Ammonia-soda-combined-soda cyclic production process and application thereof

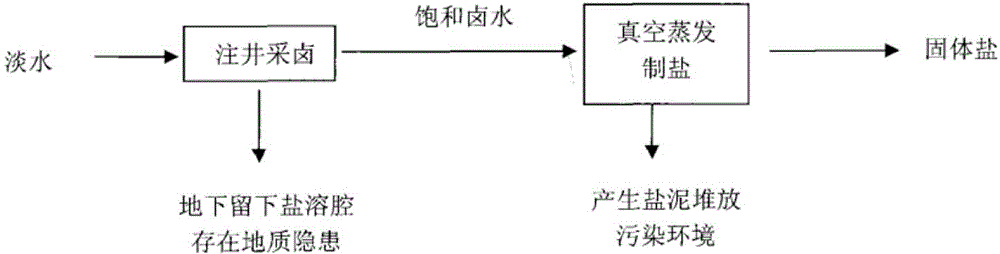

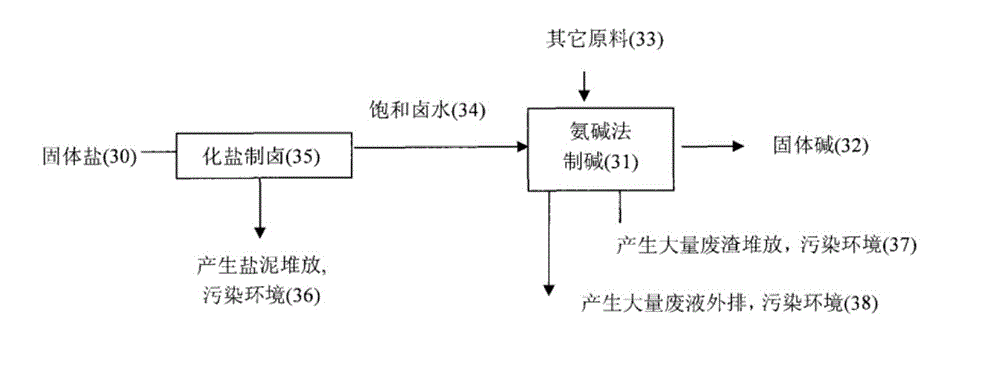

A production process and combined alkali technology, applied in the direction of alkali metal chlorides, alkali metal compounds, alkali metal carbonates, etc., can solve the problems of cycle production difficulties, waste of resources, environmental pollution, etc., to reduce capital investment and reduce resources Waste, the effect of reducing geological disasters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

