Flexible polyurethane conductive material and preparation method thereof

A conductive material and polyurethane technology, applied in the field of flexible polyurethane conductive materials and their preparation, can solve the problems of poor material performance and large filling amount of conductive fillers, and achieve the effects of good conductivity, various colors and meeting purification requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

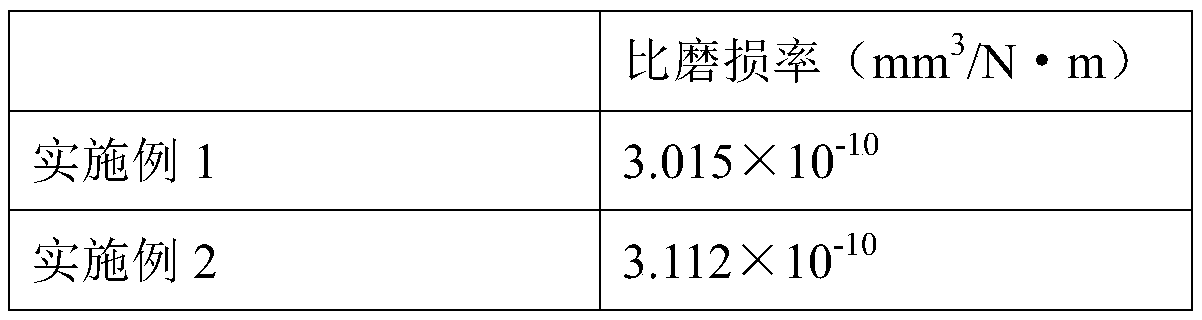

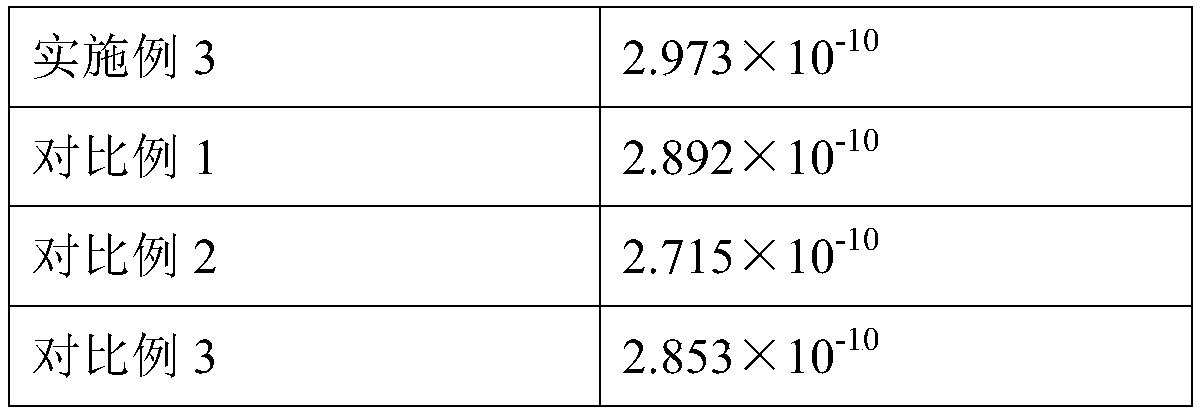

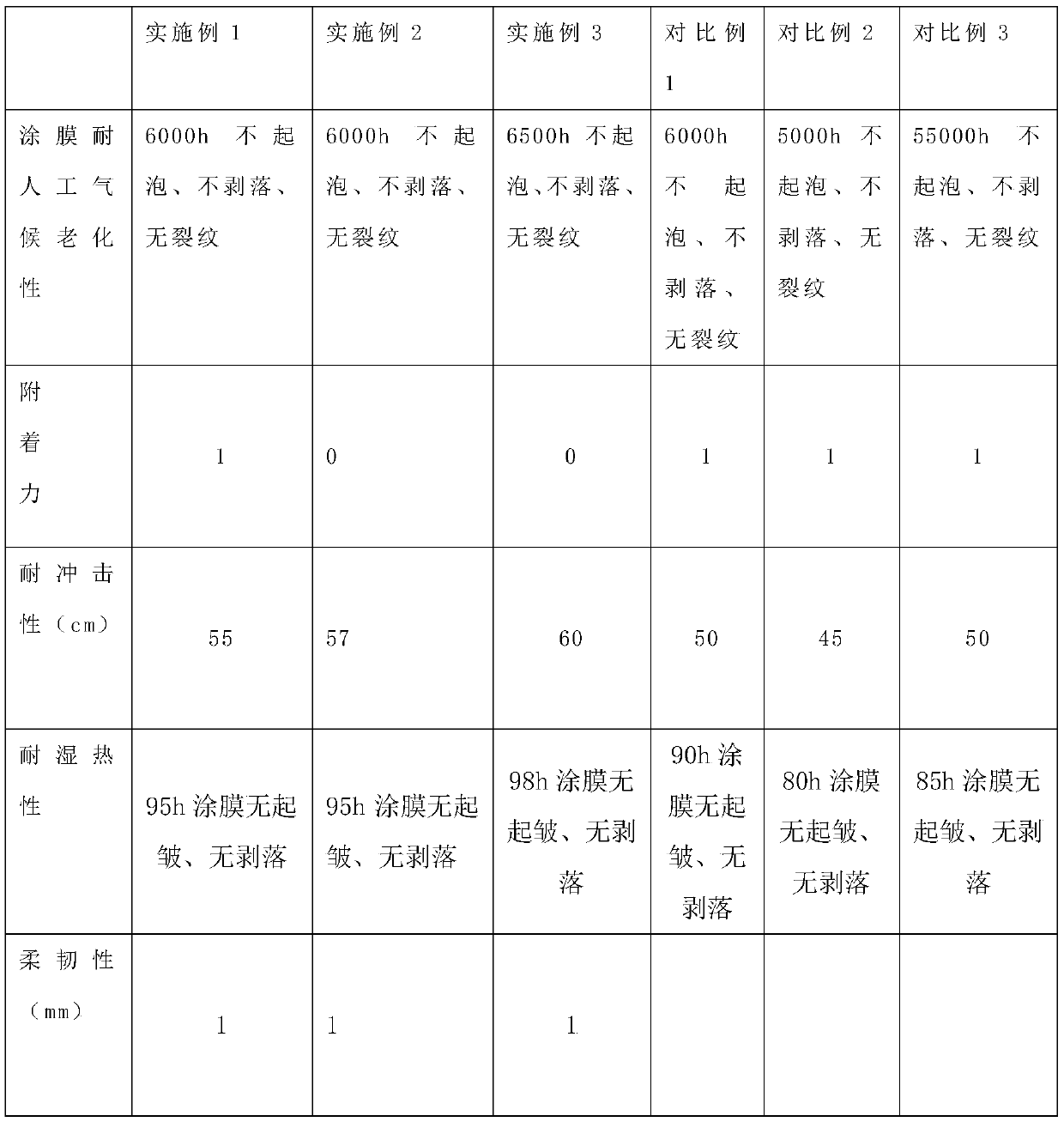

Embodiment 1

[0026] A flexible polyurethane conductive material, the formula is: polyether polyol 64%, isocyanate 18%, coated graphite powder 3%, ordered mesoporous carbon 3%, single-wall carbon nanotube 1%, dodecyl dimethicone Ammonium oxide 2%, polyethylene glycol p-toluenesulfonate 5%, 2-mercaptoethanol 3.5%, pigments and fillers 0.5%.

[0027] The preparation method that described coated graphite powder adopts is:

[0028] (1) Dissolve 1g of n-butyl titanate (1mL) and 5mL of polyvinylpyrrolidone in 10mL of a mixed solvent composed of triethanolamine and ethanol at a volume ratio of 1:3, stir until completely dissolved, and then add 0.4mL of ammonia water, Stir magnetically for 50 minutes, then add 0.1 g of mercaptopropyltriethoxysilane, and stir for 15 hours to obtain a template carrier for use;

[0029] (2) Add 10g of graphite powder to 10g of the template carrier (the step (1) is scaled up and prepared in equal proportions), stir evenly, then add hydrogen peroxide (1g) drop by drop,...

Embodiment 2

[0035] A flexible polyurethane conductive material, the formula is: polyether polyol 68%, isocyanate 15%, coated graphite powder 5%, ordered mesoporous carbon 2%, single-wall carbon nanotube 2%, dodecyl dimethicone Ammonium oxide 2%, polyethylene glycol p-toluene sulfonate 3%, 2-mercaptoethanol 2%, pigments and fillers 1%.

[0036] The preparation methods of each raw material and materials are the same as in Example 1.

Embodiment 3

[0038] A flexible polyurethane conductive material, the formula is: polyether polyol 73%, isocyanate 10%, coated graphite powder 4%, ordered mesoporous carbon 2%, single-wall carbon nanotube 2%, dodecyl dimethicone Ammonium oxide 1%, polyethylene glycol p-toluenesulfonate 4%, 2-mercaptoethanol 3.5%, pigments and fillers 0.5%.

[0039] The preparation methods of each raw material and materials are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com