Double-motor mechanical synchronization accelerator pedal assembly

A technology of mechanical synchronization and accelerator pedal, which is applied in the direction of engine control, machine/engine, mechanical equipment, etc., can solve the problems of not being in place, not returning to the position of the accelerator, etc., to ensure the transmission ratio, prolong the service life and save labor. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

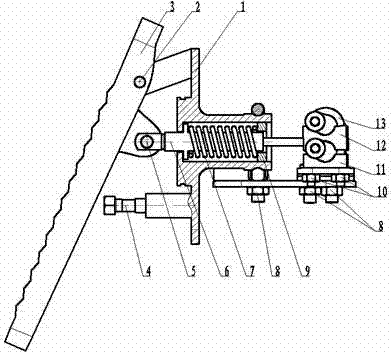

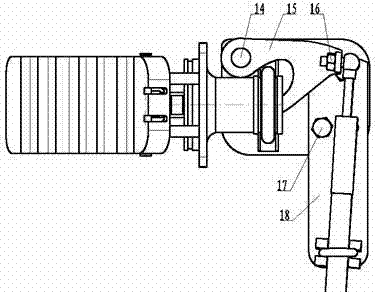

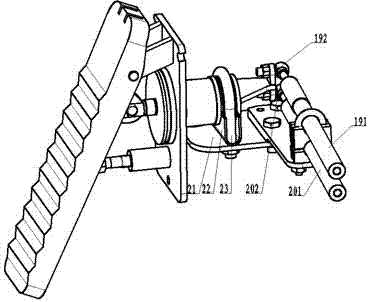

[0018] Such as figure 1 , figure 2 , image 3 As shown, the dual-engine mechanical synchronous accelerator pedal assembly of the present invention has the main structure as follows: the pedal holder 1 and the anti-skid pedal 3 are movably connected through the connecting pin 2, and one end of the mandrel 6 is connected with the anti-skid pedal 3 through the connecting pin 5; The other end of the shaft 6 is connected with a paddle 15, and the paddle 15 is connected with two equal stay wires of elongated length by a nut 16, and the two backstays are respectively connected with the valves of the two engines. After adopting the above structure, when the operator applies an external force on the anti-skid pedal 3, it will rotate around the connecting pin 2, the mandrel 6 is linked, and then the two pull wires are pulled by the paddle 15 to realize the synchronous operation of the two engines.

[0019] The paddle 15 is fixed on the rotating fixed plate 21 through the threaded pin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com