Full-automatic molding production line for decorative gypsum board

A production line, gypsum board technology, applied in ceramic molding machines, clay preparation devices, mixing operation control devices, etc., to achieve the effect of automatic and accurate measurement and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

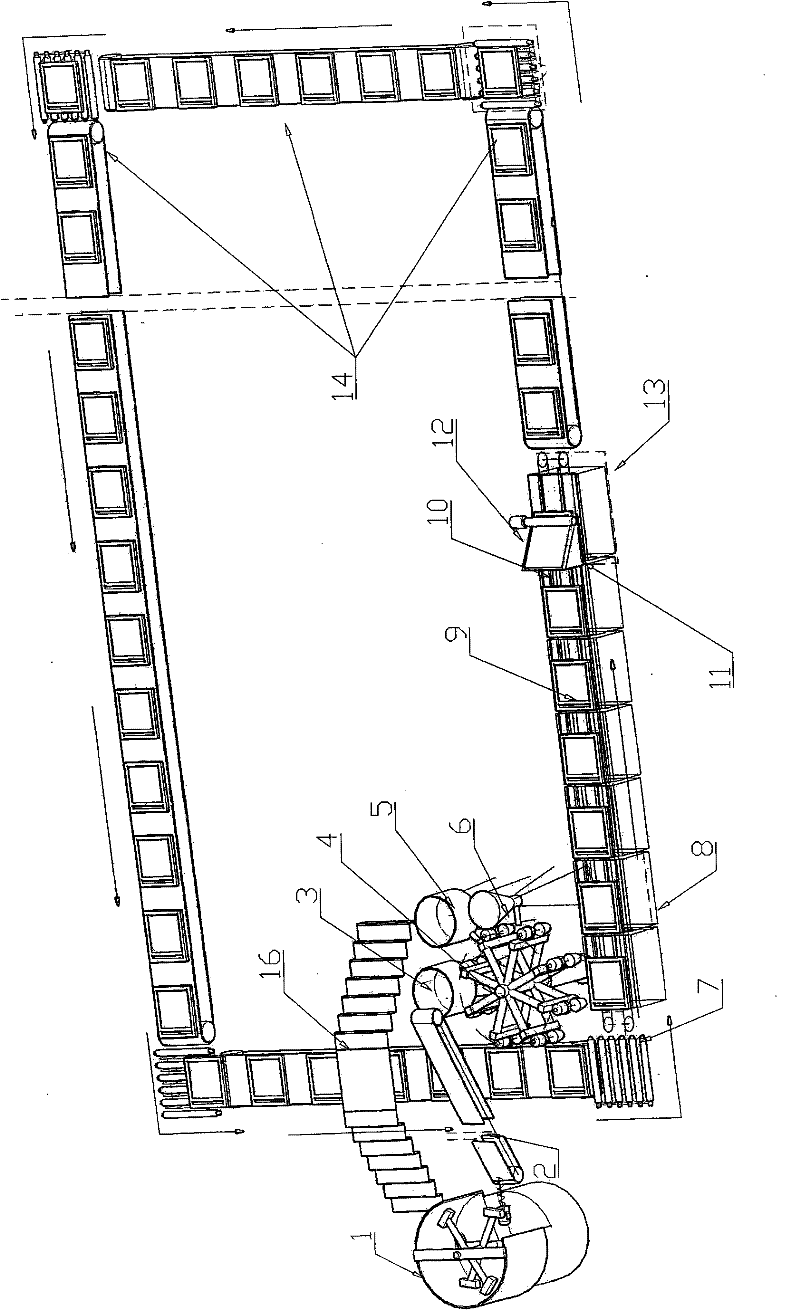

[0035] Depend on figure 1 It can be seen that in one embodiment of the present invention, the gypsum powder mixing mixer 1, the gypsum powder conveyor belt conveyor 2, the automatic gypsum slurry mixer 4, the slope vibration platform 8, the dual-frequency low-amplitude rolling forming platform 13, and the linear transmission platform are sequentially arranged. 14 and right-angle turning device 7 are formed, and its whole forms a closed automatic production line.

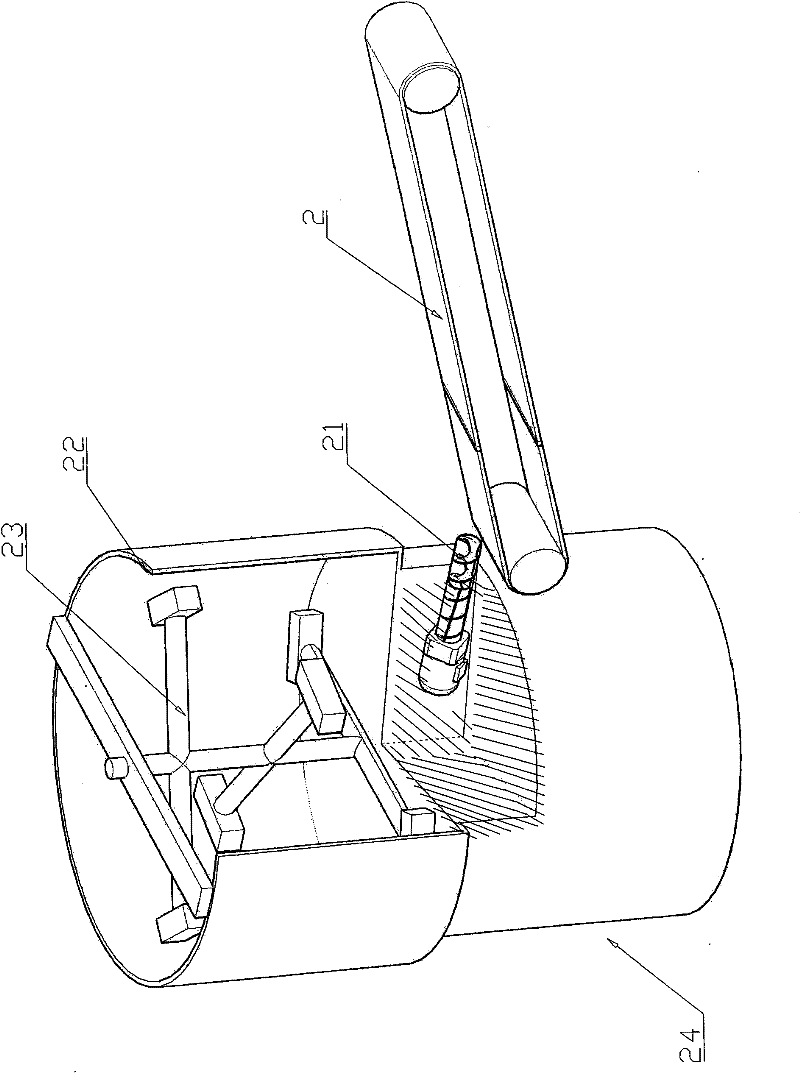

[0036] Depend on figure 2 It can be known that this gypsum powder mixing mixer 1 comprises a mixing bucket 22 installed on the base 24, the stirring blade 23 driven by the powder stirring motor is installed in the mixing bucket 22, and the bottom of the mixing bucket 22 is equipped with a speed-regulating discharge motor Driven spiral discharge device 21. The gypsum powder mixing mixer 1 fully mixes gypsum powder and other mixing materials evenly, and it can stir 3 tons of dry powder at a time, which is used for o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com