Patents

Literature

34 results about "Salt calcium" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Calcium carbonate an insoluble salt occurring naturally in bone, shells, and chalk; used as an antacid, calcium supplement, and phosphate binder, and for treatment of osteoporosis.

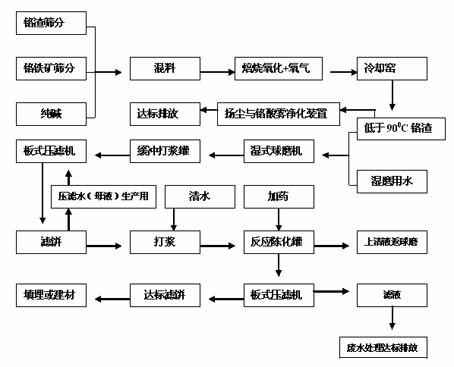

Chromium slag roasting oxidation comprehensive detoxification cleaning process

InactiveCN102285688AReduce total chromiumReduce total alkali contentSolid waste managementChromates/bichromatesSlagRaw material

The invention relates to a comprehensive detoxification and cleaning process for chromium slag by roasting and oxidation. The technical solution adopted is: a comprehensive detoxification and cleaning process of chromium slag roasting and oxidation, characterized in that: chromium slag is used as raw material, chromite and soda ash are auxiliary materials, and the material ratio is: chromium slag: chromite ore: soda ash=2:1 :0.6, at the roasting reaction temperature of 1050°C, the chromium trioxide in the mixed material is roasted and oxidized at high temperature to form sodium chromate, the conversion rate is more than 80%, and the extraction liquid is used as the mother liquor for the production of red alum sodium products. The main process flow: roasting and oxidation + ball mill leaching + plate and frame filter press dehydration + liquid production red alum sodium production + filter cake secondary beating to extract supernatant + acidification solidification + landfill or building materials. The total chromium content in the detoxification slag is low, and the comprehensive utilization rate is high, which solves the post-disposal problem existing in the traditional dry and wet chromium slag detoxification process, and the cost is low. The method is also applicable to the roasting production with calcium, less calcium and calcium-free in chromium salt production enterprises, and the effect is equally remarkable.

Owner:青海省中星化工有限公司 +1

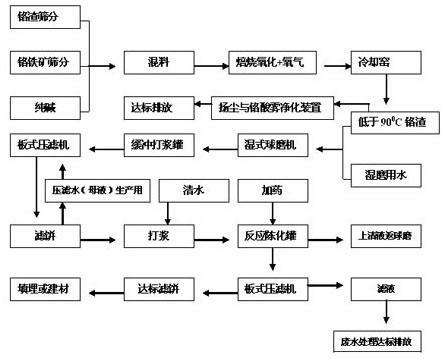

Preparation method of drilling-fluid-use high-temperature-resistant saturated-salt-resistant filtrate loss reducer

ActiveCN103130953AImprove salt resistanceIncrease the difficultyDrilling compositionPotassium hydroxideElastic solids

The invention discloses a preparation method of a drilling-fluid-use high-temperature-resistant saturated-salt-resistant filtrate loss reducer. According to the invention, acrylamide, 2-acrylamido-2-methyl propanesulfonic acid, and polyvinyl pyrrolidone are dissolved into a mixed water solution; a temperature is increased to 30-40 DEG C, and dmethyl diallyl ammonium chloride is added; the mixture is sufficiently stirred until dissolved; a potassium hydroxide water solution is added, and a pH value is regulated to 7-8; nitrogen gas is fed for protection; an azodiisobutyronitrile initiator is added and is dissolved by sufficient stirring; implosion is initiated by heating; constant-temperature reaction is carried out; a white elastic solid product is obtained; the product is cut and crushed; constant-temperature drying is carried out; and crushing and sieving are carried out, such that the drilling-fluid-use high-temperature-resistant saturated-salt-resistant filtrate loss reducer is obtained. The product can be used as a saturated brine drilling fluid filtrate loss reducer in a deep well under a high temperature of 220 DEG C. Temperature resistance of the product is improved. High-temperature high-pressure filtrate loss wall building property and salt-calcium corrosion resistance of the drilling fluid are stabilized. The product is suitable to be used in drilling fluids of high-temperature deep-well salt rock strata, gypsum salt beds, and high-water-sensitive shale strata.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA) +1

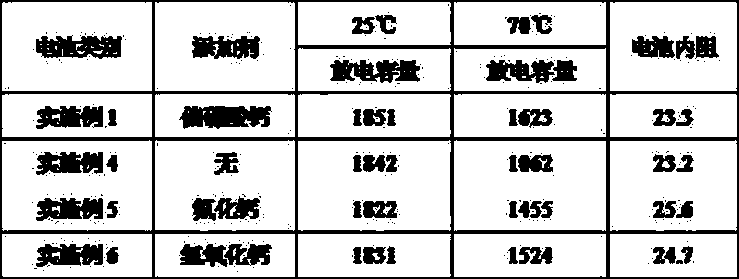

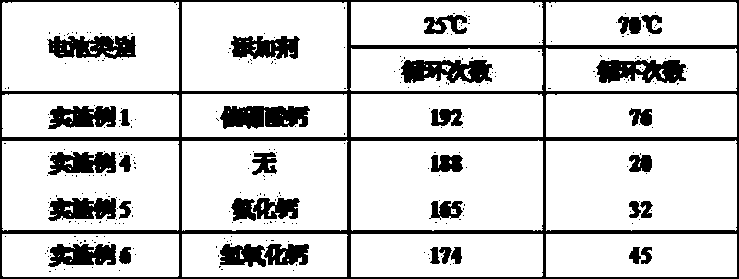

Nickel-based cell anode, its preparation method and nickel-based cell by using anode

ActiveCN103647054AEvenly distributedImprove performanceAlkaline accumulator electrodesNickel accumulatorsCalcium borateSalt calcium

The invention discloses a nickel-based cell anode, its preparation method and a nickel-based cell by using the anode. A technical scheme main point is characterized in that the nickel-based cell anode comprises an anode active material, the anode active material contains nickel hydroxide and soluble calcium salt calcium metaborate or calcium borate calcium borate, wherein the content of soluble calcium salt calcium metaborate or calcium borate accounts for 0.01-5% of weight of nickel hydroxide. The invention also discloses a preparation method of the nickel-based cell anode and an alkalescence nickel-based secondary cell by using the nickel-based cell anode. According to the invention, calcium ion uniform distribution and introduction of beneficial anion in the soluble calcium salt can effectively improve the comprehensive performance of the nickel-based cell, the nickel-based cell internal resistance is reduced, the high temperature performance is increased, and the cycle performance is improved.

Owner:河南省恒明新能源有限公司

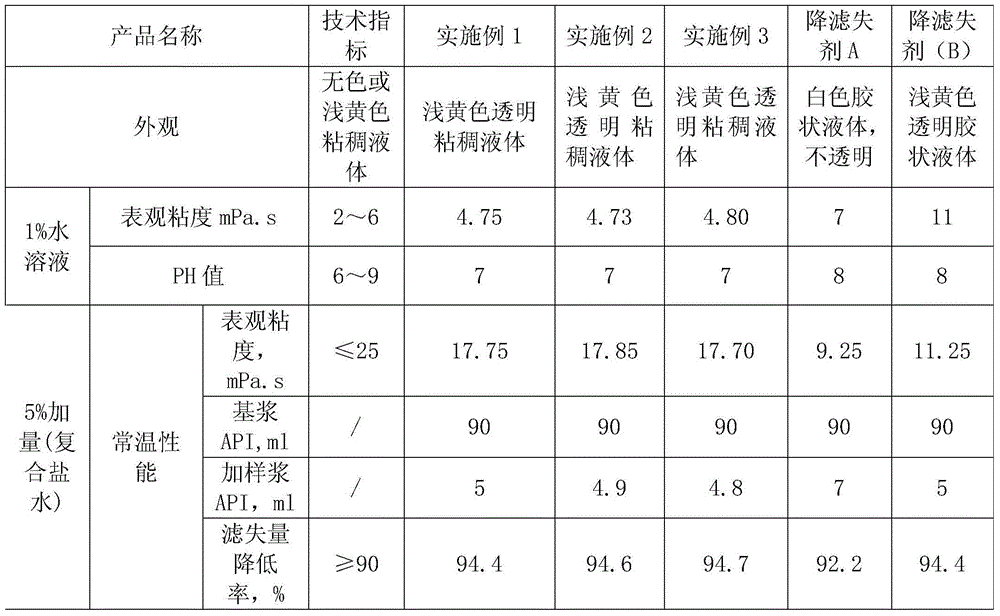

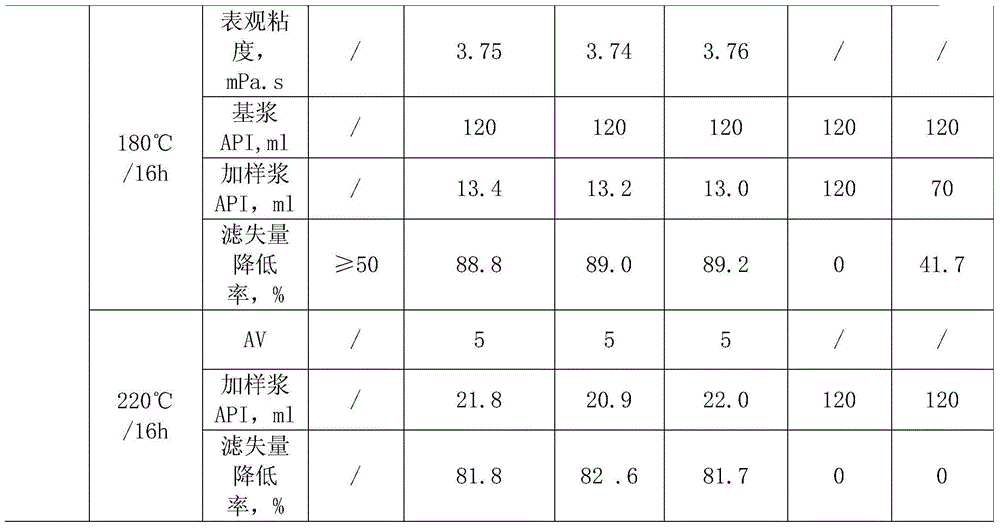

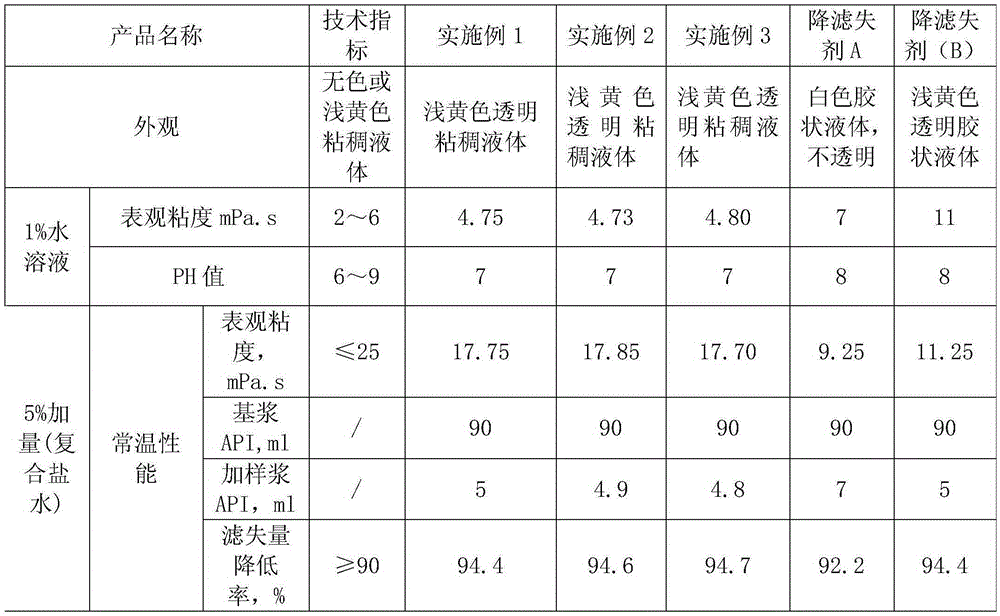

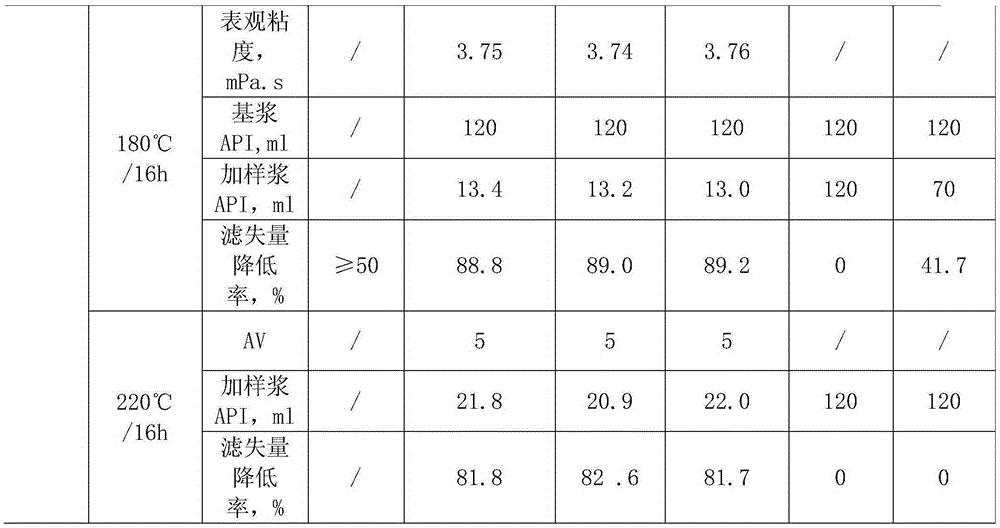

Fluid loss agent for high-temperature-resistant compound salt resistant polymer for drilling fluid and preparation method thereof

ActiveCN103555296AImprove temperature resistanceGood resistance to salt and calciumDrilling compositionHigh pressurePollution

The invention provides a fluid loss agent for a high-temperature-resistant compound salt resistant polymer for drilling fluid and a preparation method thereof. The fluid loss agent consists of the following raw materials in percentage by weight: 10-15 percent of acrylic acid, 6-8.5 percent of sodium hydroxide, 60-65 percent of deionized water, 4-8 percent of acrylamide, 5-6 percent of tetraphenyl ethylene sodium sulfonate, 6-8 percent of N-vinyl pyrrolidone and 0.1-0.5 percent of initiator. Compared with the prior art, the fluid loss agent has the beneficial effects that the high-temperature high-pressure filter loss of the drilling fluid can be obviously reduced, and the temperature resistance and salt calcium pollution resistance of the drilling fluid system are entirely improved. Moreover, the mud cake quality is improved, a permeability recovery rate is increased, and a hydrocarbon reservoir is effectively protected. The fluid loss agent can resist high temperature of 180 DEG C and compound salts and can serve as a fluid loss agent of deep walls, drilled evaporite beds and seawater drilling.

