Tire type tail car conveying ship loader

A ship loader and tire-type technology, which is applied in the field of tire-type tail truck conveying ship loader, can solve the problems of low ship loading efficiency, large occupied width of the wharf, and small ship loading capacity, so as to improve the utilization rate and improve the unloading capacity. Effects of height, quick docking and detachment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

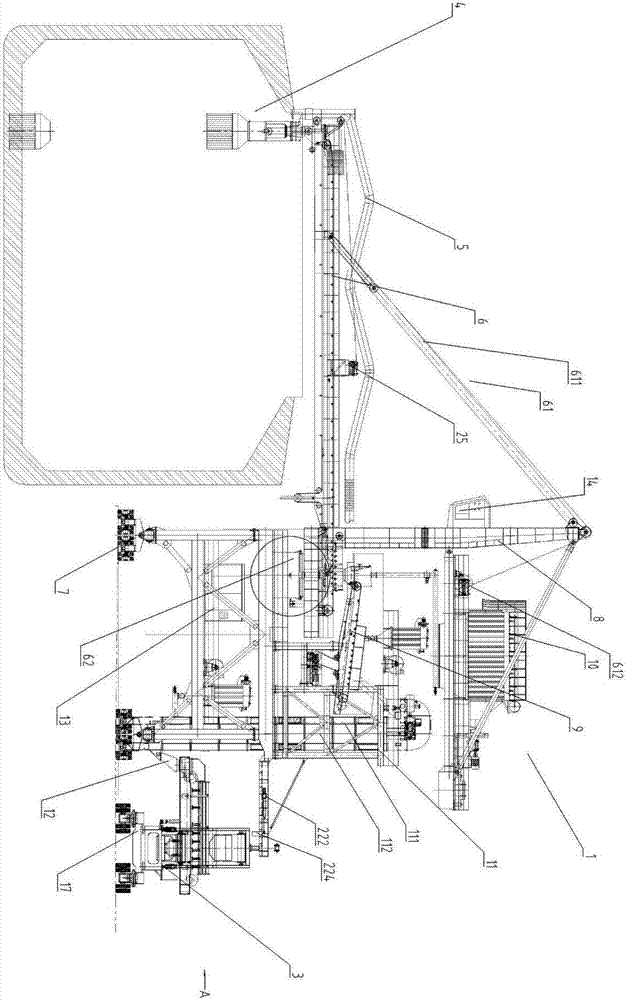

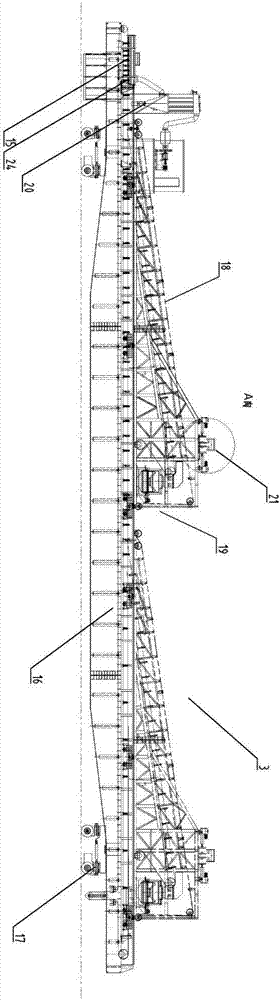

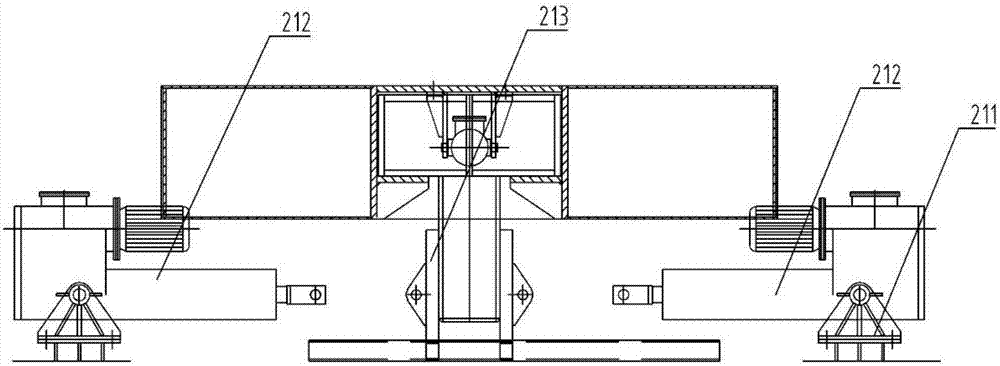

[0028] The invention discloses a tire-type tail car conveying ship loading machine, referring to figure 1 and figure 2, including a mobile ship loader 1, an automatic docking system 2 and a tail car belt conveyor 3; the mobile ship loader 1 is placed in parallel along the wharf line, and the tail car belt conveyor 3 and the mobile ship loader 1 are at right angles to each other , is connected with the mobile ship loader 1 through the automatic docking system 2, the automatic docking system 2 includes the trailer conveyor docking system 21, the ship loader docking system 22 and the remote control system 23; the mobile ship loader 1 is from left to On the right, there are discharge cylinder s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com