Strong-strength machine-made handmade sandwich board

A sandwich panel, high-strength technology, used in covering/lining, building, building structure, etc., can solve the problems of high cost, insufficient transverse end face compressive strength, and complicated connection between panels and panels, and achieves increased strength and assembly. Easy and fast positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

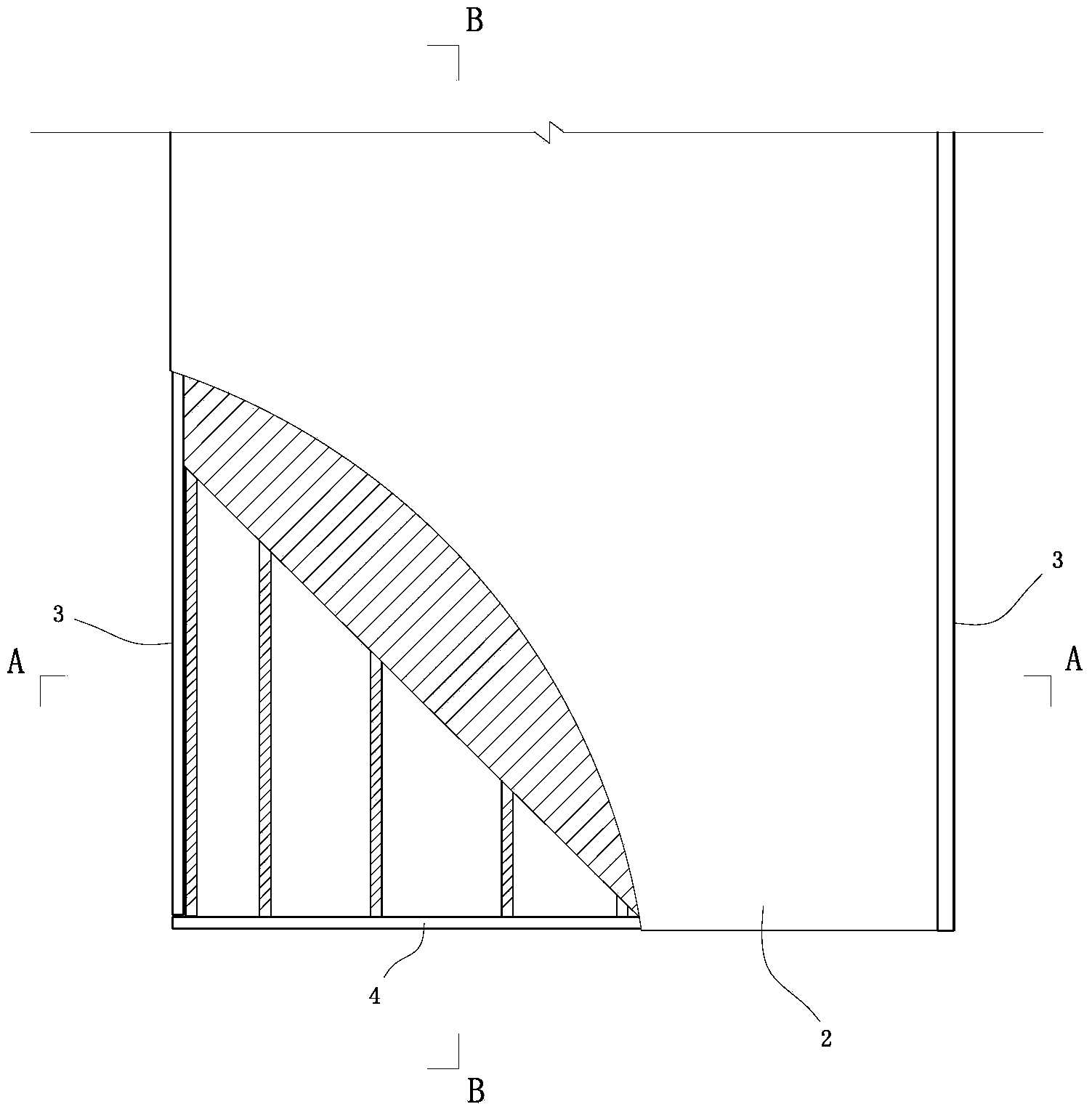

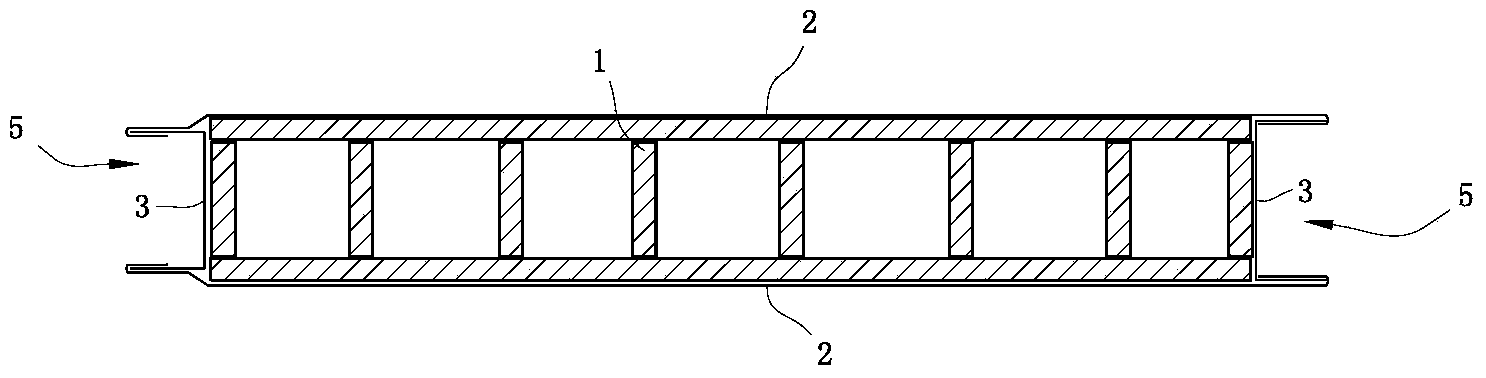

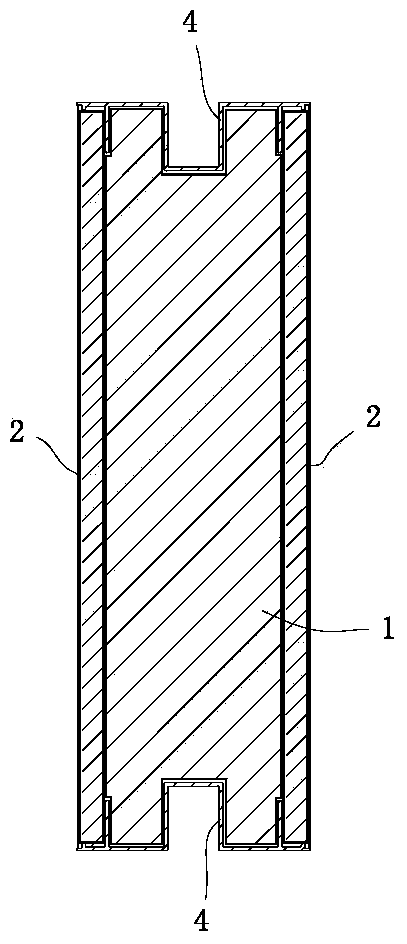

[0022] refer to Figure 1 to Figure 14 , a high-strength machine-made sandwich panel of the present invention, comprising a sandwich core material 1 and panels 2 covering the surfaces on both sides of the sandwich core material 1, the left and right sides of the sandwich core material 1 are respectively provided with a cross-section in the shape of U Shaped side panels 3, the longitudinal edge ends of the two panels 2 stretch out respectively and are turned over to be rolled and connected with the side panels 3 to form male and female grooves 5 at the left and right ends of the sandwich core material 1. The upper and lower sides of the sandwich core material 1 The side end is also provided with a reinforced connection belt 4, and the middle part of the reinforced connection belt 4 is formed with a groove structure or a tenon structure, which is embedded and connected with the sandwich core material 1, and is closely connected with the panel to enhance the transverse strength of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com