Owner:KORLA TONGYI IND TRADE CO LTD

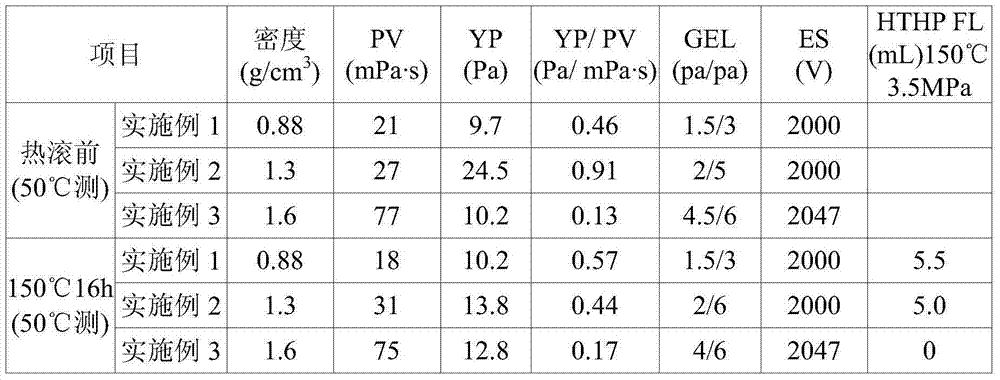

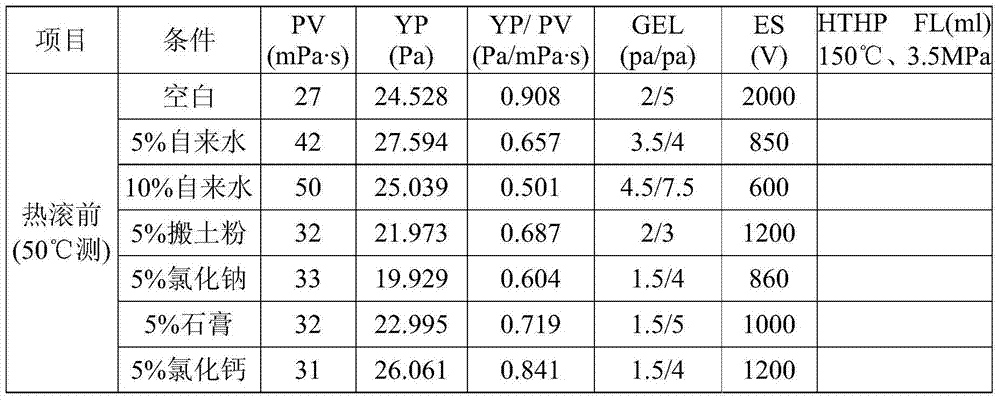

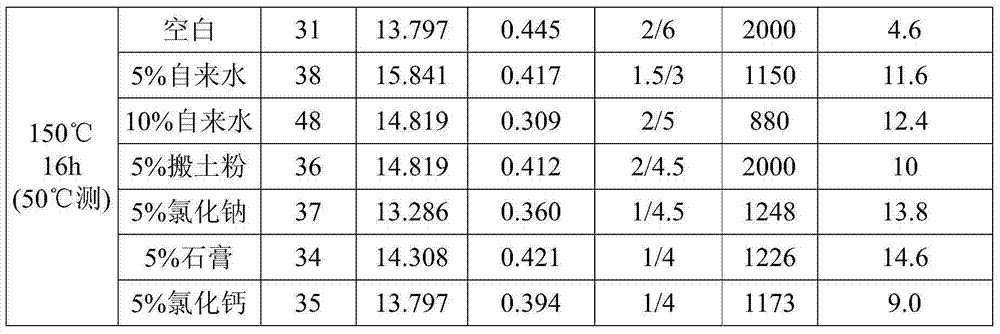

Plant oil-based drilling fluid and preparation method thereof

The invention provides a plant oil-based drilling fluid and a preparation method thereof. The plant oil-based drilling fluid comprises plant oil, a saline solution and a treating agent, wherein the volume ratio of the plant oil to the saline solution is (80:20) to (95:5); the treating agent comprises an emulsifier, a wetting agent, organic soil and a filtrate reducer. Based on 100mL of plant oil and saline solution, the content of the emulsifier is 2.5-3.5g, content of the wetting agent is 0.5-0.8g, the content of the organic soil is 0.5-2g and content of the filtrate reducer is 3-5g; the density of the drilling fluid is 0.88-1.6g / cm<3>. As the selected base oil is plant oil in the natural biologic chain, the plant oil-based drilling fluid provided by the invention can be biodegraded and further has the advantages of good emulsion stability, low high-temperature and high-pressure filter loss and good water-resisting, soil-resisting, salt calcium-resisting and gypsum pollution-resisting capacities.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

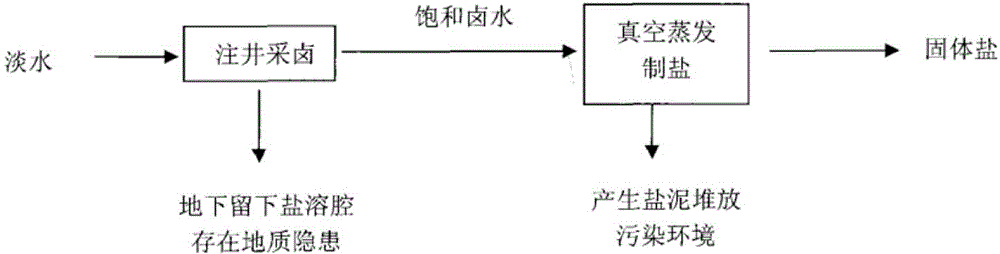

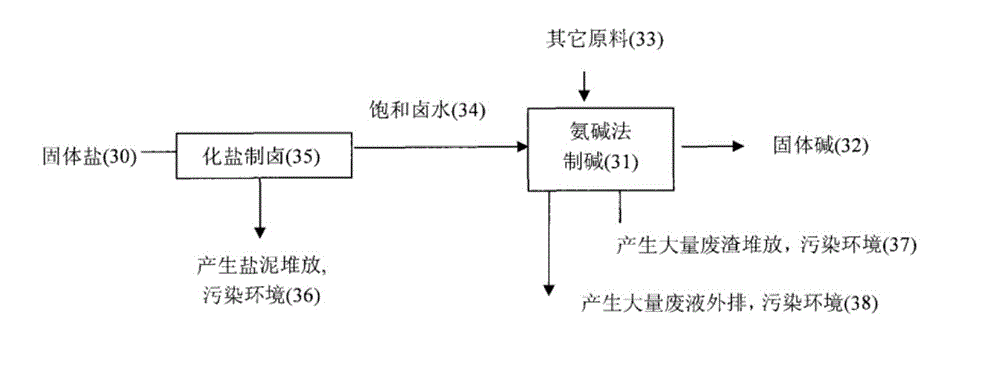

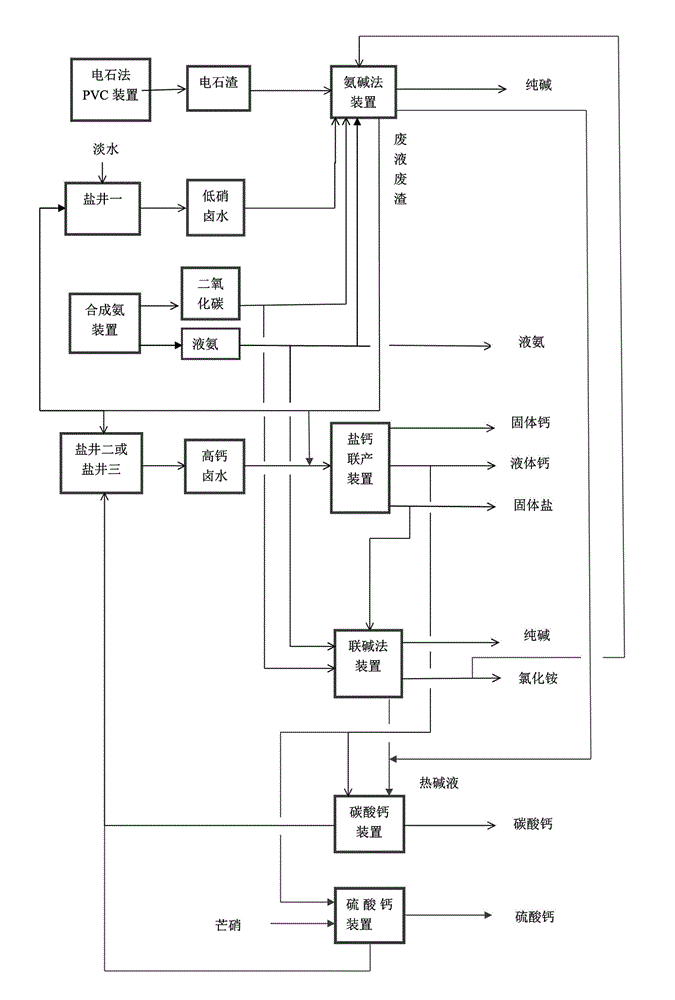

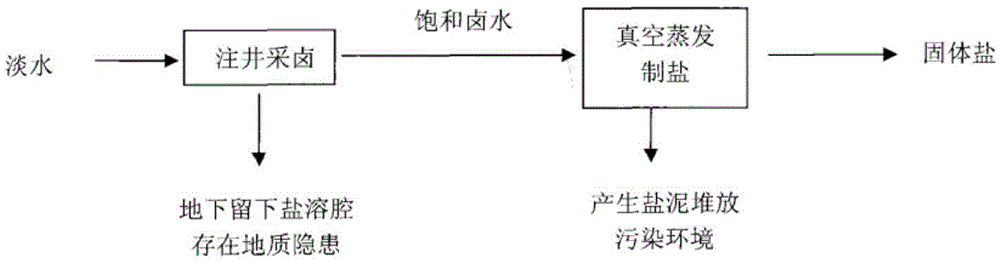

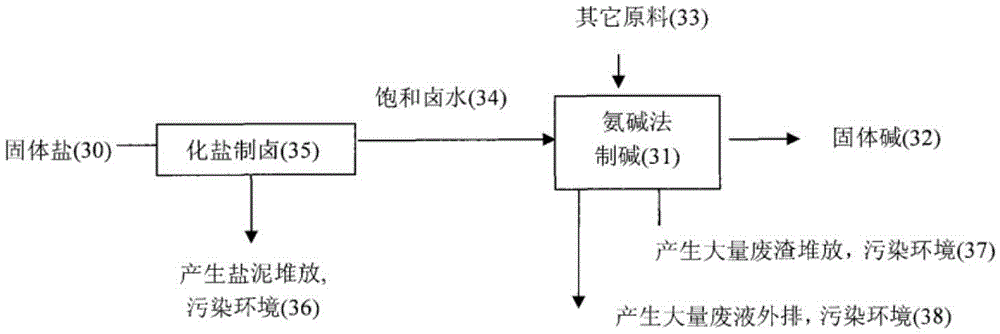

Ammonia-soda-combined-soda cyclic production process and application thereof

ActiveCN104528765AReduce pollutionReduce wasteCalcium/strontium/barium carbonatesCalcium/strontium/barium chloridesSludgeSalt calcium

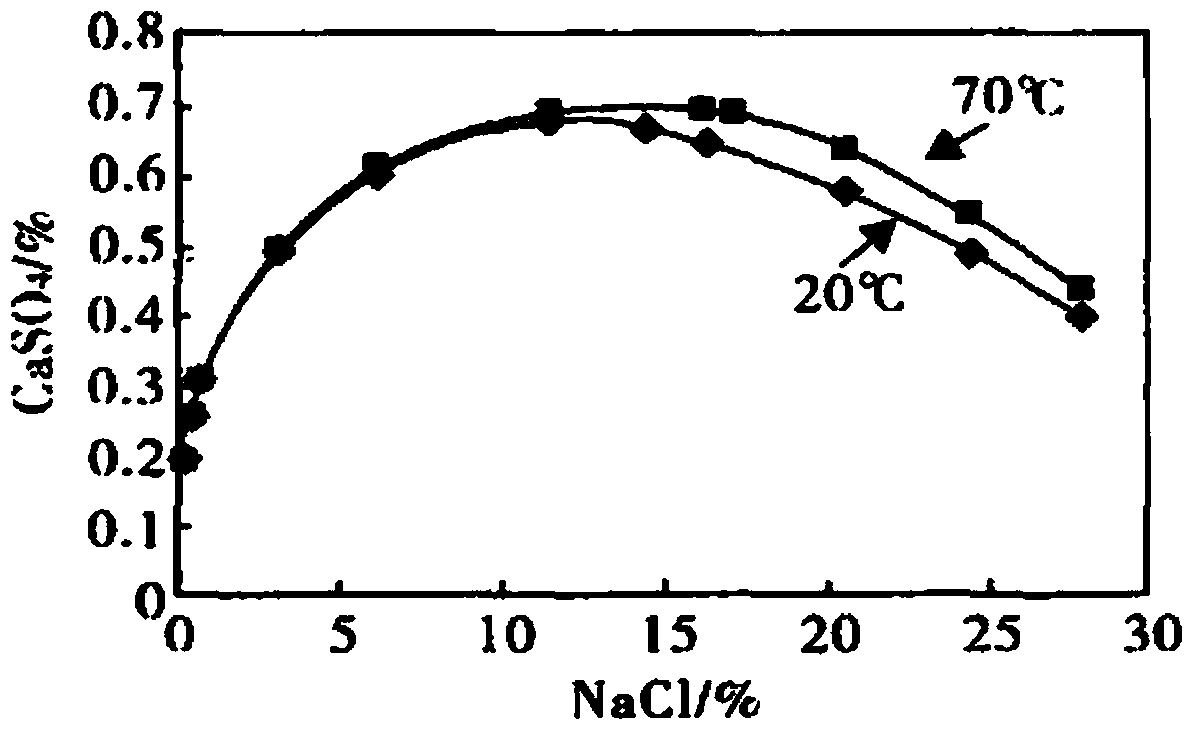

The invention relates to a process of ammonia-soda-combined-soda cyclic production for sodium chloride, sodium carbonate, liquid ammonia, ammonium chloride, calcium chloride and calcium carbonate. The process comprises the following steps: using brine, carbon dioxide and acetylene sludge as raw materials for producing sodium carbonate by an ammonia-soda method, injecting the generated waste liquid in a salt well and extracting brine, leaving and storing the calcium sulphate generated after nitrate removal and the injected soda sludge in the salt well, conveying the extracted brine into a salt calcium co-production device, producing a solid salt, reacting a part of the remainder solution with sodium carbonate to produce calcium carbonate, using a part as liquid calcium chloride, and evaporating the other part to produce calcium chloride dehydrate; using the obtained solid salt, ammonia and carbon dioxide as raw materials for producing sodium carbonate and ammonium chloride by a combined-soda method; adding wet ammonium chloride in the ammonia-soda waste liquid and decomposing. According to the process, the efficiency and yield of cyclic production are increased, and environmental pollution is reduced; the purities of sodium carbonate, calcium carbonate, ammonium chloride and solid salt are up to 99.0%, 99.9%, 99.5% and 95% respectively, the content of solid calcium is 74%, liquid calcium can be optimally configured, and the particle size of calcium carbonate is nanometre-submicron order.

