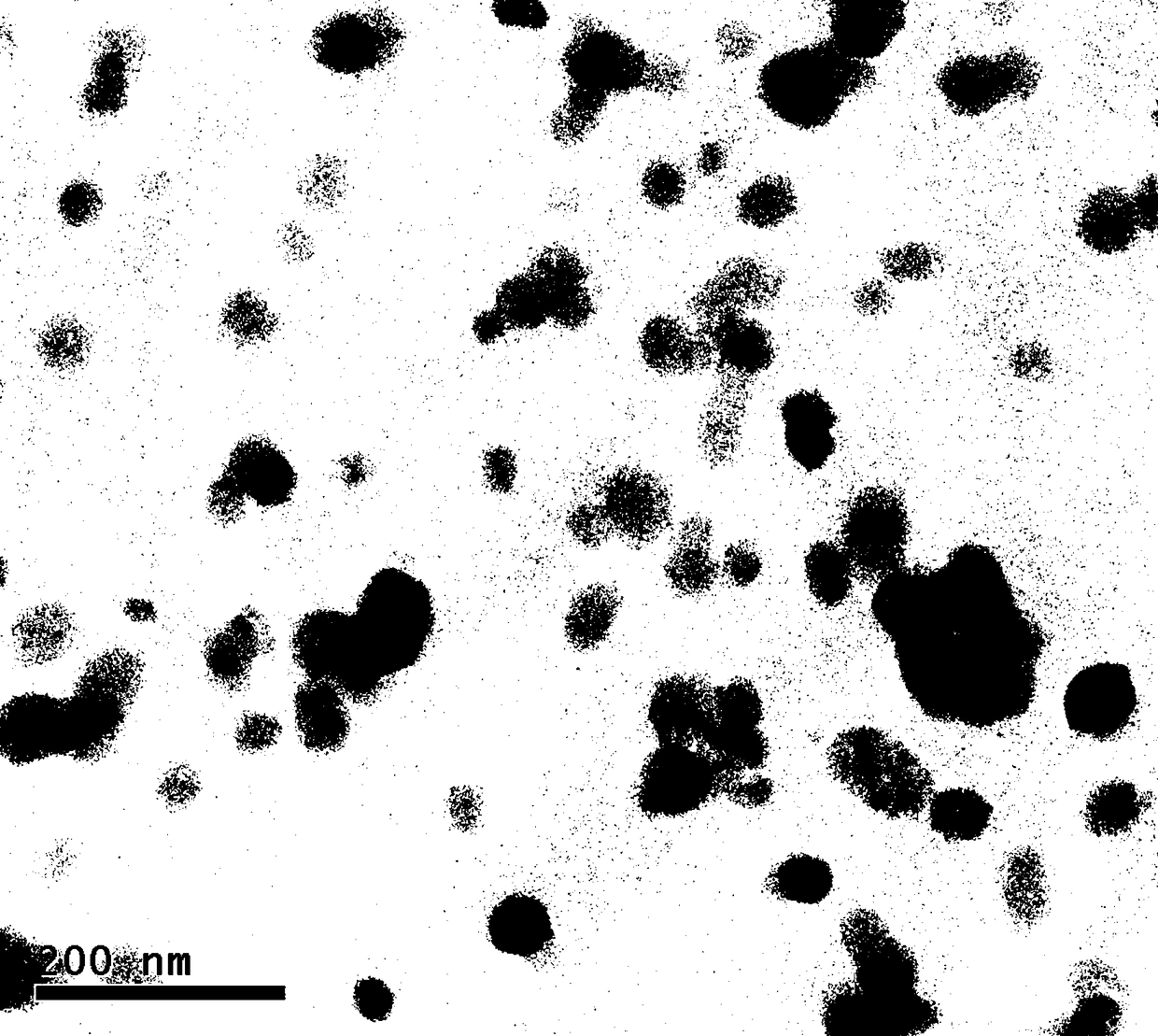

Nano calcium carbonate emulsion and preparation method thereof

A nano-calcium carbonate and emulsion technology, which is applied in the field of rubber additives, can solve the problems of affecting the storage period of the emulsion and transportation costs, poor improvement of metal mold surface defects, and affecting the separation of raw materials and metal molds, so as to achieve excellent results and protect the mold Effect of reduction of surface and surface defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

