Die bonder and semiconductor device packaging method thereof

A semiconductor and die bonder technology, applied in semiconductor devices, semiconductor/solid-state device manufacturing, electric solid-state devices, etc., can solve the problems of high viscosity and inability to dispense glue by conventional methods, avoid mutual interference, improve yield, and improve work The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

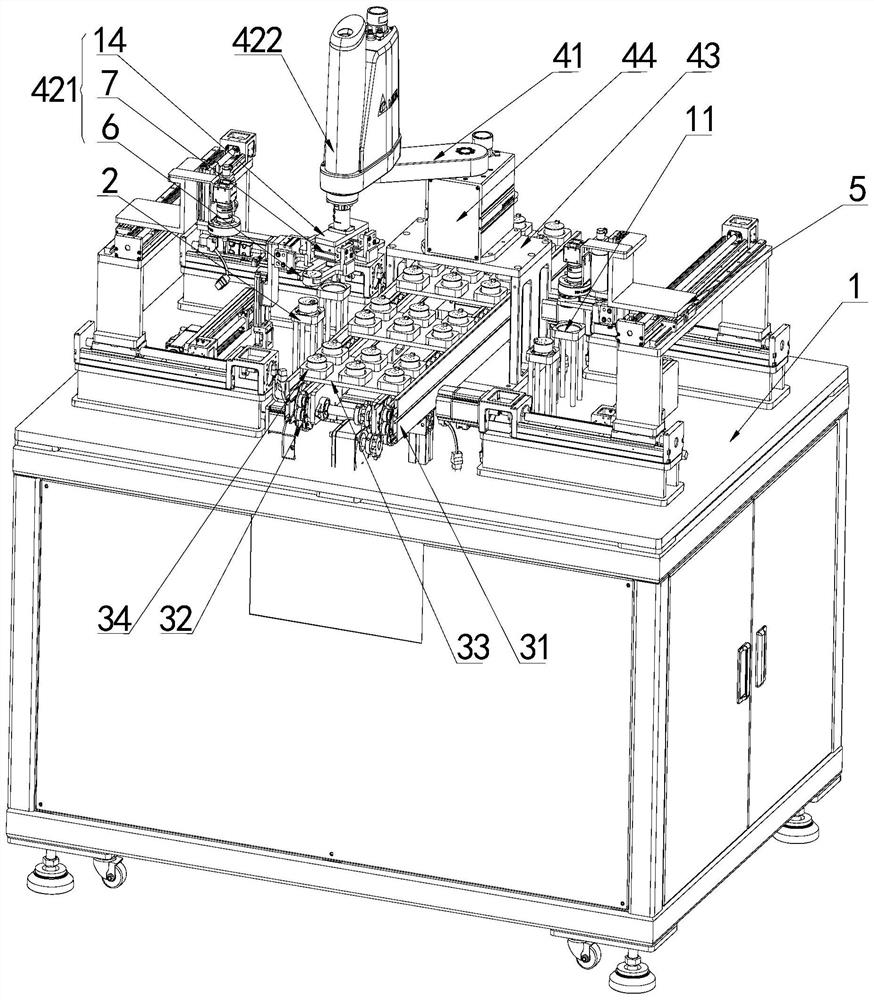

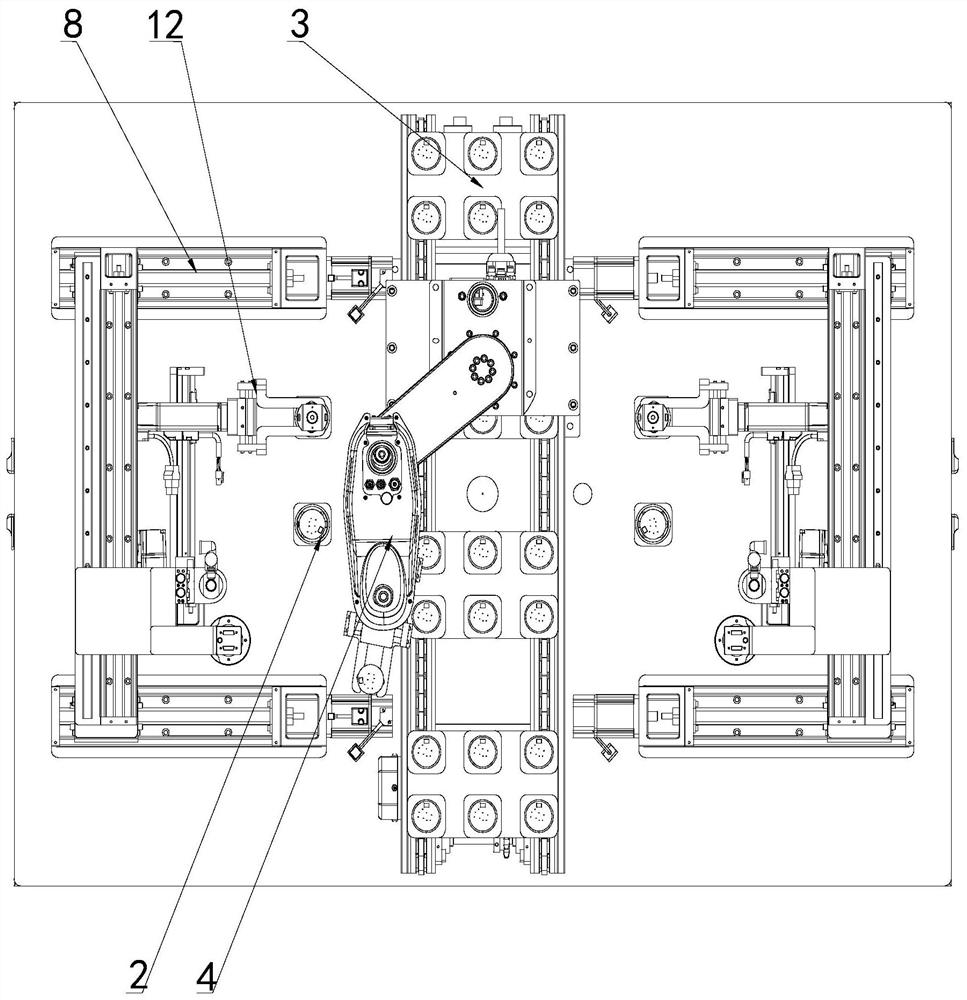

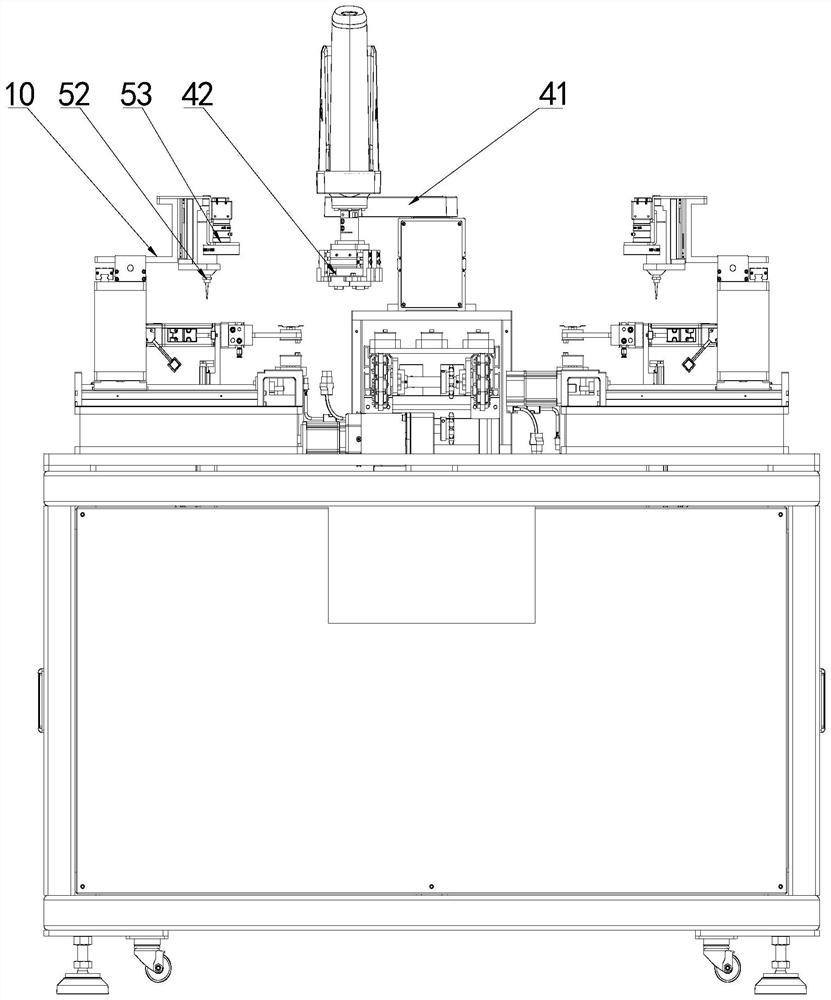

[0033] Such as Figure 1~5 A kind of solid crystal machine shown, it comprises workbench 1; Said workbench 1 is provided with the placement platform 2 that is used to place the semiconductor device to be dispensed, is used to transport the delivery device 3 that is to be dispensed semiconductor device, is used for The clamping device 4 and the dispensing device 5 that transfer the semiconductor device to be glued between the placement table 2 and the delivery device 3; frame 51, and the dispensing head 52 that is located on the frame 51 and the detection device 53 for the dispensing quality of the quality inspection semiconductor device; the detection device 53 includes a camera and is connected with the camera for communication A processing module; the processing module includes an image processing unit, an abnormal point identification unit and a dispensing failure analysis unit.

[0034] This embodiment 1 is provided with the placement table 2 and the conveying device 3, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com