Owner:HUBEI SHUANGHUAN SCIENCE AND TECHNOLOGY STOCK CO LTD

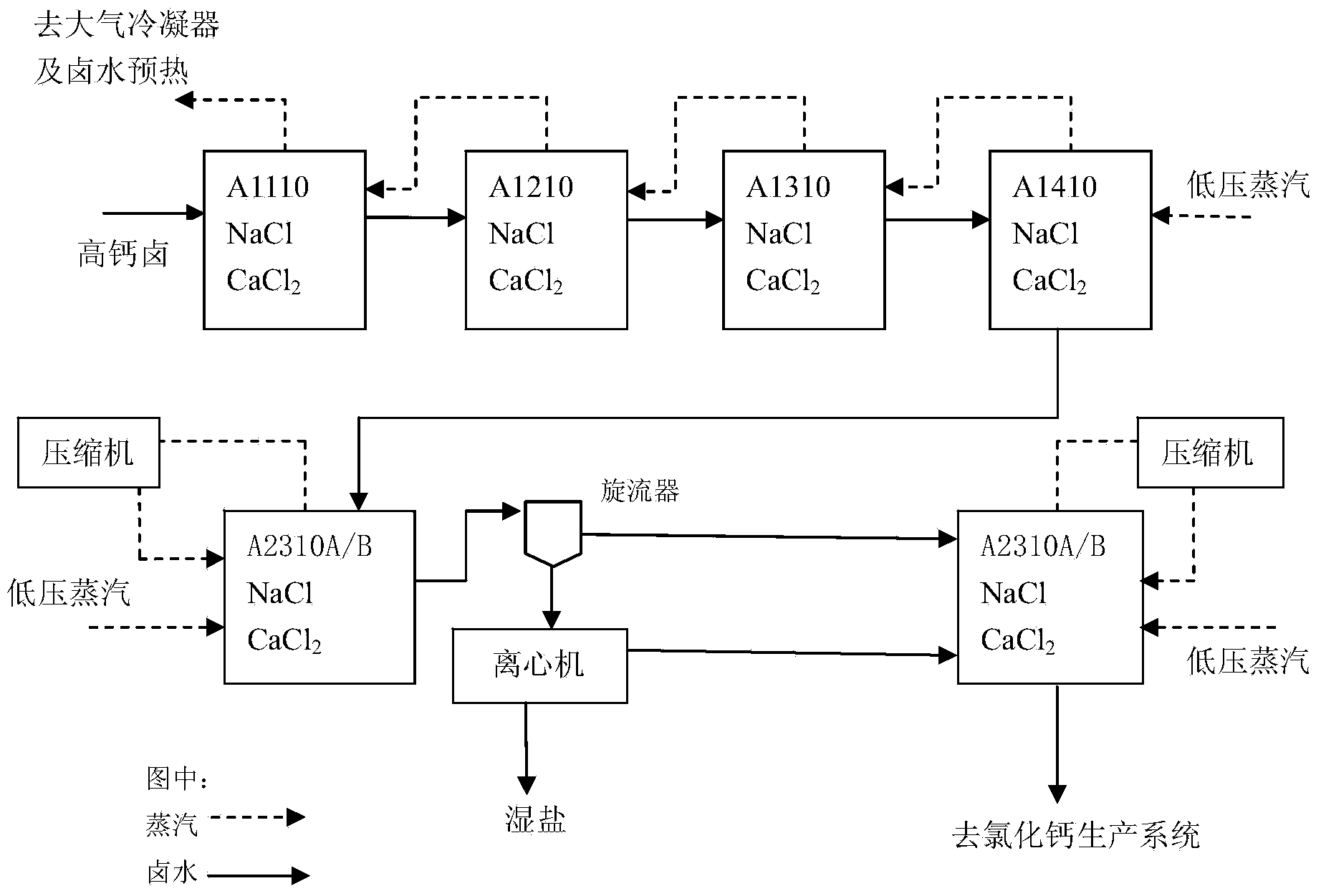

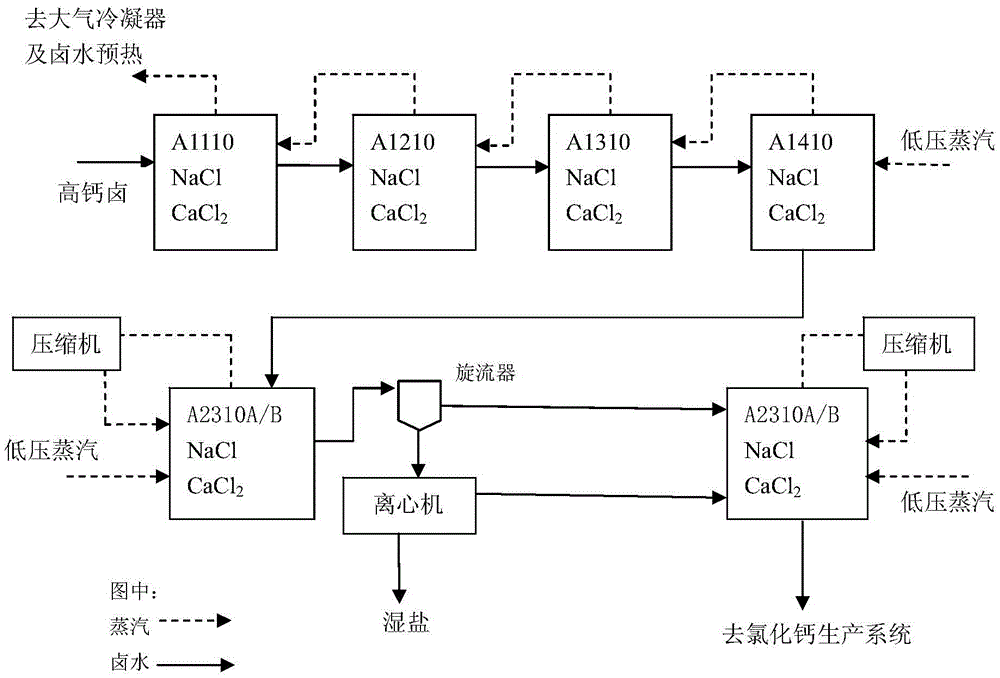

Low-sulfur large-grained salt produced from sodium sulfate type salt mine and preparation method thereof

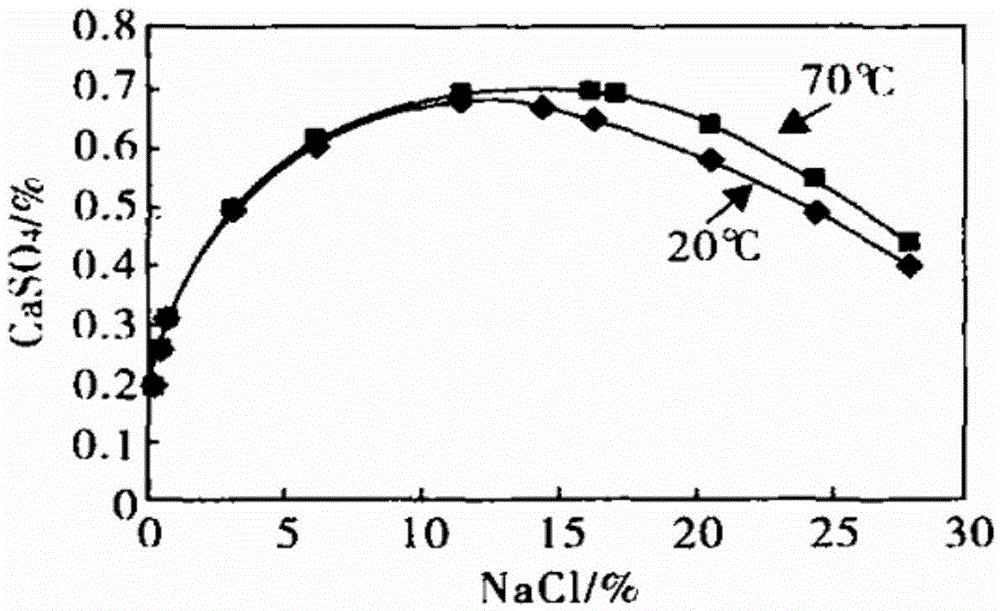

ActiveCN104016378ALess investmentEmission reductionCalcium/strontium/barium chloridesAlkali metal chloridesSulfate radicalsSodium sulfate

The invention relates to a low-sulfur large-grained salt produced from sodium sulfate type salt mine and a preparation method thereof. Liquid calcium from ammonia alkali factory is blended with water and injected into sodium sulfate type salt mine for underground desulfurization to form high calcium brine, and the high calcium brine as a raw material is subjected to salt calcium coproduction to produce low-sulfur large-grained salt by using an MVR (mechanical vapor recompression) evaporator with a crystal cultivation baffling cylinder and a unique production process. The product comprises not less than 99.50% of sodium chloride (dry basis), no more than 0.2% of sulfate radical, more than 70% of granularity greater than 0.4 mm, and no more than 1% of granularity less than 0.15 mm; the product does not contain any anti-caking agent, and has anti-caking period more than 4 months, so as to meet the needs of industrial production turnover.

Owner:江苏苏盐井神股份有限公司 +1

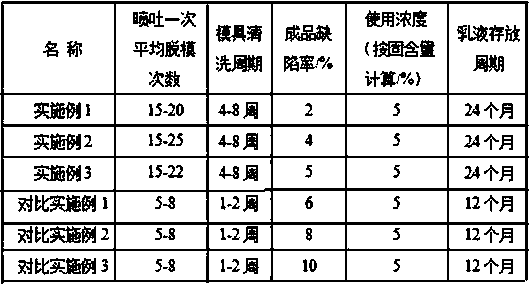

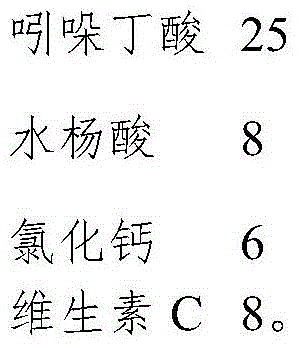

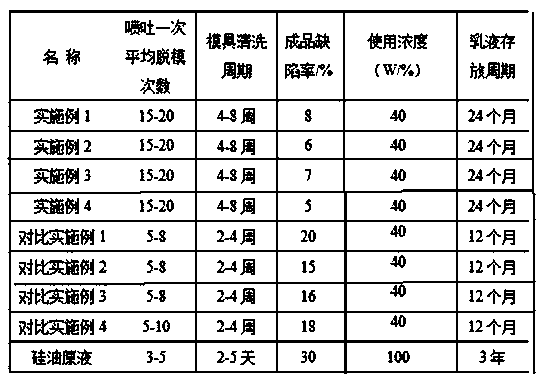

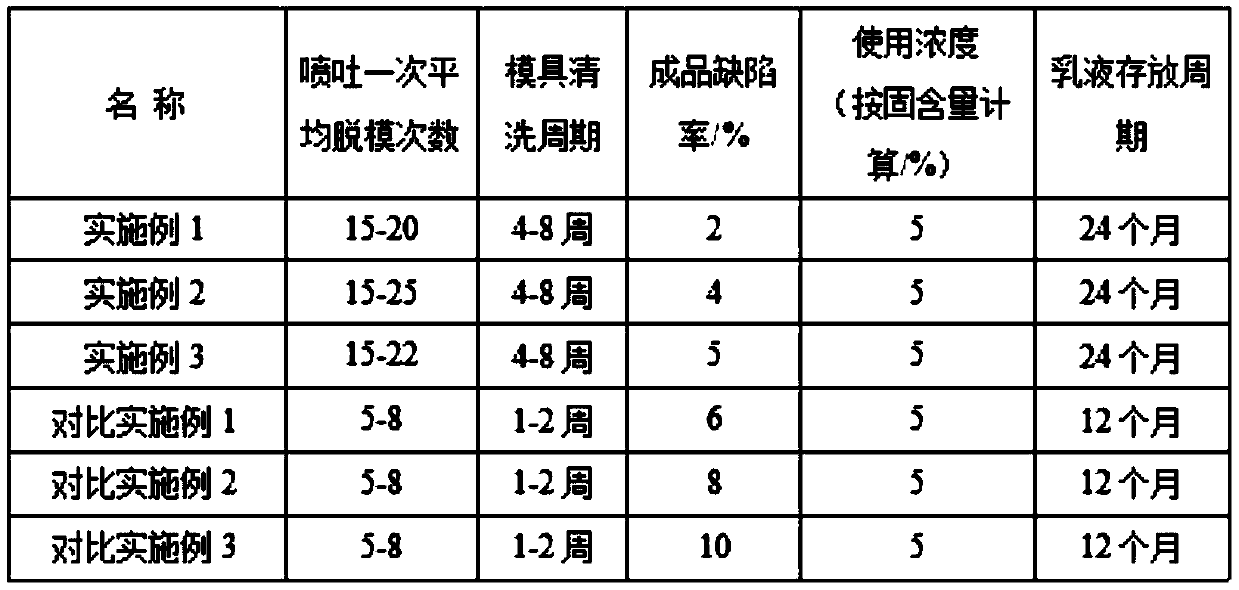

Concrete product isolation mold releasing agent and preparation method thereof

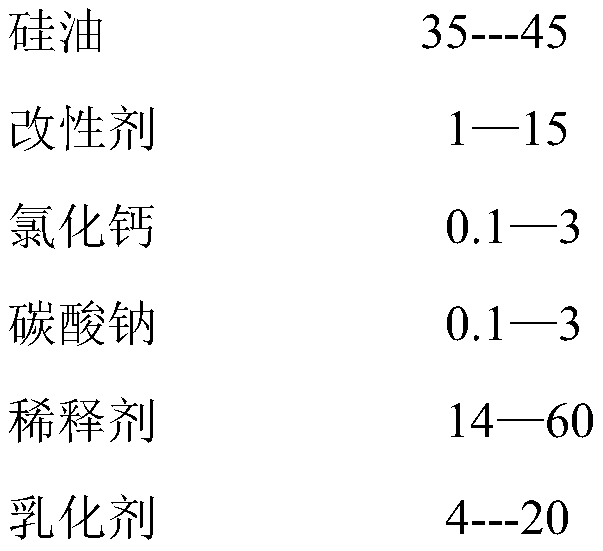

ActiveCN109576043AIncreased durabilityExtended service lifeMaterial nanotechnologyLubricant compositionMicro gapRaw material

The invention discloses a preparation method of a concrete product isolation mold releasing agent, and belongs to the field of concrete additives. The preparation method includes the steps: firstly, taking film-forming substances, emulsifying agents, water-soluble salt calcium chloride and sodium carbonate as raw materials to prepare W / O-type activated nano-calcium carbonate silicone oil compositeemulsion; adding water to perform phase inversion to obtain the W / O-type activated nano-calcium carbonate silicone oil composite emulsion. The emulsion is applicable to isolation among the raw materials and molds in the machining process of concrete products, the surfaces of the molds can be easily cleaned, nano-calcium carbonate components are added, micro-gaps and damage of the surfaces of themolds can be repaired, the service lives of the molds are prolonged, and the surface of a product is bright and clean, defects are decreased, and finished product ratio is increased.

Owner:HIGH & NEW TECH RES CENT OF HENAN ACAD OF SCI

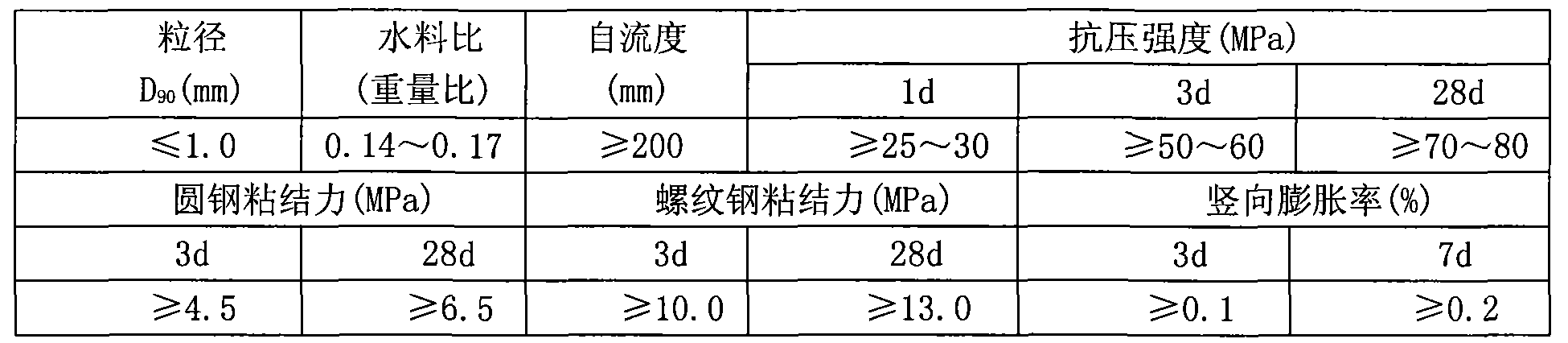

High-strength borehole anchorage agent

The invention relates to a high-strength drilling anchoring agent and is suitable for various building projects requiring higher durability such as large-tonnage anchor rods, anchor cables and tail anchorage of equipment. The high-strength drilling anchoring agent is mainly formed by the mixture of powder mainly consisting of silicate minerals; volcanic ash activated powder, coal ashes or slag or silicon powder, reduced and contracted activated powder, sulphoaluminate minerals; reduced and contracted inert particles, surfactants, naphthalenesulfonic formaldehyde condensation compound, sulfate, amine, retarders, salt calcium or ignosulfonate and water retaining agent and cellulose ethers. The high-strength drilling anchoring agent is characterized by long operation time, no toxicity or harm to human and environment, high early strength, stable development of later strength, strong erosion-resistance and high durability.

