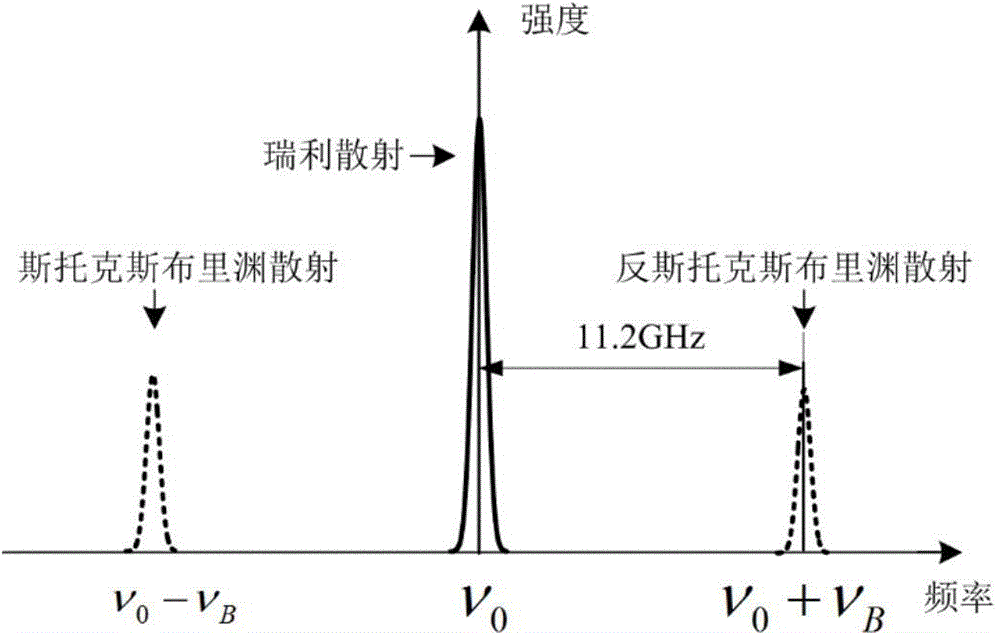

Optical fiber temperature and strain sensing device and method based on high spectral resolution technology

An optical fiber temperature and stress sensing technology, applied in the direction of measurement devices, instruments, etc., can solve the problems of affecting measurement accuracy, increasing system costs, increasing the difficulty and complexity of signal detection and processing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

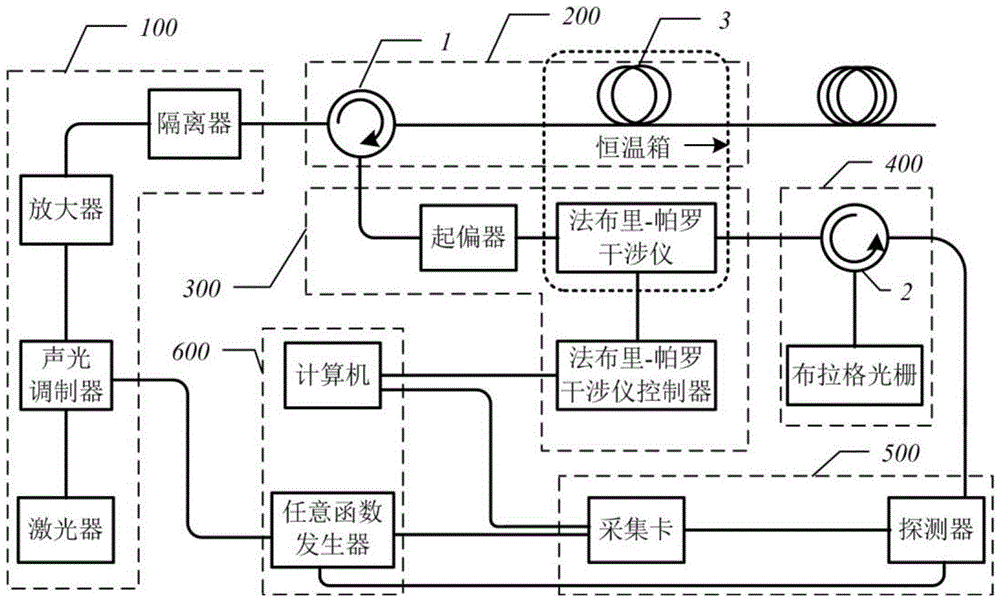

[0082] See figure 2 , the embodiment of the present invention provides an optical fiber temperature and stress sensing device based on hyperspectral resolution technology, including an optical emission system 100, an optical fiber sensing system 200, a hyperspectral resolution scanning system 300, an optical filtering system 400, and a data acquisition system 500 and control system 600, wherein,