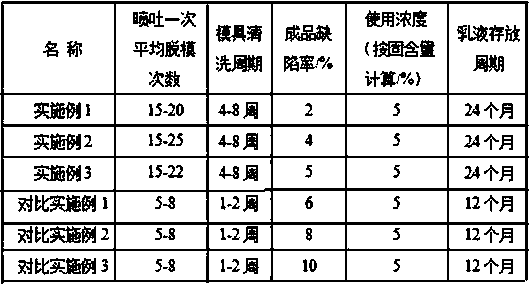

Embodiment 1

[0023] Weigh 45 parts of silicone oil with an average viscosity of 1000cp, emulsifier: 20 parts of TX-100, measure 10 parts of deionized water, weigh 5 parts of stearic acid, 10 parts of ethylene glycol, and 3 parts of calcium chloride for deionized The water is prepared into a calcium chloride aqueous solution with a concentration of 2.5M, which is added into a reactor with a stirring reflux device, and stirred at 30°C-45°C to form a transparent solution. Slowly add sodium carbonate powder or 2.5M aqueous sodium carbonate solution into the above silicone oil-calcium chloride solution under stirring. The molar ratio of calcium ions to carbonate ions is 1:1. After the addition is complete, the system is heated to 45-55°C. Stir and reflux for 28 h-30 h, stop heating, add the remaining amount of deionized water, stir slowly, cool down and invert the phase, and obtain a silicone oil nano-calcium carbonate emulsion with a solid content of about 45% high temperature resistant isolati...

Embodiment 2

[0025] Weigh 35 parts of silicone oil with an average viscosity of 2000cp, pipette 2 parts of TX-100, 1 part of OP-10, 1 part of AEO3 for emulsifier, measure 5 parts of deionized water, weigh 0.5 part of glycerin, 0.5 part of polyethylene glycol Alcohol 500, 0.1 part of calcium chloride is prepared with deionized water to make a calcium chloride aqueous solution with a concentration of 0.5M, put it into a reactor with a stirring reflux device, and stir at 30°C-45°C to form a transparent solution. Sodium carbonate was prepared with deionized water to make a sodium carbonate aqueous solution with a concentration of 0.5M, and slowly added to the above silicone oil-calcium chloride solution under stirring. The molar ratio of calcium ions to carbonate ions was 1:1. After the addition was complete, the system Raise the temperature to 55-65°C, stir and reflux for 24-26 hours, stop heating, add the remaining deionized water, stir slowly, cool down and invert the phase, and obtain a sil...

Embodiment 3

[0027] Weigh 20 parts of silicone oil with an average viscosity of 2000cp, 20 parts of silicone oil with an average viscosity of 1000cp, 3 parts of TX-100, 1 part of OP-4, 6 parts of AEO3, 10 parts of deionized water, and 2.5 parts of emulsifier Ethylene glycol, 5 parts of oleic acid, and 1.5 parts of calcium chloride are prepared with deionized water to make a calcium chloride aqueous solution with a concentration of 2M, put it into a reactor with a stirring reflux device, and stir at 30°C-45°C to form a transparent solution . Prepare sodium carbonate with deionized water to make a sodium carbonate aqueous solution with a concentration of 1.5M, and slowly add it to the above silicone oil-calcium chloride solution under stirring. The molar ratio of calcium ions to carbonate ions is 1:1. After the addition is complete, the system Raise the temperature to 65-75°C, stir and reflux for 20h-24h, stop heating, add the remaining amount of deionized water, stir slowly, cool down and i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com