Owner:HUBEI GEZHOUBA TESTING

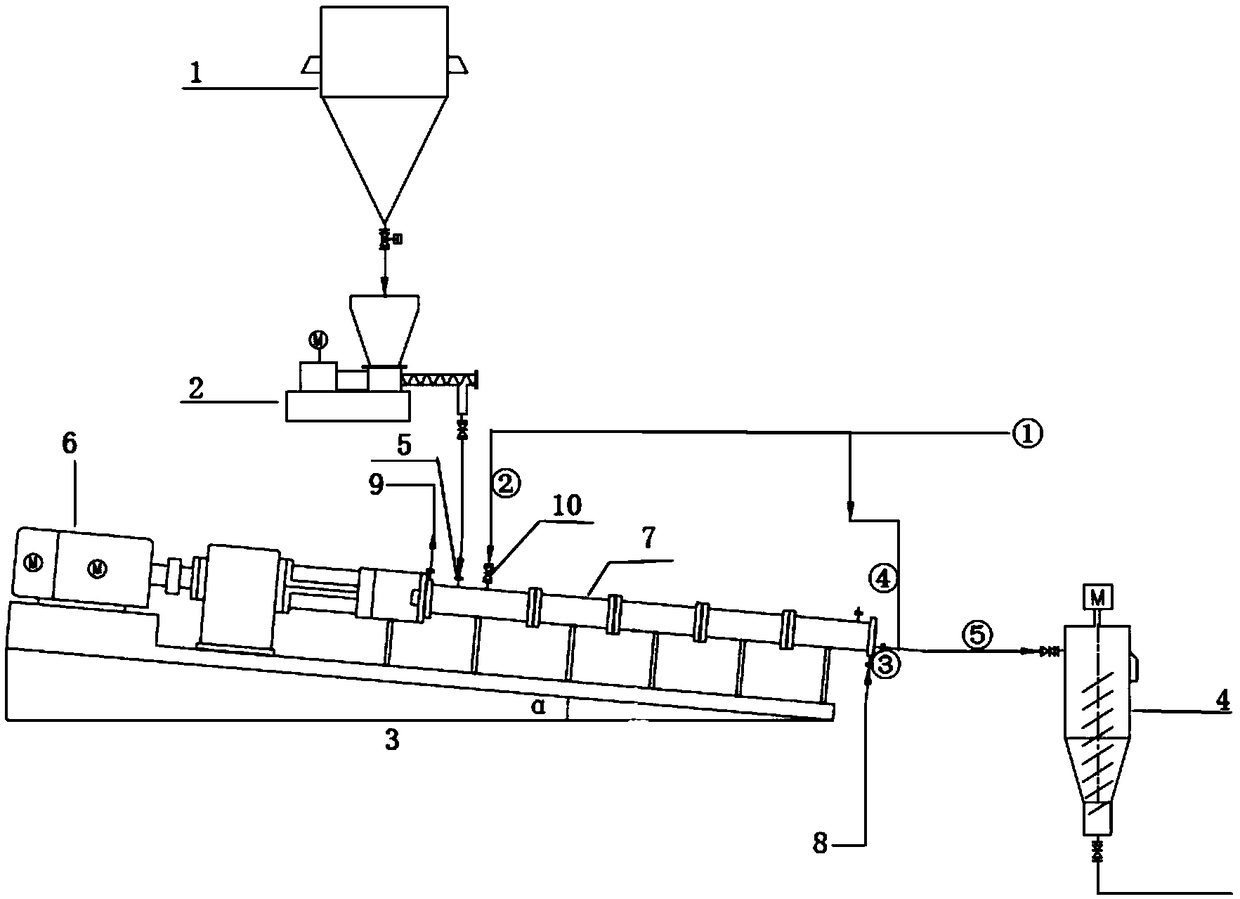

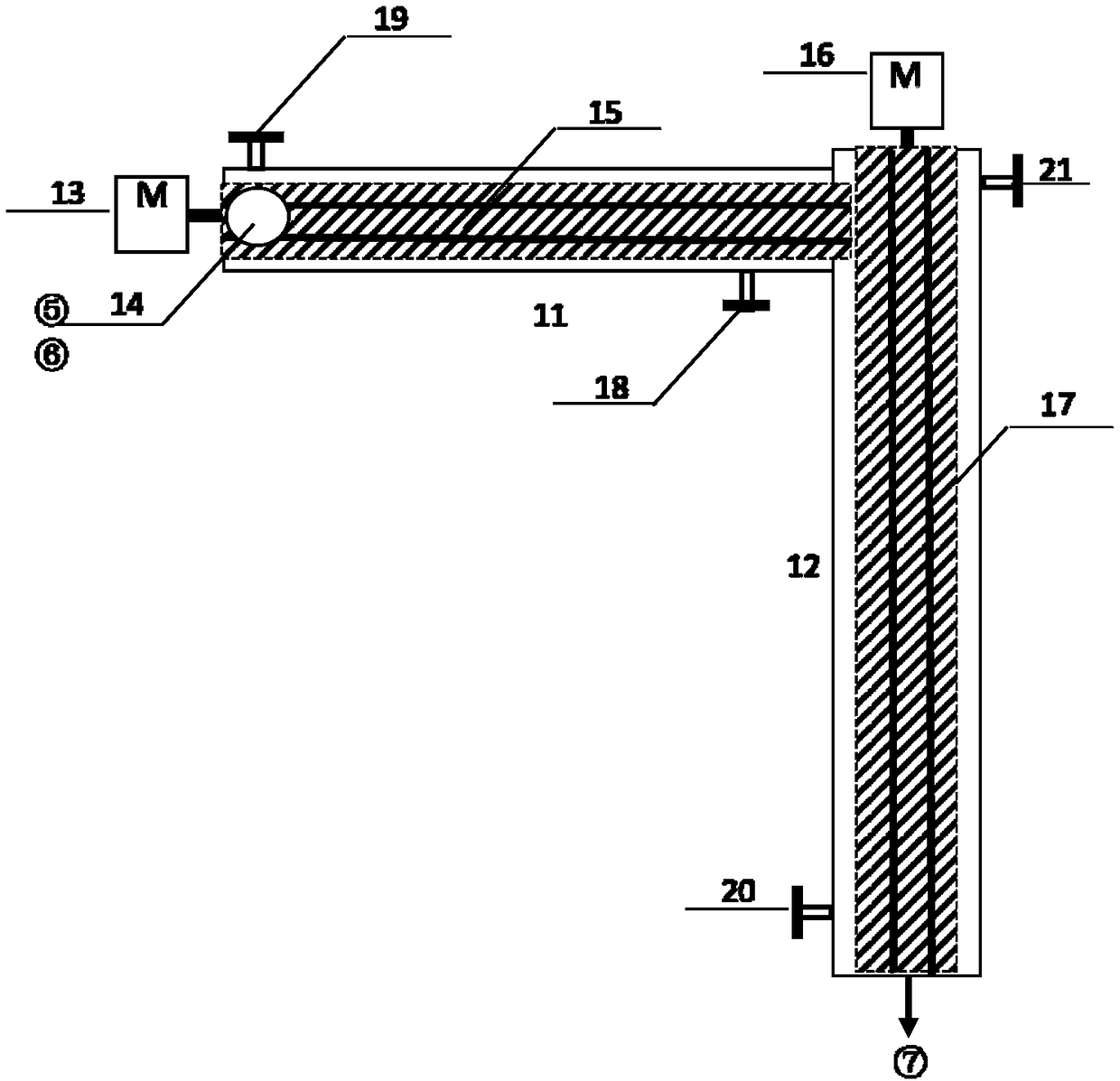

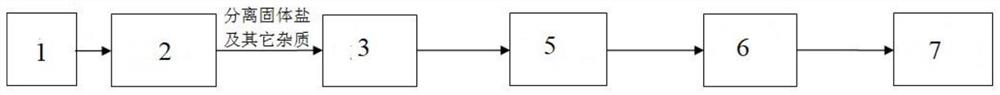

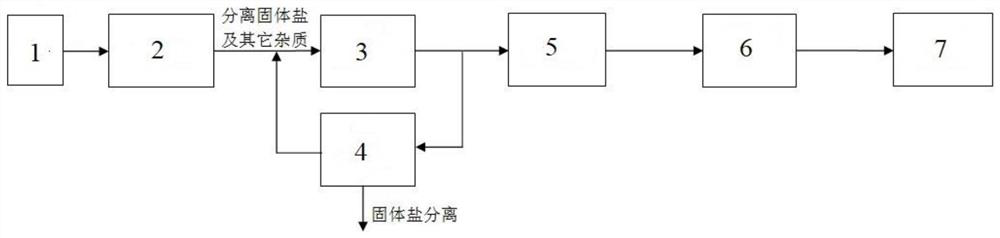

High-concentration continuous and stable polymerization method and system for poly-p-phenylene terephthamide

ActiveCN108623803AGuaranteed stabilityReduced dissolution time and stabilityHigh concentrationScrew system

The invention relates to a high-concentration continuous and stable polymerization method and system for poly-p-phenylene terephthamide, and belongs to the technical field of polymer synthesis. The high-concentration continuous and stable polymerization of the poly-p-phenylene terephthamide is an important challenge in the field of para-aramid, and the high-concentration continuous and stable dissolving of the poly-p-phenylene terephthamide and dual-screw stable and continuous polymerization are two keys. According to The high-concentration continuous and stable polymerization method and system for the poly-p-phenylene terephthamide, one set of dual-screw system is designed to continuously dissolve PPD (Para Phenylene Diamine), batch differences caused by PPD batch dissolution can be eliminated, and in addition, the problem of hydrotropy salt calcium chloride precipitation caused by high-concentration PPD is eliminated; two groups of dual-screw reactors subjected to no-dead-corner connection are used for realizing the continuity and the stability of PPTA polymerization through different volumes and function configurations of two groups of dual screws. According to the method, the stability of the PPTA polymerization can be improved, in addition, the high-concentration continuous polymerization can be realized, production efficiency is greatly improved, and production cost is lowered.

Owner:TSINGHUA UNIV

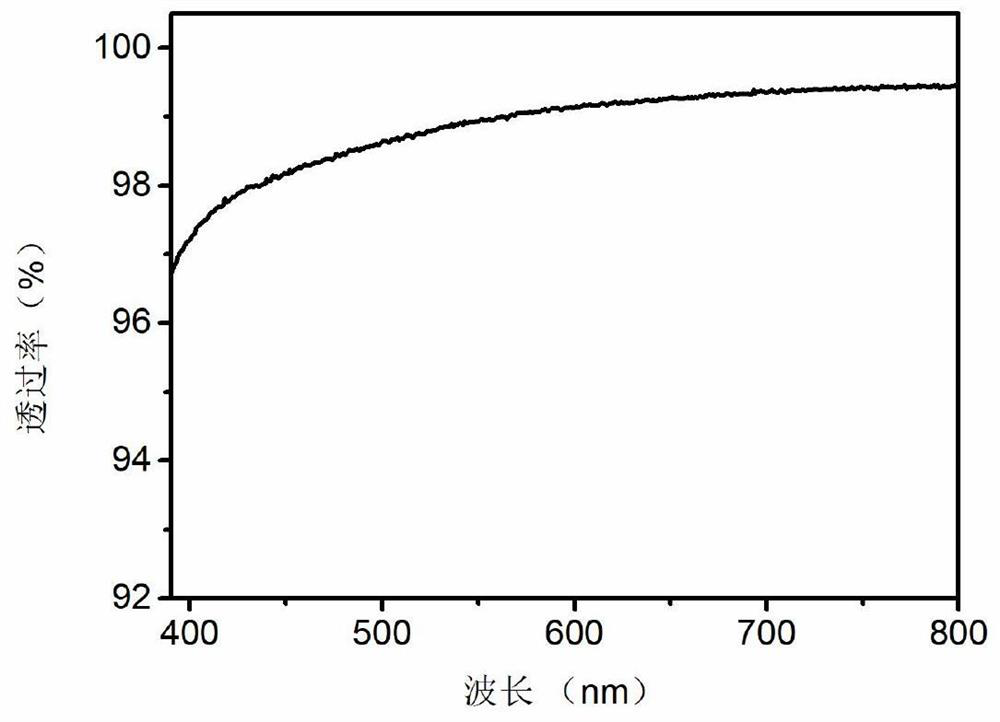

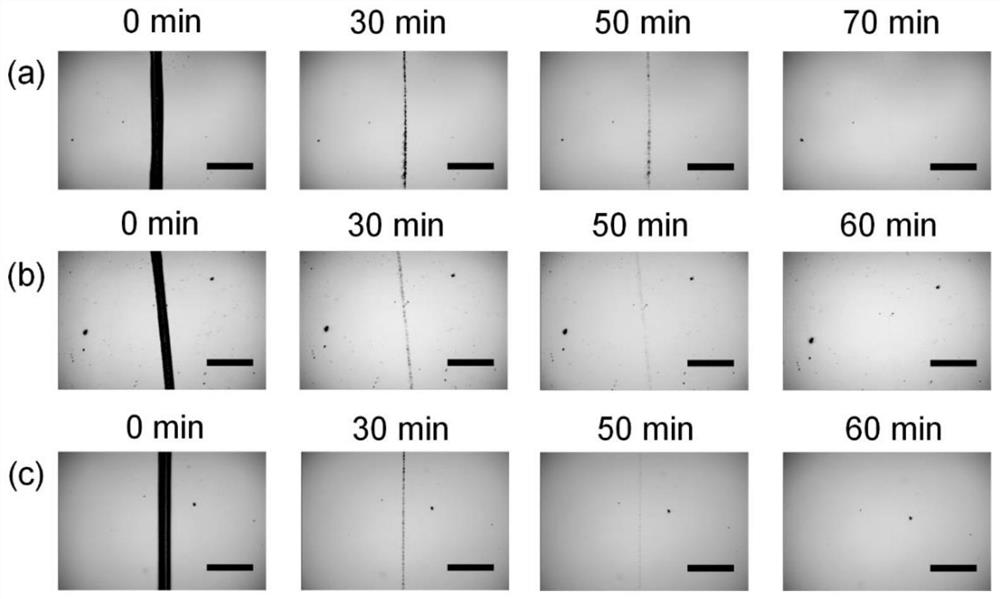

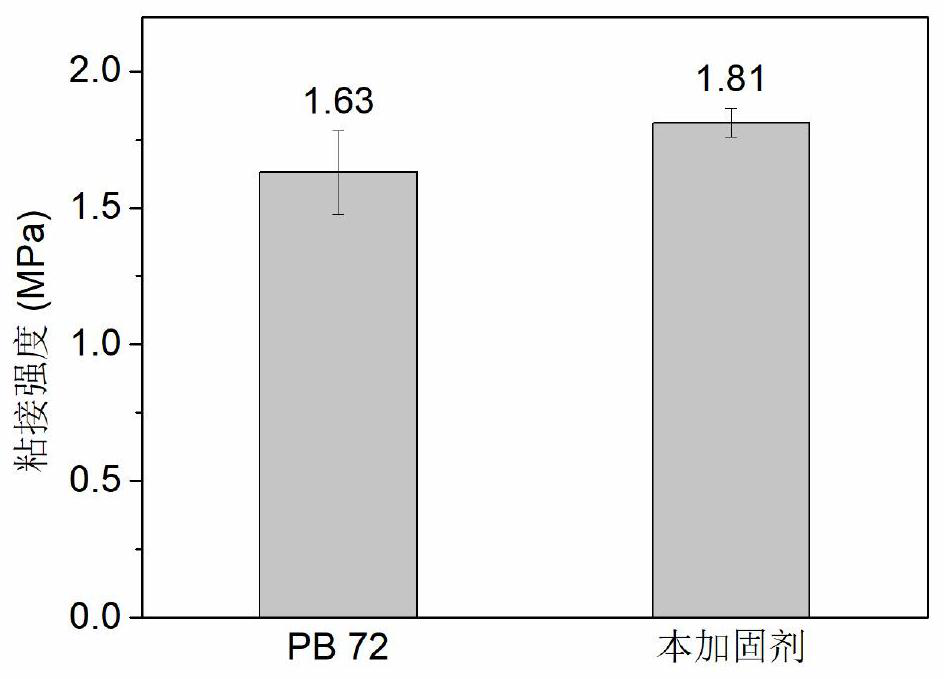

Mural and colored drawing cultural relic reinforcing agent with self-healing function and preparation method thereof

