Waste removing and plate conveying mechanism of bubble cap boxing machine

A technology of box-packing and plate-feeding, applied in packaging, packaging protection, transportation and packaging, etc., can solve problems such as low storage efficiency, inability of manipulators to accurately and timely absorb medicine plates, and synchronous actions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

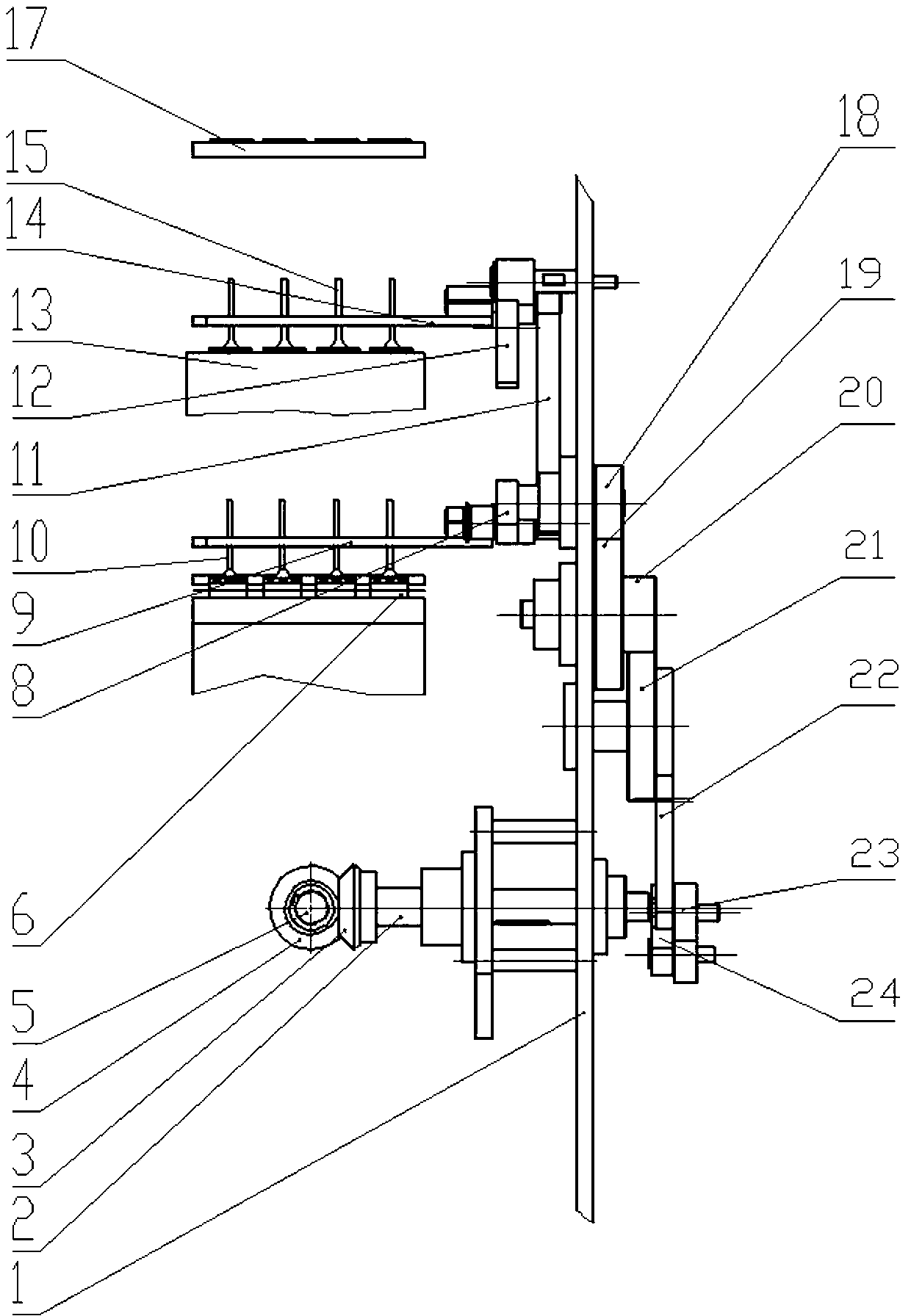

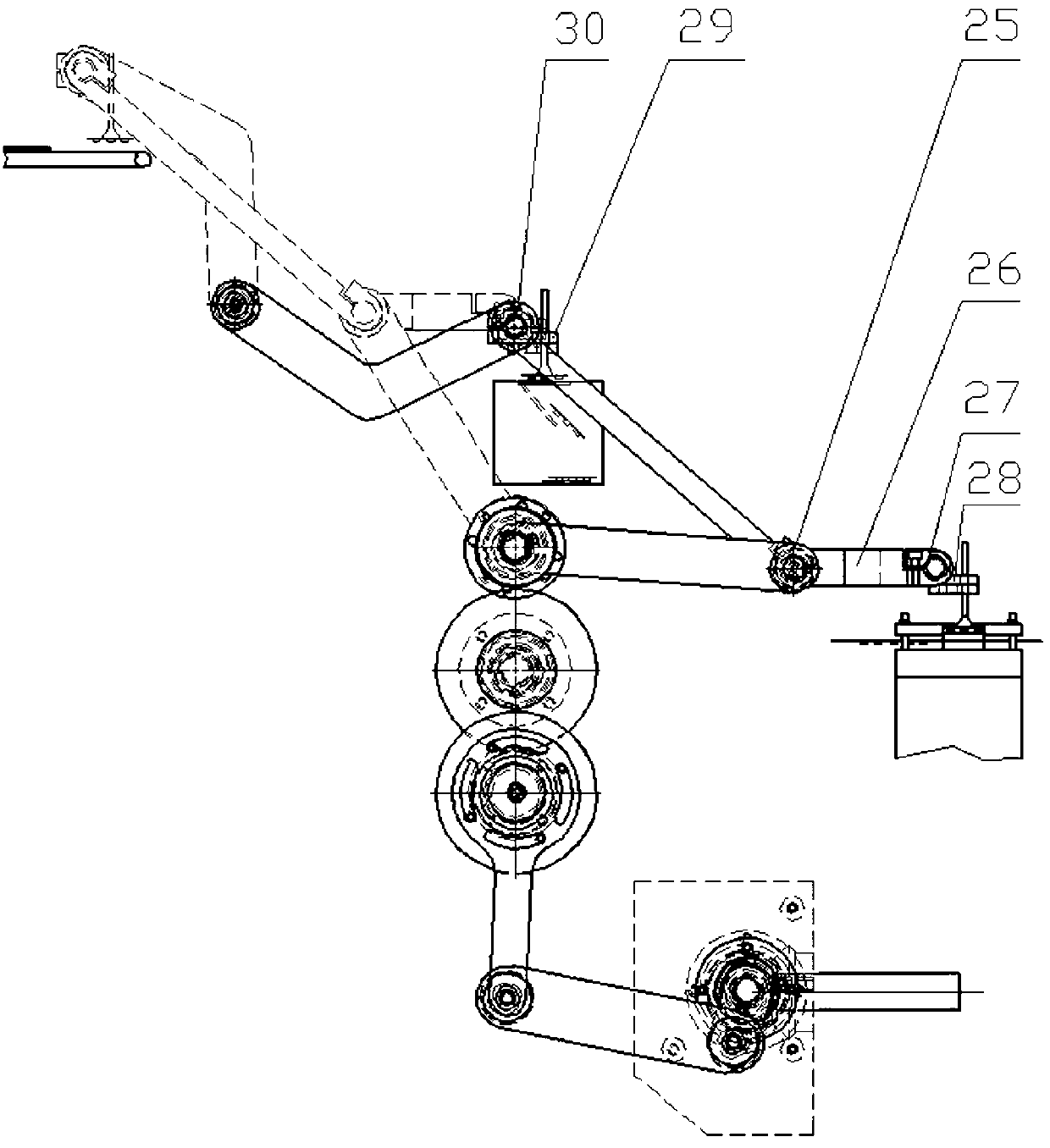

[0011] The accompanying drawings have shown the structure of the present invention and its embodiments, and describe the relevant details of its embodiments below in conjunction with the accompanying drawings. The rejecting and plate feeding mechanism of this blister cartoning machine includes a archway 1 and a transmission main shaft 5. The archway 1 is hinged with an active swing arm 8 and a driven swing arm 12, the transmission main shaft 5 is provided with a driving gear 4, and the archway 1 is provided with a transmission shaft 2, and the transmission shaft 2 is a transverse transmission shaft. The drive shaft 2 is provided with a driven gear 3, the drive gear 4 meshes with the driven gear 3, the other end of the drive shaft 2 is connected to the crank 24, and the other end of the crank 24 is connected to the lower connecting rod 23, so The swing arm on the rocker 22 at the other end of the lower connecting rod 23 is connected, and the rocker 22 is installed on the large h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com