Device and method for controlling flatness of full-width composite material

A composite material and control device technology is applied in the field of flatness control devices for full-width composite materials, and can solve the problem of adjusting the same proportional relationship of the motor speed under the open-loop control of the frequency converter, adjusting the relationship between the speed of the motor under the open-loop control of the frequency converter, and the longitudinal thickness of the film. problems such as large deviation, to achieve the effect of reducing edge material processing procedures, realizing synchronous operation, and improving surface flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

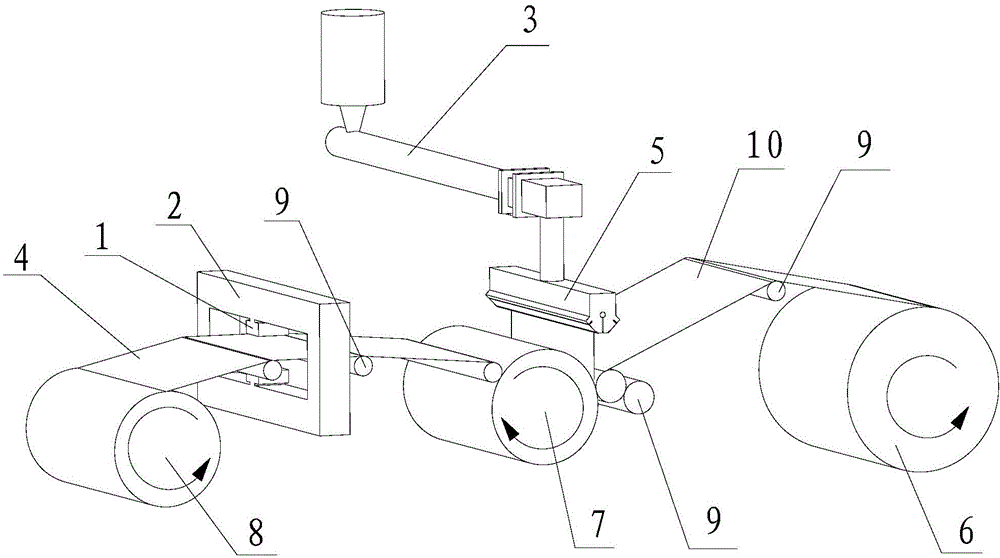

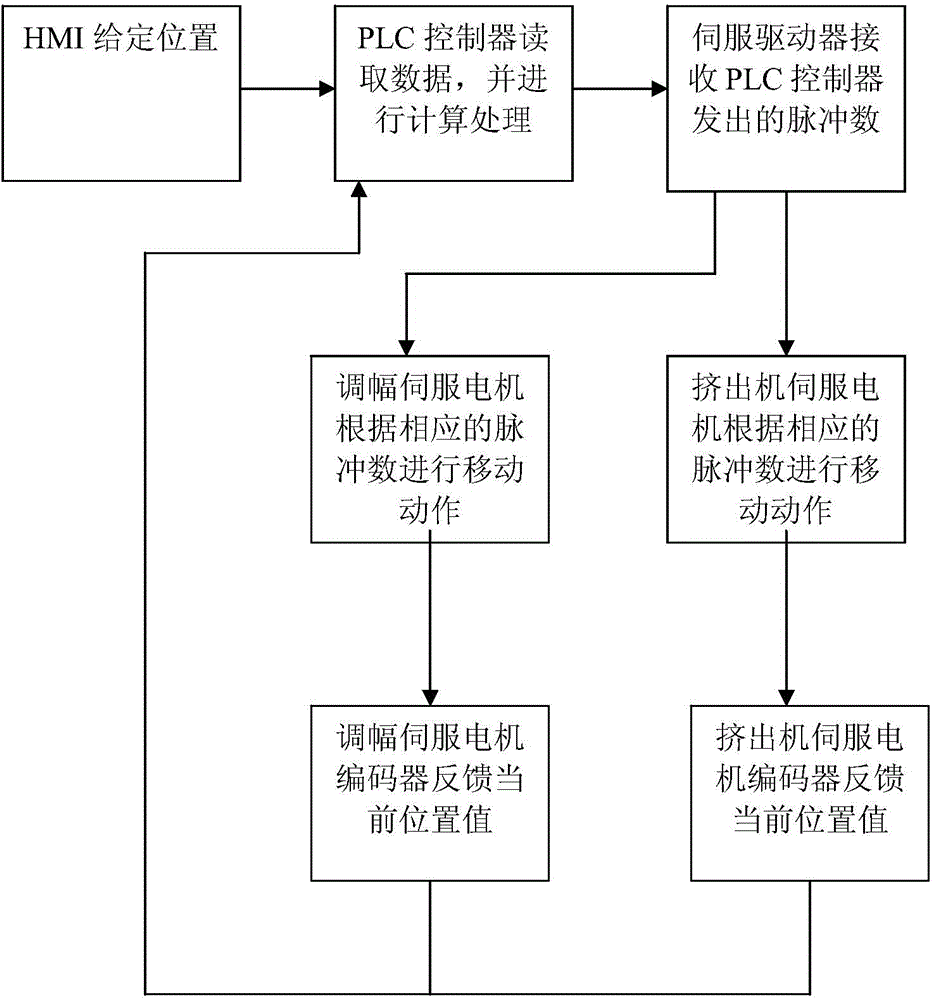

[0049] In this embodiment, a flatness control device for a full-width composite material, such as figure 1 As shown, it includes a thickness gauge (the overall structure is not shown in the figure), a probe mounting frame 2, an extruder 3, a flatness adjustment mechanism, a PLC controller (not shown in the figure) and a film conveying mechanism, and the thickness gauge The probe 1 is installed on the surface of the extruded composite film 4 through the probe installation. The extruder is equipped with a flatness adjustment mechanism. The flatness adjustment mechanism, the thickness gauge and the extruder are respectively electrically connected to the PLC controller. The extrusion composite film passes The film conveying mechanism carries out the conveying, and the die head of the extruder is arranged above the film conveying mechanism.