ActiveCN111662675AImprove permeabilityDoes not affect appearanceNon-macromolecular adhesive additivesPolyether adhesivesSalt calciumAdhesive

The invention relates to a mural and colored drawing cultural relic reinforcing agent with a self-healing function and a preparation method thereof, poly (2-ethyl-2-oxazoline) and poly(4-vinylphenol)are taken as main components, the reinforcing agent has good permeability to murals or colored drawing cultural relics, and the appearance of the reinforced cultural relics is not influenced. The reinforcing agent has a high-efficiency self-healing function in a humid environment with the normal temperature and the relative humidity of 80% or above, and the self-healing efficiency can reach 85% orabove. Besides, soluble salt calcium chloride or magnesium chloride is added, or calcium chloride or magnesium chloride contained in murals and colored drawing cultural relics can be coordinated withthe reinforcing agent, and self-healing can be better promoted. Compared with a common acrylic reinforcing agent, the reinforcing agent disclosed by the invention has higher bonding strength, the reinforcing effect is ensured, and meanwhile, the reinforcing agent can also be used as a cultural relic adhesive capable of being repeatedly bonded.

Owner:RES & DEV INST OF NORTHWESTERN POLYTECHNICAL UNIV IN SHENZHEN +1

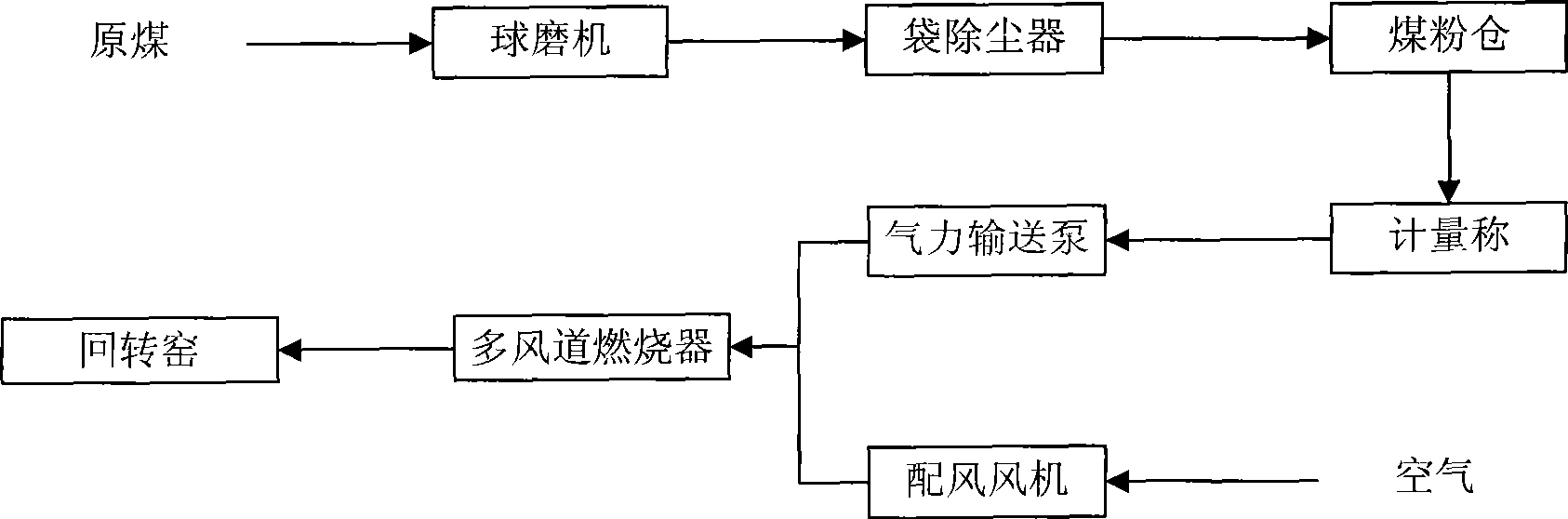

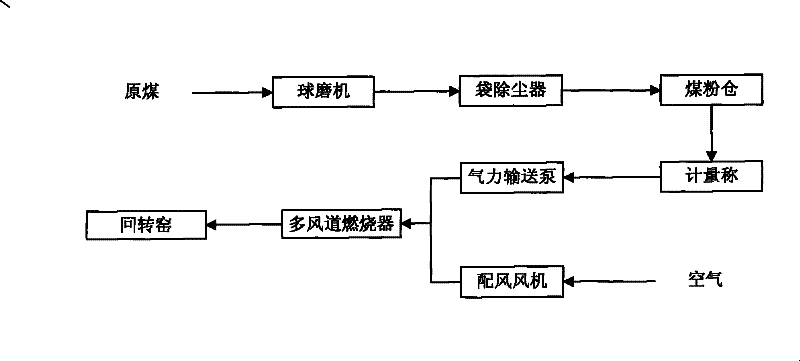

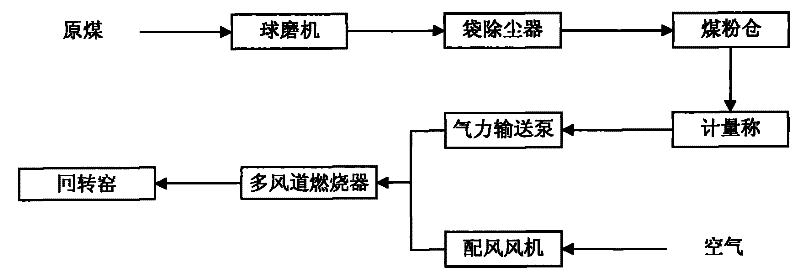

Method for burning chromium salt calcium-free roasting coal powder

The invention discloses a method for burning chromium salt calcium-free roasting coal powder. The invention adopts low sulfur coal as fuel and provides heat source to a rotary kiln through jet fire of a burner. The farthest point of the high temperature reaction zone of the rotary kiln has a distance of 11 to 19 m to the kiln port; and the burning temperature is 1,000 to 1,150 DEG C, which belongs to a strong oxidation atmosphere. The invention provides heat source to the chromium salt rotary kiln through the burning of the multi air ducts, which substitutes for light fuels such as heavy oil, liquefied gas, natural gas, etc. required to be adopted in chromium salt calcium-free roasting technology, so that the roasting cost reduced by 60% and the raw coal storage is safe, thereby specially suiting the use on any occasions. The technology is easy to improve and has remarkable effect, and can be widely applied to chromium salt production.

