Preheating systems for bulk raw materials for rock wool, basalt fiber or glass production

A basalt fiber and raw material technology, which is applied in the feeding of melting furnaces, glass manufacturing equipment, manufacturing tools, etc., can solve the problems of high-temperature flue gas purification and treatment costs, high energy consumption of kilns, and large heat absorption, etc., to reduce kiln Furnace energy consumption, cost reduction, and difficulty reduction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

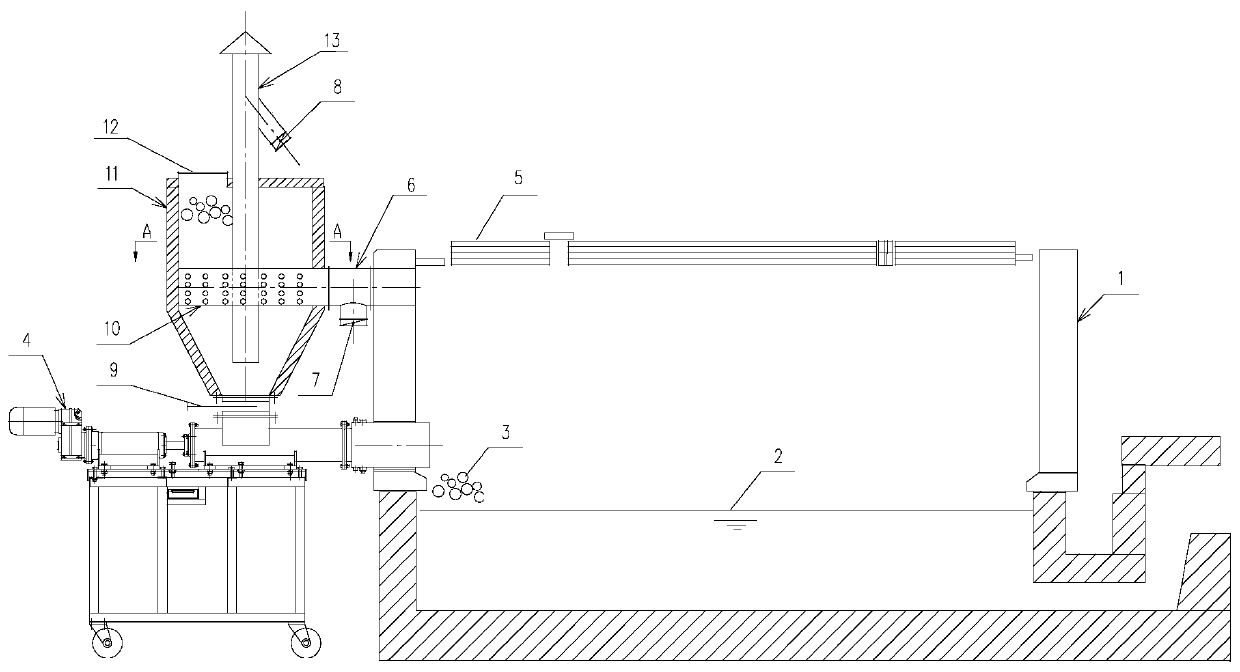

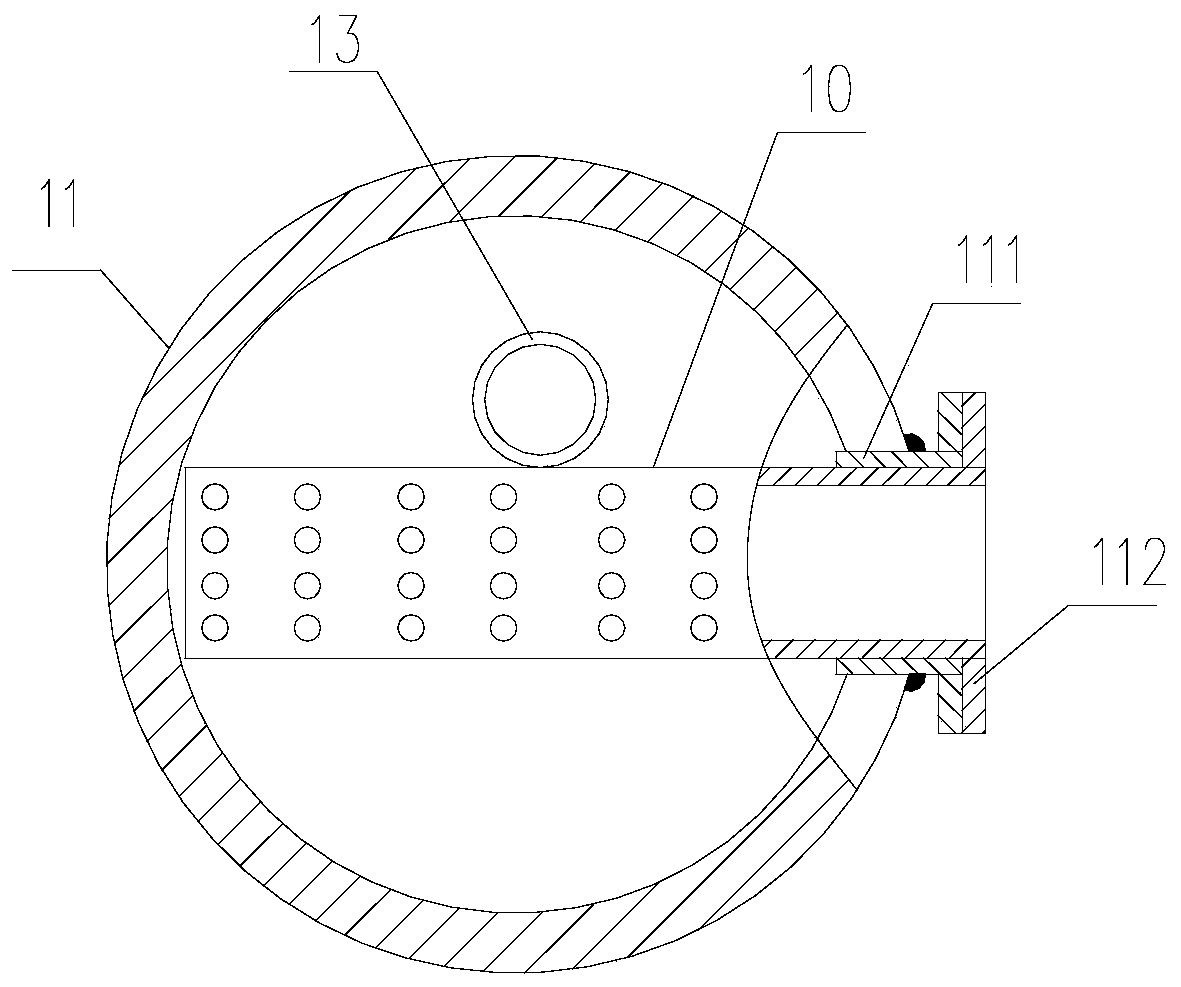

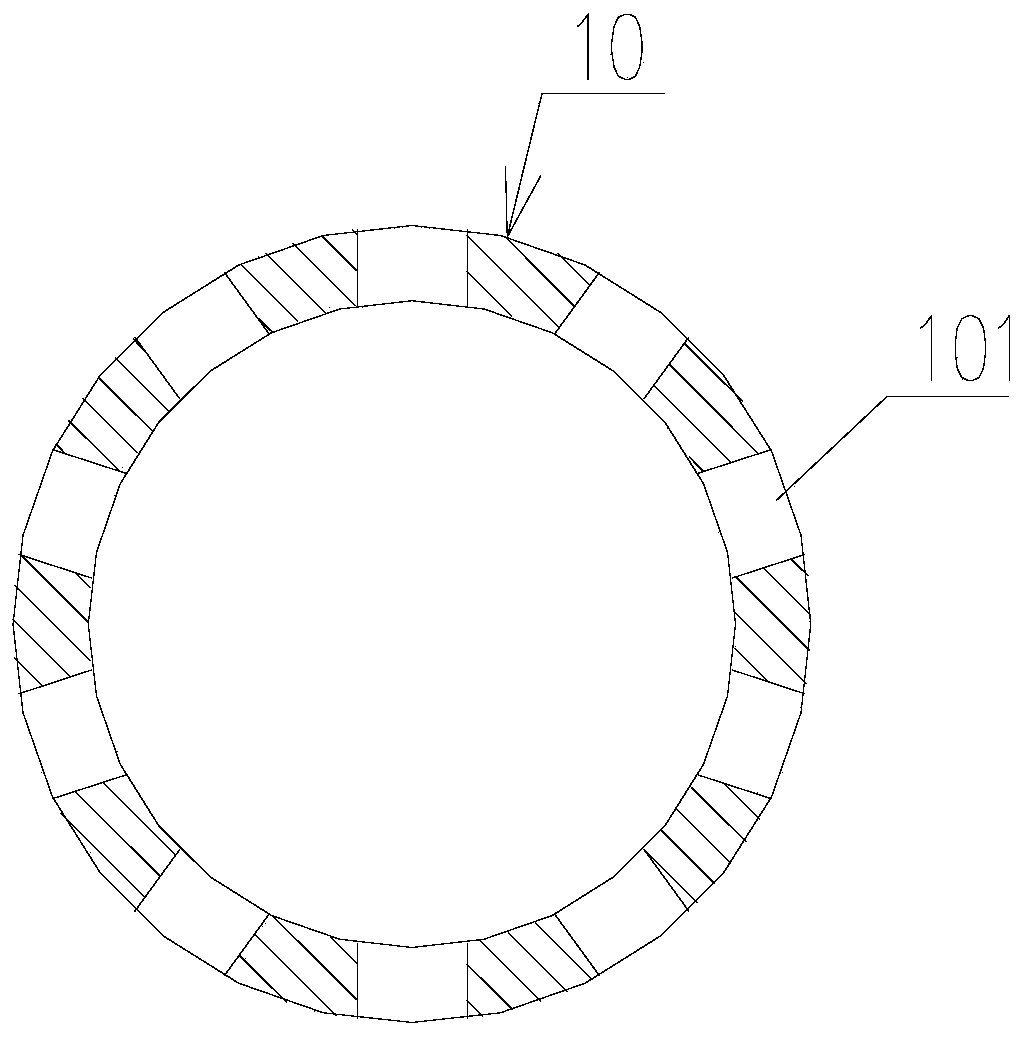

[0019] refer to Figure 1 ~ Figure 3 , a preheating system for producing rock wool, basalt fiber or glass block raw