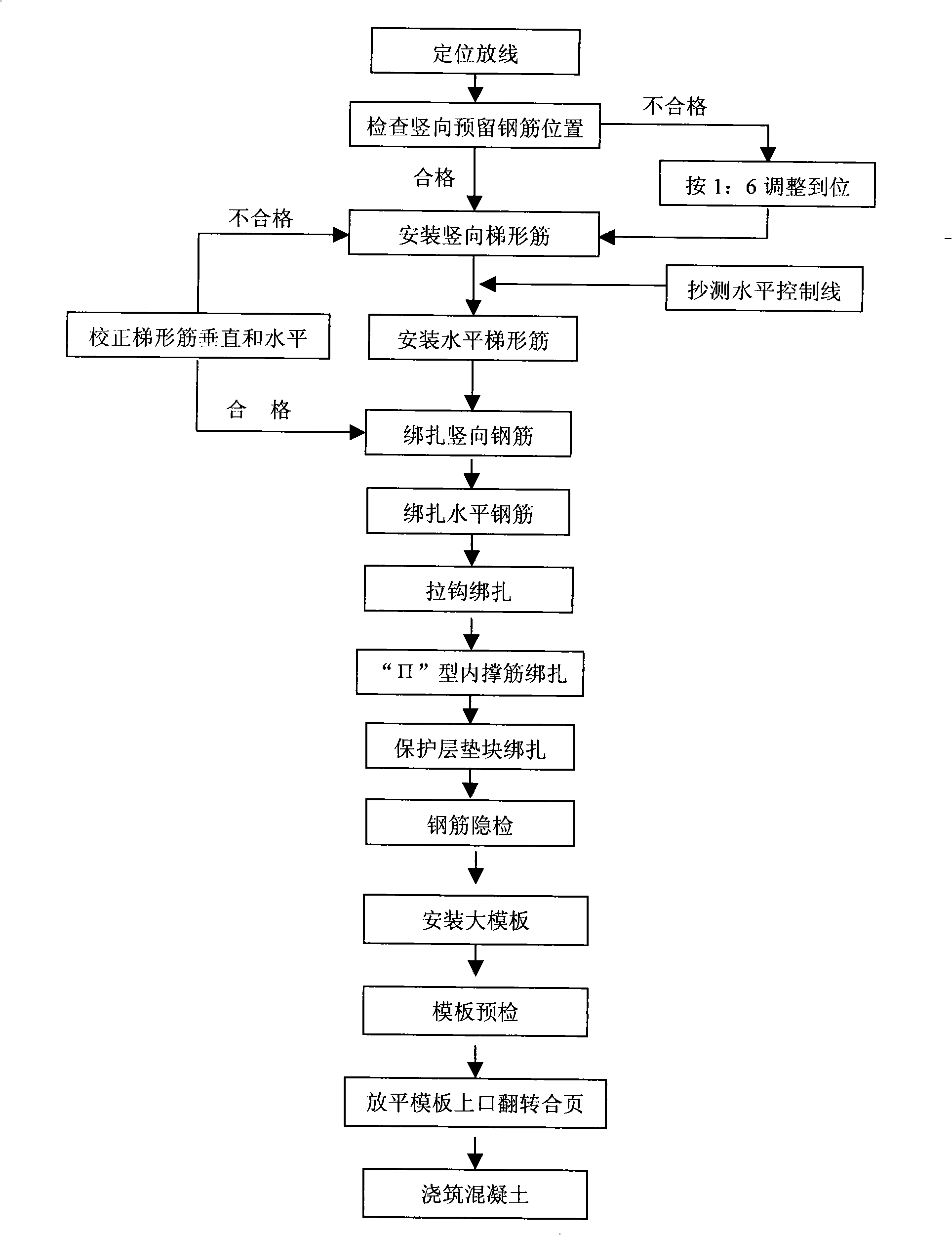

[0015] 3. The installation process of shear wall reinforcement is as follows: figure 2 shown.

[0016] 4. Operation points:

[0017] 1. Construction preparation

[0018] According to the drawings and specification requirements, draw vertical trapezoidal ribs, horizontal trapezoidal ribs, fixed-distance frames, "∏"-shaped inner b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com