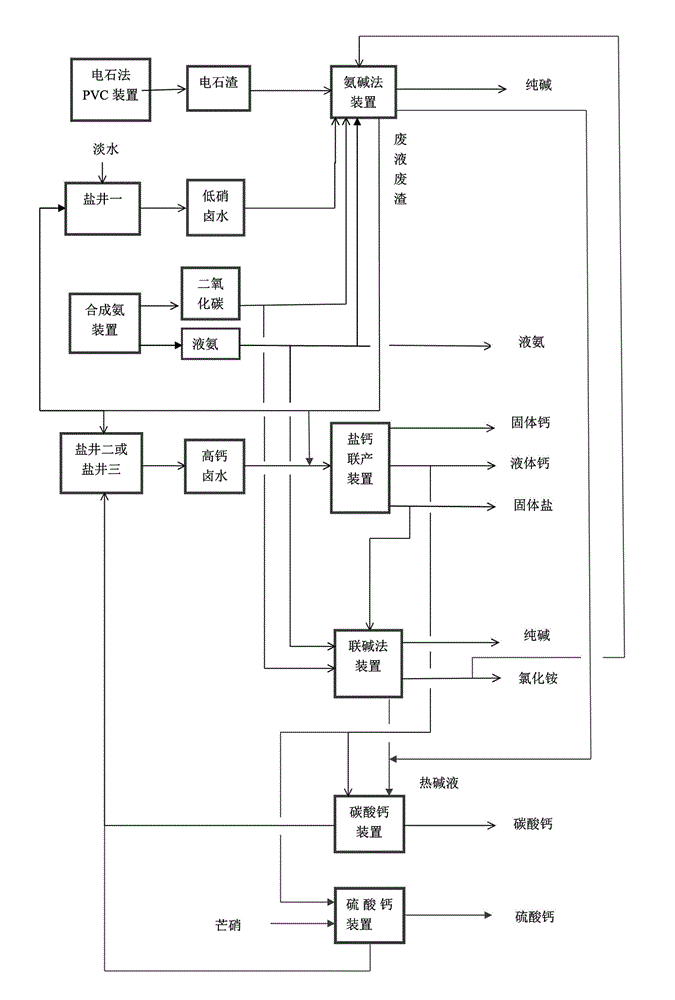

[0061] The present invention takes the production process of Hubei Yihua Shuanghuan Technology Co., Ltd. as an example.

[0062] 1) Refined brine (containing 310g / L of sodium chloride; 5g / L of sodium sulfate) obtained by refining brine extracted from salt well 1, ammonia and by-product carbon dioxide produced by synthetic ammonia plant, solid waste generated by calcium carbide method Calcium carbide slag is used as raw material, soda ash and waste slag are produced by the ammonia-soda method; the consumption ratio of the brine produced by the well salt 1, the ammonia and by-product carbon dioxide produced by the synthetic ammonia plant, and the solid waste produced by the calcium carbide method is per One ton of soda ash consumes 5.1m of brine 3 / t alkali, consumption of carbon dioxide 330Nm 3 / t alkali, consumption of calcium carbide slag 1.3t / t alkali, consumption of ammonia 3.5kg.

[0063] 2). Inject the waste liquid and slag of step 1) into another salt well two, where the well...

Embodiment 2

[0071] The present invention takes the production process of Hubei Yihua Shuanghuan Technology Co., Ltd. as an example.

[0072] 1) Refined brine (containing 305g / L of sodium chloride; 6g / L of sodium sulfate) obtained by refining brine produced from salt well 1, ammonia and by-product carbon dioxide produced by synthetic ammonia plant, solid waste generated by calcium carbide method Calcium carbide slag is used as raw material, soda ash and waste slag are produced by the ammonia-soda method; the consumption ratio of the brine produced by the well salt 1, the ammonia and by-product carbon dioxide produced by the synthetic ammonia plant, and the solid waste produced by the calcium carbide method is per Tons of soda ash consumes 5.2m of brine 3 / t alkali, consumption of carbon dioxide 335Nm 3 / t alkali, consumes 1.34t / t alkali of calcium carbide slag, consumes 3.8kg of ammonia.

[0073] 2). Inject the waste liquid and slag of step 1) into another salt well two. The well salt one is fo...

Embodiment 3

[0081] The present invention takes the production process of Hubei Yihua Shuanghuan Technology Co., Ltd. as an example.

[0082] 1) Refined brine (containing 308g / L of sodium chloride; 5.5g / L of sodium sulfate) obtained by refining brine produced from salt well 1, ammonia and by-product carbon dioxide produced by synthetic ammonia plant, solids produced by calcium carbide method Waste calcium carbide slag is used as raw material to produce soda ash and waste liquid waste slag by the ammonia-soda method; the consumption ratio of the brine produced by the well salt one, the ammonia produced by the synthetic ammonia plant and the by-product carbon dioxide, and the solid waste calcium carbide slag produced by the calcium carbide method is Each ton of soda ash consumes 5.17m of brine 3 / t alkali, consumes 332Nm of carbon dioxide 3 / t alkali, consumption of calcium carbide slag 1.32t / t alkali, consumption of ammonia 3.7kg.

[0083] 2). Inject the waste liquid and slag of step 1) into ano...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com