materials, comprising a kiln 1, a feed bin 11 and a feeding machine 4, a hot air distributor 10 and an exhaust chimney 13 are arranged in the feed bin, The upper end of the exhaust chimney 13 stretches out of the feed bin and is provided with an air outlet, and the lower end of the exhaust chimney 13 stretches into the bottom of the feed bin to be provided with an air inlet; A channel for block raw materials to pass is provided between the inner walls of the warehouse 11; the hot air distributor 10 includes a closed cavity surrounded by side walls, and the side walls are distributed with a number of air outlet holes, and the closed cavity and The high-temperature exhaust chimney 6 on the top of the kiln is connected; the top of the silo is provided with a raw material inlet, and the bottom of the silo is provided with a raw material outlet. The inlet of furnace ...

Embodiment approach 2

[0026] refer to Figure 4 Embodiment 2 is basically the same as Embodiment 1, except that the hot air distributor 100 is a cube with a closed cavity surrounded by steel plates, the top surface of the cube is a slope 110, and the side walls around the steel plate are uniform. Air outlet holes 1101 are distributed. The hot air distributor 100 can be arranged in the silo 11 through a bracket, and its inner chamber communicates with the high-temperature exhaust chimney 6 through a section of air duct.

[0027] Parts that are not specifically described in the above specification are all prior art, or can be realized by prior art.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com