Method for burning chromium salt calcium-free roasting coal powder

A combustion method, calcium-free roasting technology, applied in furnaces, gas emission reduction, lighting and heating equipment, etc., can solve problems such as long reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

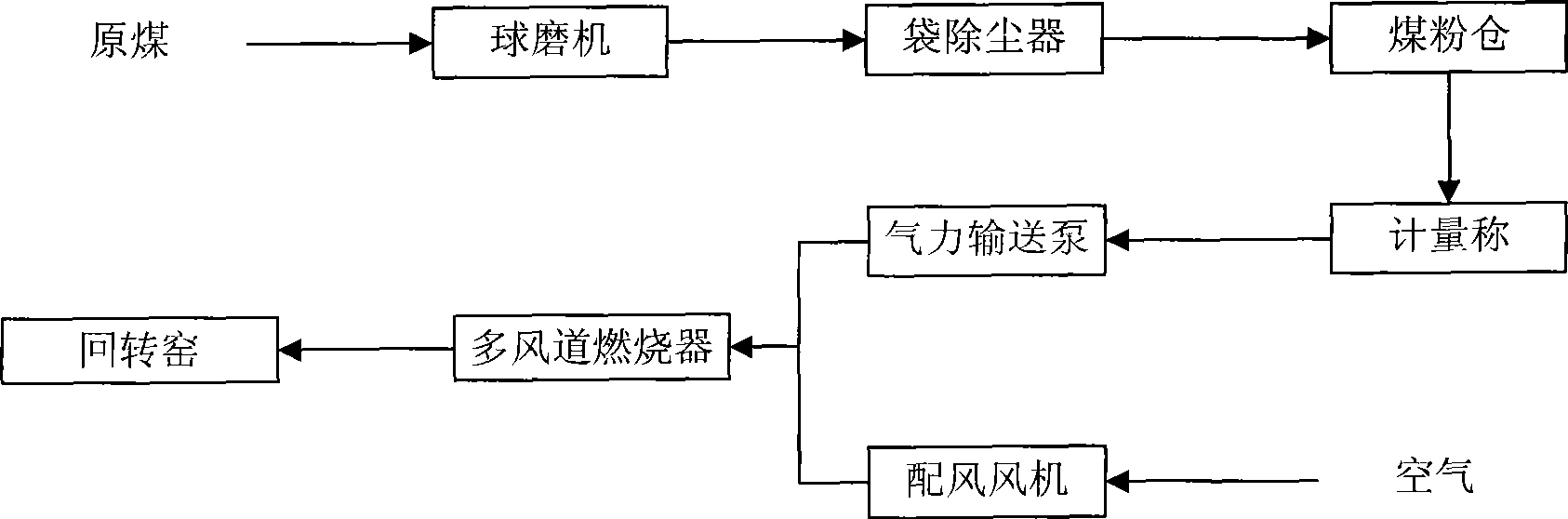

Method used

Image

Examples

Embodiment 1

[0024] The coal injection volume of the φ3×48m rotary kiln is adjusted to 1t / h, and the air volume of the coal injection fan is 5m 3 / min, the flow rate of the secondary air distribution fan is 15m 3 / min, the temperature of the high temperature zone of the rotary kiln is detected to be 1000°C, and the farthest point of the high temperature zone is away from the kiln mouth 11m, After roasting, the clinker contains 11.06% soluble hexavalent chromium, and the conversion rate is 70.2%.

Embodiment 2

[0026] The coal injection volume of the φ3×48m rotary kiln is adjusted to 1.5t / h, and the air volume of the coal injection fan is 5m 3 / min, the flow rate of the secondary air distribution fan is 15m 3 / min, the detected temperature in the high temperature zone of the rotary kiln is 1056°C, and the farthest point of the high temperature zone is 11.2m away from the kiln mouth. After roasting, the clinker contains 12.04% of soluble hexavalent chromium, and the conversion rate is 76.7%.

Embodiment 3

[0028] The coal injection volume of the φ3×48m rotary kiln is adjusted to 1.5t / h, and the air volume of the coal injection fan is 10m 3 / min, the flow rate of the secondary air distribution fan is 15m 3 / min, the detected temperature in the high temperature zone of the rotary kiln is 1080°C, and the farthest point of the high temperature zone is 13.5m away from the kiln mouth. After roasting, the clinker contains 12.87% of soluble hexavalent chromium, and the conversion rate is 77.4%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com