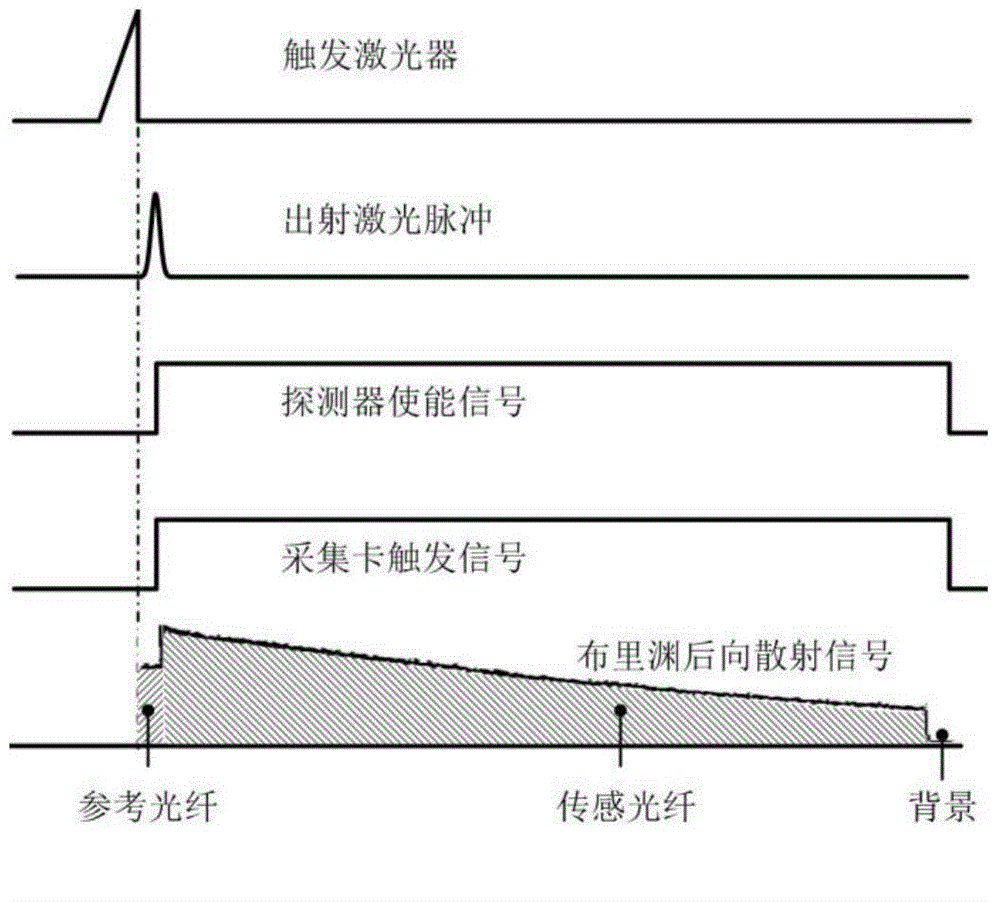

[0083] The optical transmission system 100 is used to output laser pulses; the optical fiber sensing system 200 is used to transmit the laser pulses output by the optical transmission system 100 into the reference optical fiber and the optical fiber to be tested and couple the backscattering signal of the optical fiber to the optical fiber. In the hyperspectral resolution scanning system 300; the hyperspectral resolution scanning system 300 is used to scan the optical fiber backscattering spectrum, and the hyperspectral resolution scanning system 300 includes a Fabry-Pérot interfero...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com