Full-bore pressure transmission ball seat capable of being sheared

A full-bore, ball-seat technology, which is applied in wellbore/well components, earthwork drilling, sealing/package, etc., can solve problems such as insufficient reliability, achieve convenient operation, prevent liquid flow erosion, and increase reliability. The effect of the number of repetitions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

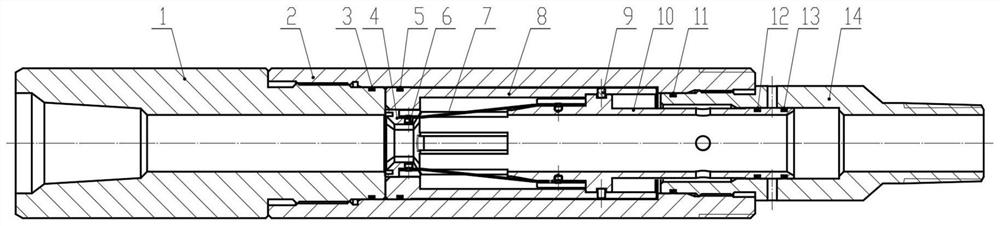

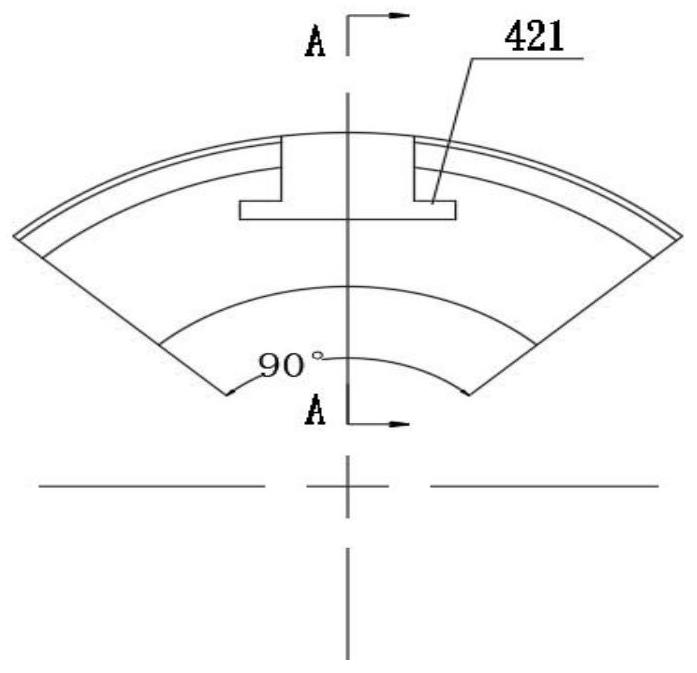

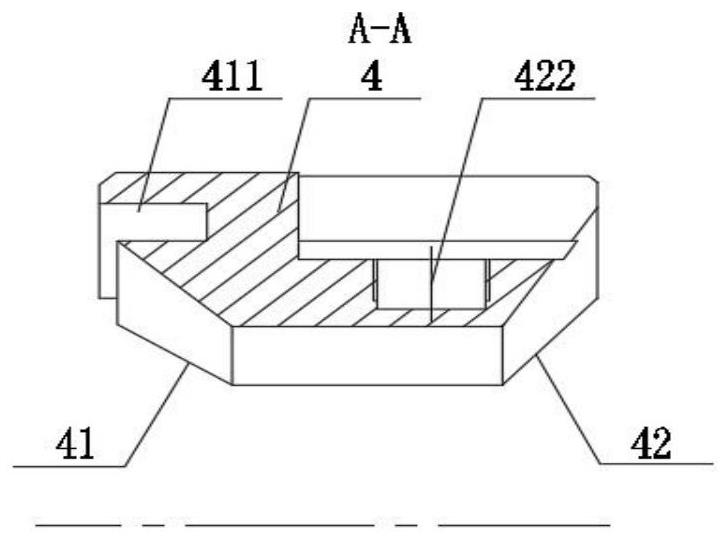

[0032] Such as figure 1 As shown, this embodiment provides a shearable rear full-bore pressure transmission ball seat, including an upper joint 1, a ball seat cover 2, a first sealing ring 3, a split ball seat 4, a second sealing ring 5, Fixing screw 6, shrapnel 7, ball seat outer cylinder 8, shear pin 9, shear mandrel 10, third sealing ring 11, fourth sealing ring 12, fifth sealing ring 13, lower joint 14; the ball seat device Connected in the completion service pipe string, the full diameter of the pipe string can be realized after the pressure transmission ball seat is sheared.

[0033] The upper inner surface of the upper joint 1 has threads for connecting with other pipe strings, and the lower outer surface is threadedly connected with the ball seat cover 2, and the seal is realized through the first sealing ring 3; the lower outer surface of the ball seat cover 2 is connected with the setting and hand-off tool assembly The inner surface of the lower part is threadedly c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com