High-viscosity epoxy resin composite material pultrusion equipment for fibers

An epoxy resin and composite material technology is applied in the field of composite material processing equipment, which can solve the problems of inconvenient mold disassembly and maintenance, and the inability of cutting and pulling mechanisms to perform synchronous work, so as to achieve convenient access, convenient fixation, and improved use effects. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

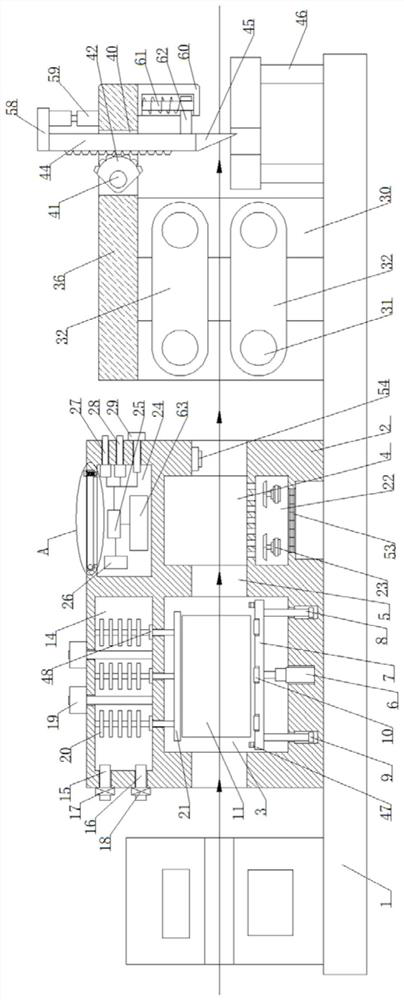

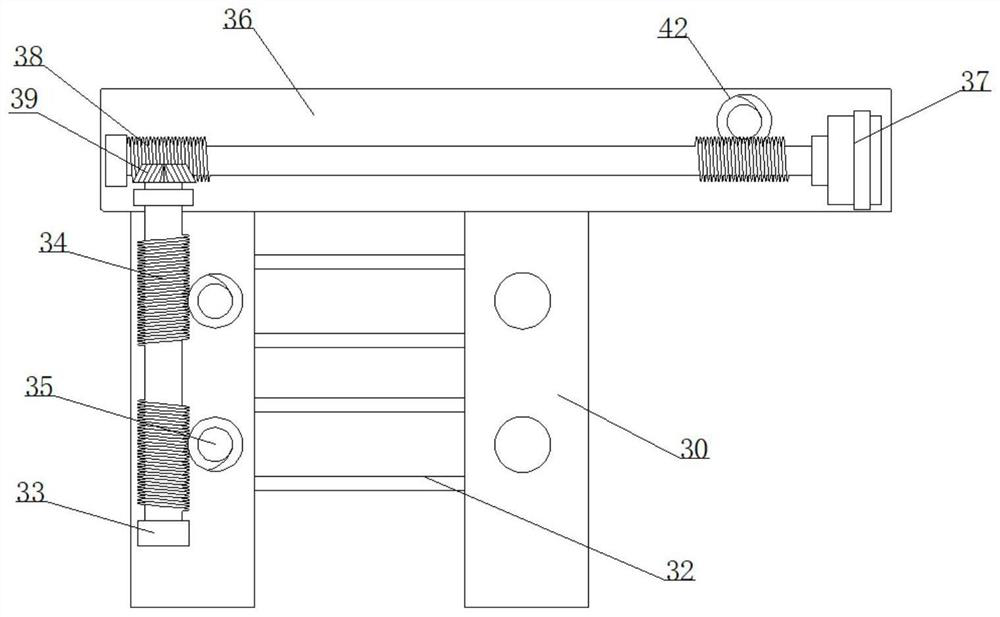

[0040] refer to Figure 1-5 , a high-viscosity epoxy resin composite material pultrusion equipment for fibers, including a mounting base 1, a preheating mechanism, a heating and curing mechanism, a traction mechanism and a cutting mechanism, and the preheating mechanism, the heating and curing mechanism, the traction mechanism and the cutting mechanism are all compatible with the installation The top of the seat 1 is fixedly connected, wherein the preheating mechanism is used to preheat the composite material, the heating and curing mechanism is used to heat and cure the composite material, and the traction mechanism can drive the composite material to move, and the cutting mechanism is used to cure the composite material in the mold. Composite materials for cutting;

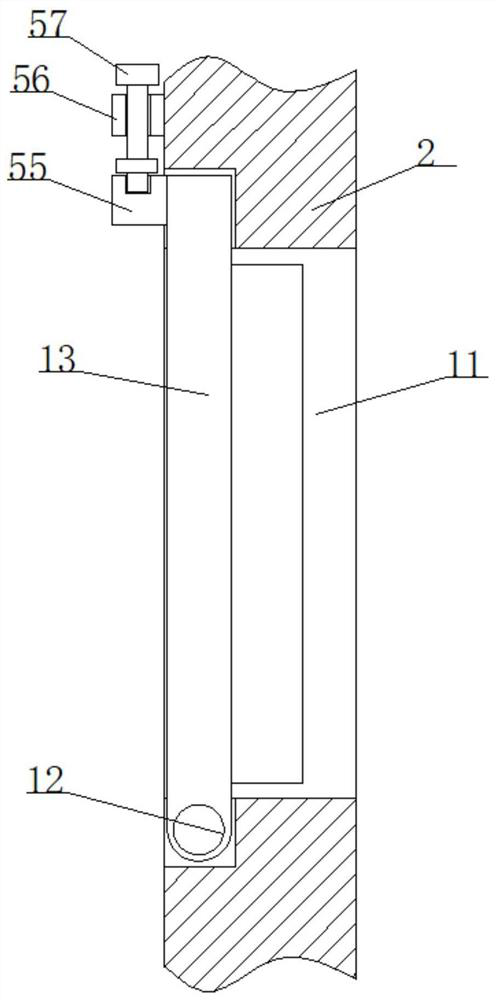

[0041] In the present invention, the heating and fixing mechanism includes a curing box 2 for setting the mould, and one end of the curing box 2 close to the preheating mechanism is provided with a heating cavit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com