Flying shear control system and flying shear control method

A technology of flying shear control and flying shear, which is applied in the field of flying shear control, can solve problems affecting enterprise benefits, difficult maintenance, and high failure rate, so as to improve work efficiency and work stability, ensure shear quality, and improve shear efficiency. Effects of Accuracy and Stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

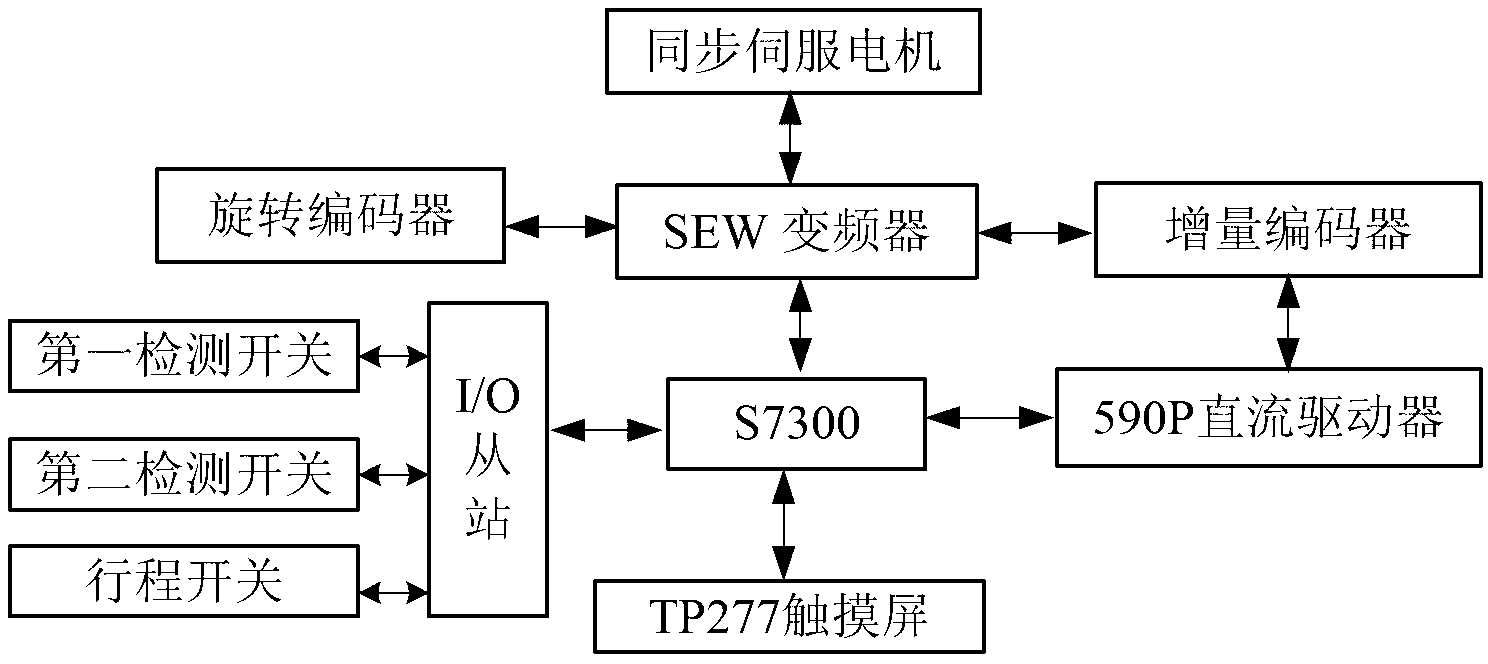

[0042] Such as figure 1 As shown, this embodiment discloses a flying shear control system, which is divided into a management layer, a control layer and an equipment layer, and the management layer includes a host computer;

[0043]The upper computer adopted in the present embodiment is the TP277 touch screen of Siemens Company, completes the setting of the cutting length parameter of material, frequency converter parameter, motor parameter and wire bar parameter, the frequency converter set by upper computer is set by DP bus Parameters, motor parameters and wire and bar parameters are sent to the DCS master station, and the DCS master station monitors the alarm through the host computer.

[0044] The control layer includes DCS master station, I / O slave station and frequency converter. The DCS master station used in this implementation is the programmable computer control system S7300 of Siemens. The programmable computer control system S7300 includes power supply module, CPU ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com