Gas purification method applied to coal-based synthetic natural gas device

A technology of gas purification and coal-based synthesis, which is applied in combustible gas purification, combustible gas purification/transformation, gas fuel, etc., and can solve the problems of large energy consumption and large consumption of methanation systems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

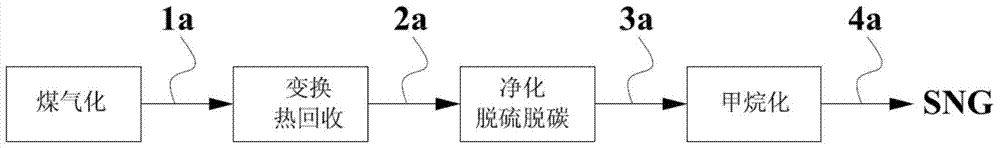

Problems solved by technology

Method used

Image

Examples

Embodiment 1

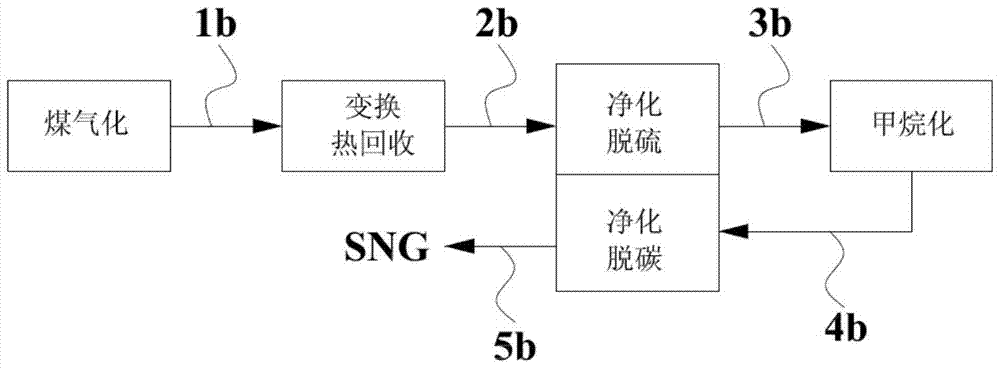

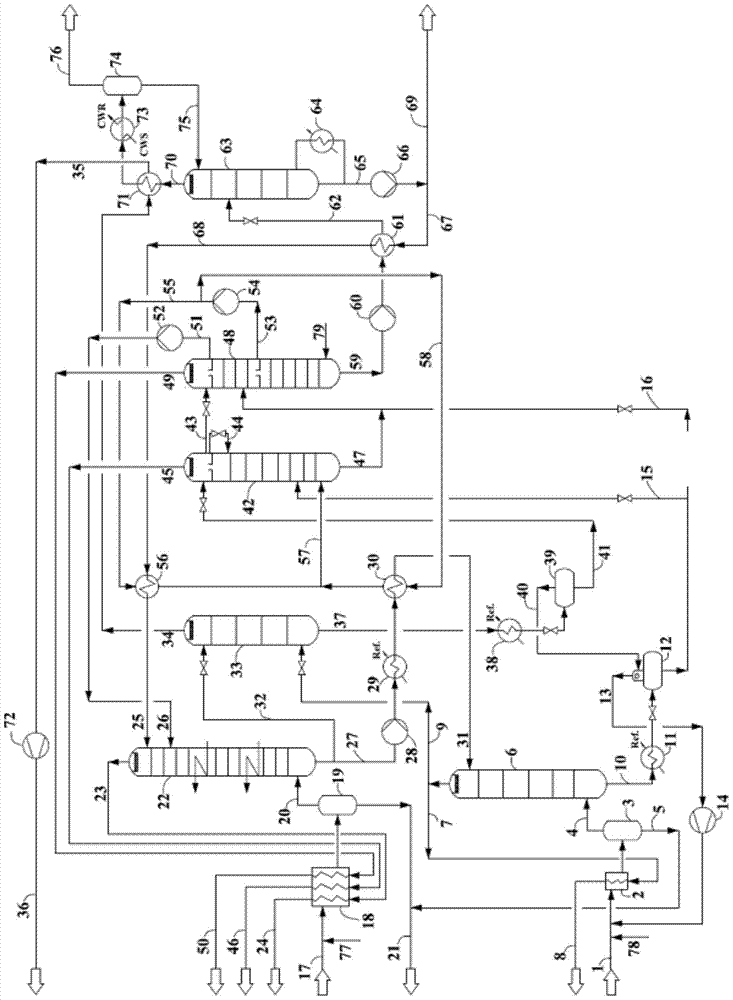

[0056] like figure 2 As shown, it is the coal-based synthetic natural gas process route of the present invention, followed by coal gasification to produce crude synthesis gas (1b), and the crude synthesis gas (1b) is adjusted by 3(H 2 -CO 2 ) / (CO+CO 2 ) ratio is approximately equal to the shift gas (2b) of 0.9~1.1, the shift gas (2b) is only desulfurized by the purification device, but does not remove CO 2 , CO 2 As the heat transfer medium or diluent gas of the methanation reaction, it passes through the methanation reactor to finally obtain the crude methane product gas (4b), and the CH in the crude methane product gas (4b) 4 Content 20%~50%, CO 2 The content is 45% to 75%, which is very different from the SNG product produced by the traditional methanation unit, and the CO must be removed centrally through the purification unit 2 In order to obtain the SNG product (5b) that meets the requirements of natural gas products. Specifically, the crude synthesis gas 1b gener...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com