Owner:GANSU JINSHI CHEM

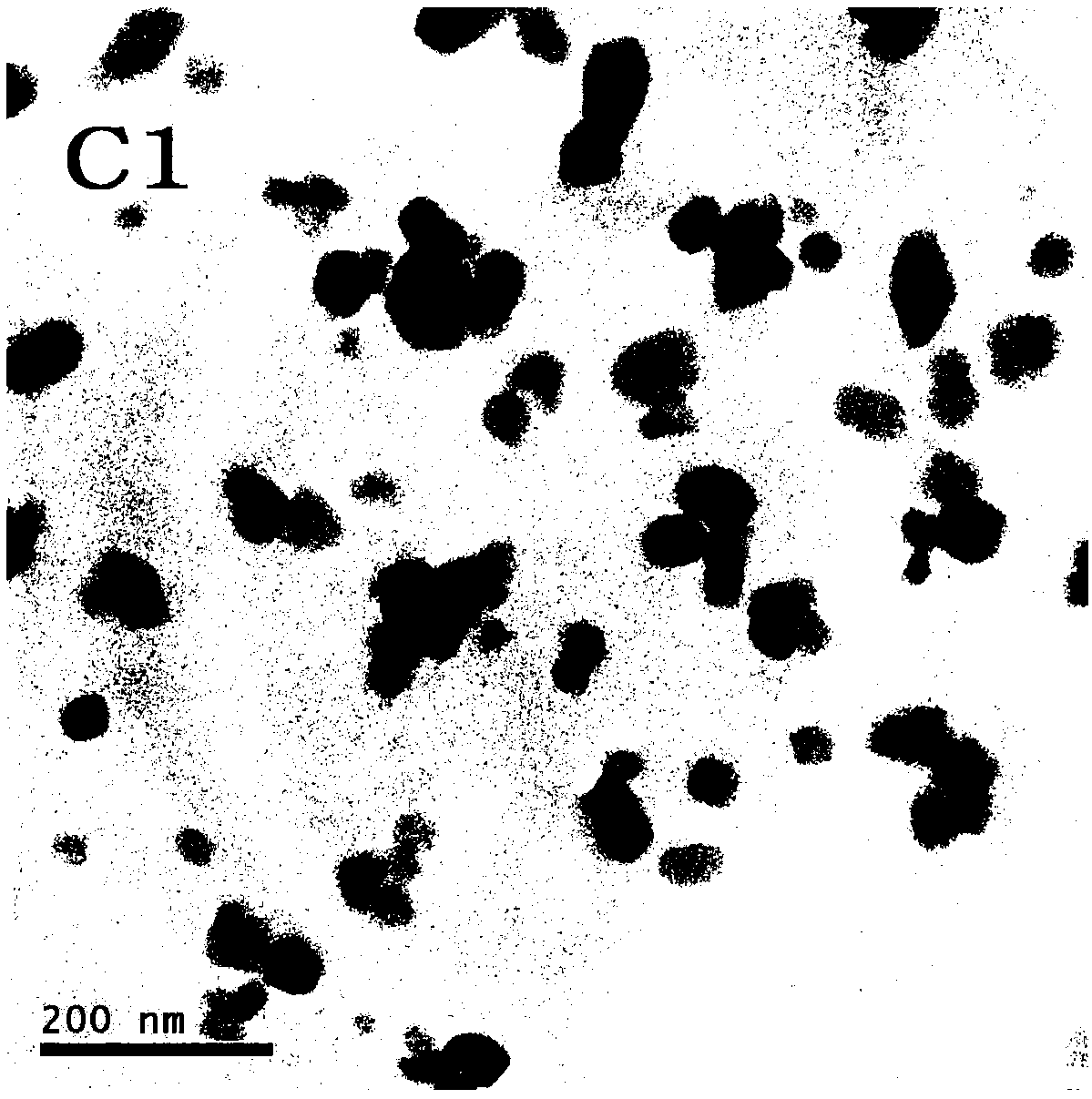

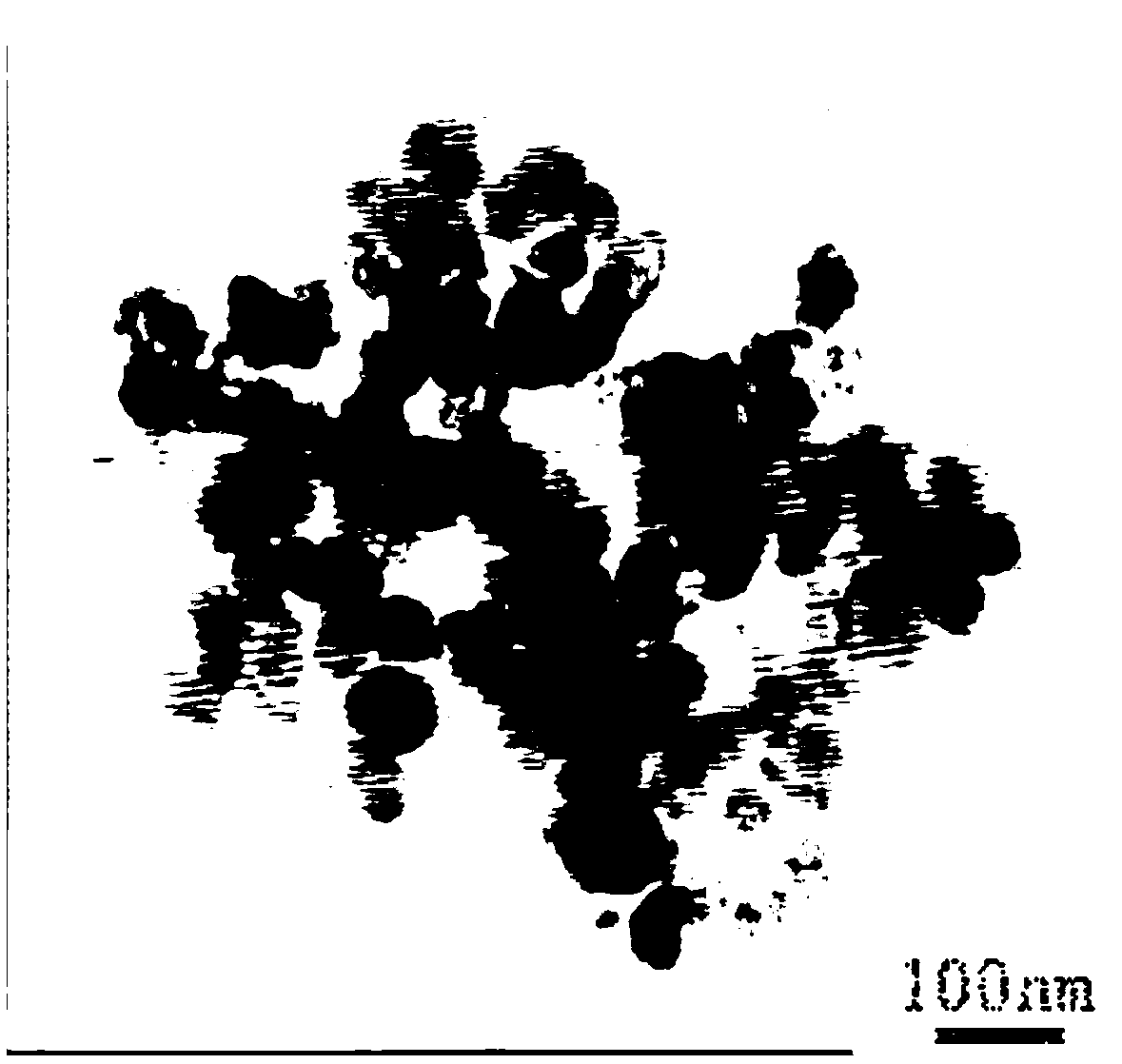

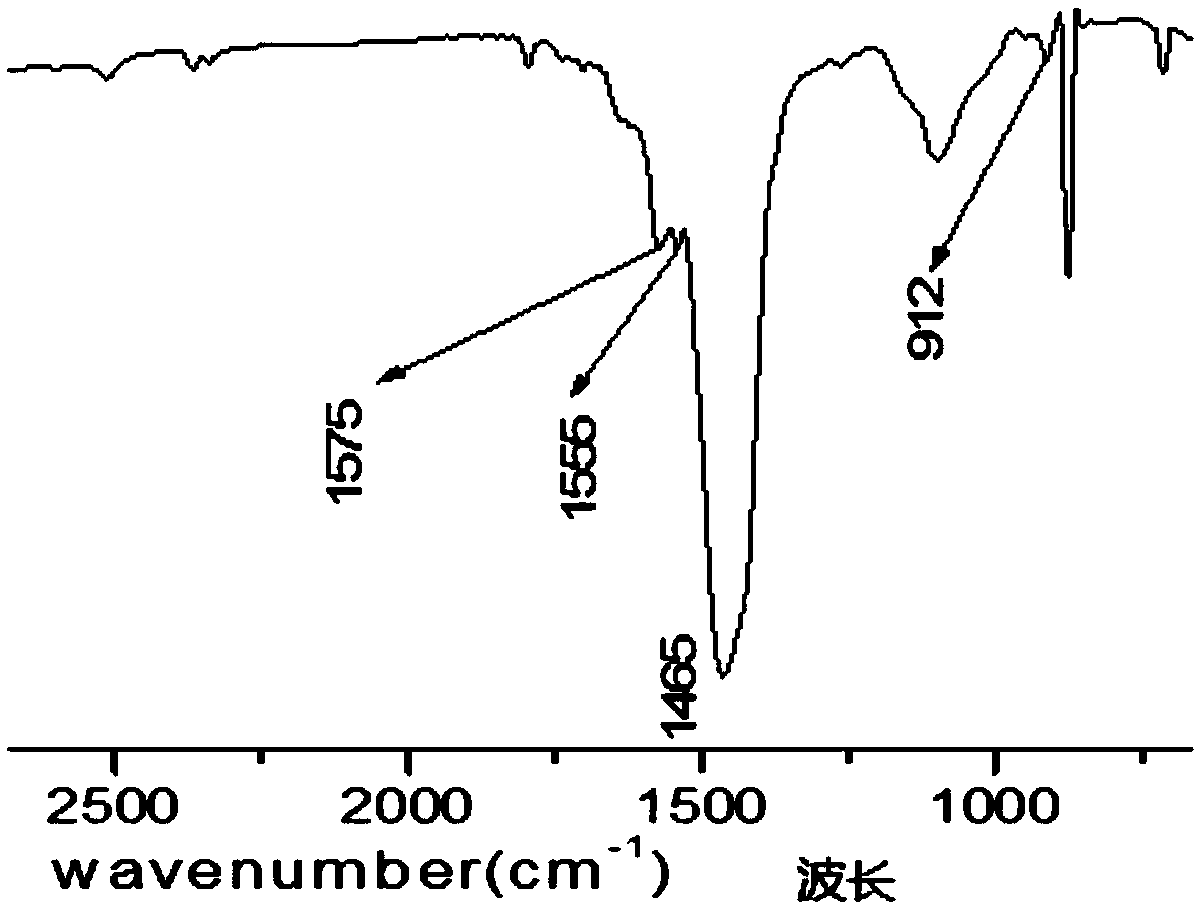

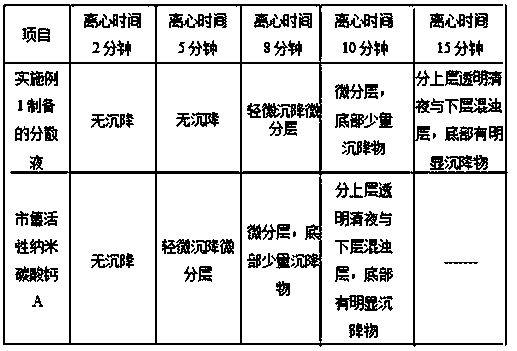

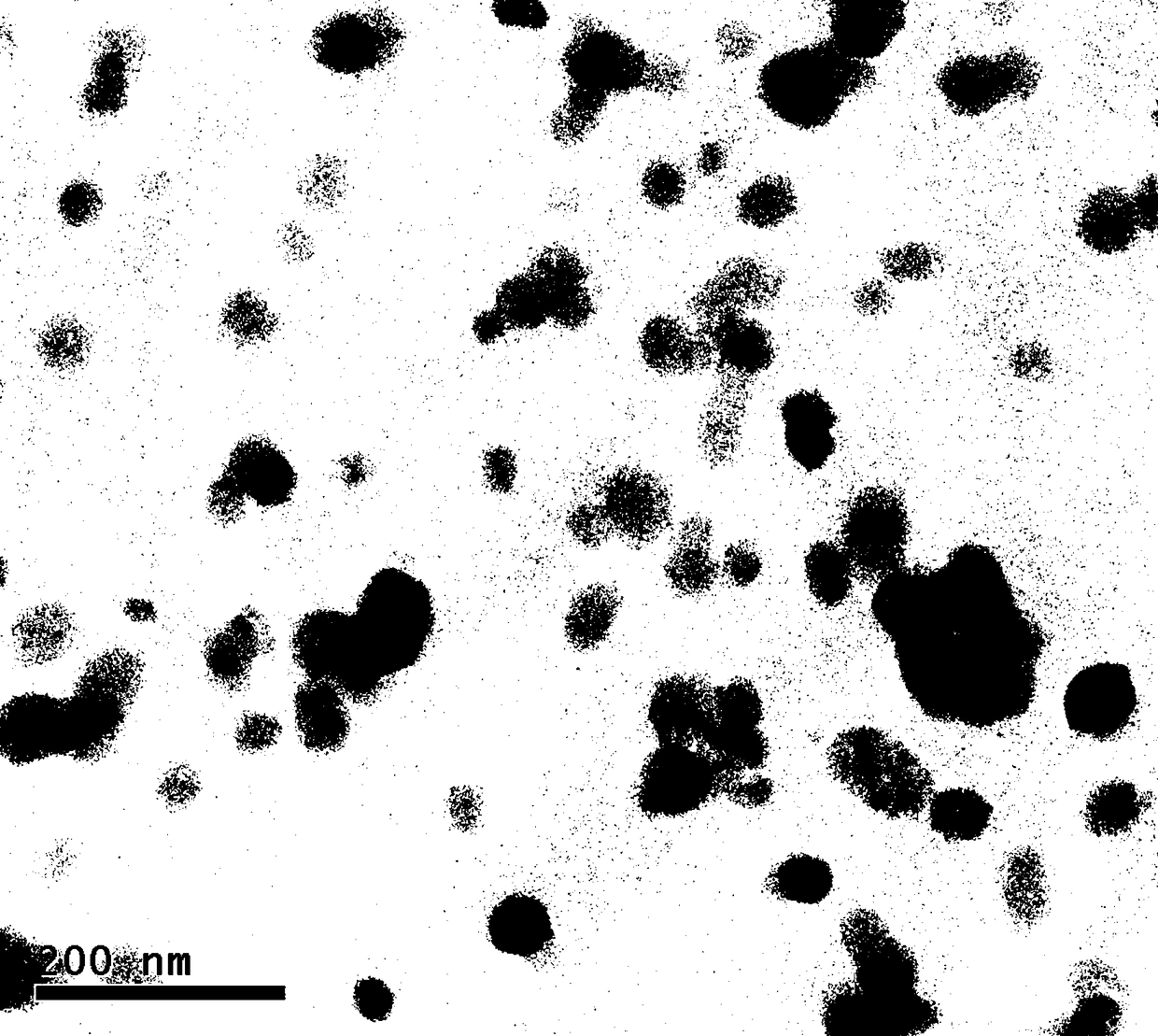

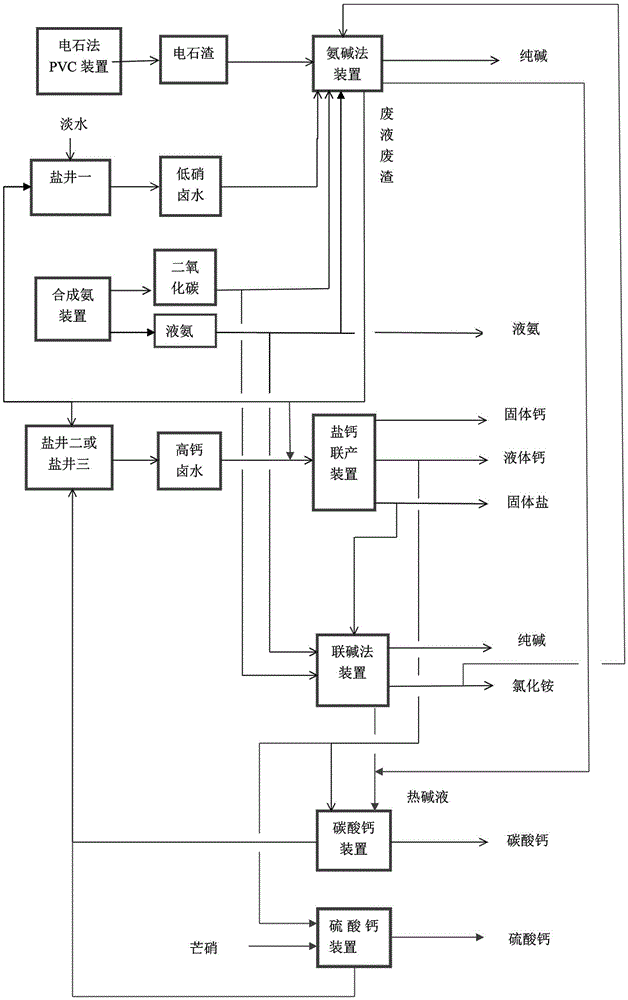

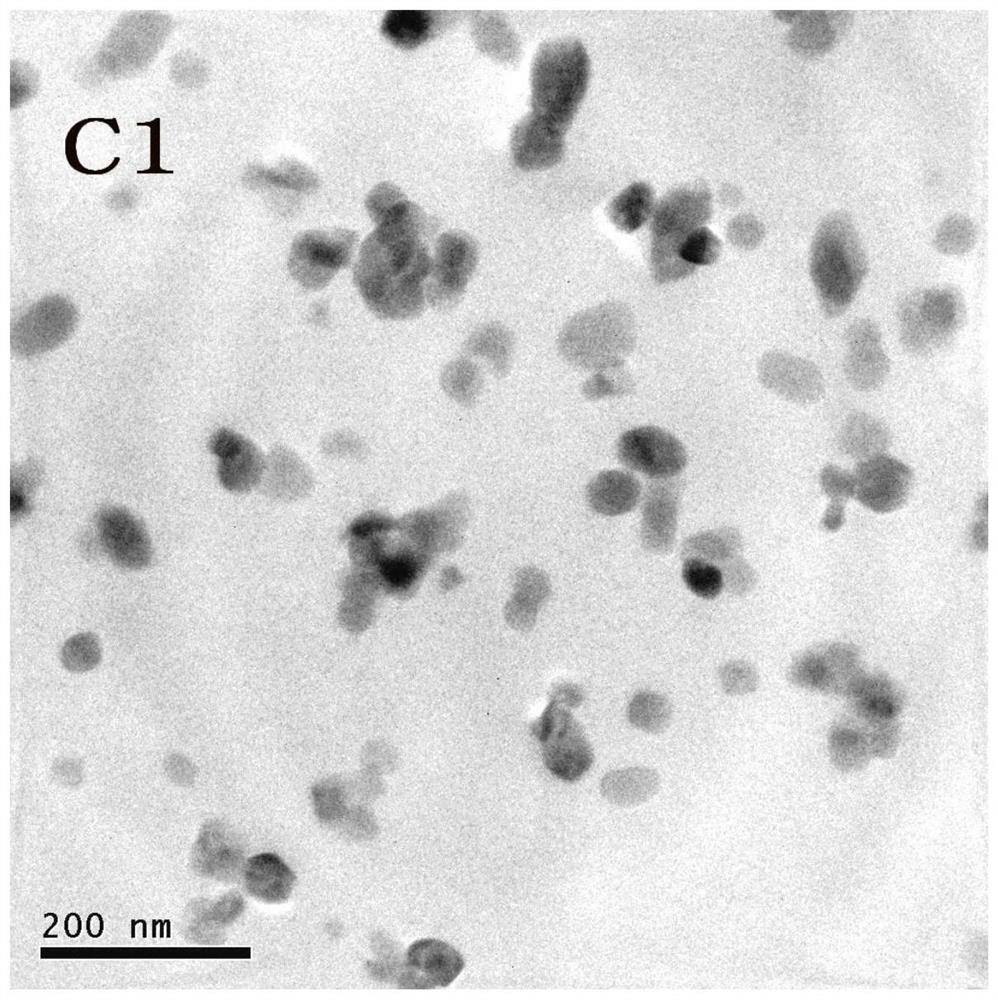

Active nano calcium carbonate for food additives and preparation method thereof

InactiveCN109399682AGood compatibilityGood dispersionCalcium/strontium/barium carbonatesMaterial nanotechnologyFood additiveHigh calcium food

The invention discloses active nano calcium carbonate for food additives and a preparation method thereof, and belongs to the field of food additives. According to the method, water-soluble salt calcium chloride and sodium carbonate are taken as primary materials, a modifier is taken as a diluter and an emulsifying agent, and active nano calcium carbonate emulsion is prepared by adopting a self-emulsifying system. The emulsion has the advantages that the emulsion can be directly used and can be used by preparing into the active nano calcium carbonate powder, the nano calcium carbonate is suitable for preparing efficient food additives and used as a calcium supplement of high calcium foods of milk products, soybean milk, cheese, cakes and the like, the dispersion performance is good, the use is convenient, and the nano calcium carbonate has no pollution and is safe and reliable.

Owner:HIGH & NEW TECH RES CENT OF HENAN ACAD OF SCI

Nano calcium carbonate emulsion and preparation method thereof

The invention discloses a nano calcium carbonate emulsion and a preparation method thereof and belongs to the field of rubber auxiliaries. The nano calcium carbonate emulsion is prepared through the following method that firstly, silicon oil, a silicon oil emulsifying agent, water-soluble salt calcium chloride and sodium carbonate serve as main raw materials to prepare a W / O type active nano calcium carbonate silicon oil composite emulsion; and then water is added for phase inversion so that an O / W type silicon oil nano calcium carbonate emulsion can be obtained. The nano calcium carbonate emulsion is suitable for isolation between raw materials and a mold in the production process of rubber products, can make the surface of the mold cleaned easily, can repair micro pits and damage on thesurface of the mold, prolongs the service life of the mold, makes surface defects of products reduced, and increases the finished product rate.