[0050] The thickness gauge is a non-contact thickness gauge, and the probe in the thickness gauge moves back and forth along the transverse s...

Embodiment 2

[0062] In this embodiment, a full-width composite material flatness control method is realized by the device described in Embodiment 1, including the integrated adjustment of the thickness uniformity of the transverse section of the extruded composite film, and the adjustment of the thickness uniformity of the longitudinal section of the extruded composite film. The surface smoothness adjustment after being superimposed with the extruded composite film is as follows:

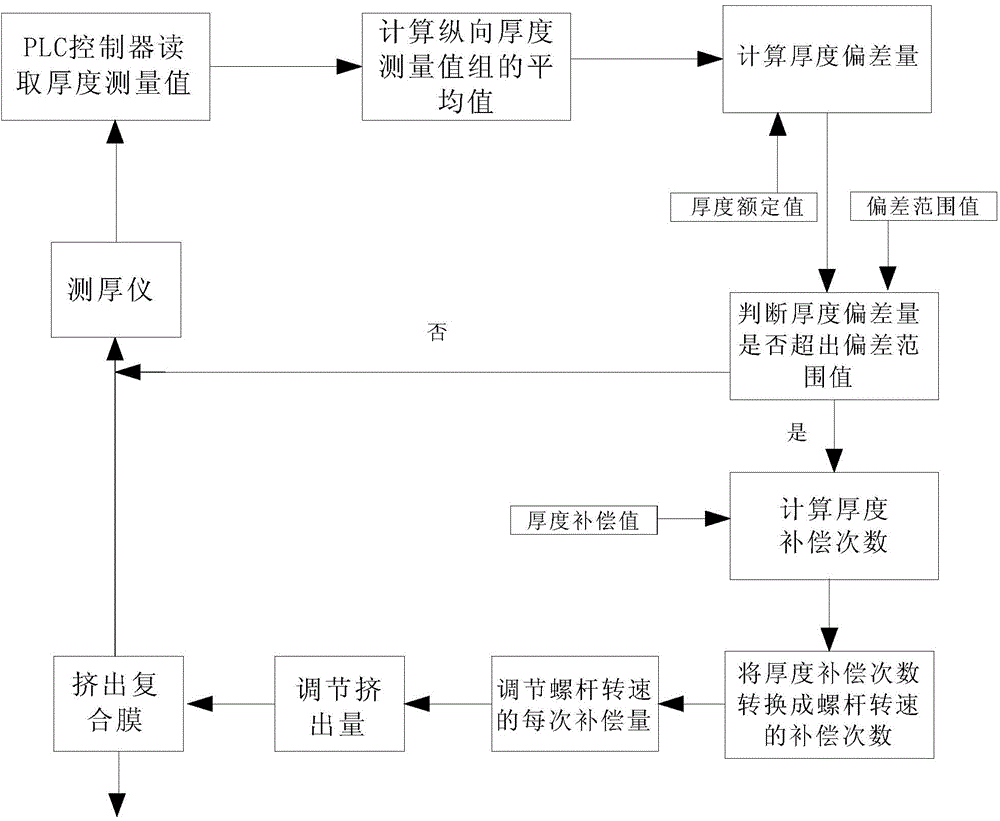

[0063] Measure the thickness value of the extruded composite film in real time through the thickness gauge, and then extract the measured thickness values through the PLC controller to obtain the transverse section thickness value and longitudinal section thickness value respectively;

[0064] Compare and analyze the thickness value of the transverse section with the preset thickness value, and then convert the analysis result into the adjustment amount of the adjusting screw at the outlet of the corresponding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com