Owner:HIGH & NEW TECH RES CENT OF HENAN ACAD OF SCI

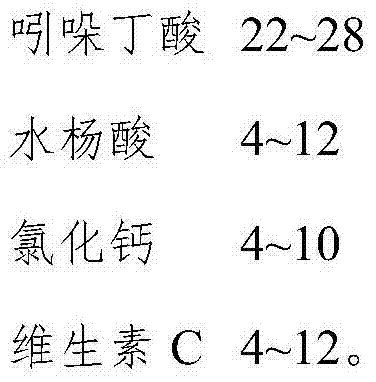

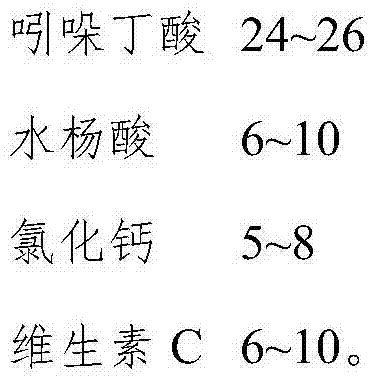

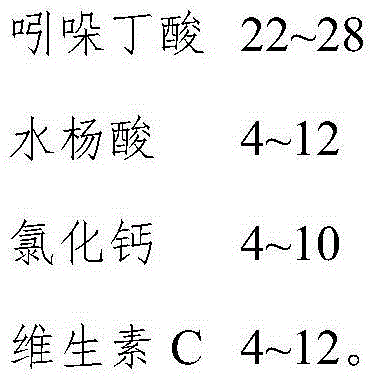

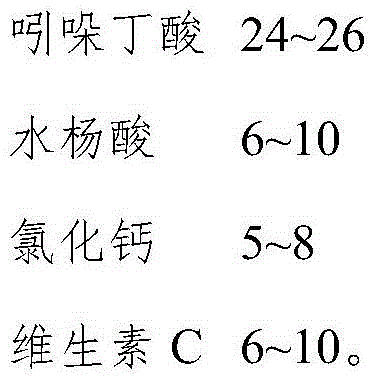

Seabuckthorn growth regulator

InactiveCN103518775AImprove the induction effectImprove survival rateBiocidePlant growth regulatorsSalicylic acidSecondary metabolite

The invention provides a seabuckthorn growth regulator. The seabuckthorn growth regulator comprises an auxin analogue indolebutyric acid, a plant secondary metabolites salicylic acid, inorganic calcium salt calcium chloride and an antioxidant vitamin C. The seabuckthorn growth regulator shows a good inductive effect on seabuckthorn cutting rooting, has a certain influence on growth and development of cutting seedlings, and can obviously improve the survival rate of cuttings. From the angle of mass production and use, compared with comparative economy, the seabuckthorn growth regulator has food economic benefits and social benefits and is suitable for popularization and application.

Owner:BEIJING FORESTRY UNIVERSITY +1

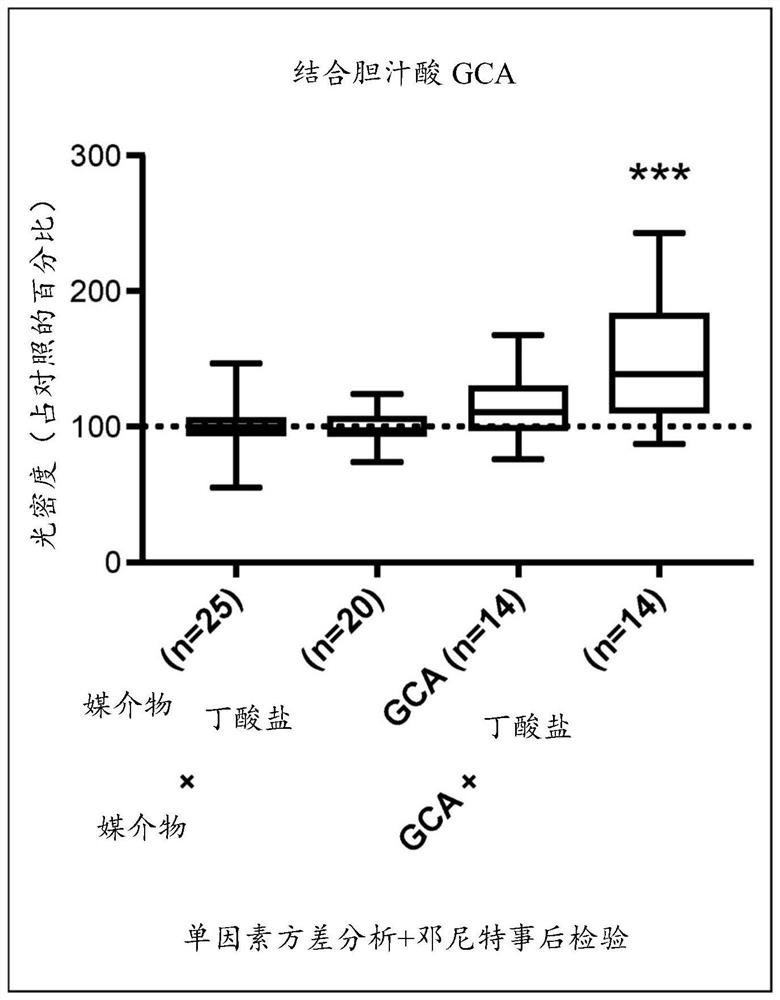

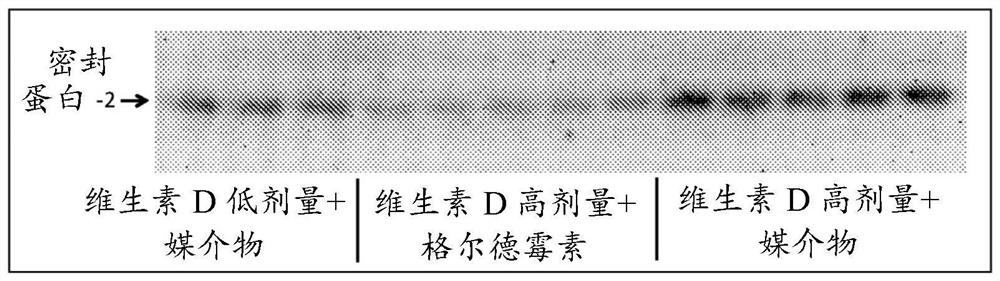

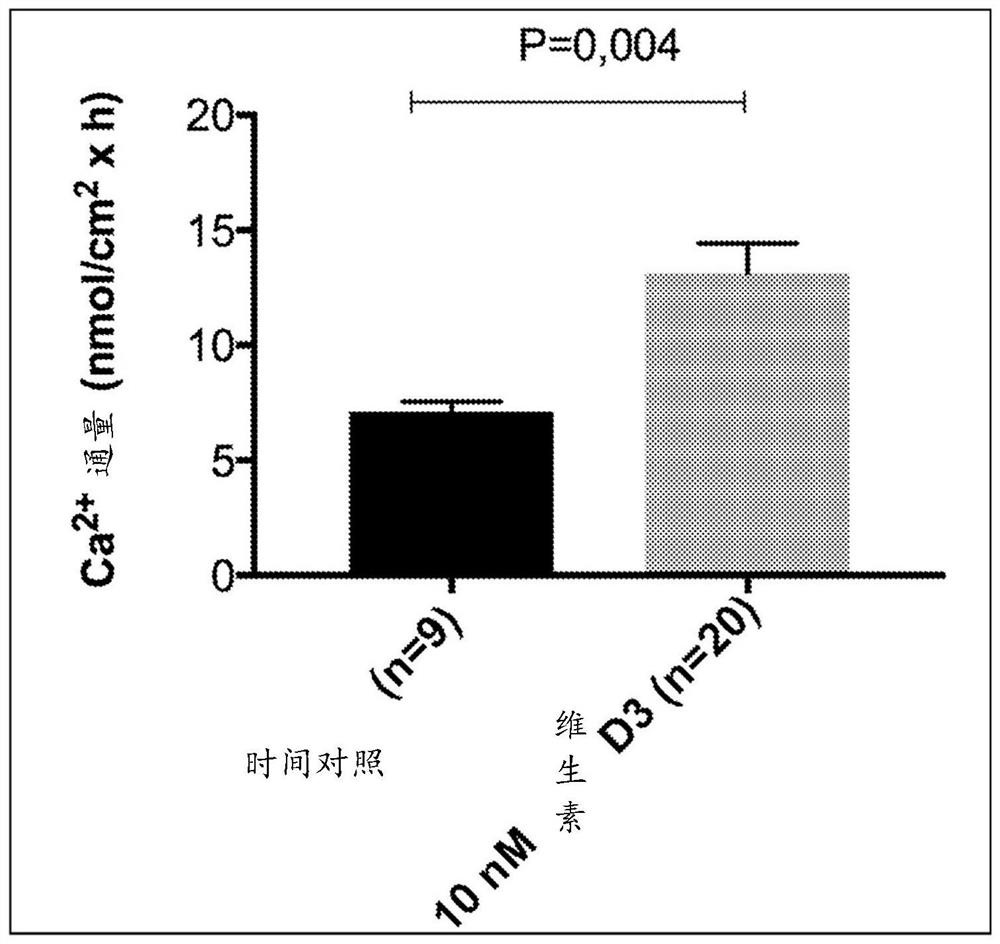

A composition for use in the treatment of conditions caused by calcium deficiency

PendingCN112074274ASkeletal disorderPharmaceutical delivery mechanismVitamin receptorDietary supplement

The present invention is related to a composition comprising at least one bile acid; at least one fatty acid or salt thereof, calcium, and vitamin D, for use as a medicament, and especially in inducing expression of vitamin D-receptor co-activator Hsp90[beta] for increasing vitamin D-induced calcium uptake in a mammal. The invention is also related to a dietary or nutritional supplement comprisinga composition as described above and comprising additionally conventional components for dietary or nutritional supplements.

Owner:艾匹赛特制药公司

A kind of low-sulfur large-grain salt produced by sodium sulfate type salt mine and production method thereof

ActiveCN104016378BLess investmentEmission reductionCalcium/strontium/barium chloridesAlkali metal chloridesSulfate radicalsSodium sulfate

The invention relates to a low-sulfur large-grained salt produced from sodium sulfate type salt mine and a preparation method thereof. Liquid calcium from ammonia alkali factory is blended with water and injected into sodium sulfate type salt mine for underground desulfurization to form high calcium brine, and the high calcium brine as a raw material is subjected to salt calcium coproduction to produce low-sulfur large-grained salt by using an MVR (mechanical vapor recompression) evaporator with a crystal cultivation baffling cylinder and a unique production process. The product comprises not less than 99.50% of sodium chloride (dry basis), no more than 0.2% of sulfate radical, more than 70% of granularity greater than 0.4 mm, and no more than 1% of granularity less than 0.15 mm; the product does not contain any anti-caking agent, and has anti-caking period more than 4 months, so as to meet the needs of industrial production turnover.

Owner:江苏苏盐井神股份有限公司 +1

A seabuckthorn growth regulator

InactiveCN103518775BImprove the induction effectImprove survival rateBiocidePlant growth regulatorsSalicylic acidSecondary metabolite

The invention provides a seabuckthorn growth regulator. The seabuckthorn growth regulator comprises an auxin analogue indolebutyric acid, a plant secondary metabolites salicylic acid, inorganic calcium salt calcium chloride and an antioxidant vitamin C. The seabuckthorn growth regulator shows a good inductive effect on seabuckthorn cutting rooting, has a certain influence on growth and development of cutting seedlings, and can obviously improve the survival rate of cuttings. From the angle of mass production and use, compared with comparative economy, the seabuckthorn growth regulator has food economic benefits and social benefits and is suitable for popularization and application.

Owner:BEIJING FORESTRY UNIVERSITY +1

Plastic product isolation releasing agent and preparing method thereof

The invention discloses a plastic product isolation releasing agent and a preparing method thereof, and belongs to the field of plastic machining auxiliaries. The agent is prepared as follows firstly,silicone oil, an emulsifying agent, water-soluble salt calcium chloride and sodium carbonate serve as raw materials for preparing W / O active nano calcium carbonate silicone oil composite emulsion, water adding for phase inversion is carried out, and the O / W silicone oil nano calcium carbonate emulsion is obtained. In the plastic product machining process, the plastic product isolation releasing agent well achieves isolation of a raw material and a mold, and the mold surface is easy to clean. Due to adding of the nano calcium carbonate, the micro pits and damage on the mold surface can be repaired, the service life of the mold is prolonged, the product surface defects are reduced, and the yield is improved.

Owner:HIGH & NEW TECH RES CENT OF HENAN ACAD OF SCI

A kind of ammonia alkali-combined alkali cycle production process and its application

ActiveCN104528765BReduce pollutionReduce wasteCalcium/strontium/barium carbonatesCalcium/strontium/barium chloridesCalcium Chloride HexahydrateSludge

Owner:HUBEI SHUANGHUAN SCIENCE AND TECHNOLOGY STOCK CO LTD

Preparation method of low-salt calcium-containing minced fillet product stored at normal temperature

PendingCN113854335AEasy to eatReduce cholesterolDough treatmentModified nutritive productsBiotechnologyVegetable oil

The invention provides a preparation method of a low-salt calcium-containing minced fillet product stored at normal temperature, namely a preparation method of a calcium glucarate-containing low-salt minced fillet biscuit stored at normal temperature. Main raw materials of calcium glucarate, enzymolysis minced fillet, cooked corn flour, corn starch and vegetable oil are used. The method comprises the following steps: preparing the calcium glucarate, preparing the enzymolysis minced fillet, mixing powder, performing forming, performing baking, and performing packaging in vacuum. The minced fillet biscuit made by the method is nutritious, healthy, fragrant and thick in taste, good in color and luster and uniform in tissue state, and the functionality of the minced fillet biscuit is particularly improved due to the fact that D-calcium glucarate which has the effects of reducing cholesterol, treating obesity, treating diabetic nephropathy, treating cancers and the like is added.

Owner:XUZHOU UNIV OF TECH

A kind of nano calcium carbonate emulsion and preparation method thereof

The invention discloses a nano calcium carbonate emulsion and a preparation method thereof and belongs to the field of rubber auxiliaries. The nano calcium carbonate emulsion is prepared through the following method that firstly, silicon oil, a silicon oil emulsifying agent, water-soluble salt calcium chloride and sodium carbonate serve as main raw materials to prepare a W / O type active nano calcium carbonate silicon oil composite emulsion; and then water is added for phase inversion so that an O / W type silicon oil nano calcium carbonate emulsion can be obtained. The nano calcium carbonate emulsion is suitable for isolation between raw materials and a mold in the production process of rubber products, can make the surface of the mold cleaned easily, can repair micro pits and damage on thesurface of the mold, prolongs the service life of the mold, makes surface defects of products reduced, and increases the finished product rate.

Owner:HIGH & NEW TECH RES CENT OF HENAN ACAD OF SCI

High temperature and anti-composite salt polymer fluid loss reducer for drilling fluid and preparation method thereof

ActiveCN103555296BImprove temperature resistanceGood resistance to salt and calciumDrilling compositionTemperature resistanceHigh pressure

The invention provides a fluid loss agent for a high-temperature-resistant compound salt resistant polymer for drilling fluid and a preparation method thereof. The fluid loss agent consists of the following raw materials in percentage by weight: 10-15 percent of acrylic acid, 6-8.5 percent of sodium hydroxide, 60-65 percent of deionized water, 4-8 percent of acrylamide, 5-6 percent of tetraphenyl ethylene sodium sulfonate, 6-8 percent of N-vinyl pyrrolidone and 0.1-0.5 percent of initiator. Compared with the prior art, the fluid loss agent has the beneficial effects that the high-temperature high-pressure filter loss of the drilling fluid can be obviously reduced, and the temperature resistance and salt calcium pollution resistance of the drilling fluid system are entirely improved. Moreover, the mud cake quality is improved, a permeability recovery rate is increased, and a hydrocarbon reservoir is effectively protected. The fluid loss agent can resist high temperature of 180 DEG C and compound salts and can serve as a fluid loss agent of deep walls, drilled evaporite beds and seawater drilling.

Owner:KORLA TONGYI IND TRADE CO LTD

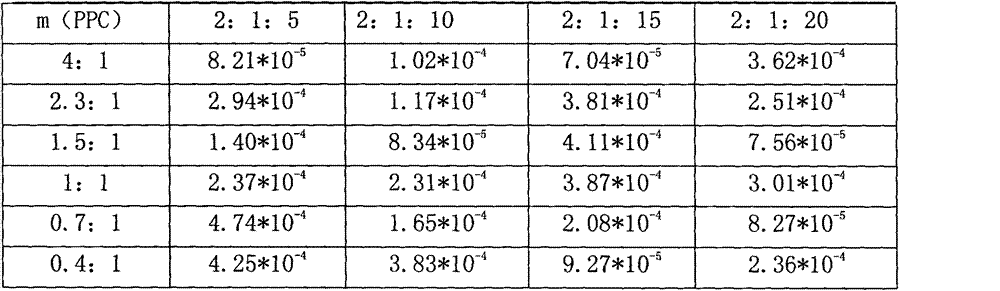

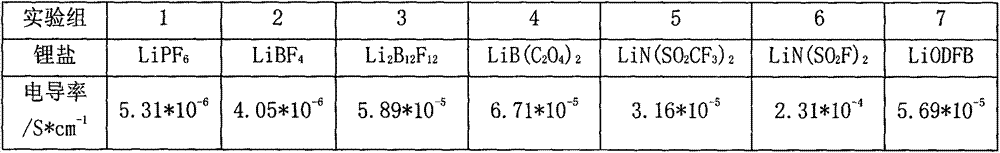

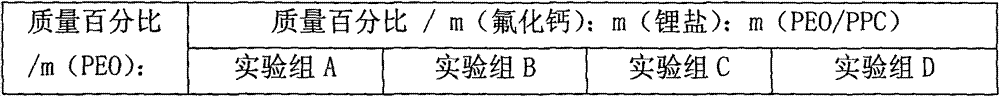

Preparation method of all-solid-state composite polymer electrolyte membrane

InactiveCN103059326BSimple preparation stepsIncrease productivityCell component detailsAll solid statePolymer science

The invention provides a preparation method of an all-solid-state composite polymer electrolyte membrane. The preparation method comprises the following specific steps of: 1) weighing and mixing a certain amount of PEO and PPC powder, adding a PEO / PPC mixture into an acetone solution, and stirring for 12 hours to obtain an even PEO / PPC-acetone solution; 2) adding a lithium salt and calcium fluoride into the acetone solution, and stirring for 12 hours to obtain an even lithium salt-calcium fluoride-acetone solution; 3) stirring the PEO / PPC-acetone solution obtained in the step 1) and the lithium salt-calcium fluoride-acetone solution obtained in the step 2) after being proportionally-mixed, and then pouring an obtained mixed solution into a polytetrafluoroethylene mould, placing at room temperature, and naturally forming a film; and drying for 24 hours at a temperature of 60 DEG C in vacuum, thereby obtaining the all-solid-state composite polymer electrolyte membrane. The all-solid-state composite polymer electrolyte membrane provided by the invention is high in conductivity.

Owner:邓丽娟

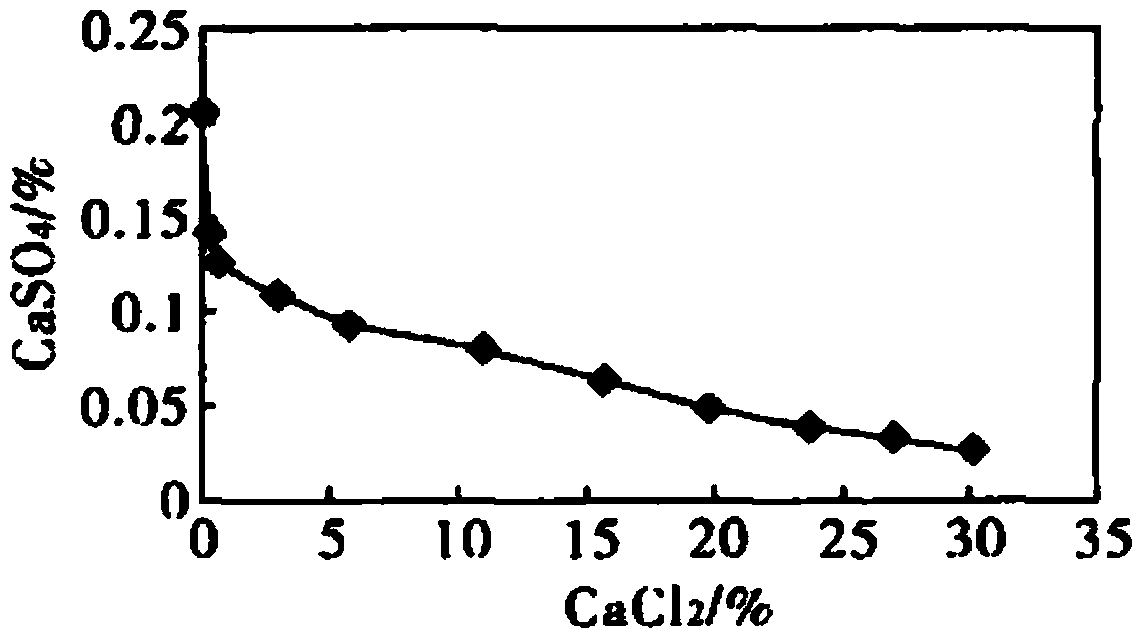

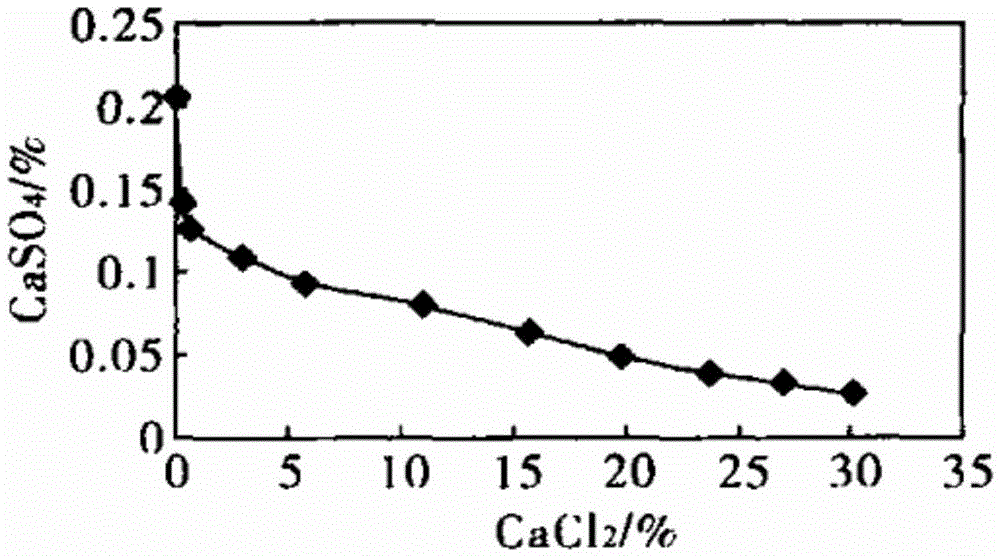

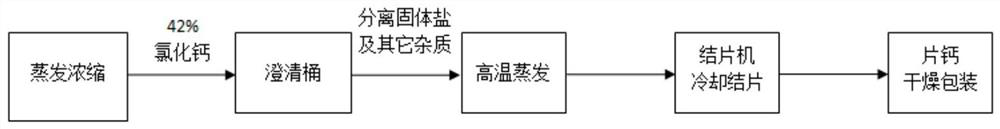

Device and process for producing low-salt calcium chloride through alkaline calcium

PendingCN112408451AReduce solubilityReduce Salt Sodium Chloride ContentCalcium/strontium/barium chloridesFluid phaseSalt calcium

The invention relates to a device and a process for producing low-salt calcium chloride by using alkaline calcium. The device comprises a 56wt% calcium liquid evaporation tank, a sedimentation centrifuge, a high-temperature evaporation tank, a cooling flaker and a calcium tablet drying and packaging device which are sequentially connected through pipelines. According to the process, the concentration of the calcium liquid is increased from 42% to 56% by increasing the evaporation and concentration concentration of the calcium liquid, the solubility of sodium chloride is reduced and separated out due to the increase of the concentration of calcium chloride by utilizing the same ion effect of calcium chloride and a sodium chloride solution, and then the 56% calcium liquid is selected as a process node; the sedimentation centrifuge is adopted to carry out centrifugal sedimentation separation on solid salt in a calcium liquid phase, and a strong centrifugal force field generated by mechanical force of the sedimentation centrifuge is utilized to remove the solid salt in the calcium liquid phase to the maximum extent, so that the content of salt and sodium chloride in a subsequent calcium chloride product is reduced, and finally calcium chloride with the salt content lower than 3.5% is obtained. The requirements of customers on low-salt calcium chloride products on the market are met.

Owner:江苏苏盐井神股份有限公司

A kind of isolation release agent for concrete products and preparation method thereof

ActiveCN109576043BIncreased durabilityExtended service lifeMaterial nanotechnologyLubricant compositionEmulsionSalt calcium

The invention discloses a preparation method of an isolation release agent for concrete products, which belongs to the field of concrete additives. It is prepared by the following method: firstly, W / O type active nano-calcium carbonate silicone oil composite emulsion is prepared from film-forming material, emulsifier, water-soluble salt calcium chloride and sodium carbonate, and then O / W type is obtained by adding water and phase inversion. Silicone oil nano calcium carbonate emulsion. The emulsion is suitable for the isolation between raw materials and molds during the processing of concrete products. It can make the surface of the mold easy to clean. The addition of nano-calcium carbonate can repair the micro-pit and damage on the surface of the mold, prolong the service life of the mold, and make the product The surface is smooth, the defects are reduced, and the yield is improved.

Owner:HIGH & NEW TECH RES CENT OF HENAN ACAD OF SCI

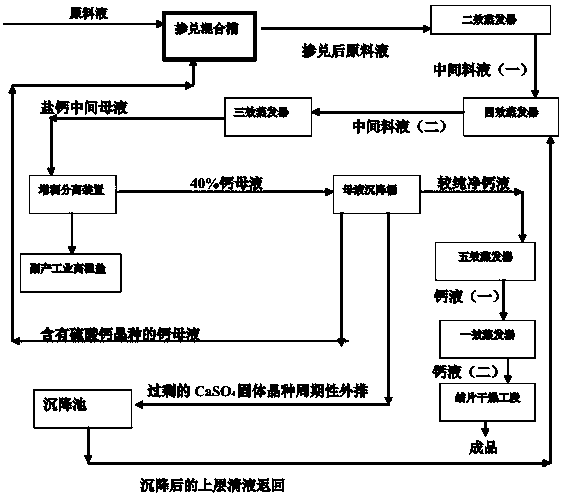

Anti-scaling method for calcium chloride production

InactiveCN108249467AIncrease feed concentrationExtended operating cycleCalcium/strontium/barium chloridesTriple effectCalcium sulfate crystals

The invention discloses an anti-scaling method for calcium chloride production. The method comprises the steps of taking soda distilled ammonia waste liquid with a calcium chloride concentration of not less than 15%(wt) as a raw material solution, performing evaporation and concentration on the raw material solution via a triple-effect evaporation device to form a salt calcium intermediate mothersolution with the calcium chloride concentration of 38-42%(wt), performing physical separation on the salt calcium intermediate mother solution to remove a byproduct, sodium chloride, then performingheat preservation and sedimentation to form a purer calcium solution and a calcium mother solution containing a calcium sulfate crystal, mixing and returning the calcium mother solution containing thecalcium sulfate crystal and the raw material solution to the above mentioned steps, conveying into a primary feeding evaporator after controlling the calcium chloride concentration to be greater than18%(wt), and performing the evaporation and concentration, sheeting and drying on the purer calcium solution obtained after the heat preservation and the sedimentation via a double-effect evaporationdevice to form a finished product, namely sheeted calcium chloride dihydrate. The method solves the problem of 2mm scaling after production for 30 days in the prior art, achieves an effect of scalingthickness not exceeding 0.5mm after continuous production operation for 105 days, lowers cleaning cost, improves device vaporization efficiency and greatly prolongs an operation cycle of the evaporators.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Electrolyte for preparing calcium through fused salt electrolysis of calcium chloride, and electrolysis method using electrolyte

ActiveCN107385474AAvoid the major drawbacks of secondary oxidationReduce the temperatureCellsElectrolysisSalt calcium

The invention discloses an electrolyte for preparing calcium through fused salt electrolysis of calcium chloride, and an electrolysis method using the electrolyte. The electrolyte is prepared from the components in molar percentage: 5 percent to 20 percent of CaCl2, 10 percent to 20 percent of LiCl, 10 percent to 20 percent of KF, 5 percent to 10 percent of CaF2, and the balance KC1. The initial crystallization temperature and the density of the electrolyte adopting the component compatibilities can be greatly reduced, the density of the electrolyte can be controlled to be smaller than the density of fused calcium, and when the electrolyte is adopted for producing, the fused metal calcium obtained through electrolysis can be deposited onto a carbon cathode surface of a bottom layer of the electrolyte. When the fused salt calcium electrolysis production is carried out based on the electrolyte, a production mode of existing calcium electrolysis can be thoroughly changed, and the obtained metal calcium is collected to the bottom part of an electrolytic tank so as to be pumped out conveniently without the need for extra processing, so that the large-scale, continuous and energy-saving production of calcium electrolysis is realized.

Owner:CENT SOUTH UNIV

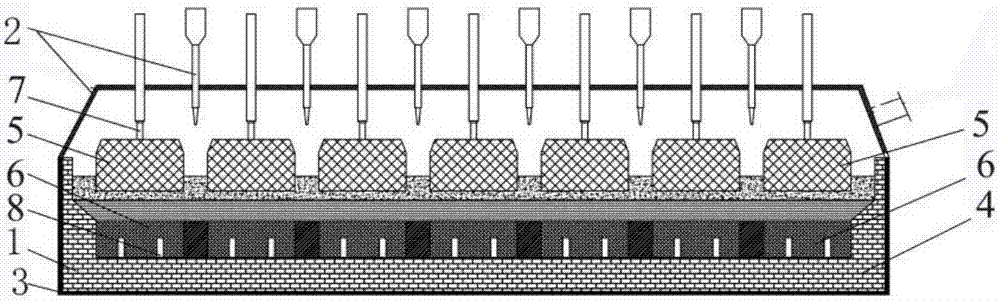

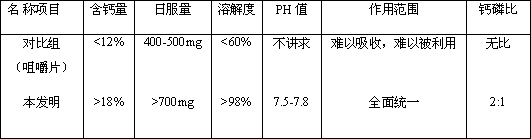

A kind of colostrum mineral salt calcium supplement preparation and preparation method thereof

The invention discloses a colostrum mineral calcium supplementing preparation and a preparation method thereof. The preparation is mainly prepared from milk minerals, biological calcium carbonate, collagen, colostrum basic protein, glucosamine, chondroitin sulfate, magnesium stearate, vitamin D3 and vitamin K2, wherein the characteristic of strong absorbing capacity of the milk minerals is sufficiently utilized, and the milk minerals are synergized with vitamin D3 to greatly improve the calcium supplementing absorptivity; nutritional ingredients provided by milk mineral calcium-source materials for osteocytes are activated by utilizing the colostrum basic protein, are deposited in the bone space cleaned by glucosamine, chondroitin sulfate and collagen under the common effect of vitamin K2,and are regenerated into new osteocytes; and the calcium supplementing utilization is greatly improved, and excellent effect of calcium supplementation is comprehensively and uniformly achieved.

Owner:刘会杰 +2

Method for burning chromium salt calcium-free roasting coal powder

Owner:GANSU JINSHI CHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com